SolidWorks, a prominent CAD software, is extensively employed across engineering and design sectors. Renowned for its intuitive interface and robust functionalities, it empowers engineers and designers to craft intricate 3D models, assemblies, and drawings with precision. This software fosters seamless collaboration through its compatibility with various tools and platforms, thereby expediting product development and optimizing design workflows effectively.

1. Describe SolidWorks.

Ans:

A 3D parametric design program called SolidWorks is used to design a wide range of things, including cars, boats, airplane parts, cameras, phones, furniture, electrical assemblies, toys, vacuum cleaners, lighting fixtures, and electrical assemblies. Dassault Systems produces and distributes solid modeling computer-aided design and engineering, 3D CAD design and collaboration, analysis, and product data management software.

2. How do SolidWorks Quora and AutoCAD differ from one another?

Ans:

SolidWorks is far more productive in 3D work than AutoCAD, which is mostly used for two-dimensional tasks like technical drawings. This includes component modeling and simulations. Thus, SolidWorks is a very useful program to learn because it has a lot of advanced capabilities for complex design work. This does not, however, imply that AutoCAD is any less helpful in broad applications.

3. How do CAD and AutoCAD differ from one another?

Ans:

CAD is the technique of using computers to make technical drawings; AutoCAD is a specific form of professional CAD software that can create both 2D and 3D drawings and models. In the upcoming years, employment prospects for drafters generally are predicted to decrease, but occupations specifically for electrical and electronics drafters are expected to grow dramatically.

4. What are the primary distinctions between Inventor and SolidWorks?

Ans:

| Aspect | Inventor | SolidWorks |

|---|---|---|

| User Interface | May be perceived as slightly complex | Often praised for its intuitive design |

| Feature Set | Strong assembly management tools | Advanced surfacing capabilities |

| Integration Capabilities | Seamless integration with other Autodesk products | Extensive community support and third-party integration |

| Sheet Metal Design Tools | Offers robust sheet metal design capabilities | Notably strong sheet metal design tools |

5. What distinguishes AutoCAD Electrical from AutoCAD?

Ans:

Nail board drawings, BOM tables for wiring lengths and components, and an extensive toolkit for electrical harnessing are all provided by AutoCAD Electrical through its connection with Autodesk Inventor. All the normal capabilities of AutoCAD are included in this specialist version, along with extra tools and a library made especially for electrical schematic design, reporting, and panel layouts.

6. Define Solidworks Electrical.

Ans:

Tool for engineering and design is SolidWorks Electrical. Its intelligent features facilitate the efficient development of electrical systems by engineers. Furthermore, it offers seamless integration between 2D schematics and 3D models, making it easier for information to be absorbed in real time and greatly enhancing project accuracy and efficiency overall.

7. What is the use of SolidWorks?

Ans:

SOLIDWORKS is used throughout the entire process of developing mechatronic systems, enabling an extensive design procedure. Project management, planning, modeling, visual ideation, feasibility research, and prototyping are the initial uses of the software. After this stage, the electrical and mechanical components of the system, as well as the required software, are designed and built using SOLIDWORKS.

8. What is Solidworks’ complete name?

Ans:

SOLIDWORKS Corp. provides the Dassault Systemes Complete 3D software tools, which help users design, simulate, publish, and manage data efficiently. When combined, the SOLIDWORKS product line makes learning easier and improves usability, enabling teams to produce better, faster, and more reasonably priced products for a variety of markets and uses.

9. How does SolidWorks vary from SolidWorks for Makers?

Ans:

3D Sight Cloud data management is integrated into SOLIDWORKS while maintaining the robust, industry-leading functionality, features, and tools of SOLIDWORKS Professional. Share and work together with other makers and creators more easily by storing all design data on the cloud. This method makes projects more creative and collaborative while also improving teamwork, making the design process more dynamic and effective, and facilitating seamless team connections.

10. How can a reference image be added into SolidWorks?

Ans:

- Open a new sketch on the front plane.

- Draw some reference geometry to aid in the image’s sizing and positioning.

- Select the desired image to insert by going to Tools -> Sketch Picture.

- Then, press “Open.” Once the image has been added, Use the command box on the left of the panel to change its size.

11. What is the process for engraving text onto a part in SolidWorks?

Ans:

- In order to engrave text in SolidWorks: After creating the components or having design prepared in SolidWorks; must main menu bar; below it, select Tools; Tools -> Sketch Entities; Sketch Entities -> Text;

- Enter text into the text box; To modify font, uncheck Use Document Font and choose font type and size;

- To engrave text, select Features -> Tap on Extruded Cut; from the lower left view menu, select Direction 1 Blind; and finally, click Isometric.

