- Introduction to Inventory Management

- The Role of Inventory in Supply Chain

- Types of Inventory

- Inventory Management Techniques and Strategies

- Importance of Inventory Management in Supply Chain

- Technology and Tools in Inventory Management

- Common Challenges in Inventory Management

- Best Practices for Effective Inventory Management

Introduction to Inventory Management

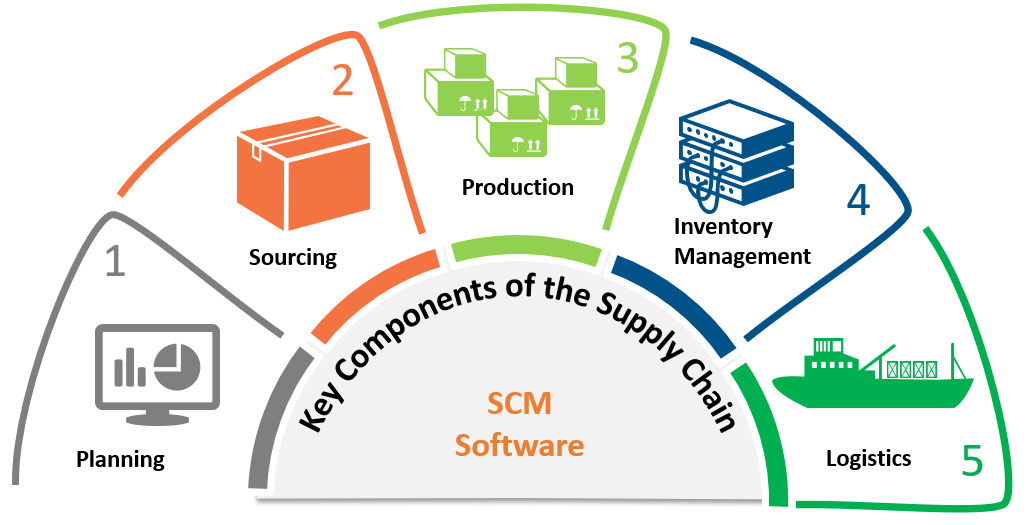

Inventory management is a critical component of any efficient business operation, especially when integrated within broader logistics strategies. At its core, Inventory Management in Supply Chain focuses on tracking, controlling, and optimizing stock levels to meet customer demand without overstocking or causing delays. A well-executed system ensures that the right products are available at the right time, minimizing costs and maximizing service levels. This is closely tied to Supply Chain Order Management, where accuracy in forecasting, purchasing, and fulfillment becomes vital to streamlining the entire order lifecycle skills often emphasized in PMP Training for effective project execution. Effective inventory practices also play a central role in Supply Chain Warehouse Management, where space utilization, picking accuracy, and inventory turnover significantly impact overall productivity. From raw materials to finished goods, proper inventory management allows businesses to adapt to market fluctuations, avoid stockouts, and respond quickly to customer needs. In today’s fast-paced, digitally driven market, technologies like real-time tracking, automation, and data analytics are transforming how inventory is monitored and controlled. Companies that prioritize integrated inventory strategies gain better visibility, reduced operational costs, and improved customer satisfaction. Overall, mastering inventory management is not just about storing goods it’s about synchronizing supply chain operations for smarter, faster, and more reliable performance.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

The Role of Inventory in Supply Chain

- Balancing Supply and Demand: Inventory helps businesses maintain the right balance between supply and demand, ensuring that products are available when needed without overstocking or understocking.

- Supporting SMC Order Management: Accurate inventory data is essential for SMC order management, allowing businesses to fulfill orders promptly, reduce errors, and enhance customer satisfaction an approach aligned with Managerial Economics concepts such as cost minimization, demand forecasting, and efficient resource allocation.

- Enhancing Inventory SMC Efficiency: Through Inventory SMC, companies can streamline stock tracking, automate replenishment processes, and improve overall inventory visibility.

Inventory plays a foundational role in ensuring the smooth functioning of the supply chain. It acts as a buffer between production and consumption, helping businesses meet customer demands promptly while managing costs effectively. A well-managed inventory system directly influences the efficiency of Inventory supply, responsiveness to market changes, and overall business profitability. Below are six key points that highlight the role of inventory in the supply chain, integrating essential components such as SMC order management, Inventory SMC, NFC inventory, and Inventory logistics:

- Leveraging NFC Inventory Technologies: NFC inventory systems allow real-time tracking and quick identification of stock, reducing shrinkage and increasing inventory accuracy.

- Improving Inventory Logistics: Efficient Inventory logistics enables timely movement of goods within the supply chain, minimizing delays and cutting transportation costs.

- Strengthening Inventory Supply Chains: Robust inventory practices strengthen the overall inventory supply chain by ensuring continuity, minimizing disruptions, and enabling agile responses to market changes.

