- Introduction to Supply Chain Optimization

- Importance of Supply Chain Optimization in Business

- Key Elements of Supply Chain Optimization

- Techniques and Tools for Supply Chain Optimization

- Benefits of Optimizing Supply Chains

- Common Challenges in Supply Chain Optimization

- Real-World Examples and Case Studies

- Future Trends in Supply Chain Optimization

Introduction to Supply Chain Optimization

Supply Chain Optimization is a strategic approach that aims to enhance the efficiency and effectiveness of the entire supply chain process, from raw material sourcing to final product delivery. It involves the careful coordination of operations, resources, and information flow to reduce costs, improve service levels, and boost overall performance. One critical aspect of Supply Chain Optimization is inventory optimization in supply chain, which ensures the right amount of stock is available at the right time and place, minimizing excess inventory and stockouts. Integrating PMP Training into supply chain roles enhances project planning, execution, and monitoring, enabling professionals to manage inventory processes more effectively and align them with overall business goals. By leveraging data analytics, forecasting tools, and demand planning, businesses can better manage inventory turnover and customer satisfaction. Another essential component is logistics network optimization, which focuses on refining the transportation and distribution systems to achieve faster, more reliable, and cost-effective delivery. This includes optimizing warehouse locations, selecting the most efficient transportation routes, and utilizing technology to track shipments in real-time. As global supply chains become increasingly complex, companies that invest in robust optimization strategies can gain a significant competitive edge. Ultimately, Supply Chain Optimization not only supports operational excellence but also drives agility and resilience in the face of market volatility, enabling organizations to adapt quickly while maintaining seamless product flow and customer satisfaction.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

Importance of Supply Chain Optimization in Business

- Improves logistics optimization: By analyzing and refining transportation routes, delivery schedules, and distribution centers, businesses can reduce delays, cut fuel costs, and improve on-time delivery performance.

- Enhances value chain optimization: Supply Chain Optimization aligns sourcing, production, and distribution to add value and boost efficiency. Using Managerial Economics Concepts supports better decisions through cost-benefit analysis and resource planning.

- Strengthens logistics management: It helps companies better manage warehousing, transportation, and inventory flow, resulting in smoother operations and reduced operational costs.

Supply Chain Optimization plays a crucial role in enhancing business performance by streamlining operations, reducing costs, and improving customer satisfaction. In today’s fast-paced and competitive market, businesses must focus on optimizing every aspect of their supply chain to stay ahead. Here’s why Supply Chain Optimization is vital for business success:

- Supports effective supplier risk management: By identifying and mitigating risks associated with suppliers, such as delivery delays or quality issues, businesses can avoid disruptions and maintain continuity.

- Improves supplier management: Optimization enables better collaboration and communication with suppliers, leading to improved reliability, cost-efficiency, and long-term partnerships.

- Boosts customer satisfaction: A well-optimized supply chain ensures faster delivery, accurate order fulfillment, and consistent product availability key factors that directly impact customer loyalty and business growth.

Key Elements of Supply Chain Optimizationt

Supply Chain Optimization is a multi-faceted approach that involves aligning various components of the supply chain to operate at peak efficiency while meeting customer demand and minimizing costs. One of the key elements is inventory optimization in supply chain, which ensures the right quantity of products is maintained across different stages, preventing both excess stock and shortages. This involves accurate demand forecasting, safety stock management, and real-time inventory tracking. Another critical component is logistics network optimization, which focuses on enhancing the performance of the transportation and distribution systems. This includes strategically locating warehouses, optimizing delivery routes, and improving shipment consolidation to reduce transit time and costs. Additionally, effective supplier collaboration, integrated planning systems, real-time data visibility, and the use of advanced analytics tools also contribute significantly to the success of Supply Chain Optimization. Understanding What is Leadership And Its Importance empowers supply chain leaders to drive these initiatives with clarity, influence, and strategic direction. Businesses must also prioritize flexibility and responsiveness to adapt to market changes, disruptions, or shifts in customer preferences. By optimizing these key elements, companies can achieve a resilient, agile, and cost-efficient supply chain that not only improves operational performance but also drives better service levels and customer satisfaction. Ultimately, Supply Chain Optimization is not a one-time effort but a continuous process of improvement that fuels sustainable business growth.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Techniques and Tools for Supply Chain Optimization

- Advanced analytics and AI: These tools enable predictive modeling for demand forecasting, which plays a crucial role in logistics optimization by reducing lead times and enhancing delivery accuracy. With PMP Training, professionals can better manage forecasting projects, ensuring structured planning, risk mitigation, and timely implementation of advanced analytics tools.

