- Introduction to Warehousing and Logistics

- The Role of Warehousing in Supply Chain

- Types of Warehousing

- Understanding Logistics and Its Functions

- Integration of Warehousing and Logistics

- Technology and Innovations in Warehousing and Logistics

- Challenges in Warehousing and Logistics

- Best Practices for Efficient Warehousing and Logistics Management

- Conclusion

Introduction to Warehousing and Logistics

Warehousing involves the safe storage of goods before they are distributed to customers or further processed. It serves as a critical node that connects production with consumption. Logistics, on the other hand, refers to the entire process of planning, implementing, and controlling the efficient flow and storage of goods, logistics and warehousing services, and related information from the point of origin to the point of consumption to meet customer requirements. Together, warehousing and logistics ensure that products are available in the right quantity, at the right place, and at the right time. Effective coordination between these functions can lead to significant cost savings and improved service levels.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

The Role of Warehousing in Supply Chain

Warehousing plays a vital role by acting as a buffer to balance supply and demand fluctuations. It facilitates the consolidation of goods from multiple suppliers, breaking down bulk shipments for retail distribution, and ensuring product availability. Warehouses also provide value-added logistics and warehousing services such as packaging, labeling, sorting, and quality inspections. Additionally, warehousing supports seasonal inventory buildup, enabling companies to prepare for peak demand periods. Without proper warehousing, supply chains would face delays, stockouts, and inefficiencies that negatively impact customer satisfaction.

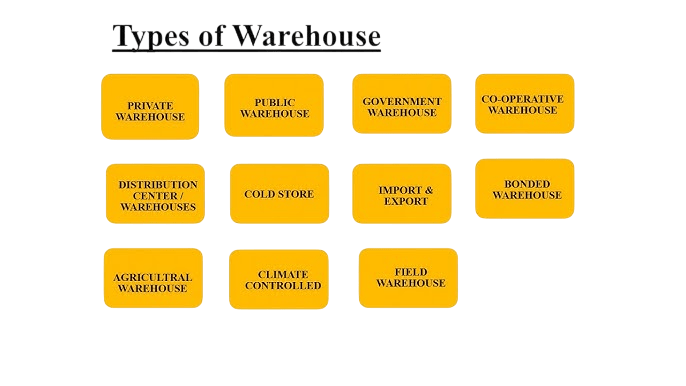

Types of Warehousing

Warehousing comes in various forms depending on business needs and product types:

- Private Warehouses: Owned and operated by manufacturers or retailers for exclusive use. They provide complete control but require significant capital investment.

- Public Warehouses: Available for rent to any business, offering flexibility without heavy upfront costs.

- Contract Warehouses: Operated by third parties under long-term contracts, combining benefits of private and public warehouses.

- Distribution Centers: Facilities focused on quick turnover and redistribution rather than long-term storage, often supporting e-commerce operations.

- Automated Warehouses: Use robotics and automation to enhance speed and accuracy in storage and retrieval processes.

Each type addresses different logistical challenges and cost considerations.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Understanding Logistics and Its Functions

Logistics encompasses all activities that facilitate the movement of goods, including transportation, inventory management, order fulfillment, and material handling. Its primary functions include:

- Transportation warehouse logistics management: Selecting modes and carriers to deliver goods efficiently and cost-effectively.

- Inventory Control: Monitoring stock levels to avoid overstocking or shortages.

- Order Processing: Coordinating order receipt, picking, packing, and dispatch.

- Material Handling: Using equipment and systems to move goods within warehouses and distribution centers.

- Reverse Logistics: Managing returns, recycling, and disposal of products.

Logistics ensures seamless flow across the supply chain, minimizing lead times and reducing costs while maintaining quality and service standards.

Integration of Warehousing and Logistics

Integration between warehousing and logistics is critical to optimizing supply chain operations. Warehousing provides the physical space and resources for storing goods, while logistics plans the movement and delivery. Synchronizing these functions involves coordinating inventory levels, shipping schedules, transportation modes, and delivery routes. Advanced planning systems enable real-time visibility into stock and shipments, facilitating better decision-making. A well-integrated system reduces lead times, enhances responsiveness, and lowers total supply chain costs. Companies that fail to align warehousing with logistics often suffer from inefficiencies, delayed shipments, and dissatisfied customers.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Technology and Innovations in Warehousing and Logistics

Technology is revolutionizing warehousing and logistics, driving greater efficiency and accuracy. Modern supply chains have been completely transformed by cutting-edge technology, making operations smoother and much more efficient. Warehouse logistics management (WMS) are basically the control center for inventory, handling everything from automated tracking and smart space usage to speeding up the order fulfillment process. Working alongside WMS, Transportation Management Systems (TMS) are great at finding the best delivery routes, choosing the right carriers, and managing freight costs to save money. Plus, automation and robotics in warehouses have really changed the game for picking items, making it much faster and slashing the number of costly mistakes people used to make. And then there’s the Internet of Things (IoT) devices that give us real-time updates on things like inventory levels, how equipment is running, and where vehicles are, which helps us make smarter decisions ahead of time. Artificial Intelligence and better route planning algorithms are also playing a big role, while blockchain technology adds a layer of trust and security to every transaction in the logistics world. All these innovative tools help companies not only meet but often exceed what customers expect today, even as they juggle the complexities and costs of running a business in a tough market.