12. Explain what Groups and Cut Lists are in SOLIDWORKS.

Ans:

- Groups: Assemblies of connected segments in SolidWorks that are frequently used in structural members to make managing and modifying complex designs easier.

- Cut Lists: Especially for welded or sheet metal components, cut lists arrange comparable entities in an assembly. They streamline the fabrication preparation process by providing an overview of the necessary parts, together with their dimensions and quantities.

13. List the items that are part of the Build Check Tools.

Ans:

- Annotation checks

- Drawing checks

- Dimension checks

- Part checks

- Assembly document checks

- Feature checks and document checks.

14. Describe two primary ways that SolidWorks allows for design studies.

Ans:

A Design Study can be conducted in two major modes- Evaluation, in which discrete values are specified for each variable and sensors are used as constraints. The program carries out the analysis with multiple value combinations and reports the results for each combination. Provide values for every variable, either as a range or as discrete numbers. Sensors can be used as objectives and limitations.

15. What is the process for creating a multi-body sheet metal part?

Ans:

- Using base flange instructions, add a new body to an existing sheet metal item. Add bends, lofted bends, and sheet metal conversions.

- Divide a single sheet of metal into several bodies.

- Mirror a sheet metal body in a part, add one or more sheet metal, weldments, or other bodies to an existing sheet metal part, or use the Move/Copy body command to copy a sheet metal body in a part in a circular or linear pattern.

16. How may sustainability data be included in a customized material?

Ans:

Visit FeatureManager to add sustainability statistics to a bespoke material. Select the custom material in the material dialog box from the left panel. Select the material that most closely resembles custom material in the match sustainability information dialog box. Click OK to make the linked material appear in Sustainability. In the design tree, right-click Material, select Edit Material, and tap on Edit Material. Select “Apply” then Close.

17. In SolidWorks, what is sustainability analysis?

Ans:

SOLIDWORKS Sustainability assesses each design’s potential effects on the environment at each phase of the product life cycle. Analyzing the effects of components, production techniques, assembly, and transportation is part of this. In doing so, it provides designers with useful information that they can use to make decisions that will reduce their projects’ negative environmental effects and increase their sustainability.

18. What four roles does environmental sustainability play?

Ans:

- Providing resources (both non-renewable and renewable)

- Taking in garbage

- Provides aesthetics

- Promotes biodiversity, which sustains life.

19. What distinguishes environmental sustainability from sustainability?

Ans:

Sustainable development is more inclusive than environmental protection because it incorporates social and economic factors alongside environmental considerations. The three pillars of sustainable development economy, ecology, and society form a comprehensive framework that most people can understand and relate to, emphasizing the interconnectedness of these elements in creating a sustainable future.

20. What does environmental sustainability have in the following situations?

Ans:

Sustainable energy, sustainable forestry, and sustainable agriculture are some examples of applications of environmental sustainability. However, since fossil fuels inevitably contribute to greenhouse gas emissions and environmental deterioration, which undermine the objective of a sustainable future, the idea of sustainable fossil fuels is frequently viewed as incompatible with actual environmental sustainability.

21. What does the drawing’s Bill of Materials say?

Ans:

A bill of materials (BOM) is a comprehensive list of all the parts, assemblies, commodities, documentation, intermediate assemblies, subassemblies, and other materials needed to make a product. The BOM offers a thorough overview of all the components required for production and is arranged hierarchically, acting as a formula for producing the finished product.

22. What is BOM in its entirety?

Ans:

The phrase “bill of materials,” or BOM for short, refers to an inventory of all the components and materials required to manufacture a product. To ensure that all required components are located and ready for production, bill of materials (BOMs) are a useful tool for engineers and sales teams as well as being crucial to manufacturing and assembly operations.

23. What kinds of BOM are there?

Ans:

- Bill of Materials for Manufacturing

- Bill of Materials for Engineering

- BOMs include service, Sales, Assembly, Production, Template, Assembly, Sales, and Configurable BOM

24. What advantages does BOM offer?

Ans:

- Organization: Gives components a distinct framework.

- Efficiency: Reduces manufacturing costs by determining the parts that are needed.

- Cost management: Supports resource allocation and budgeting.

- Communication: Collaboration between teams is improved.

- Quality control: Verifies that the right parts are utilized.

- Version control: Tracks design changes with the aid.

- Inventory control: Helps with the best possible stock scheduling.

