The CATIA interview questions and answers offered by our ACTE Training Institute provide a comprehensive resource for individuals preparing for CATIA-related job interviews. These questions cover a diverse range of topics and explore fundamental concepts, advanced functionalities, and practical applications within CATIA software. The guide is structured to enhance the understanding of CATIA, from basic features to complex design scenarios. Whether you’re a beginner or an experienced professional, the resource is a valuable tool to reinforce CATIA skills and confidently navigate interviews in various job roles related to computer-aided design and engineering.

1. What does CATIA stand for?

Ans:

CATIA stands for Computer-Aided Three-Dimensional Interactive Application. Developed by Dassault Systèmes, it is a powerful and versatile CAD (Computer-Aided Design) software widely used in industries for product design and development. The software supports multi-disciplinary design processes, aiding in complex projects.

2. Explain the primary purpose of CATIA.

Ans:

The primary purpose of CATIA is to facilitate the creation, modification, and analysis of 3D models for product design. It is a comprehensive tool for engineers and designers to collaboratively work on various aspects of product development, including conceptualization, detailed design, simulation, and manufacturing. It integrates seamlessly with product data management systems for efficient information handling.

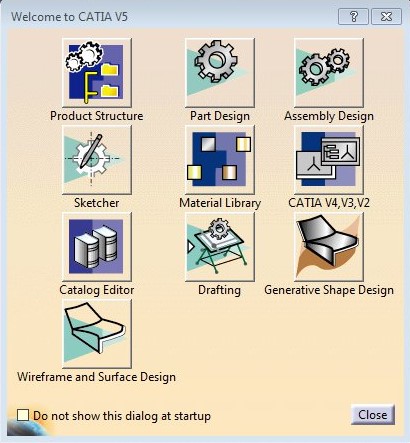

3. Name the various workbenches in CATIA.

Ans:

CATIA encompasses diverse workbenches, each tailored to specific facets of the product development process. The Part Design workbench focuses on creating detailed 3D models for individual components, providing tools for sketching and defining parameters.

4. Differentiate between Part Design and Assembly Design workbenches.

Ans:

| Aspect | |||

| Purpose | Focused on creating and defining individual part models. | Concentrates on assembling and managing multiple parts to create an entire product. | |

| Scope | Deals with designing a single part or component. | Assembly of multiple parts into a complete product structure. | |

| Functionality | Provides tools for sketching, extruding, and shaping individual parts. | Offers tools for assembling, constraining, and managing relationships between parts. | |

| Dependencies | Operates independently of other parts within an assembly. | Relies on the relationships and dependencies between various parts. | |

| Final Output | Generates a finalized part model. | Produces a finalized product structure consisting of assembled parts. | |

| Examples | Creating a single component like a bracket or a gear. | Assembling multiple components like an engine or a machine. |

5. How does CATIA contribute to product lifecycle management (PLM)?

Ans:

CATIA contributes to Product Lifecycle Management (PLM) by providing a platform for collaborative product development. It enables teams to work seamlessly across different stages of product creation, from initial design to simulation, analysis, and manufacturing, fostering efficient communication and data management.

6. How do you create a new sketch in CATIA?

Ans:

To create a new sketch in CATIA, you typically select the Sketcher workbench, choose a plane or surface, and then use sketching tools to draw 2D geometry. This can include lines, circles, arcs, and other shapes, forming the basis for creating 3D features. Access the sketching tools in the “Sketch” toolbar or a similar menu.

7. Explain the difference between absolute and relative coordinate systems in the Sketcher workbench.

Ans:

| Absolute Coordinate System | Relative Coordinate System |

| Positioned with respect to a fixed reference point. | Positioned relative to other sketch elements or a reference. |

| Positions remain constant, unaffected by changes elsewhere. | Positions adjust dynamically based on changes in referenced elements. |

| Stable and precise, less flexible for dynamic adjustments. | Flexible, adaptable to changes within the sketch. |

| Preferred for precise and static designs. | Useful for maintaining relationships and dynamic adjustments. |

| Point (5, 8) fixed in relation to the origin. | Line starting from the endpoint of another |

8. What are the constraints in CATIA Sketcher, and how are they applied?

Ans:

In CATIA’s Sketcher workbench, constraints are geometric relationships and rules applied to sketch elements to control their dimensions, shapes, and positions. These constraints ensure the sketch maintains design intent and behaves predictably during modifications. To apply constraints, users select the relevant sketch elements and choose the appropriate constraint from the constraint toolbar or menu.

9. How can you modify a sketch in CATIA?

Ans:

- Modifying a sketch in CATIA involves a series of actions to refine or alter existing geometry within the Sketcher workbench.

