- Introduction to Operations and Supply Chain Management

- Core Components of Operations Management

- Fundamentals of Supply Chain Management

- The Relationship Between Operations and Supply Chain Management

- Technologies Transforming Operations and Supply Chains

- Challenges in Operations and Supply Chain Management

- Best Practices for Effective Management

- Future Trends in Operations and Supply Chain Management

- Conclusion

Introduction to Operations and Supply Chain Management

Operations and supply chain management (OSCM) are critical disciplines that ensure organizations deliver products and services efficiently, effectively, and profitably. While operations management focuses on optimizing internal processes, supply chain management extends across the network of suppliers, manufacturers, distributors, and customers. Together, these functions influence organizational competitiveness, customer satisfaction, and profitability. In today’s dynamic global market, efficient operations and agile supply chains are essential for managing supply chain operations complexity and responding to rapidly changing demands.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

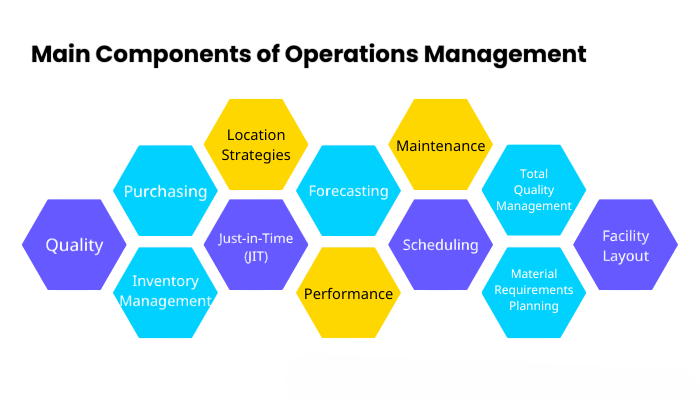

Core Components of Operations Management

Think of operations management as the strategic core that really drives a company’s success. It’s all about the detailed planning, organizing, and overseeing of how goods and services get produced. This field covers a lot of ground, starting with designing and analyzing processes. Teams carefully map out workflows, arrange things efficiently, and make sure resources are used where they’re needed most, all aimed at boosting productivity and quality. Just as important is figuring out capacity planning making sure a company knows exactly how much it can produce to meet customer demand, even when that demand changes. Then there’s inventory management, which is crucial for keeping the right balance: avoiding the costly problem of running out of stock while also preventing the drain on resources that comes from holding too much inventory. Quality management is another key piece, using strong systems like Total Quality Management and Six Sigma to ensure products and services always meet the standards set.

Finally, production scheduling brings all these parts together by carefully coordinating the resources and timelines needed. This allows organizations to hit their production targets efficiently. When all these elements work together, they create a solid foundation for top-notch operations and help a business grow sustainably over time.

Fundamentals of Supply Chain Management

Supply chain management (SCM) oversees the flow of goods, information, and finances from raw materials to end consumers. Key elements include:

- Supplier Relationship Management: Building partnerships with suppliers to ensure quality, reliability, and cost-effectiveness.

- Logistics and Transportation: Managing the movement and storage of materials and finished products.

- Demand Forecasting: Predicting customer demand to align supply chain activities.

- Order Fulfillment: Ensuring timely delivery of products to customers.

- Supply Chain Integration: Coordinating activities across partners for seamless operations.

- Operations: Focus on transforming inputs into finished goods within the organization.

- Supply Chain: Manages the broader network of suppliers and distribution channels.

- Collaborative Planning: Foster cooperation between suppliers, manufacturers, and distributors.

- Lean Principles: Eliminate waste and streamline processes.

- Agile Methodologies: Adapt quickly to changing market conditions.

- Data-Driven Decisions: Use analytics for forecasting, inventory management, and performance monitoring.

- Supplier Development: Invest in supplier capabilities and relationships.

- Digital Supply Chains: Fully integrated digital platforms will enable real-time end-to-end visibility and control.

- Sustainable Operations: Green supply chains and circular economy principles will become standard.

- Artificial Intelligence and Automation: AI-driven autonomous supply chains will optimize operations with minimal human intervention.

- Customization and On-Demand Production: Advances in manufacturing will support personalized products and rapid fulfillment.