25. What drawbacks does BOM have?

Ans:

Main drawbacks of a manual or spreadsheet-based BOM process is the increased possibility of inconsistent and inaccurate data. In manual data input, errors, omissions, duplications, and out-of-date information are common examples of human error. These errors have the potential to cause serious problems with manufacturing, impacting overall effectiveness, product quality, and on-time delivery.

26. What are the drawbacks of using the Bill of Exchange as a financing source?

Ans:

- The discount paid for the Bill of Exchange is an additional expense for the drawer, even though discounting provides for rapid funds.

- The drawee is legally obligated to clear the payment upon demand or on the designated date.

- It might be a temporary method of obtaining payments from creditors.

27. What’s the complete form of SAP?

Ans:

A German software provider, Systems Applications and Products in Data Processing, or SAP for short, is a corporation that helps businesses monitor their consumers and business processes. SAP is also the abbreviation for its ERP (Enterprise Resource Planning) software, which unifies several business operations to improve productivity and data administration between departments in a company.

28. What is the operation of the SolidWorks routed system?

Ans:

Using a database, SOLIDWORKS Routing automatically gathers the required parts according to the chosen timetable. For instance, the program will group all connected parts, including elbows and pipes, under the same schedule and select an edge flange Schedule 40. This feature ensures that all parts are arranged and conveniently accessible for assembly, streamlining the design process.

29. How is routing in SOLIDWORKS done?

Ans:

Users can design custom subassemblies for routing pipes, tubes, electrical cables, or ducts between components with the Routing program, which is an add-in for SOLIDWORKS Premium. An autonomous route subassembly is created when particular components are added to an assembly. This makes the design process easier and guarantees precise connections in intricate assemblies.

30. How can SOLIDWORKS Routing be enabled?

Ans:

- Turning on the Routing Add-In Click in the SOLIDWORKS menu bar.

- Select Tools > Add-Ins from the SOLIDWORKS menu bar.

- In the Add-Ins dialog box under SOLIDWORKS Premium Add-ins, select Routing under Active Add-ins to use it in current SOLIDWORKS session. Choose Routing under Startup to use it in every SOLIDWORKS session.

- Press the OK button.

31. Where in SolidWorks is routing located?

Ans:

Expanding the Design Library folder in the SOLIDWORKS Task Pane, which holds the SOLIDWORKS Design Library, will allows to access the Routing subfolder. All the materials and parts required to construct a piping route are contained in the Piping folder, which is located inside the Routing folder. This comprises components and equipment that are necessary for efficient routing design and to improve workflow.

32. What is the process for creating routing components in SOLIDWORKS?

Ans:

To pick Routing, go to Tools > Options > System Options and choose “Configure Components.” Choose from the following actions to take place in an existing assembly: To add an element to assemble, either drag it from the Design Library or choose “Insert Components” from the Assembly toolbar. This makes it possible to integrate routing components efficiently.

33. What are the steps to configure routing in SolidWorks?

Ans:

- In the routing setup, a default route is added, as routes to networks that are reachable via route-based VPNs and networks that are not directly connected. Include routers.

- An element of a router indicates the IP address of a next-hop gateway in routing settings. Sections in certain documents.

- It facilitates the automatic creation of simplified configurations, assembly documentation, and parts.

34. Define ‘Pipe routing’.

Ans:

Pipe routing encompasses the strategic arrangement of a pipeline’s layout, prioritizing factors such as economic efficiency, organizational neatness, and operational safety. It involves meticulous planning to determine the optimal placement of pipes, considering aspects such as regular service accessibility, susceptibility to corrosion, and potential for vibration-induced damage.

35. How is the route object checked?

Ans:

- First, select the “Query” tab.

- Enter the IP prefix that wish to examine, For instance; 196.192.48.0/20.

- Verify the human check on the “I’m not a robot” form.

- Choose “route” from the “Object Types” menu.

36. Describe the services offered by SolidWorks Utilities.

Ans:

- Evaluate Geometry: It enables to contrast the variations in geometry between two designs utilizing View synchronization, Face synchronization, or Geometry comparison.

- Compare Document: This feature allows to compare two SolidWorks documents’ attributes.

- Power Select: Using geometric criteria, it assists in choosing features, faces, loops, and edges.

- Power Editing: This tool assists in finding, modifying, and altering aspects inside a model according to its specifications.

- Thickness Analysis: It offers a tool for analysis to determine what is thick and thin.

37. What abilities are required of Solidworks designers?

Ans:

- The ability to use SolidWorks to develop parts, assemblies, design tables, and drawings.

- Skilled at producing 2D drawings with AutoCAD.

