- Introduction to Sourcing in Supply Chain Management

- Definition and Importance of Sourcing

- Types of Sourcing Strategies

- The Sourcing Process Explained

- Key Factors Influencing Sourcing Decisions

- Sourcing Challenges in Modern Supply Chains

- The Role of Technology in Sourcing

- Conclusion

Introduction to Sourcing in Supply Chain Management

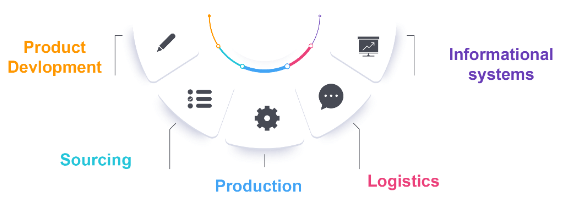

Supply chain management (SCM) involves the coordination of all activities required to produce and deliver a product or service to the end customer. A key component of this process is sourcing, which focuses on acquiring the raw materials, goods, and services necessary for production and business operations. Sourcing goes beyond simply selecting suppliers. It involves evaluating vendor capabilities, negotiating contracts, managing supplier relationships, and ensuring quality, cost-effectiveness, and reliability across the supply network. Effective sourcing plays a major role in driving cost efficiency, maintaining product quality, and creating a competitive advantage. When sourcing is well-managed, companies can reduce production costs, respond more quickly to market demands, and build a more flexible and resilient supply chain. It also enables businesses to access innovation and new technologies by partnering with the right suppliers and incorporating PMP Training. As markets become increasingly global and competitive, sourcing decisions have grown more complex and influential in overall supply chain strategy. In today’s dynamic business environment, sourcing must also address additional challenges such as fluctuating prices, global supply risks, regulatory compliance, sustainability, and ethical sourcing practices. Companies are expected to ensure transparency, environmental responsibility, and social accountability across their supply chains. At the same time, the rise of digital tools and technologies like artificial intelligence, data analytics, and cloud-based procurement systems has significantly improved the efficiency and accuracy of sourcing decisions. As a result, sourcing professionals must combine analytical thinking, negotiation skills, market insight, and the ability to adapt to global trends. In the broader context of supply chain management, strategic sourcing is no longer just a supporting function. It is a critical factor that shapes a company’s performance, resilience, and long-term success.

Do You Want to Learn More About PMP? Get Info From Our PMP Certification Training Today!

Definition and Importance of Sourcing

Sourcing is the process of identifying, evaluating, and selecting suppliers that can provide the goods or services necessary for an organization’s operations. It represents the first step in the procurement lifecycle and plays a foundational role in shaping the efficiency and reliability of a company’s supply chain. Sourcing involves more than just finding vendors. It includes conducting supplier assessments, negotiating contracts, ensuring compliance with quality standards, and managing long-term supplier relationships to support business goals. One of the most important benefits of effective sourcing is cost management, which highlights Why A PMO Is Second In Line To A Project Manager in overseeing project efficiency. By selecting suppliers that offer the best balance between price and quality, organizations can significantly reduce operational expenses without compromising performance. Beyond cost, quality assurance is another critical outcome. Partnering with reliable suppliers helps ensure consistent quality in raw materials, components, or services, which directly impacts product reliability and customer satisfaction. Sourcing also contributes to risk mitigation. By diversifying the supplier base or working with partners known for operational stability, companies can reduce the risk of disruptions caused by delays, shortages, or external shocks such as geopolitical events or natural disasters. In addition, sourcing can drive innovation. Collaborating closely with suppliers enables businesses to tap into new technologies, improve product designs, or find more efficient production methods.

An effective sourcing strategy can also deliver a significant competitive advantage. When a company is able to ensure timely delivery, cost efficiency, and high product quality, it stands out in the marketplace. In a global and fast-changing business environment, sourcing is no longer a back-office function. It is a strategic activity that helps companies strengthen their supply chains, enhance performance, and meet evolving customer expectations.

Types of Sourcing Strategies

- Single Sourcing: This strategy involves procuring a particular product or service from one supplier exclusively. It helps build a strong supplier relationship and may lead to better prices and quality due to volume consolidation, but it carries risks if the supplier fails to deliver.