- Resilience and Risk Management: Post-pandemic, companies will prioritize building resilient supply chains to withstand disruptions.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

The Relationship Between Operations and Supply Chain Management

Operations management and supply chain management are closely intertwined:

Effective coordination between these functions enhances efficiency, reduces costs, and improves service levels. For example, operations depend on supply chain for timely raw materials, while supply chain relies on operations for production capacity and quality.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

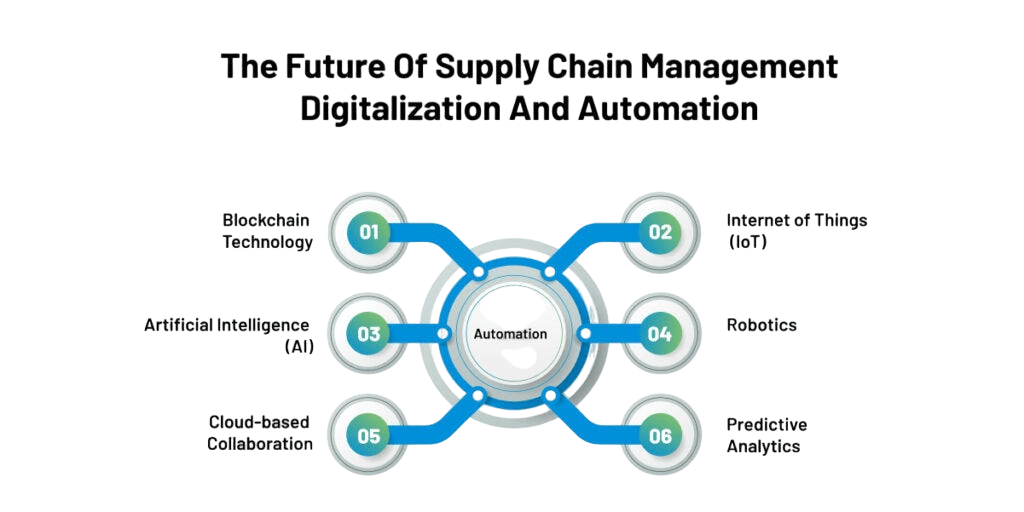

Technologies Transforming Operations and Supply Chains

These days, supply chain management is being completely transformed by the smart use of the latest tech, leading to operations that run incredibly smoothly. The Internet of Things (IoT) is really the bedrock of this change, making it possible to keep tabs on inventory levels in real time, check on the condition of equipment, and get a full picture of shipments all along the logistics route. On top of this connectivity, Artificial Intelligence and Machine Learning are boosting key business activities. They’re making demand forecasting much more accurate, letting companies predict when maintenance is needed before a breakdown happens, and streamlining complex operations. Meanwhile, robotics and automation are making a huge difference in factories and warehouses, boosting precision and efficiency while cutting down on human mistakes and speeding up the whole process. And then there’s blockchain technology, which brings a level of transparency and traceability to supply chains that was previously unheard of. This really helps cut down on fraud and those expensive errors that can throw a wrench in operations. Finally, cloud computing platforms paired with big data analytics give companies the solid foundation they need to integrate data seamlessly and make smart decisions across vast, global supply networks.

Challenges in Operations and Supply Chain Management

Organizations face several challenges in managing supply chain operations and supply chains effectively: Today’s supply chain management is facing challenges like never before, demanding that companies adapt their strategies and find innovative ways forward. When customer demand keeps changing, it really complicates planning, making it tough for organizations to keep just the right amount of inventory and allocate resources optimally. Plus, globalization adds another layer of complexity, since businesses now have to manage diverse international suppliers while also navigating different rules and regulations in various countries. Supply disruptions are another huge worry. Things like natural disasters, pandemics, or geopolitical conflicts can literally bring entire supply networks to a halt. At the same time, there’s growing pressure to adopt environmentally friendly practices, forcing companies to rethink how they operate while still staying competitive. And perhaps the trickiest part of all is trying to balance keeping costs down with maintaining high service quality. Businesses need to deliver fantastic customer experiences even when their budgets are tight. Tackling all these connected issues successfully means needing a well-rounded strategy that embraces new technology, builds strong, resilient partnerships, and keeps a constant focus on both running operations smoothly and acting responsibly towards the environment. Addressing these challenges requires flexibility, robust risk management, and continuous improvement.

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

Best Practices for Effective Management

To excel in OSCM, organizations can adopt several best practices:

These practices improve responsiveness, reduce costs, and enhance customer satisfaction.

Future Trends in Operations and Supply Chain Management

Looking ahead, several trends will shape OSCM:

Conclusion

Operations and supply chain management are foundational to business success in an increasingly complex world. By optimizing internal processes and managing supply chain operations external networks effectively, organizations can improve efficiency, reduce costs, and enhance customer experiences. Technology adoption, best practices, and strategic planning will be critical in navigating future challenges and unlocking new opportunities. Embracing innovation and agility in OSCM will position businesses for sustained growth and competitiveness.