- Once a sketch is created, users can access various modification tools to make changes.

- These tools include options for adding or removing sketch elements, adjusting dimensions, and applying constraints.

- For instance, to move a sketch entity, users can select and drag it to the desired position.

10. How do you create a new part in CATIA?

Ans:

To create a new part in CATIA, you typically follow a series of steps within the software. After launching CATIA, select the “Part Design” workbench from the available workbenches specifically designed for creating and modelling 3D parts. Once in the Part Design workbench, you can define the basic parameters of your part, such as its name, material, and other specifications.

11. Explain the role of the Pad feature in Part Design.

Ans:

- Extrusion: The Pad feature in Part Design is used for extruding a 2D sketch in a linear direction to create a 3D solid.

- Creating Volume: It helps add material and create volume to the part, extending it along a specified axis.

- Customizable Parameters: Users can define parameters such as length, draft angle, and more to customize the extruded shape.

- Basic Building Block: The Pad is a fundamental feature used in creating complex 3D models by building upon or subtracting from it.

12. What is the pocket feature used for in Part Design?

Ans:

- Material Removal: The Pocket feature removes material from a part, creating a cavity or recess.

- Inverse of Pad: It is essentially the inverse of the Pad feature, allowing for the creation of voids within a part.

- Customizable Dimensions: Similar to Pad, users can customize parameters like depth and shape to create pockets of varying sizes and configurations.

- Complex Shapes: Enables the creation of complex internal geometries within a part.

13. How can you create a hole in a part using CATIA?

Ans:

Open the Part Design workbench and enter the Sketcher workbench. Use sketching tools to draw the hole profile on the desired face or plane. Add dimensions and constraints to specify the hole’s size, position, and other characteristics. Exit the Sketcher workbench once the hole profile is complete.

14. What is the purpose of the Assembly Design workbench?

Ans:

- Managing Assemblies: The Assembly Design workbench in CATIA is used for creating and managing assemblies of multiple parts.

- Component Relationships: It allows users to define relationships and constraints between components within an assembly.

- Assembly Visualization: Provides tools for visualizing and organizing the components in an assembly.

- Motion Simulation: This can be used for basic motion simulation and checking interferences between components.

15. How do you insert components into an assembly in CATIA?

Ans:

- Drag-and-Drop: Components can be inserted into an assembly by dragging and dropping them from the Part Design or other workbenches.

- Assembly Constraints: Users can define constraints like coincident, parallel, etc., to position components relative to each other.

- Catalog Browser: Components can be inserted from a catalogue browser, organizing and streamlining the assembly process.

- Multi-Document Environment: CATIA’s multi-document environment allows users to open multiple part documents and insert them into an assembly.

16. Explain the difference between rigid and flexible sub-assemblies.

Ans:

- Rigid Sub-Assembly: In a rigid sub-assembly, the components are constrained, so they cannot move relative to each other.

- Limited Movement: Changes in the position of one component are constrained, affecting the overall geometry of the sub-assembly.

- High Precision: Suitable for situations where high precision and stability are essential.

- Flexible Sub-Assembly: In a flexible sub-assembly, some degree of movement is allowed between the components.

17. What is a constraint, and how is it used in assembly design?

Ans:

- Relationship Definition: A constraint defines the relationship between two or more components in an assembly.

- Ensuring Alignment: It ensures that specific geometric or positional conditions are met, like aligning faces or maintaining a certain distance.

- Degrees of Freedom: Constraints restrict the degrees of freedom of components, preventing unintended movement.

- Interactive Adjustment: Constraints can be interactively adjusted, facilitating design changes while maintaining assembly integrity.

18. Describe the role of the Generative Shape Design workbench.

Ans:

- Advanced Surface Modeling: The Generative Shape Design workbench uses advanced surface modelling techniques.

- Complex Curves and Surfaces: It allows the creation of complex curves and surfaces that might be challenging with traditional solid modelling.

- Aesthetic Design: Often used for aesthetic design, the emphasis is on the form and appearance of the product.

19. How do you create a wireframe in CATIA?

Ans:

Wireframes are created by sketching 2D profiles in the Sketcher workbench. Basic lines, arcs, and other curves form the foundation of wireframe creation. Wireframes can be edited and modified easily by adjusting sketch elements. Wireframes are the basis for creating 3D models through extrusion, revolution, or other operations.

20. Explain the concept of surface modelling in Generative Shape Design.

Ans:

- Non-Solid Modeling: Unlike traditional solid modelling, Generative Shape Design focuses on creating surfaces without necessarily forming closed, solid volumes.

