- Introduction to Supply Chain Management

- Overview of Supply Chain Components

- Procurement and Supplier Management

- Manufacturing and Production

- Inventory Management system

- Warehousing and Storage

- Transportation and Logistics

- Demand Planning and Customer Service

- Conclusion

Introduction to Supply Chain Management

Supply Chain Management (SCM) refers to the strategic coordination of the end-to-end business processes involved in delivering products and services from raw materials to final consumption. SCM encompasses planning, sourcing, production, inventory, logistics, and customer service. As global markets expand and competition intensifies, efficient supply chains have become critical to gaining a competitive edge PMP Training. A well-optimized supply chain helps organizations reduce costs, improve delivery timelines, maintain product quality, logistics storage warehouse, Inventory Management System and enhance customer satisfaction. SCM also plays a vital role in sustainability by minimizing waste and optimizing resource utilization.

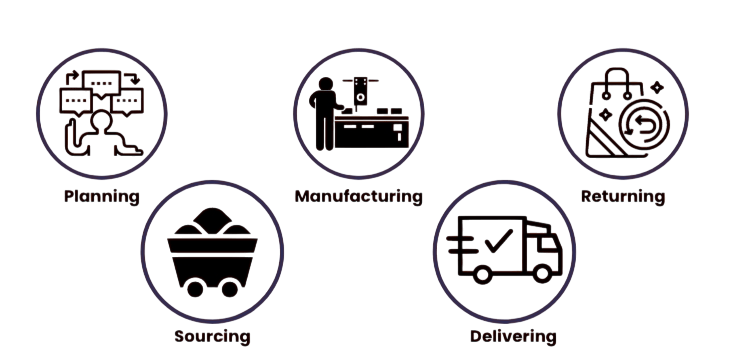

Overview of Supply Chain Components

A supply chain comprises various interconnected components, each playing a crucial role. The main elements include:

- Suppliers and Procurement: Responsible for sourcing raw materials and services.

- Manufacturing: Involves converting raw materials into finished goods.

- Warehousing and Inventory: Stores and manages stock levels efficiently.

- Logistics and Transportation: Ensures timely movement of goods across the network.

- Retail and Distribution: Delivers products to customers through retail stores or direct shipping.

- Customer Service: Provides after-sales support, feedback collection, and returns management.

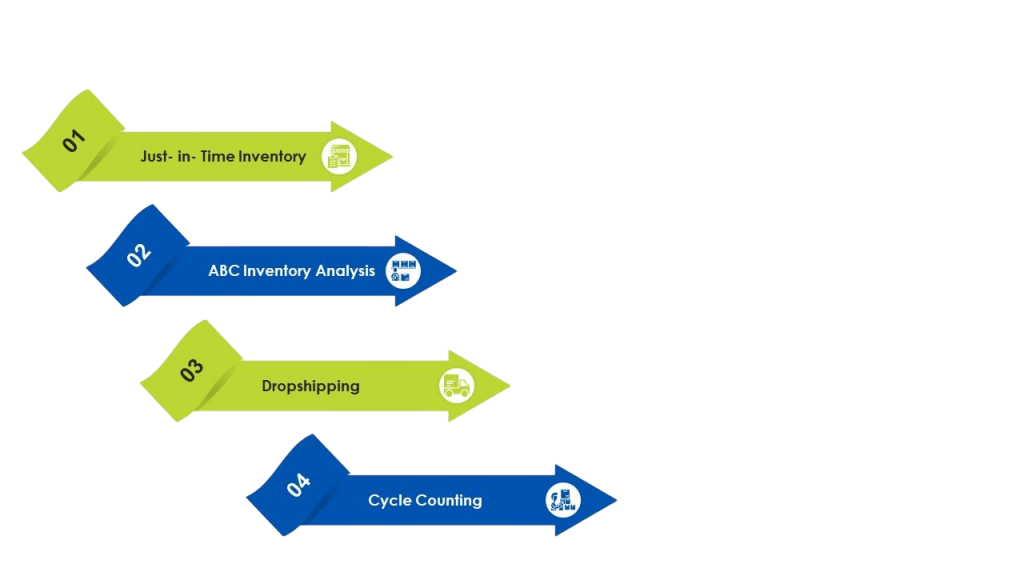

- ABC Analysis: Prioritizing items based on their value and consumption rate.

- Safety Stock and Reorder Points: Ensuring inventory buffers to prevent stockouts.

- Just-in-Time (JIT): Minimizing inventory levels and ordering just when needed.

- Economic Order Quantity (EOQ): Balancing order size with holding and ordering costs.