Types of Inventory

Understanding the types of inventory is essential for businesses aiming to streamline operations and enhance efficiency across the supply chain. There are several key inventory types, each serving a distinct purpose: raw materials, work-in-progress (WIP), finished goods, and maintenance, repair, and operations (MRO) inventory. Raw materials are the basic components used in production, while WIP includes items currently being manufactured. Finished goods are ready-for-sale products, and MRO items support production but are not part of the final product. Effective categorization and tracking of these inventory types are crucial for optimizing Inventory Management in Supply Chain, as it helps in reducing waste, controlling costs, and improving product availability core principles often explored when understanding What is an MBA Degree and its focus on strategic business operations. Integrating these inventory types into Supply Chain Order Management ensures that businesses can accurately forecast demand, place timely orders, and meet customer expectations efficiently. Additionally, the role of inventory becomes even more critical in Supply Chain Warehouse Management, where space allocation, stock rotation, and accurate inventory levels directly impact operational productivity. Leveraging data-driven insights and modern inventory systems enables companies to maintain the right stock at the right time and place. Ultimately, recognizing and managing different types of inventory supports a more agile, responsive, and profitable supply chain ecosystem.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Inventory Management Techniques and Strategies

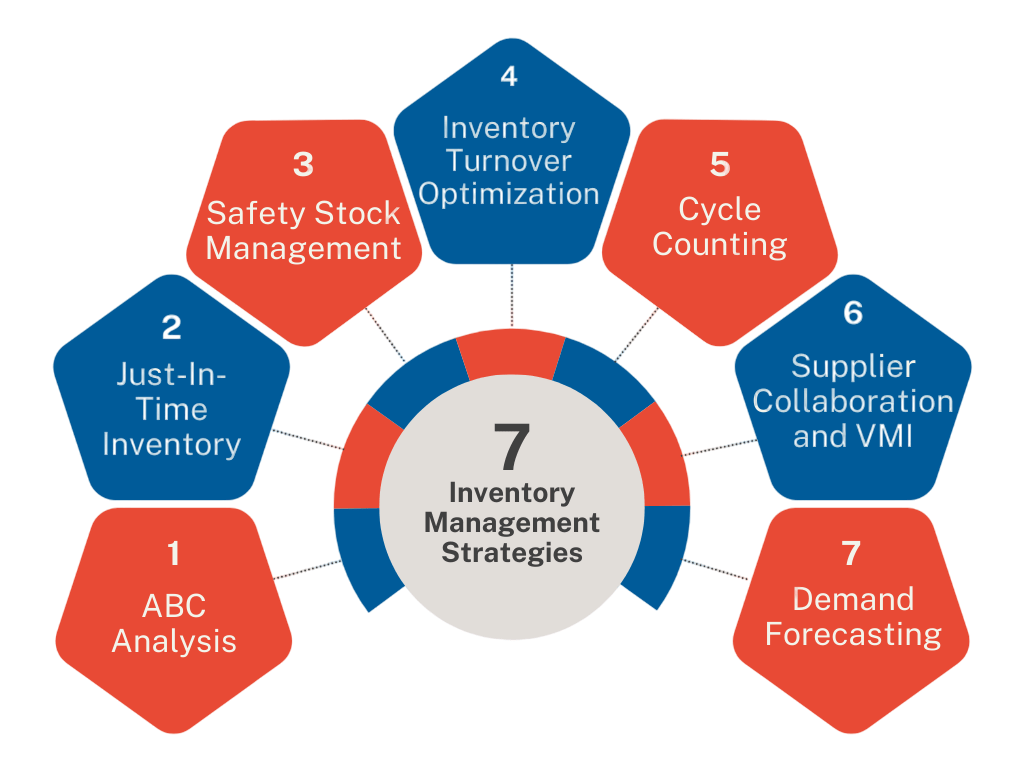

- Just-in-Time (JIT) Inventory: This strategy reduces holding costs by receiving goods only as they are needed in the production process, enhancing efficiency and minimizing waste.

- ABC Analysis: Inventory is categorized into A (high value), B (moderate value), and C (low value) items to focus management efforts where they matter most, improving control across Inventory SMC systems a methodology often emphasized in PMP Training for prioritizing resources and optimizing outcomes.

- Economic Order Quantity (EOQ): EOQ helps determine the optimal order quantity to minimize both ordering and holding costs, supporting balanced inventory supply.

Effective inventory management is vital for minimizing costs and ensuring product availability across all stages of the supply chain. By adopting the right techniques and strategies, businesses can enhance operational efficiency, avoid stockouts, and improve customer satisfaction. These methods are especially valuable in systems involving SMC order management, Inventory SMC, and Inventory logistics, where accuracy and real-time insights are essential. Below are key inventory management techniques and strategies that support smooth inventory supply and incorporate modern tools like NFC inventory tracking:

- First-In, First-Out (FIFO): Ensures older inventory is sold first, which is especially useful for perishable goods and contributes to better Inventory logistics.

- NFC Inventory Tracking: Using NFC inventory systems allows real-time monitoring, reducing human error and enhancing data accuracy throughout the supply chain.

- Integrated SMC Order Management Systems: Leveraging digital SMC order management tools ensures seamless coordination between order processing and inventory levels for accurate, timely fulfillment.