- Multiple Sourcing: Companies source the same product or service from multiple suppliers. This approach reduces risk by diversifying supply sources and encourages competitive pricing, but it can increase complexity in supplier management.

- Global Sourcing: Organizations procure goods or services from international suppliers to leverage cost advantages, access unique resources, or tap into specialized skills, raising the question Can Business Analyst be a Project Manager?

- Local Sourcing: This strategy focuses on buying from suppliers within the same region or country. It supports local economies, reduces transportation costs and lead times, and enhances supply chain resilience.

- Outsourcing: Companies delegate specific business processes or production activities to third-party vendors. Outsourcing can improve efficiency, reduce costs, and allow the company to focus on core competencies, but it requires careful vendor selection and contract management.

- Insourcing: The opposite of outsourcing, insourcing means performing activities internally within the organization. It offers greater control over quality and processes but can increase operational costs.

- Strategic Sourcing: This long-term approach focuses on developing close relationships with suppliers to create value, improve quality, and reduce costs.

- Identify Requirements: The sourcing process begins by clearly defining the goods or services needed. This includes specifying quality standards, quantities, delivery timelines, and budget constraints to ensure alignment with business objectives.

- Market Research and Supplier Identification: Research potential suppliers through industry databases, trade shows, PMP Training, and recommendations.

- Request for Proposal (RFP) or Quotation (RFQ): Send detailed RFPs or RFQs to shortlisted suppliers, outlining requirements and expectations. This step gathers competitive bids and information necessary for supplier evaluation.

- Supplier Evaluation and Selection: Assess supplier responses based on price, quality, delivery capabilities, compliance, and risk factors. Conduct site visits or audits if needed before selecting the most suitable supplier(s).

- Contract Negotiation and Agreement: Negotiate terms including pricing, delivery schedules, payment terms, and service levels. Formalize agreements through contracts that protect both parties and set clear performance expectations.

- Order Placement and Fulfillment: Place purchase orders according to the contract terms. Monitor order fulfillment, ensuring suppliers meet delivery dates, quality standards, and quantity requirements.

- Ongoing Communication and Continuous Improvement: Regularly monitor supplier performance through key metrics, conduct reviews, and collaborate on process improvements to enhance quality, reduce costs, and foster long-term partnerships.

- Supplier Risk and Reliability: Modern supply chains often face risks related to supplier instability, such as financial difficulties, quality issues, or disruptions caused by natural disasters.

- Globalization and Complexity: Sourcing from multiple countries increases complexity in logistics, customs regulations, tariffs, and cultural differences.

- Cost Pressure and Price Volatility: Fluctuating raw material prices, currency exchange rates, and transportation costs create pressure to keep sourcing expenses low while maintaining quality and service levels.

- Sustainability and Ethical Sourcing: Increasing consumer and regulatory demand for environmentally friendly and ethical sourcing practices adds complexity, highlighting the importance of understanding What is Business Agility.

- Technology Integration: Incorporating advanced technologies like AI, blockchain, and IoT in sourcing processes requires investment and expertise.

- Supplier Collaboration and Communication: Maintaining effective collaboration with suppliers is difficult, especially with remote or global partners.

- Supply Chain Disruptions: Events like pandemics, geopolitical tensions, or natural disasters can abruptly disrupt sourcing channels. Building resilient and flexible sourcing strategies to mitigate such risks remains a key challenge.

Would You Like to Know More About PMP? Sign Up For Our PMP Certification Training Now!