- Value stream mapping: This lean management technique identifies bottlenecks and waste within the supply chain, supporting value chain optimization by ensuring each step adds maximum value.

- Transportation Management Systems (TMS): TMS solutions automate route planning, carrier selection, and freight auditing, improving logistics management and reducing transportation costs.

To achieve efficiency and resilience in today’s complex global markets, businesses must rely on a range of techniques and tools for effective Supply Chain Optimization. These methods help streamline operations, reduce costs, and improve visibility across the supply chain. Below are six key techniques and tools that support robust optimization:

- Supplier Scorecards and Dashboards: These tools monitor supplier performance in real time, helping businesses strengthen supplier management by making data-driven decisions.

- Risk Assessment Software: Such tools identify vulnerabilities in the supply chain and support supplier risk management by allowing businesses to create contingency plans for potential disruptions.

- Enterprise resource planning (ERP) systems: ERP integrates supply chain data across departments, improving coordination and enhancing overall supply chain visibility and efficiency.

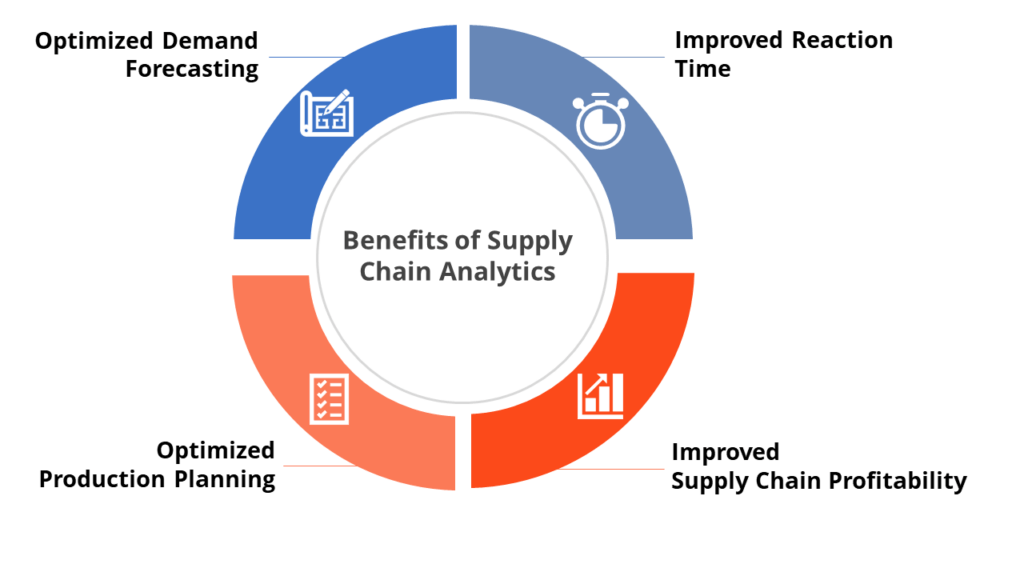

Benefits of Optimizing Supply Chains

Optimizing supply chains delivers numerous strategic and operational benefits that directly impact a business’s bottom line and long-term competitiveness. One of the most significant advantages is improved logistics optimization, where streamlined transportation routes, reduced delivery times, and efficient warehousing lead to lower operational costs and better customer service. Additionally, value chain optimization ensures that every step in the process from raw material sourcing to final product delivery adds maximum value with minimal waste, enhancing overall productivity. Effective logistics management enables real-time visibility, better coordination among departments, and faster response to demand fluctuations, contributing to improved service levels. Another critical benefit is strengthened supplier risk management, which allows businesses to proactively identify potential disruptions, such as geopolitical issues or material shortages, and develop mitigation strategies. Understanding the Nature Of Managerial Economics Importance helps in evaluating such risks economically and making informed, strategic decisions to ensure supply chain resilience. Moreover, robust supplier management leads to stronger relationships, improved communication, and better contract compliance, which in turn enhances reliability and reduces procurement costs. Together, these benefits result in a more agile, resilient, and customer-centric supply chain that not only supports day-to-day operations but also drives innovation and scalability. In an increasingly volatile global market, companies that invest in supply chain optimization are better equipped to adapt, compete, and grow sustainably.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Common Challenges in Supply Chain Optimization