Importance of Inventory Management in Supply Chain

The importance of inventory management in supply chain operations cannot be overstated, as it directly influences cost efficiency, customer satisfaction, and overall business performance. Effective Inventory Management in Supply Chain ensures the right products are available at the right time, preventing costly stockouts or excess inventory that ties up capital. It plays a central role in maintaining a smooth flow of goods from suppliers to end customers, optimizing each stage of the logistics process an effort that also relies on effective Human Resource Management to coordinate teams, improve productivity, and ensure operational efficiency. Moreover, inventory management supports accurate Supply Chain Order Management by providing real-time data on stock levels, enabling timely and precise order fulfillment. This reduces lead times, minimizes order errors, and enhances customer trust. Within Supply Chain Warehouse Management, efficient inventory practices help in organizing storage, improving picking accuracy, and maximizing space utilization. By using demand forecasting, safety stock planning, and automated tracking systems, businesses can maintain lean inventory without compromising on service quality. In a fast-paced market environment, strong inventory management creates a competitive advantage by enabling agility, reducing waste, and improving profit margins. Ultimately, it forms the backbone of a responsive and resilient supply chain, ensuring operational continuity and the ability to adapt quickly to market changes or disruptions.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Technology and Tools in Inventory Management

Technology has transformed the landscape of modern inventory management, enabling businesses to operate with greater speed, accuracy, and efficiency. Advanced tools and systems streamline every aspect of inventory control, from forecasting demand to real-time stock tracking. Solutions like SMC order management integrate seamlessly with inventory databases, ensuring that orders are processed based on accurate, up-to-date stock levels. This reduces errors, prevents overstocking or stockouts, and enhances overall customer satisfaction. Inventory SMC systems offer centralized visibility and automation, allowing businesses to monitor inventory movements across multiple locations while optimizing storage and replenishment processes functions that align closely with the Scope of Management Accounting, including cost control, performance measurement, and strategic planning. One of the most innovative advancements is NFC inventory technology, which uses near-field communication to provide real-time tracking, improved traceability, and faster audits. These technologies significantly strengthen inventory supply chains by reducing manual workload, increasing data accuracy, and improving decision-making. Additionally, digital tools in inventory logistics help coordinate the movement of goods, ensuring timely delivery and reduced transit times. From AI-powered demand forecasting to cloud-based warehouse platforms, the integration of smart tools in inventory management enhances agility, supports scalability, and provides the analytical insights needed to stay competitive in today’s dynamic market environment. Embracing these technologies is no longer optional; it’s essential for sustainable inventory control.

Common Challenges in Inventory Management

Inventory management, while essential to supply chain efficiency, comes with a variety of challenges that can impact operations, profitability, and customer satisfaction. One of the most common issues is inaccurate inventory tracking, which leads to discrepancies between actual stock and recorded data, affecting SMC order management and causing delays or missed sales. Without proper oversight, businesses may experience overstocking or stockouts, both of which strain resources and customer trust. Another major hurdle is poor visibility across supply chain networks, especially in complex systems that rely on manual processes. Implementing Inventory SMC solutions helps, but without the right training and system integration, inconsistencies may persist highlighting the importance of Financial Management Skills for Success in budgeting, cost analysis, and aligning inventory strategies with overall financial goals. Additionally, many companies struggle with a lack of real-time updates, which is where NFC inventory technology becomes valuable yet adoption can be slow due to costs or technical limitations. Supply chain disruptions, such as delays from suppliers or transportation issues, further complicate inventory supply and can affect forecasting accuracy. Meanwhile, inefficient inventory logistics including poor warehouse layout, disorganized storage, or slow picking processes can reduce fulfillment speed and increase operational costs. Overcoming these challenges requires a combination of strategic planning, technological adoption, and continuous process improvement to build a resilient and responsive inventory management system.

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

Best Practices for Effective Inventory Management

Adopting best practices for effective inventory management is essential for optimizing operations, reducing costs, and ensuring product availability across the supply chain. One key practice is maintaining accurate, real-time data, which can be achieved by integrating technologies like NFC inventory systems. These allow instant tracking and verification of stock, minimizing errors and enhancing transparency. Implementing Inventory SMC solutions also helps centralize inventory data, automate stock replenishment, and improve decision-making. Aligning inventory practices with SMC order management ensures seamless coordination between inventory levels and customer orders, reducing lead times and enhancing fulfillment accuracy. Regular audits and cycle counts, supported by digital tools, are also critical to catching discrepancies early principles reinforced through PMP Training for structured project and process management. Forecasting demand using historical data and market trends enables better planning for inventory supply, helping avoid overstocking or stockouts. Moreover, efficient inventory logistics practices such as optimizing warehouse layout, using barcode systems, and training staff can significantly speed up inventory movement and reduce picking errors. Collaboration across departments and with suppliers ensures that everyone in the chain is aligned on stock levels and delivery schedules. Overall, by combining advanced tools with strategic planning and regular monitoring, businesses can build a resilient, scalable, and highly efficient inventory management system that supports long-term growth.