- Introduction to Global Supply Chain Management

- Key Components of Global Supply Chains

- Global Logistics and Transportation

- Supply Chain Planning and Forecasting

- Technology in Global Supply Chains

- Risk Management and Compliance

- Sustainability and Ethical Sourcing

- Global Supply Chain Challenges

Introduction to Global Supply Chain Management

Global Supply Chain Management, or GSCM, refers to the comprehensive handling and oversight of the flow of goods, services, information, and finances from the point of origin to the final customer on an international scale. It involves managing and coordinating complex networks that span multiple countries, industries, and business functions. In today’s interconnected and highly competitive world, businesses no longer operate in isolation. Instead, they are part of vast global networks that include suppliers, manufacturers, distributors, and retailers across different regions. The primary focus of GSCM is to optimize these flows to ensure cost efficiency, high quality, and timely delivery of products and services. The rapid growth of e-commerce, the expansion of global sourcing, the establishment of international trade agreements, and the adoption of PMP Training have all contributed to making supply chains more intricate and widespread than ever before. GSCM encompasses a wide range of activities such as procurement, production planning, inventory management, transportation logistics, and customer service. Because these processes involve many stakeholders across different time zones and cultural contexts, successful global supply chain management requires seamless collaboration and communication. It also demands the integration of advanced technologies and streamlined processes to enhance visibility and responsiveness throughout the supply chain. As globalization continues to accelerate, GSCM is increasingly critical for organizations seeking to remain competitive in international markets. By effectively managing their global supply chains, companies can reduce operational costs, improve efficiency, and better satisfy customer expectations. Overall, mastering GSCM is essential for businesses aiming to navigate the complexities of the global economy and achieve long-term success.

Interested in Obtaining Your PMP Certificate? View The PMP Certification Training Offered By ACTE Right Now!

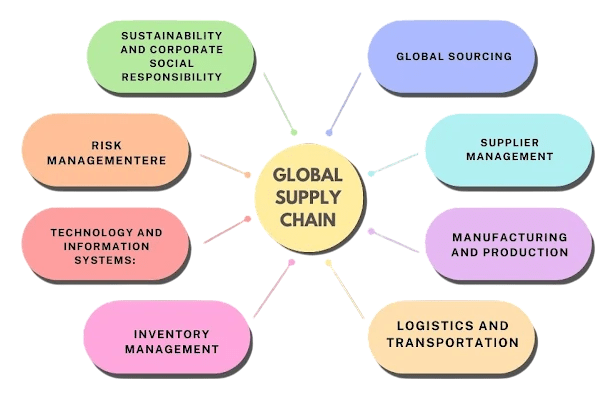

Key Components of Global Supply Chains

The key components of a global supply chain include suppliers, manufacturers, logistics, distribution, and customers, each playing a crucial role in ensuring products reach their destinations on time, within budget, and at the desired quality. Suppliers are the starting point, providing the raw materials or components necessary for manufacturing. They are responsible for sourcing and delivering these inputs reliably and consistently, which forms the foundation for the entire supply chain. Next, manufacturers transform these raw materials into finished products. This process often involves multiple stages, which may occur in different locations worldwide, requiring careful coordination and quality control to maintain standards and efficiency, similar to the differing focus areas in the roles of Business Analyst vs Financial Analyst. Logistics is another vital component, encompassing the planning and management of moving goods between locations. This includes transportation, warehousing, and inventory management. Effective logistics ensures that materials and finished products flow smoothly through the supply chain without unnecessary delays or costs. Once the products are ready to be sold, the distribution network takes over. Distribution channels can include wholesalers, retailers, and increasingly, e-commerce platforms. Their role is to ensure products are delivered to customers efficiently, handling everything from order fulfillment to last-mile delivery. At the center of the entire supply chain are the customers. As the end users, their needs and preferences drive the demand for products, shaping how the supply chain operates.

Successful global supply chain management depends on the efficient coordination and integration of all these components. Any delay, inefficiency, or breakdown in one area can cause disruptions or increase costs throughout the system. Therefore, companies must carefully manage and optimize each component to build a resilient and competitive supply chain capable of meeting the challenges of the global market.

Global Logistics and Transportation

- Core Role of Logistics: Logistics is central to global supply chains, managing the movement of goods from one location to another. It involves planning, implementing, and controlling the efficient flow of products over long distances, often crossing international borders.