- Warehouse Management Systems (WMS): To manage inventory locations, picking, packing, and order tracking.

- Automated Storage and Retrieval Systems (AS/RS): Robotics that enhance storage efficiency.

- Barcoding and RFID: For fast and accurate item identification.

- Mode Selection: Road, rail, air, sea, or a combination.

- Carrier Contracts: Partnering with third-party logistics (3PL) providers or managing in-house fleets.

- Route Optimization: Using GPS and traffic data to plan the most efficient delivery paths.

- Quantitative Models: Based on historical data using statistical tools.

- Qualitative Methods: Based on market research, expert opinion, and sales feedback.

- Collaborative Planning: Involving customers and supply chain partners in the planning process.

Modern supply chains are data-driven and integrated with technologies like ERP systems, IoT, and AI for real-time visibility and decision-making Supply Chain Management Salary Breakdown .

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

Procurement and Supplier Management

Procurement is the process of sourcing goods and services required for production. Effective procurement ensures that the right quality and quantity of raw materials are obtained at the best price and time. Supplier management, on the other hand, involves developing and maintaining relationships with vendors. It includes selecting suppliers,logistics storage warehouse,Inventory Management system negotiating contracts, monitoring performance, and managing risks. Stages in the Supply Chain Management In strategic sourcing, companies evaluate suppliers not only on price but also on sustainability, reliability, and compliance. Building long-term partnerships with key suppliers leads to improved innovation, cost savings, and stability in the supply chain. Tools like e-procurement platforms, vendor management systems (VMS), and automated purchasing workflows streamline procurement processes.

Manufacturing and Production

The production phase transforms raw materials into finished goods. Manufacturing strategies vary based on demand and industry type examples include make-to-stock (MTS), make-to-order (MTO), and just-in-time (JIT) production. Efficient production planning involves balancing resource capacity, material availability, and labor to meet demand forecasts Successful Supply Chain Strategy. Lean manufacturing and Six Sigma methodologies help eliminate waste, reduce cycle time, logistics storage warehouse and improve quality. Smart factories powered by Industry 4.0 technologies (IoT, robotics, and AI) enhance visibility, automation, and flexibility in production operations. Integration between manufacturing execution systems (MES) and supply chain platforms ensures real-time data sharing and performance monitoring.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Inventory Management System

Inventory management System ensures that the right amount of stock is maintained to meet customer demand while minimizing carrying costs. PMP Training It involves tracking goods throughout the supply chain raw materials, work-in-progress (WIP), and finished products. Key techniques include:

Advanced inventory systems use real-time analytics, RFID tracking, and demand forecasting tools to optimize stock levels, reduce waste, and improve cash flow.

Warehousing and Storage

Warehousing involves the storage and handling of goods in a centralized location before distribution. An efficient warehouse supports the entire supply chain by improving inventory accuracy, Supply Chain Management logistics storage warehouse, order fulfillment speed, and transportation planning. Modern warehouses use automated systems such as:

Choosing the right warehouse layout, location, and storage method (e.g., pallet racking, shelving, or cold storage) depends on product type and turnover rate. Cross-docking and consolidation centers also help streamline logistics and reduce handling times.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Transportation and Logistics

Transportation and logistics play a vital role in moving goods from suppliers to manufacturers and eventually to end customers. Key goals of transportation management include minimizing fuel and labor costs, ensuring on-time delivery, and reducing carbon emissions. Technology such as Transportation Management Systems (TMS), GPS tracking, and fleet analytics enables real-time Supply Chain Analyst monitoring and performance optimization.Logistics includes planning, implementing, and controlling the movement and storage of goods, services, and related information. Transportation decisions include:

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

Demand Planning and Customer Service

Demand planning is the forecasting and planning process that anticipates customer demand to align production and inventory strategies accordingly. Accurate demand planning helps reduce overstocks, minimize stockouts, logistics storage warehouses and improve overall Objectives of Supply Chain Management supply chain agility. Forecasting methods include:

Customer service, the final link in the supply chain, focuses on order accuracy, timely delivery, returns processing, and customer support. A responsive service system enhances brand reputation, increases customer loyalty, and feeds insights back into the supply chain for continuous improvement.

Conclusion

Supply Chain Management is a multidisciplinary function that integrates procurement, manufacturing, inventory, logistics, Inventory Management System and customer service into a unified system. With global competition and digital transformation accelerating,PMP Training businesses must continuously optimize their supply chain strategies using data analytics, automation, logistics storage warehouse and agile practices. A well-executed supply chain not only ensures product availability and quality but also serves as a strategic driver of growth, efficiency, and customer satisfaction.