- Sculpting and Shaping: It allows more freedom and creativity to sculpt and shape surfaces.

- Class-A Surfaces: Often used in the automotive and industrial design industries to achieve Class-A surfaces with high aesthetic and manufacturing standards.

- Complex Geometry: Suitable for generating intricate and complex surface geometries that might be challenging with other modelling approaches.

21. How do you create a drawing in CATIA?

Ans:

To create a drawing in CATIA, navigate to the Drafting workbench, select the desired views of the 3D model, and arrange them on the drawing sheet. The Drafting workbench provides tools for precise control over the presentation of the model on the drawing sheet, ensuring accurate and comprehensive documentation.

22. What are the key elements of a CATIA drawing sheet?

Ans:

Key elements of a CATIA drawing sheet include title blocks, views of the 3D model, dimensions, annotations, symbols, and other detailed elements. The title block typically contains the part name, revision, scale, and other important metadata. The drawing may include section views, exploded views, and auxiliary views to comprehensively represent the design.

23. How can you add dimensions and annotations in the Drafting workbench?

Ans:

CATIA provides a range of dimensioning options, allowing users to specify lengths, angles, and other geometric properties for clear communication of design intent. This process allows designers and engineers to create comprehensive and detailed drawings in CATIA’s Drafting workbench, aiding in effective communication during a project’s manufacturing and assembly phases.

24. What is the purpose of the DMU Kinematics workbench?

Ans:

The DMU Kinematics workbench in CATIA simulates and analyses the motion of analyzing assemblies within a 3D digital environment. This workbench is instrumental in studying the dynamic behaviour of complex mechanisms, such as automotive components, machinery, or any assembly involving moving parts.

25. Explain the difference between joint and mechanical connections in kinematics.

Ans:

In kinematics, the terms “joint” and “mechanical connection” refer to distinct concepts related to modelling connections and relationships between components in a mechanical assembly. A joint represents a specific type of connection that allows relative motion between two components.

26. How do you simulate motion in DMU Kinematics?

Ans:

In DMU Kinematics, simulating motion involves defining connections, constraints, and parameters to replicate the dynamic behaviour of mechanical assemblies within a 3D digital environment. The process typically begins by selecting the components involved in the assembly and specifying the type of joints or mechanical connections between them.

27. Discuss the major differences between CATIA V5 and CATIA V6.

Ans:

CATIA V5 and CATIA V6 are two different versions of Dassault Systèmes’ CATIA software, each with its features and architecture. CATIA V5 operates on a file-based system, storing each model in a separate file, making collaboration more challenging. The licensing and pricing models differ between the two versions, with CATIA V6 often adopting a subscription-based model that aligns with Dassault Systèmes’ 3DEXPERIENCE platform.

28. What are the advantages of upgrading from CATIA V5 to CATIA V6?

Ans:

Upgrading from CATIA V5 to CATIA V6 offers several advantages that align with the evolving needs of modern product development. One key advantage is the shift to a more collaborative and integrated platform. This facilitates real-time collaboration, allowing multiple users to simultaneously work on the same project, leading to increased efficiency and streamlined workflows.

29. How can you customize the toolbars in CATIA?

Ans:

Customizing toolbars and CustomizingATIA allow users to tailor the software interface to their specific workflow and preferences. Customizers can access the “Customize” command in the “Tools” menu to customize toolbars. This opens the customization window, which adds, removes, or rearranges commands on toolbars and menus.

30. Explain the use of macros in CATIA customization.

Ans:

In CATIA customization, macros customization automates repetitive tasks and enhances user efficiency. A macro in CATIA is a set of recorded actions or a scripted sequence of commands that can be executed to perform a specific task. Users can create and customize macros to auto-customize the actions, reducing the time and effort required for routine processes.

31. Name the analysis workbenches in CATIA.

Ans:

- Structural Analysis

- Thermal Analysis

- Dynamic Response Analysis

- Fluid Flow Analysis

- Kinematics and Dynamics Analysis

32. How does the Finite Element Analysis (FEA) workbench contribute to design validation?

Ans:

- FEA in CATIA assesses the structural integrity of components by simulating how they respond to various loads and constraints.

- It helps identify potential weaknesses, optimize designs, and optimize whether the product meets performance and safety requirements.

- FEA involves dividing a complex structure into smaller, finite elements to numerically analyze and predict how the analysis will respond to various physical conditions and loads.

33. What is the role of the CATIA Simulation workbench?

Ans:

- The Simulation workbench in CATIA provides a comprehensive environment for simulating and validating product behaviour under various conditions.

- It encompasses a range of analyses, including stress analysis, thermal analysis, and kinematics, aiding in optimization and validation optimizing.