- Global Transportation Modes: Transportation is a key element of logistics, utilizing multiple modes including air, sea, rail, and road. Each mode offers different advantages depending on factors like cost, speed, and cargo type.

- Transportation Management Factors: Effective transportation management must balance cost, transit time, route optimization, and regulatory compliance to ensure smooth and efficient delivery processes.

- International Shipping Complexities: Shipping goods internationally involves additional challenges such as customs clearance and international tariffs, which can impact delivery schedules and costs, much like how understanding What are Scrum Ceremonies helps manage workflow and timelines in agile projects.

- Mode Selection Considerations: Choosing the right transportation mode depends on the product type, customer urgency, and budget constraints. For example, sea freight is cost-effective for bulk shipments but slower, while air freight is faster but significantly more expensive.

- Technology in Logistics: Modern logistics increasingly relies on technologies like GPS for tracking, IoT devices for real-time monitoring, and advanced analytics for route optimization and predictive planning, enhancing efficiency and visibility.

- Customer-Centric Logistics: Effective logistics management ensures timely deliveries that meet customer expectations by carefully selecting transportation methods and leveraging technology to adapt to changing demands and market conditions.

- Definition of Supply Chain Planning: Supply chain planning coordinates all activities from procurement through production to final delivery, ensuring the smooth flow of goods and services within the supply chain.

- Role of Forecasting: Forecasting is a critical part of supply chain planning, predicting product demand to help businesses determine optimal inventory levels, production schedules, and supply chain operations.

- Importance of Accurate Forecasting: Accurate forecasts, supported by PMP Training, prevent overstocking, which raises inventory holding costs, and understocking, which causes lost sales and customer dissatisfaction.

- Forecasting Methods: Businesses use a variety of forecasting techniques, including historical data analysis, trend extrapolation, and advanced approaches like machine learning algorithms to improve prediction accuracy.

- Real-Time Data Integration: Successful supply chain planning relies on integrating real-time data from diverse sources such as sales figures, market trends, and supplier performance to enable timely and informed decision-making.

- Cross-Departmental Collaboration: Coordination among departments like procurement, production, and sales is essential to align production schedules with inventory needs and customer demand, ensuring efficiency and responsiveness.

- Global Complexity: Supply chain planning on a global scale is more complex, requiring forecasting across different regions with diverse market conditions, customer preferences, and economic factors, demanding sophisticated tools and strategies.

- Vulnerabilities in Global Supply Chains: Global supply chains are exposed to various risks such as natural disasters, geopolitical instability, cyber threats, and disruptions that can significantly impact operations.

- Critical Role of Risk Management: Managing these risks is a key part of Global Supply Chain Management (GSCM). Companies must develop strategies to reduce the negative effects of potential supply chain disruptions.

- Risk Identification and Assessment: Effective risk management involves identifying potential threats, evaluating how likely they are to happen, and understanding their possible impact on the supply chain.

- Mitigation Through Diversification: One common approach is diversifying suppliers and sourcing materials from multiple regions, similar to how teams choose tools like Jira vs Trello based on their specific project management needs.

- Complex Compliance Requirements: Companies must comply with a variety of international regulations, including trade laws, tariffs, labor standards, and environmental policies, which can be complex and vary by country.

- Consequences of Non-Compliance: Failing to meet regulatory requirements can result in fines, damage to brand reputation, and loss of access to key markets, making compliance a critical priority.

- Technology’s Role in Risk and Compliance Management: Technological tools, such as supply chain software and predictive analytics, help companies monitor compliance in real-time and forecast risks before they disrupt operations, enhancing supply chain resilience.

To Earn Your PMP Certification, Gain Insights From Leading Blockchain Experts And Advance Your Career With ACTE’s PMP Certification Training Today!