The Sourcing Process Explained

Key Factors Influencing Sourcing Decisions

When developing a sourcing strategy, one of the most important steps is carefully evaluating potential suppliers. The selection process must go beyond basic pricing considerations and take into account a range of operational, strategic, and ethical factors. A supplier’s ability to scale production and meet specific technical requirements is essential, especially for businesses that deal with fluctuating demand or operate in industries with high product complexity. Suppliers must be capable of adapting to changing production volumes while maintaining quality standards and meeting delivery deadlines. This ensures business continuity and supports long-term growth. Another critical area to assess is the geopolitical and financial stability of the supplier, which is among The Most Important Benefits of Blended Learning in risk management education. Companies should consider risks related to political unrest, economic volatility, and regulatory challenges in the supplier’s country of operation. Ensuring that a supplier can remain compliant with relevant trade regulations and industry standards helps prevent legal issues and potential disruptions in the supply chain. Financial health is also important, as working with suppliers that are financially unstable could lead to unexpected delays, bankruptcy, or failure to fulfill contracts. Beyond operational and financial considerations, sustainability and ethics are becoming central to supplier selection. Organizations are increasingly expected to evaluate the environmental impact of their sourcing decisions, including emissions, energy usage, and waste generation. In addition, factors such as labor practices, workplace safety, and corporate social responsibility (CSR) play a growing role. Choosing suppliers that follow ethical standards and promote social responsibility helps companies align with global sustainability goals and maintain a positive brand image. By balancing technical capability, risk management, and ethical responsibility, businesses can build a resilient, responsible, and future-ready supply chain.

Are You Considering Pursuing a Master’s Degree in PMP? Enroll in the PMP Master Program Training Course Today!

Sourcing Challenges in Modern Supply Chains

The Role of Technology in Sourcing

Technology is playing a transformative role in the way companies approach sourcing, making processes more efficient, transparent, and data-driven. One of the key advancements is the rise of e-procurement platforms. These platforms automate many of the manual tasks involved in sourcing, such as issuing requests for proposals, managing bids, and communicating with suppliers. By streamlining these workflows, organizations can reduce errors, save time, and improve the speed of procurement cycles. Another important innovation is the use of supplier portals. These online portals serve as centralized hubs where buyers and suppliers can share critical data, track orders, and collaborate in real time. Supplier portals improve communication, reduce misunderstandings, and enhance overall coordination across the supply chain, leading to better supplier relationships and more responsive sourcing operations in Projects in Business Environments. The integration of artificial intelligence (AI) and advanced analytics has further elevated sourcing capabilities. AI-powered tools enable companies to perform deeper supplier risk assessments by analyzing large volumes of data from diverse sources. Additionally, AI enhances demand forecasting accuracy and provides detailed spend analysis, helping organizations make smarter Technology in Sourcing decisions and identify cost-saving opportunities. Blockchain technology is gaining traction for its ability to provide greater transparency and traceability in supply chains. By creating immutable records of transactions and product movements, blockchain helps verify the authenticity of goods, reduces fraud, and builds trust among supply chain partners. Finally, cloud-based solutions offer the flexibility and scalability needed for global sourcing operations. Cloud technology enables organizations to access sourcing tools from anywhere, easily scale their processes up or down, and integrate with other systems, facilitating seamless global collaboration. Together, these technological innovations are reshaping sourcing into a more strategic, efficient, and resilient function.

Go Through These PMP Interview Questions and Answers to Excel in Your Upcoming Interview.

Conclusion

Sourcing is a pivotal element in supply chain management that directly impacts an organization’s cost structure, product quality, and overall operational efficiency. As companies navigate the complexities of an increasingly globalized market, the ability to develop and execute effective sourcing strategies has become more important than ever. Successful sourcing ensures that businesses acquire the right materials and services at the best possible price without compromising quality or reliability. This balance helps control expenses while maintaining high standards, ultimately improving profitability and customer satisfaction. In today’s fast-changing environment, sourcing is not simply a transactional function. It requires a strategic approach that takes into account various critical factors such as supplier reliability, risk mitigation, regulatory compliance, and ethical considerations. Companies that can evaluate these factors effectively through PMP Training are better equipped to avoid disruptions and build long-lasting supplier relationships. Additionally, sourcing plays a central role in driving innovation by collaborating with suppliers to introduce new materials, processes, or technologies that can improve products or reduce costs. Technology is also transforming sourcing by enabling greater efficiency, transparency, and data-driven decision-making. Digital tools like e-procurement platforms, artificial intelligence, blockchain, and cloud-based systems allow organizations to streamline workflows, assess supplier risks, and enhance collaboration. Embracing these innovations helps companies build sourcing processes that are agile and scalable, capable of adapting to market fluctuations and global challenges. By gaining a thorough understanding of the sourcing process, key success factors, and emerging technological trends, companies can develop robust and sustainable supply chains. These supply chains will be better positioned to respond to future challenges and deliver competitive advantage in an ever-evolving business landscape.