- It helps predict the response to forces, vibrations, and other dynamic inputs.

34. How can you perform structural analysis in CATIA?

Ans:

In CATIA, structural analysis is performed in the Structural Analysis workbench. Users define material properties, loads, and constraints and then analyze how structures banalyzender different conditions to ensure they meet performance criteria. Evaluate whether the structure meets design criteria and performance requirements. CATIA allows you to generate detailed reports summarising the structural analysis results.

35. Name some additional modules or add-ons available in CATIA.

Ans:

- CATIA Machining (CAM)

- CATIA V5 Robotics

- CATIA Composites Design

- CATIA Electrical Design

- CATIA Piping and Tubing Design

36. How does CATIA support CNC machining?

Ans:

- CATIA’s Machining workbench provides tools for creating CNC programs, defining toolpaths, and simulating machining operations, ensuring accurate and efficient manufacturing.

- This ensures that the generated toolpaths are compatible with the specific capabilities of the target machine.

- This includes tool lists, setup sheets, and other information necessary for the efficient execution of machining operations.

37. How does CATIA facilitate collaboration between design teams?

Ans:

- CATIA supports collaborative design through its integrated platform, enabling multiple team members to simultaneously work on the same project.

- CATIA supports real-time collaboration features, enabling team members to simultaneously work on the same project.

- This is especially valuable for distributed teams or situations where multiple designers must contribute to a project concurrently.

- Access control mechanisms contribute to data security and confidentiality.

38. Explain the integration of CATIA with other PLM tools.

Ans:

CATIA integrates with other PLM (Product Lifecycle Management) tools through standard data exchange formats, promoting seamless collaboration across the product development lifecycle. Integration ensures consistent and up-to-date data across different stages of product development. ENOVIA acts as a centralized data repository.

39. Why is CATIA certification beneficial for a professional?

Ans:

CATIA certification validates a professional’s proficiency in using the software. It enhances career prospects, demonstrates expertise to employers, and increases credibility in product design and engineering. Dassault Systems, the developer of CATIA, typically endorses CATIA certifications. This assures employers that the certification aligns with industry standards and reflects software proficiency.

40. Name some popular CATIA certifications and their significance.

Ans:

- CATIA Associate Certification: Validates foundational skills.

- CATIA Professional Certification: Demonstrates advanced proficiency.

- CATIA Specialist Certification: Focuses on specific modules, such as Part Design or Assembly Design.

41. Discuss the use of CATIA in the aerospace industry.

Ans:

CATIA plays a crucial role in the aerospace industry, serving as a comprehensive aircraft design and manufacturing tool. Engineers utilize CATIA to create detailed 3D models of aircraft components, perform structural and aerodynamic analyses, and simulate complex assembly processes.

42. How is CATIA utilized in the automotive design and manufacturing sector?

Ans:

CATIA to create detailed 3D models of automotive components, including the chassis, body, and interior. The software’s parametric modelling and assembly design features allow for efficient exploration of design alternatives. CATIA is also instrumental in simulating crash tests, aerodynamics, and manufacturing processes, ensuring the development of safe, fuel-efficient, and aesthetically pleasing vehicles.

43. What are some best practices for efficient modelling in CATIA?

Ans:

Best practices for efficient modelling in CATIA include maintaining a well-organized product structure, utilizing parametric design principles, and leveraging design templates. Efficient file management, naming conventions, and strategic use of part design features contribute to a streamlined modelling process.

44. How can you optimize large assemblies in CATIA?

Ans:

Users can utilize features like simplified representations, level of detail management, and selective loading of components to optimize large assemblies in CATIA. Employing lightweight representations, suppressing non-essential features, and utilizing caching mechanisms help enhance performance.

45. What are the capabilities of the CATIA Imagine and Shape module?

Ans:

The CATIA Imagine and Shape module is designed for freeform surface modelling. It enables designers to create aesthetically pleasing and highly stylized shapes by manipulating control points on a surface. This module is particularly valuable in automotive and industrial design industries.

46. Explain the use of the CATIA Live Rendering feature.

Ans:

- The CATIA Live Rendering feature provides real-time visualization of 3D models with high-quality rendering effects.

- Designers can interactively assess the visual appearance of the product, including materials, lighting, and shadows, making informed decisions during the design process.

- The rendering process involves applying materials, textures, lighting, and other visual properties to a 3D model to simulate how it would appear in a real-world environment.

47. How can you use VBScript or Python for automation in CATIA?

Ans:

Automation in CATIA can be achieved using VBScript or Python scripting languages. Users can create scripts to automate repetitive tasks, generate parametric designs, and perform batch operations. Scripting in CATIA enables enhanced efficiency, consistency, and customization, especially in scenarios involving repetitive actions or complex algorithms.