- Design expertise using sheet metal.

- Organised, detail-oriented, and capable of managing several ongoing projects.

38. What technical competencies are required of a mechanical engineer?

Ans:

The individual possesses a strong foundation in mathematics and analysis, problem-solving skills, proficiency in physics and mechanics, technical drawing and computer-aided design (CAD), and other related abilities. Proficiency in Materials Knowledge, Thermodynamics and Fluid Dynamics, Manufacturing Process Knowledge, and Programming Skills.

39. What purposes does mechanical engineering use SolidWorks?

Ans:

Engineers may create a visual depiction of a product with SolidWorks, which is a dependable tool. Its powerful 3D modeling tools enable users to produce intricate and lifelike illustrations of their projects. This capacity facilitates better communication and teamwork between clients, stakeholders, and team members, which promotes a more efficient design process and well-informed decision-making.

40. What is the purpose of SolidWorks to engineers?

Ans:

The main advantage of SolidWorks is that it may expedite the design process. Engineers and designers may quickly generate 3D models of parts and assemblies with its easy-to-use interface. Their ability to visualize and develop designs more effectively is enhanced by this efficiency, which allows for faster iterations and a notable increase in workflow productivity across a range of projects.

41. What applications does mechanical engineering use SolidWorks for?

Ans:

Mechanical engineering utilizes SolidWorks for various applications, including 3D modeling, simulation, and design validation of mechanical components and systems. SolidWorks facilitates the creation of detailed and accurate designs for products ranging from consumer electronics to heavy machinery. It enables engineers to analyze factors such as stress, heat transfer, and fluid dynamics to optimize performance and durability.

42. What advantages does SOLIDWORKS have over AutoCAD?

Ans:

SOLIDWORKS is a very accurate and efficient 3D modeling tool for mechanical design and assembly modeling. On the other hand, AutoCAD is a mainstay in the engineering, architectural, and construction sectors due to its adaptability, which enables it to effectively meet a wide range of design requirements and workflows across various industries and applications.

43. Which soft or technical skills need improvement?

Ans:

Effective communication is essential for professionals to have with clients, coworkers, and stakeholders. To give updates on operations and projects, they must communicate technical knowledge succinctly and clearly. Good communication skills are also necessary to guarantee safety and efficient emergency response since in these crucial times, decision-making can be greatly impacted by the clarity of information.

44. What is Data Exchange for SLD XML?

Ans:

Customers can choose to store their designs in the. Applications using SOLIDWORKS 3DEXPERIENCE use the SLD XML file format. Information from these SLD XML documents is used for They are included in an assembly. In contrast to other subassemblies, a route assembly is not made in a separate window and is then added as a component to the higher-level assembly.

45. What kinds of patterns do SOLIDWORKS use?

Ans:

- Fill Patterns

- Sketch Driven Patterns

- Table Driven Patterns

- Saving and Loading Table Driven Patterns

- Curve Driven Patterns and the Curve Driven Pattern PropertyManager

- Linear Patterns and the Linear Pattern PropertyManager

- Circular Patterns

46. What is a fill pattern in Solidworks?

Ans:

Choose a sketch that lies on co-planar faces or a region around those faces to fill with the Fill Pattern tool. This command covers the specified region with a sliced version of a feature pattern or preset shape. With a sketch serving as the boundary, it may be necessary to precisely ascertain the pattern orientation to get the desired appearance as quickly and effectively as possible.

47. Which two categories of patterns are there?

Ans:

- Repeating Pattern: A pattern that appears in the numerical sequence repeatedly is referred to as a repeating pattern.

- Growing Pattern: A pattern is said to be growing if the numbers or objects are placed in a series in an increasing order.

48. Describe pattern shapes.

Ans:

Shape patterns are specifically ordered repetitions of a given shape. These sequences make use of a variety of 2D shapes, including squares, rectangles, and circles, in addition to pictures of other items, like chocolates, stars, spoons, arrows, and many more. In a variety of contexts, shape patterns can improve visual appeal and produce captivating designs.

49. What is a flat pattern in Solidworks?

Ans:

A folded sheet metal part’s flat pattern characteristic is meant to be its final design. Every feature in the FeatureManager design tree that comes before Flat-Pattern1 is present in the sections for folded and flattened sheet metal. All of the characteristics that adhere to Flat-Pattern1, however, are only present in the flattened sheet metal part, guaranteeing precise representation for manufacture and examination.

