Every project requires a calculation of time that is taken to operate. Such times are briefly classified into three main categories. Popularly in the project management industry, they are known as ‘the Lead’, ‘the Cycle’ and ‘the TAKT’ time. All of these three concepts are of utmost importance to a project or a quality management professional. The following article will take you through each of these times. It will highlight its relevance. The method of calculation for each of these timings has also been mentioned. The reader will be able to comprehend through the comparisons shown between Lead Vs Takt, and Cycle Vs Takt.

What is Takt Time?

Takt is basically a German word for “baton” that a conductor uses in the orchestra to manage the tempo of music. In simple words, Takt means a beat or a pulse in the music. In terms of business, Takt Time means the rate at which the product needs to be manufactured to satisfy the customer demand.

How To Calculate Takt Time (Ideal)?

Suppose you have 500 minutes per day for manufacturing, and the customer demand is 500 units per day, you have 1 minute to produce a unit. That’s your Takt Time.

Takt time can be calculated using this simple formula below:

Takt Time = Available Time For Production/Number of Units Required

How To Calculate Takt Time (Real)?

As we all know, ideal calculations are way different than the real situations. So, let’s try and calculate Takt Time using some real conditions.

- Total Hours of Working = 8 Hours

- Total Minutes of Working = 480 Minutes

- Lunch Break = 30 Minutes

- Tea Breaks = 2* 15 Minutes = 30 Minutes

- Total Productive Minutes = Total Minutes Of Working – (Lunch Break + Tea Breaks)

- = 480 – (30+30)

- = 420 Minutes

- Total Requirements from client = 250 Units/day

- Takt time = Total Productive Minutes/Total Requirement

- = 420250

- = 1.68

What Are The Benefits Of Calculating Takt Time?

There are some important benefits of calculating Takt Time, let’s have a glance:

- You can find the exact time to produce one unit.

- Avoid the situation of overproduction.

- You can decide a precise guideline for the delivery.

- Can also be used to determine the organizational efficiency.

- You can manage overtime calculations.

- Production rate can be streamlined.

What is Cycle Time?

As the name suggests, Cycle Time is the time taken to produce one unit from the start to the end. Cycle time gives you the idea of how much time will it take to complete the demand, according to the current rate.

How To Calculate Cycle Time?

Let’s take an example:

Suppose, your team is working 50 hours a week, producing a total of 100 units. Here’s the formula to calculate the Cycle Time:

Cycle time = No. Of Productive Hours/Total Units Produced

- = 50/100

- = 0.5 Hour

If your Takt Time is more than 0.5 hour, you must do something about it. But if your Takt Time is below 0.5 hour, everything looks smooth!

Benefits of Calculating Cycle Time

- Gives an actual idea of the production rate.

- Gives data to make changes in the production rate to satisfy the demand.

- Deciding the actual time of delivery.

Takt Time Vs Cycle Time

Takt time and Cycle Time has different uses. In simple terms, Takt Time is to find the maximum time one can spend on one unit before getting the order. Cycle time simple means, how much time it is taken to complete one unit.

You can simply use Takt Time as the reference to complete the delivery on time. And when you find Cycle Time, your efforts should be about matching it with the Takt Time.

What is Lead Time?

Lead time has different use compared to Takt Time and Cycle Time. Lead time consists of the entire journey of one unit from the scratch to the end. In simple words, Lead time is the total time taken for a unit from getting an order to receiving payment. So, Lead Time is not only about the production but it is about the entire process of your organization.

How To Calculate Lead Time?

To calculate Lead Time, we must take an example to clearly understand the concept.

Let’s assume, the client gives the order on January 1st. You receive the order on January 2nd. After receiving the order, your team starts the process of manufacturing units on January 3rd. Entire cycle to manufacture the order takes 10 days, so January 13th is the day you complete the manufacturing. Now, the delivery takes about 2 days, so we have reached January 15th. After checking your entire order, the client takes 4 days to make the payment, hence January 19th.

To sum up, the Lead Time for this example will be 19 days. An interesting thing about Lead Time is, no matter how less time you take in manufacturing, you have to cut down other processing time to shorten the Lead Time.

Cycle Time Vs Lead Time

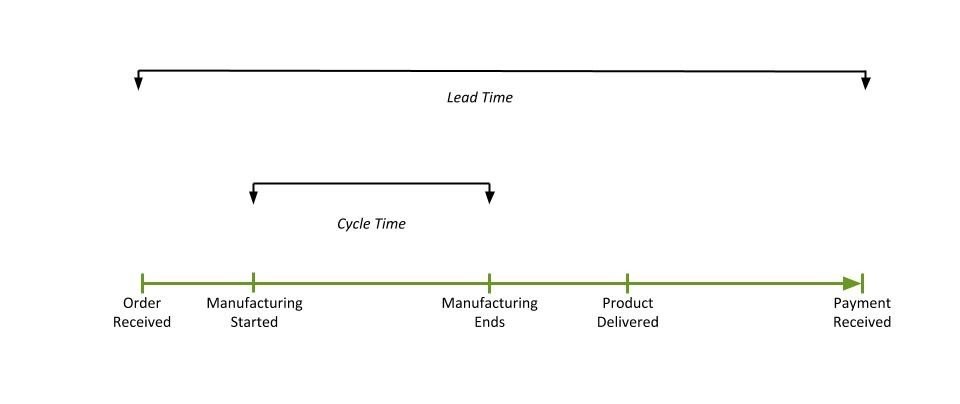

Here is an image that completely explains the difference between Cycle Time and Lead Time. Let’s have a look:

The cycle suggests the manufacturing process of your company, where Lead Time shows the entire process of your company including the Cycle Time. In terms of maths, Cycle Time is the subset of Lead Time.

CT ⊂ LT

How to measure Lead Time, Cycle Time & Takt Time?

Measurement of these times can be carried out in many ways. It usually depends on the type of work that is taking place. For a restaurant, the lead time can be calculated by taking an average of all the processing times of orders placed. The start time can be taken for the time of order that is recorded in the software. This time is also printed on the bill.

The cycle time can be taken from the point when the order reaches the chef and he starts cooking. This time can be obtained from the software or apps which are prevalent for the customers. These software and apps help the customer track their order.

Takt time is discoverable through studying daily orders and dedicated working hours. Suppose the daily number of orders (including the footfall and the deliveries) is one hundred. Sometimes the daily number of orders is not the same. In that case, an average maybe is taken. The number of working hours for the chef is eight hours a day. Then the hours (rather converted into minutes) are divided by the daily number of orders.

Purpose

The purpose of calculating these times help in preventing the wastage of time and money. Wastage of time and money can still be reflected in papers. When it comes to time though, the wastage is not easily visible as it is not a tangible thing. The waste cannot be seen lying around on the factory floors. Therefore, these formulae largely help in the detection of the time being lost. Taking corrective measures on the detection of time, wastage can increase productivity exponentially. Profit on the graphs can also show a rising trend with this frequent check. Sometimes a good profit making organization can run into losses due to its neglect of the timings of the processes.

Takeaway

Learning the above mentioned specifications comes very handy to a quality management professional. These are some of the very basic tools that a Project Management Professional or a Six Sigma Professional ought to know. GreyCampus provides training and certification for the PMP and the Lean Six Sigma Green/Black Belt. The trainers are extremely resourceful industry personnel who dive into topics like these in a greater detail.