48. Discuss the benefits of scripting in CATIA.

Ans:

Scripting in CATIA offers benefits such as improved productivity, consistency in design practices, and the ability to handle complex and repetitive tasks. Automation through scripting reduces manual errors, accelerates design iterations, and allows users to tailor CATIA’s functionality to specific project requirements.

49. What are common issues faced in CATIA, and how can they be resolved?

Ans:

Common issues faced in CATIA include software crashes, slow performance, and compatibility issues. These can often be resolved by updating the latest software version, optimizing hardware resources, and addressing conflicts with other installed software.

50. How do you recover a corrupted CATIA file?

Ans:

- To recover a corrupted CATIA file, users can try opening the file in “Recovery Mode” or using the “Recover Document” feature in CATIA.

- Creating a new CATIA file and importing components from the corrupted file can be a workaround if unsuccessful.

- Regularly saving incremental backups during the modelling process can also mitigate the impact of file corruption by providing earlier versions to revert to in case of issues.

51. Explain the significance of ergonomics design in CATIA.

Ans:

Ergonomics design in CATIA ensures products are user-friendly and comfortable. It considers human factors in design, improving usability and reducing the risk of injuries or discomfort. Products designed with ergonomics in mind are more likely to meet or exceed user expectations.

52. How can you simulate human interactions with a product in CATIA?

Ans:

- CATIA Human Builder allows designers to simulate human postures and movements.

- It aids in evaluating product ergonomics and assessing how users interact with the design.

- Based on the simulation results, make design adjustments to optimize the product for human interactions.

- This may involve modifying the product’s geometry, controls, or other features to enhance usability and comfort.

53. Describe the process of reverse engineering in CATIA.

Ans:

Reverse engineering in CATIA involves creating a digital model from a physical part. It utilizes tools like scanning and point cloud processing to capture the geometry of existing objects. Use CATIA’s surface modelling tools to reconstruct the part’s surfaces based on the point cloud or mesh data. This involves fitting surfaces to the captured data, digitally representing the part’s external shape.

54. How can CATIA be used to recreate a physical part digitally?

Ans:

- CATIA’s Reverse Engineering workbench allows users to import scanned data, create a surface model, and generate a digital representation of a physical part.

- Use CATIA’s analysis and validation tools to compare the digital model with the physical part.

- This step helps ensure the recreated digital model aligns closely with the original physical part.

55. Discuss the key features of the Sheet Metal Design workbench.

Ans:

- CATIA’s Sheet Metal Design workbench facilitates creating and modifying sheet metal parts.

- Features include defining parameters, creating bends, and generating flat patterns.

- CATIA Sheet Metal Design includes various features specifically for sheet metal modelling.

- These features include walls, flanges, bends, corners, and reliefs. Users can employ these features to model the various elements of sheet metal parts.

56. How can you create a flat pattern in CATIA for a sheet metal part?

Ans:

In the Sheet Metal Design workbench, users can unfold the 3D sheet metal part to create a flat pattern for manufacturing. Model the sheet metal part by adding features such as flanges, cuts, and bends. Ensure that the design reflects the intended geometry and configuration of the sheet metal component.

57. What is the purpose of the CATIA Electrical Harness Design workbench?

Ans:

The Electrical Harness Design workbench in CATIA is dedicated to designing and routing electrical harnesses in a 3D environment. CATIA allows designers to route individual wires and cables along specified paths within the product assembly.

The workbench provides:

- Tools for guiding the routing through complex geometries.

- Avoiding clashes with other components.

- Ensuring proper bundling.

58. How does CATIA support the design of piping and tubing systems?

Ans:

CATIA provides a dedicated Piping and Tubing Design workbench for creating and routing complex piping and tubing systems within a product assembly. This ensures the design is free from collisions and fits seamlessly into the overall product structure.

59. How can you apply GD&T to a CATIA drawing?

Ans:

In the Drafting workbench, users can apply Geometric Dimensioning and Tolerancing (GD&T) symbols to specify the desired tolerances and geometric conditions on the drawing. After placing GD&T annotations, thoroughly check and validate the dimensions and tolerances to ensure they accurately represent the design intent.

60. Explain the significance of GD&T in product design.

Ans:

- GD&T ensures precise communication of design requirements, enhancing the manufacturability and interchangeability of components.

- It provides a standardized language for expressing geometric and dimensional tolerances in engineering drawings.

- GD&T provides a flexible framework that allows for design changes without overhauling the entire set of dimensioning and tolerancing.