50. How are SolidWorks’ convert entities used?

Ans:

Regardless of whether the face is parallel to the drawing or not, users can project a face’s edges onto the active sketch using the SOLIDWORKS Convert Entities tool. The tool is both effective and powerful because of this feature. These boundaries are continually projected as they appear when seen normally about the sketch, guaranteeing correct depiction and user-friendliness throughout the design process.

51. List the primary SolidWorks mechanical mates.

Ans:

- Standard mates with limitations like parallel, tangent concentric, and more.

- Advanced mates with limitations on width, symmetry, profile centers, and other aspects.

- Mechanical mates with features like gears, hinges, slots, and other restrictions.

52. Describe relations in SolidWorks.

Ans:

By linking or limiting a sketch entity to other sketch entities, sketch relations aid in its definition. With the use of built-in tools like the polygon tool, SOLIDWORKS can automatically establish or assume these relationships. To further improve control over the sketch design process, users can inspect and change all existing relations by using the display/delete relation icon.

53. What are the PDM Server Components listed?

Ans:

The Archive Server, Database Server, License Server, Web Server, and Dispatch Server are examples of PDM Server Components. The roles of the various components are as follows: the Dispatch Server automates processes, the License Server distributes licenses, the Web Server offers web-based access, the Archive Server maintains file data, and the Database Server supervises metadata.

54. How may text be engraved onto a part of Solidworks?

Ans:

- In order to engrave text onto a component using this application, begin with design preparation and follow these steps:

- Go to Tools > Sketch Entities > Text and type in the message want to send.

- If necessary, uncheck “Use Document Font” and choose a different font.

- To set up D1 under Features > Extruded Cut, first “Blind Direction 1.”

- Afterward, select “Isometric” from the view selection on the lower left for optimal results.

55. What parts of the FeatureManager Design Tree are there?

Ans:

The current part, assembly, or drawing can be seen as an outline in the FeatureManager design tree, which is situated on the left side of the SOLIDWORKS window. The FeatureManager design tree can be set up to show features in part documents in chronological order instead of a hierarchical one. Because of this versatility, users can view the design process whichever best fits their interests and workflow.

56. Where is the SolidWorks API accessible?

Ans:

We can use the SolidWorks Developer Portal to gain access to the SolidWorks API. It offers developers the tools and documentation they need to work with SolidWorks through the API. On the portal, we may find software development kits, forums, sample codes, and API documentation. These will allow us to begin utilizing the SolidWorks API.

57. What are SolidWorks and AutoCAD’s primary distinctions?

Ans:

The main area of distinction between AutoCAD and SolidWorks is that AutoCAD was first created as a tool for 2D product design. Using pierce points in SolidWorks can give users more control and precision while working on more complex projects that demand intricacy beyond simple forms or lines, allowing them to accomplish the necessary goals more quickly and effectively.

58. What advantages can SOLIDWORKS flow simulation offer?

Ans:

The technology enables users to rapidly model fluid flow, heat transfer, and fluid forces early in the design phase all essential for the successful completion of the design. It can also handle numerous “what if” scenarios, allowing for quick design optimization and assisting teams in reaching well-informed decisions to improve productivity and efficiency.

59. How can a reference image be inserted in SolidWorks?

Ans:

- The front plane must be opened in SolidWorks before inserting a picture.

- Next, sketch some geometry that will assist in determining the size and placement of reference image.

- Go to “Tools,” choose “Sketch Picture,” and choose the desired image from PC to accomplish this.

- After that, can precisely customize the size of the screen by using the Command Box, which is situated in the left panel.

60. What is the purpose of SolidWorks’ draft feature?

Ans:

- Draft tapers face to specific faces in the model at a given angle. One use for it is making a molded object easier to remove from the mold.

- When extruding a feature, can insert a draft into an already-existing section or draft. The draft can be used on the surface or solid models.

- While cut lists are elements under the Feature Manager Design Tree that group similar entities together for components comprising sheet metal features or weldments, groups are collections of linked segments within structural members.

61. Which are the two primary modes for design studies in Solidworks?

Ans:

- Evaluate: This process entails configuring each variable to a unique value with the aid of sensors acting as constraints. Software is then used to execute simulations, which provide reports on the combinations and permutations of those particular variables.

- Optimization Study: In this mode, numerous scenarios are applied with diverse targets (sensors) established for multiple purposes in mind. A range of discrete parameters are used. It is possible to produce and appropriately optimize the best combination, providing maximum value by iteratively going over all available possibilities.