Despite its strategic importance, Supply Chain Optimization often faces several common challenges that can hinder performance and efficiency. One major issue is inaccurate demand forecasting, which directly affects inventory optimization in supply chain, leading to either stockouts or excess inventory. Both scenarios can increase holding costs and reduce customer satisfaction. Additionally, data silos across departments make it difficult to gain real-time visibility into supply chain operations, limiting the ability to make informed decisions. Strong Human Resource Management ensures cross-functional collaboration and effective communication, helping break down these silos and improve operational efficiency. Another significant challenge is the complexity of logistics network optimization, particularly when managing global operations with multiple suppliers, warehouses, and transportation modes. This complexity often leads to inefficiencies in routing, scheduling, and distribution. Integration of legacy systems with modern technology is also a persistent hurdle, as outdated infrastructure can restrict scalability and agility. Moreover, supply chain disruptions caused by external factors like geopolitical tensions, pandemics, or natural disasters further complicate optimization efforts. Inadequate collaboration between partners and lack of transparency across the supply chain also pose risks to efficient operations. These challenges highlight the need for a strategic, technology-driven approach to Supply Chain Optimization, one that combines real-time data, predictive analytics, and cross-functional coordination to build a more resilient and efficient supply chain.

Real-World Examples and Case Studies

Real-world examples and case studies provide valuable insights into how leading companies leverage supply chain strategies for competitive advantage. For instance, Amazon’s use of advanced automation and data analytics has transformed logistics optimization, enabling same-day deliveries through smart routing, efficient warehousing, and predictive demand planning. Another example is Toyota, which excels in value chain optimization by integrating lean manufacturing and just-in-time inventory practices, ensuring that every step in the production process adds value while minimizing waste. In the area of logistics management, companies like DHL utilize cutting-edge transportation management systems to streamline global shipping operations, improving visibility, speed, and accuracy. Meanwhile, Apple has set benchmarks in supplier management by maintaining strong relationships with its suppliers, supported by rigorous performance monitoring and shared technology platforms. When businesses Learn Objectives of Management Accounting, they can better track supplier performance, control costs, and align financial insights with strategic supply chain goals. This has not only improved quality but also reduced time-to-market. Procter & Gamble offers a compelling case in supplier risk management, having developed robust risk assessment models and contingency planning to ensure business continuity during global disruptions. These real-world applications demonstrate that strategic investment in supply chain technologies and best practices can significantly enhance efficiency, reduce risks, and drive long-term business growth across industries.

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

Future Trends in Supply Chain Optimization

The future of Supply Chain Optimization is being shaped by rapid advancements in technology, changing consumer expectations, and a heightened focus on resilience and sustainability. One of the key trends is the increasing use of artificial intelligence and machine learning, which enable smarter decision-making, predictive analytics, and real-time responses to demand fluctuations drastically improving inventory optimization in supply chain. Companies are adopting automated systems and IoT-enabled devices to monitor inventory levels, track shipments, and forecast needs with greater accuracy. Another major trend is the evolution of logistics network optimization, driven by the rise of e-commerce and global trade complexities. Businesses are redesigning their logistics networks to be more agile, incorporating micro-fulfillment centers, autonomous vehicles, and drone deliveries to meet faster delivery expectations. Incorporating PMP Training helps logistics professionals manage these complex projects efficiently, ensuring timely execution and strategic alignment. Additionally, digital twins and blockchain technology are gaining traction, offering enhanced visibility and transparency across the entire supply chain. Sustainability is also emerging as a top priority, with companies rethinking their supply chain strategies to reduce carbon footprints and embrace circular economy models. As these innovations converge, the future of Supply Chain Optimization will focus not only on cost and efficiency but also on adaptability, risk mitigation, and long-term value creation in an increasingly interconnected world.