61. What is parametric design in CATIA?

Ans:

Parametric design in CATIA refers to using parameters and constraints to create models that can be easily modified by changing these parameters. It involves associating dimensions, relationships, and constraints with the geometry, enabling designers to create flexible and adaptive models.

62. How can you use parameters and formulas in CATIA?

Ans:

In CATIA, parameters and formulas are utilised to introduce intelligence and flexibility into the design. Parameters represent geometric dimensions or other design attributes, while formulas define relationships between these parameters. By using the Formulas workbench, designers can create mathematical expressions that link parameters, allowing for the dynamic adjustment of model dimensions.

63. Discuss the concept of Model-Based Definition in CATIA.

Ans:

- Model-Based Definition (MBD) in CATIA involves embedding product information, such as dimensions, tolerances, and annotations, directly within the 3D model.

- It eliminates the need for 2D drawings by providing a comprehensive digital representation of the product.

- MBD enhances communication between design and manufacturing teams by offering a single source of truth and reducing reliance on traditional 2D documentation.

64. How does MBD contribute to a paperless manufacturing environment?

Ans:

MBD contributes to a paperless manufacturing environment by eliminating the need for 2D drawings, reducing errors associated with interpretation, and streamlining the transfer of information from design to manufacturing. It enhances collaboration, reduces lead times, and promotes a more efficient and accurate manufacturing process.

65. What are the key features of CATIA’s data management system?

Ans:

CATIA’s data management system encompasses features like version control, access control, and lifecycle management. It ensures that design data is organised, secure, and easily accessible. These features collectively contribute to CATIA’s robust data management capabilities, ensuring that organisations can effectively control, organise, and collaborate on their design data throughout the product lifecycle.

66. Explain the role of CATIA ENOVIA in data management.

Ans:

CATIA ENOVIA is a collaborative data management solution that integrates seamlessly with CATIA. It extends the capabilities of CATIA’s native data management system, providing advanced features for managing complex product data across the entire product lifecycle. ENOVIA facilitates collaboration, version control, and secure access to design information, ensuring data integrity and traceability.

67. How can you create realistic renderings in CATIA?

Ans:

- Realistic renderings in CATIA can be achieved using the Live Rendering feature, which provides real-time visualisation of 3D models with high-quality rendering effects.

- Designers can control lighting, materials, and environments, allowing them to create visually appealing and realistic representations of their designs.

- This feature aids in design reviews, presentations, and marketing materials.

68. Discuss the importance of visualisation in product design.

Ans:

Visualisation in product design is crucial for communicating design intent, evaluating aesthetics, and gaining insights into product performance. It enables stakeholders to understand the appearance and functionality of a product before it is physically produced.

69. How does CATIA support 3D printing?

Ans:

CATIA supports 3D printing by providing tools for preparing and optimising models for additive manufacturing. Designers can use the Generative Shape Design workbench to create complex geometries suitable for 3D printing. Additionally, CATIA supports the export of STL files, a common format for 3D printing, ensuring compatibility with various additive manufacturing processes.

70. What considerations are important when designing a part for 3D printing in CATIA?

Ans:

When designing a part for 3D printing in CATIA, considerations include:

- Ensuring watertight geometry.

- Accounting for support structures.

- Optimising the orientation of the part to minimise layer lines.

71. How can CATIA be used for CNC programming?

Ans:

- Part Design: CATIA allows users to create 3D models of parts.

- Generative Shape Design: Useful for creating complex surfaces.

- Assembly Design: Helps in assembling parts and defining toolpaths.

- Machining Workbench: Specifically designed for CNC programming.

- Toolpath Generation: CATIA generates toolpaths for machining operations.

72. Discuss the steps involved in creating a CNC program in CATIA.

Ans:

- Create or import the 3D model of the part.

- Specify cutting tools and their parameters.

- Choose operations such as milling or turning.

- CATIA automatically generates toolpaths based on selected operations.

- Verify the toolpaths using simulation to detect and correct errors.

- Once satisfied, CATIA can generate the CNC code for the machine.

73. Explain the role of CATIA Robotics Simulation in industrial automation.

Ans:

- Digital Twin: Creates a virtual representation of the robotic system.

- Programming and Simulation: Allows offline programming and simulation of robot movements.

- Collision Detection: Identifies and avoids potential collisions in the workspace.

- Cycle Time Analysis: Assesses the efficiency of robot movements in a given process.

74. How can you simulate robot movements in CATIA?

Ans:

CATIA Robotics Simulation provides a dedicated workbench. Import the 3D model of the robot and the environment. Specify tasks and movements for the robot. Simulate robot movements, check for collisions, and optimise paths. Evaluate the efficiency and safety of the robotic system.