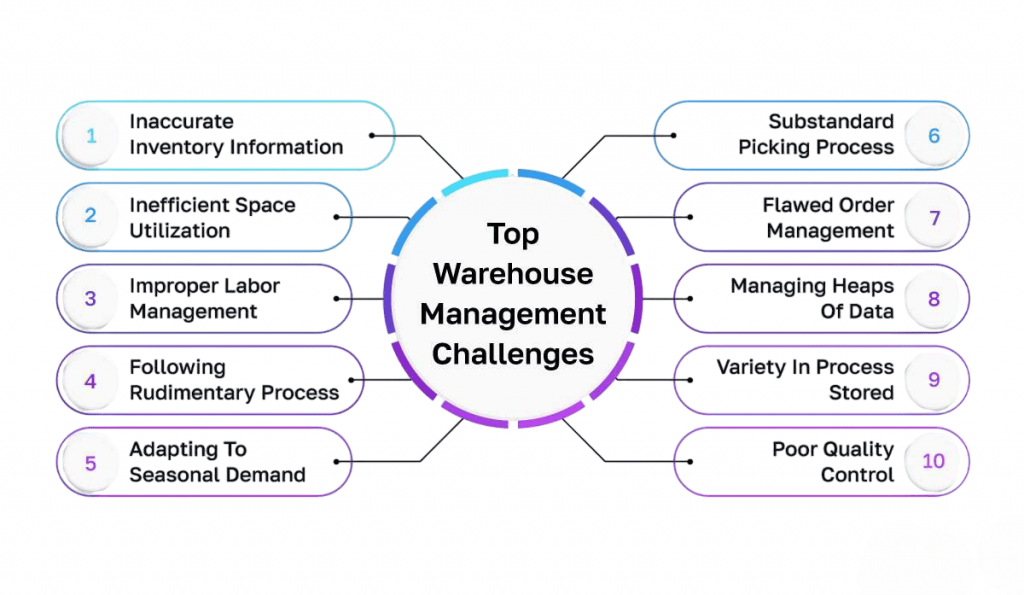

Challenges in Warehousing and Logistics

Despite technological advancements, warehousing and logistics face numerous challenges:

- Demand Volatility: Makes forecasting difficult, risking over or understocking.

- Rising Transportation Costs: Impact overall logistics budgets.

- Labor Shortages: Affect warehouse productivity and quality.

- Space Constraints: Limit warehousing capacity in urban areas.

- Complex Regulations: Around customs, safety, and environmental standards increase operational burdens.

- Supply Chain Disruptions: Events like natural disasters or pandemics cause delays and uncertainty.

- Data Silos: Between warehousing and logistics systems hinder integration and real-time visibility.

Overcoming these challenges requires strategic planning, investment, and collaboration across supply chain partners.

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

Best Practices for Efficient Warehousing and Logistics Management

To maximize performance, companies should adopt best practices such as: Implementing Integrated Technology Solutions to connect warehousing and logistics functions seamlessly. Continuous Training of Workforce to enhance skills and safety awareness. Optimizing Warehouse Layouts for efficient flow and space utilization. Adopting Lean Principles to reduce waste and streamline processes. Building Strong Relationships with Carriers and Suppliers to improve reliability and flexibility. Regularly Monitoring KPIs such as order accuracy, cycle time, and transportation costs to drive continuous improvement. Planning for Scalability and Flexibility to adapt to changing market conditions. By embracing these practices, organizations can build resilient, responsive, and cost-effective warehousing and logistics operations.

Conclusion

Warehousing and logistics are indispensable elements of supply chain management that ensure products move efficiently from production to consumers. Their seamless integration supported by advanced technologies and sound warehouse logistics management practices is essential for meeting today’s fast-paced and demanding markets. While challenges persist, adopting innovative solutions and best practices enables businesses to optimize storage, transportation, and distribution, ultimately improving customer satisfaction and profitability. Whether you operate a small business or a global enterprise, mastering warehousing and logistics is key to sustaining competitive advantage in the dynamic supply chain landscape. In today’s busy market, companies that focus on strong logistics and warehousing services gain advantages over competitors. They can better handle unexpected problems, respond quickly to market needs, and adapt to new trends. As consumer expectations rise, investing in better storage and transportation makes a big difference. Every business, from small local shops to big international brands, must see warehousing and logistics as key parts of their success story. Those who get it right will remain competitive and grow in a fast-changing world.