62. What checks are included in the Build Checks Tools?

Ans:

- Checks for Part Documents, Drawing Documents, and Assembly Documents Measurement Verifications

- Verification of Documents

- Annotation Checks

- Feature Evaluations

63. What is the purpose of the Motion Studies feature in SolidWorks?

Ans:

The Motion Studies feature in SolidWorks adds lighting and camera viewpoints to visual simulations of assembly model motions. This tool just animates the motion set for a model; it has no effect on any model’s characteristics. Additionally, use specific mates to specify how parts should move in relation to one another within an assembly.

64. When using SolidWorks, how would one convert solid parts into sheet metal forms?

Ans:

- Navigate to the “Sheet Metal” module, then choose Switch to Sheet Metal.

- Choose to utilize a gauge table or not.

- After choosing an appropriate gauge table, if necessary, set required parameters for that particular task.

- Select the edges that indicate bends and the accompanying edge sides that are mentioned in this feature.

- When implementing compliant perimeters later, define corner defaults and bespoke bend treatments for the areas that were chosen.

- After finishing, confirm the last adjustments made. Upon completion of all revisions, a green checkmark appears.

65. What is the process for calculating assembly weights in SolidWorks?

Ans:

It is crucial to make sure that all part densities are entered into SolidWorks precisely to determine the weight of an assembly. Choose “Mass Properties” from the “Evaluate” option after navigating there. Subsequently, a dialog box will show the mass properties of the assembly, including weight, volume, surface area, and center of mass all of which are critical for the success of project.

66. What procedures must someone follow in order to create new SolidWorks templates?

Ans:

- Use SolidWorks to make new templates by following these easy steps

- Navigate to the desired module (Drawing, Assembly, or Part).

- Tailor the software’s settings to needs by modifying the menus and submenus accordingly.

- Finally, save the modified files as assembly template files or drawings.

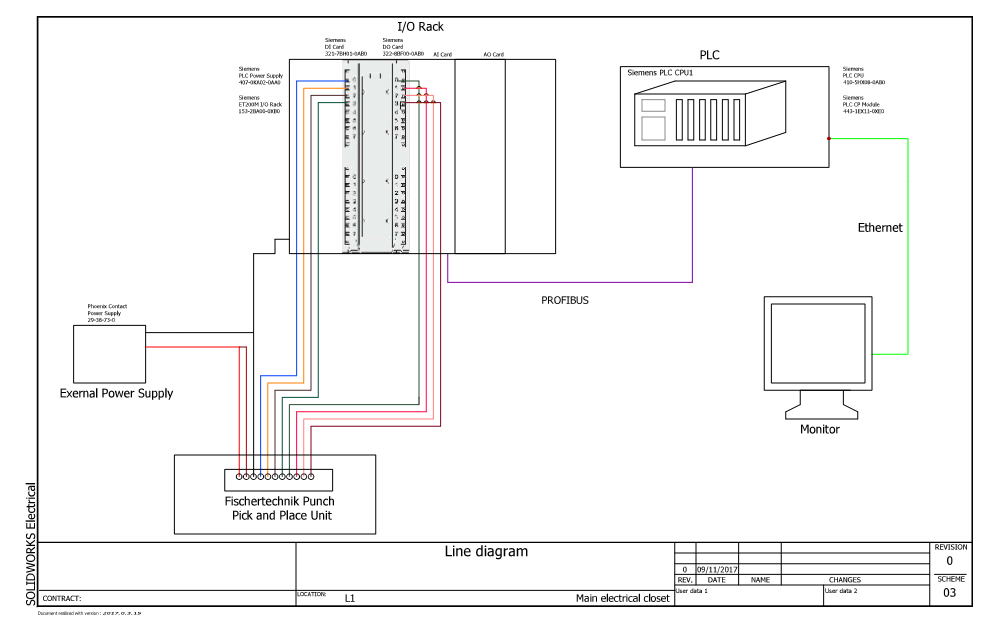

67. Which elements make up SOLIDWORKS Electrical’s core?

Ans:

- Schematic design: Tools for drawing circuits and electrical schematics.

- 3D Routing: Using SOLIDWORKS to model electrical systems in three dimensions.

- Component Management: Electrical symbol and component libraries.

- Automatic Reports: Generated automatically including the bill of materials (BOM) and other reports.

- Collaboration Tools: Functionalities that facilitate cross-disciplinary design sharing and teamwork.

- Customizable Templates: The capacity to design unique templates for particular tasks.

68. What is PCB in SolidWorks?

Ans:

The robust platform for creating printed circuit boards (PCBs) that smoothly interact with SolidWorks’ potent modeling features is available to users of SolidWorks PCB. With the help of this integration, engineers can produce complex designs more rapidly without sacrificing accuracy or quality, which improves efficiency and productivity throughout the design process.