75. Discuss the specific features of CATIA used in aerospace design.

Ans:

- Generative Shape Design: For creating aerodynamic and complex shapes.

- Structural Analysis: Evaluates the structural integrity of components.

- Aerospace Sheet Metal Design: Tailored for designing aircraft sheet metal parts.

- Assembly Design: Facilitates the assembly of various aircraft components.

- Drafting: Creates detailed 2D drawings for manufacturing.

76. How does CATIA support the design of complex aircraft structures?

Ans:

Shapes complex and organic aircraft components. Tailored for creating intricate sheet metal parts. Enables the assembly and integration of various aircraft structures. Validates the structural integrity of complex structures. Ensures effective communication and coordination across the various aspects of aircraft design.

77. How is CATIA utilised in automotive styling and design?

Ans:

- Surface Modeling: Utilises Generative Shape Design for creating aesthetic surfaces.

- Class-A Surfacing: Achieves high-quality surfaces with precise curvature continuity.

- Reverse Engineering: Useful for capturing and modelling existing vehicle shapes.

- Conceptual Design: Digital sketches and 3D models can be quickly created and modified, facilitating the early stages of the design process.

78. Discuss the role of CATIA in designing vehicle interiors.

Ans:

Specialised tools for creating vehicle interiors. Ensures high-quality and aesthetically pleasing surfaces. Facilitates the integration of interior components. Simulates and optimises the ergonomics of interior layouts.

79. Explain the process of mould design in CATIA.

Ans:

- Part Design: Create the 3D model of the part to be moulded.

- Generative Shape Design: Design the mould cavity and core.

- Assembly Design: Assemble mould components and define parting lines.

- Draft Analysis: Ensure draft angles for easy part ejection.

- Tooling Design: Create details like ejector pins, sliders, and cooling channels.

80. Discuss the applications of CATIA in biomedical engineering.

Ans:

CATIA finds valuable applications in biomedical engineering, contributing to the design and development of various medical devices and prosthetics. The software’s capabilities in parametric design, surface modelling, and simulation aid in creating complex anatomical models for surgical planning and training.

81. What are the key considerations for designing moulds using CATIA?

Ans:

- Parting Line: Define a clear parting line for mould separation.

- Draft Angles: Ensure sufficient draft angles for easy demolding.

- Cooling Channels: Design efficient cooling channels for uniform cooling.

- Material Selection: Choose appropriate materials for mould components.

- Tooling Design: Design robust and reliable features like ejector pins and lifters.

82. How can CATIA be used for designing medical devices?

Ans:

CATIA is employed in designing medical devices by providing a comprehensive suite of tools for 3D modelling, simulation, and manufacturing. The software facilitates the integration of electronic components, ergonomic considerations, and regulatory compliance, ensuring that medical devices meet industry standards and user requirements.

83. How does CATIA support the design of marine structures and vessels?

Ans:

CATIA supports the design of marine structures and vessels by providing specialized tools for naval architects and marine engineers. It enables the creation of 3D models of hulls, decks, and other components, allowing for accurate simulations and analyses of hydrodynamic performance. Specific tools in CATIA for marine design include the Ship Structure Design workbench, which facilitates the creation and management of ship structures.

84. Discuss the specific tools in CATIA for marine design.

Ans:

The software provides features for defining ship compartments and structural elements and integrating mechanical systems. They address the unique challenges and requirements of marine engineering, ensuring that designers and engineers can efficiently develop innovative and seaworthy vessels.

85. Explain the role of CATIA in aerospace manufacturing processes.

Ans:

CATIA plays a crucial role in aerospace manufacturing processes by providing tools for 3D modelling, simulation, and analysis. The software supports the creation of intricate aerospace components, such as aircraft wings, fuselage structures, and engine components. CATIA’s capabilities in structural analysis and simulation contribute to ensuring the structural integrity and performance of aerospace parts.

86. How can CATIA assist in the production of complex aerospace components?

Ans:

- CATIA assists in the production of complex aerospace components by offering advanced features for design optimization, assembly management, and manufacturing preparation.

- The software enables engineers to create detailed 3D models, simulate manufacturing processes, and generate accurate toolpaths for machining and assembly.

- CATIA’s integration with other aerospace engineering tools ensures a seamless workflow from design to manufacturing.

87. Discuss the use of CATIA in automotive manufacturing.

Ans:

CATIA is extensively used in automotive manufacturing for 3D modelling, simulation, and analysis. Designers utilize its Class-A Surfacing tools for creating aesthetically pleasing and aerodynamic automotive designs. The software supports integrating mechanical and electrical systems, facilitating the design of complex automotive components.