Supply Chain Planning and Forecasting

Technology in Global Supply Chains

Technology has become a vital factor in managing global supply chains, significantly transforming how companies operate and compete in today’s complex markets. Advancements in automation, data analytics, and communication technologies have revolutionized supply chain management by making processes more efficient, transparent, and adaptable to change. One of the key areas where technology has had a major impact is automation. Robotics and automated systems have streamlined manufacturing and warehouse operations, reducing human error and boosting overall efficiency. Automated equipment can handle repetitive tasks quickly and accurately, freeing up human workers to focus on higher-value activities. Data analytics is another powerful tool shaping supply chain management. Advanced analytics enable companies to collect and analyze vast amounts of data generated throughout the supply chain, aligning with the Key Values and Principles Behind the Agile Manifesto that emphasize responsiveness and continuous improvement. This helps businesses forecast demand more accurately, monitor the performance of suppliers and logistics providers, and optimize inventory levels and production schedules. By leveraging these insights, organizations can reduce costs, improve service levels, and anticipate potential issues before they escalate. The Internet of Things (IoT) adds further value by providing real-time visibility of goods in transit. IoT devices such as sensors and GPS trackers allow companies to monitor the location and condition of shipments, including factors like temperature and humidity. This real-time data helps companies respond quickly to disruptions, such as delays or product spoilage, ensuring customer satisfaction. Artificial intelligence (AI) enhances decision-making across various supply chain functions. AI algorithms can optimize delivery routes to save time and fuel, predict equipment failures to avoid costly downtime, and improve demand forecasting by analyzing complex patterns. Together, these technologies enable companies to make more informed decisions, improve supply chain visibility, and respond rapidly to changes and disruptions. As a result, technology is now a central driver of effective global supply chain strategies and business success.

Looking to Master PMP? Discover the PMP Master Program Training Course Available at ACTE Now!

Risk Management and Compliance

Sustainability and Ethical Sourcing

Sustainability has become a central concern for today’s supply chains as environmental and social awareness continues to grow worldwide. Businesses face increasing pressure from customers, regulators, and stakeholders to adopt sustainable practices throughout their supply chains. This involves a broad range of actions, including reducing carbon footprints, minimizing waste, and ensuring that the sourcing of materials is ethical and responsible. Ethical sourcing means working with suppliers who follow strict standards related to human rights, fair labor practices, and minimizing environmental damage. Many companies now prioritize partnerships with suppliers who are committed to these values and who use environmentally friendly materials in their production processes. Sustainability efforts also extend into the logistics side of the supply chain, much like the comparison between Agile vs Waterfall in project management approaches. Transportation is a significant contributor to greenhouse gas emissions, so companies are actively seeking ways to reduce their environmental impact in this area. This includes investing in electric or alternative fuel vehicles, optimizing delivery routes to minimize fuel consumption, and adopting more efficient packaging to reduce waste. By improving the environmental performance of logistics operations, companies not only reduce their carbon footprint but also often realize cost savings. Beyond being a matter of corporate responsibility, sustainability has evolved into a strong competitive advantage. Consumers are increasingly making purchasing decisions based on the environmental and social impact of the products they buy. They expect companies to demonstrate transparency and commitment to sustainable practices. In response, businesses are integrating sustainability into their overall supply chain strategies, not only to meet consumer demand but also to comply with new regulations and standards. Embracing sustainability in the supply chain has become essential for companies aiming to succeed in a market that values ethical and environmentally conscious business practices.

Want to Learn About PMP? Explore Our PMP Interview Questions and Answers Featuring the Most Frequently Asked Questions in Job Interviews.

Global Supply Chain Challenges

Managing a global supply chain is a complex task that presents several significant challenges despite its critical importance to business success. One major challenge is geopolitical instability. Political changes, trade tensions, tariffs, and regulatory shifts can disrupt the smooth flow of goods across borders. These factors can increase costs and lead to delays, making it difficult for companies to plan and execute their supply chain strategies effectively. Another significant issue is supply chain disruptions caused by natural disasters, pandemics like COVID-19, or other unforeseen events. Such disruptions can halt production lines, delay shipments, and create shortages, forcing companies to quickly adapt to maintain operations and customer satisfaction. Operating across multiple countries also brings cultural and language barriers. Differences in business practices, communication styles, and languages can lead to misunderstandings and coordination difficulties among global teams and suppliers, making PMP Training essential for effective management. This challenge requires companies to invest in cross-cultural training and develop clear communication protocols. Another persistent challenge is inventory management. Finding the right balance between having enough inventory to meet customer demand and avoiding excess stock that ties up capital and increases storage costs is especially difficult in global supply chains where lead times can be long and unpredictable. To address these challenges, companies need to adopt a flexible and resilient approach. Diversifying suppliers across different regions reduces dependency on any single source and mitigates risks. Building robust contingency plans ensures readiness to respond to disruptions promptly. Additionally, embracing modern technologies that enhance supply chain visibility and agility allows organizations to monitor operations in real time and make data-driven decisions. By combining strategic planning, risk management, and technological innovation, companies can better navigate the complexities of global supply chains and maintain competitive advantage.