69. How does Visualise in SolidWorks operate?

Ans:

With the advanced software capabilities provided by SolidWorks Visualise, users can produce realistic 3D CAD model representations. Its user-friendly design assists in ensuring that every element is displayed flawlessly. Furthermore, it comes in Standard and Professional editions and offers a set of capabilities designed especially for visualizing projects.

70. What is Visualise Boost for SolidWorks?

Ans:

- Visualize Boost for SolidWorks is an add-on feature that accelerates rendering tasks by leveraging the power of networked computers.

- It allows users to distribute rendering jobs across multiple machines, significantly reducing rendering times and improving productivity.

- With Visualize Boost, users can achieve faster and more efficient rendering workflows, enhancing the visualization process for SolidWorks models.

71. What is a Design Checker for SolidWorks?

Ans:

SolidWorks Design Checker is a priceless tool for confirming that designs adhere to the necessary requirements. It checks that dimensions, typefaces, materials, and designs are all in line with the requirements specified by product stakeholders or other individuals in charge of the design process. Thanks to this potent tool, perfectionism is now more accessible than ever.CAD representations.

72. How can SOLIDWORKS Explorer be used to manage SOLIDWORKS files?

Ans:

A robust file management application created especially for SolidWorks users is SolidWorks Explorer. It makes it simple to move, rename, and duplicate SolidWorks files while guaranteeing that any referenced documents may still be accessed once modifications are made. It also facilitates the management of complicated projects by letting users search for documents using particular criteria and displaying an extensive list of document references.

73. What Tasks Are Assigned to SolidWorks Administrators?

Ans:

- Administrators manage online licenses and login credentials. The SolidWorks program is configured to use machine activation by default.

- Administrators must manually cancel all active licences for all SolidWorks products installed on a single computer to enable online licensing through the Admin Portal.

- Select between options for machine activation or online licensing. The selected product. Grant users/memberships access to the goods and services that the particular product offers.

74. What is a Bill of Materials (BOM), and how is this functionality integrated into SolidWorks?

Ans:

SolidWorks’ Bill of Materials (BOM) function automatically creates a document listing all parts, components, and elements pertinent to a particular project. Then, this data can be utilized for a number of things, like purchasing or manufacturing procedures. A bill of materials (BOM) is a product’s manufacturing process’s principal repository of data. It is a list of the materials required to make a product, together with directions.

75. What features are available to users of the SolidWorks Routing System add-in?

Ans:

With the help of the SOLIDWORKS Electrical Routing Add-In, we may design unique subassemblies intended only for 3D electrical pathways. Three fundamental components make up these kinds of routes: parts, features, and routing components. With pre-made libraries available within the application, users may quickly alter piping, tubing, and electrical cable fittings to suit their needs, thanks to the add-in functionality provided by SolidWorks Routing Systems.

76. What is the purpose of CircuitWorks in SolidWorks?

Ans:

- SOLIDWORKS CircuitWorks is designed to generate solid models from ECAD files of formats such as PADS ASCII (.asc) or Intermediate Data Format (.emn).

- It may then be used to add features, such as mounting holes, and export the finished product back to the ECAD format. Format for files.

- Using file formats produced by several CAD systems, SolidWorks CircuitWorks creates 3D models that may be integrated into the design process.

77. What is Routing in SolidWorks?

Ans:

SolidWorks Routing is an add-on for SolidWorks Premium. With its help, users can assemble specific subassemblies that connect elements via electrical cables, pipelines, and tubes. Unlike other subassemblies that must be made independently before being incorporated into the main structure, route assemblies are automatically built when specific components are added to a higher-level assembly.

78. Describe the TolAnalyst.

Ans:

TolAnalyst is a feature in SolidWorks used for tolerance analysis of parts and assemblies. It helps engineers simulate manufacturing variations and assess the impact on product quality and performance. TolAnalyst identifies critical dimensions and suggests improvements to meet tolerances, aiding in design optimization. This tool enables users to make informed decisions early in the design process, reducing the costly rework and ensuring reliability.

79. Define SolidWorks Utilities.

Ans:

SolidWorks Utilities offers a reliable way to analyze solid models, from straightforward comparisons and measurements to complex geometry inspections. By enabling users to compare their designs with pre-existing models, this program improves the review process overall and provides insightful information on the structure of the design. Through the utilization of these functionalities, customers can guarantee increased precision.