88. How does CATIA contribute to improving manufacturing efficiency in the automotive industry?

Ans:

CATIA improves manufacturing efficiency in the automotive industry by streamlining the design-to-manufacturing process. Its parametric design, simulation, and virtual prototyping capabilities reduce the need for physical prototypes, accelerating product development cycles. CATIA’s integration with Computer-Aided Manufacturing (CAM) tools enables the efficient generation of toolpaths for machining, optimizing the manufacturing workflow.

89. What is the role of CATIA in PLM?

Ans:

CATIA plays a key role in Product Lifecycle Management (PLM) by serving as a comprehensive platform for product development. It facilitates the creation, management, and collaboration of design data throughout the product lifecycle.

90. How does CATIA contribute to collaboration and data sharing in a PLM environment?

Ans:

CATIA contributes to collaboration and data sharing in a PLM environment by providing a centralized repository for design data. It allows multiple users to work collaboratively on the same project, ensuring real-time synchronization of changes. CATIA’s integration with PLM tools like ENOVIA enables seamless data exchange, fostering efficient collaboration across different stages of product development and among global design teams.

91. Explain the tools and features in CATIA used for electrical design.

Ans:

- Electrical Harness Design Workbench: Facilitates creating and managing electrical harnesses.

- Electrical Part Design: Allows the design of electrical components and connectors.

- Wire Routing: Provides tools for routing wires and cables within a product assembly.

- Electrical 3D Design: Integrates electrical components into the 3D product model.

92. How can CATIA support integrating electrical systems in a product?

Ans:

CATIA provides a unified environment where mechanical and electrical design teams can collaborate seamlessly. Allows the integration of electrical components and systems directly into the 3D product model. Assesses the impact of electrical systems on electromagnetic compatibility. CATIA supports the preparation of manufacturing documentation for electrical harnesses.

93. Discuss the use of CATIA in virtual reality applications.

Ans:

- CATIA allows the creation of 3D models that can be experienced in virtual reality.

- Designers can conduct immersive design reviews in a virtual environment.

- Supports virtual prototyping and validation of designs before physical production.

- CATIA’s VR features are often integrated with Product Lifecycle Management (PLM) systems.

94. How can CATIA help in creating virtual prototypes for product testing?

Ans:

- CATIA’s digital mockup capabilities enable the creation of virtual prototypes.

- Helps simulate the movement and behaviour of product components.

- Assesses the structural and thermal performance of virtual prototypes.

- CATIA provides realistic visualization capabilities, allowing users to visualize the virtual prototype in a lifelike manner.

- CATIA supports collaborative design and concurrent engineering.

95. What is Simulation Data Management (SDM) in CATIA?

Ans:

- SDM centralizes simulation data, ensuring a single source of truth.

- Manages different versions of simulation models.

- Controls access to simulation data to ensure data integrity.

- CATIA PLM supports workflow automation for simulation processes.

96. How does SDM contribute to the simulation process in CATIA?

Ans:

Enhances collaboration by providing a common platform for simulation data sharing. SDM ensures the traceability of simulation results back to the original design data. Streamlines simulation processes by automating data management tasks. This includes the analysis of fluid flow, heat transfer, and pressure distribution within components.

97. Discuss the role of topology optimization in CATIA.

Ans:

Utilises topology optimization to explore and generate optimal shapes. Determines the most efficient distribution of material within a given design space. Helps in achieving weight reduction while maintaining structural integrity. CATIA seamlessly integrates topology optimization with Finite Element Analysis (FEA). The optimized material layout is often further analyzed using FEA to validate and refine the design.

98. How can CATIA be used to optimize the shape and structure of a product?

Ans:

Utilises parametric modelling for iterative shape optimization. Integrates with simulation tools to analyze and optimize structural performance. Employs generative design algorithms for automated shape exploration. CATIA’s DMU Kinematics workbench allows designers to simulate the motion of mechanical assemblies.

99. Explain how CATIA can be used for ergonomic analysis.

Ans:

Simulates human interactions with products to assess ergonomics. Evaluate the accessibility of controls and interfaces. Assesses the comfort and safety of user postures during product interaction. CATIA provides visualization tools to represent ergonomic analysis results graphically. This aids in the interpretation of data and facilitates communication within design teams.

100. Discuss the benefits of considering ergonomic factors in product design using CATIA.

Ans:

- Enhances product usability and comfort for end-users.

- Helps in minimizing the risk of user fatigue and ergonomic-related injuries.

- Ensures products comply with ergonomic standards and regulations.

- Optimising ergonomic factors contribute to more efficient and effective user workflows.