80. What is SOLIDWORKS MBD?

Ans:

SolidWorks MBD provides integrated production solutions that make use of data interchange standards and 3D scenes that are frequently used by industry-standard applications. This method streamlines communication with engineering teams and stakeholders, lowers production costs, and improves quality assurance. SolidWorks MBD encourages cooperation and guarantees that all stakeholders agree on the design.

81. What applications does SolidWorks MBD have?

Ans:

- Using DimXpert and benchmark dimensions, SolidWorks MBD offers 3D PMI (product and manufacturing information) definition capabilities.

- Users may arrange PMIs in an orderly and easily accessible manner using 3D views, colourful view planes of annotations, and annotation views.

- It also allows for the creation of output files in 3D PDFs/eDrawings or native SolidWorks file formats for improved visualization efficiency.

82. What is FloXpress for Solidworks?

Ans:

SolidWorks FloXpress is an invaluable fluid dynamics program integrated into SolidWorks, facilitating the identification of potential design flaws in parts or assemblies. By meticulously analyzing fluid flow through components prior to mass production, it enables engineers to preemptively detect inefficiencies or performance issues.

83. What goes into an LCA?

Ans:

Several critical phases are covered by the Life Cycle Assessment (LCA) method, such as consumer product usage, mine ore extraction, and end-of-life (EOL) demolition. It also takes into account the production and assembly of parts, as well as recycling and burning. LCA also takes into consideration all related transit between these phases, guaranteeing a thorough assessment of the environmental effects over a product’s whole lifecycle.

84. Which PDM Server Components are mentioned?

Ans:

- Microsoft SQL Express for PDM Standard is the data management tool for SOLIDWORKS PDM data vaults.

- SQL Server for PDM Professional is used to handle data in SOLIDWORKS PDM data vaults.

- The SolidNetWork License Manager oversees SOLIDWORKS PDM licenses.

- Web Server and Web2 Server -> Offers online file vault access to clients that use browsers.

- ExalEAD is the server for the Web API. A Web API server allows OnePart users to index and get SOLIDWORKS PDM data.

85. What is the function of the SOLIDWORKS Costing Tool?

Ans:

The tool helps manufacturers provide precise quotes to clients and helps designers make well-informed decisions based on manufacturing costs. The revised pricing and a comprehensive cost breakdown are always readily apparent when making changes to a design. Furthermore, Create thorough cost reports automatically. In addition, users can designate team members to particular products and services.

86. What are the fundamental components of SOLIDWORKS Electrical?

Ans:

- SOLIDWORKS offers electrical schematic generation tools for two-dimensional dynamic systems.

- SOLIDWORKS Electrical 3D offers tools for combining 2D schematics with 3D models so that electrical systems, including cables and wires, can be modeled in three dimensions.

- Data is a database of parts, symbols, libraries, and catalogs that users can exchange.

- A device A collaborative server is used to manage the entry and updating of electrical designs.

- An instance of a Microsoft SQL Server database.

87. How does SOLIDWORKS Electrical handle data?

Ans:

Every project in SOLIDWORKS Electrical is given a unique ID number, which may be used to access the linked database for that project. In the SOLIDWORKS Electrical Project Leader, for example, the database for a project with the ID number 112 is named “tew project data 112.” Having its own database can greatly reduce each project’s processing time.

88. How is the Visualise function in SOLIDWORKS?

Ans:

To create exceptionally lifelike renderings of 3D CAD models, SOLIDWORKS Visualise provides a set of stand-alone software tools that combine state-of-the-art rendering technology with visual design-oriented features and workflows.

There are two packages available for SOLIDWORKS Visualise products:

- Expert.

- Conventional.

89. Explain DFMXpress?

Ans:

- To make sure that designs can be built using standard manufacturing processes, DFMXpress is a tool that can assess a rule set particular to manufacturing processes.

- Sheet metal, injection molding, turning and milling, and milling are the operations that can be assessed.

- The simplest parameters offered by injection molding include figuring out whether design falls into the specified range of wall thickness.

90. How can access be gained to the SOLIDWORKS admin portal?

Ans:

Must have a Guest, Standard, or Professional account on MySolidWorks in addition to a SOLIDWORKS ID in order to use the Admin Portal. Any advertising customer with a valid SOLIDWORKS ID, however, can login to MySolidWorks.com and, if eligible, access the Admin Portal, regardless of their subscription status.

Go into the program:

- Click Login in the Welcome dialog box or Login in the SOLIDWORKS title bar.

- Type in SOLIDWORKS ID in E-mail. E-mail address may be found in the SOLIDWORKS ID.

- Type password into Password.

- Select “Log in.”