- Introduction Understanding Supply Chain Management

- Early History and Traditional Supply Chains

- The Impact of Industrial Revolution on Supply Chains

- Emergence of Modern Supply Chain Concepts

- The Role of Technology in Transforming Supply Chains

- Globalization and Its Effect on Supply Chain Management

- The Rise of Sustainable and Ethical Supply Chains

- Conclusion

Introduction Understanding Supply Chain Management

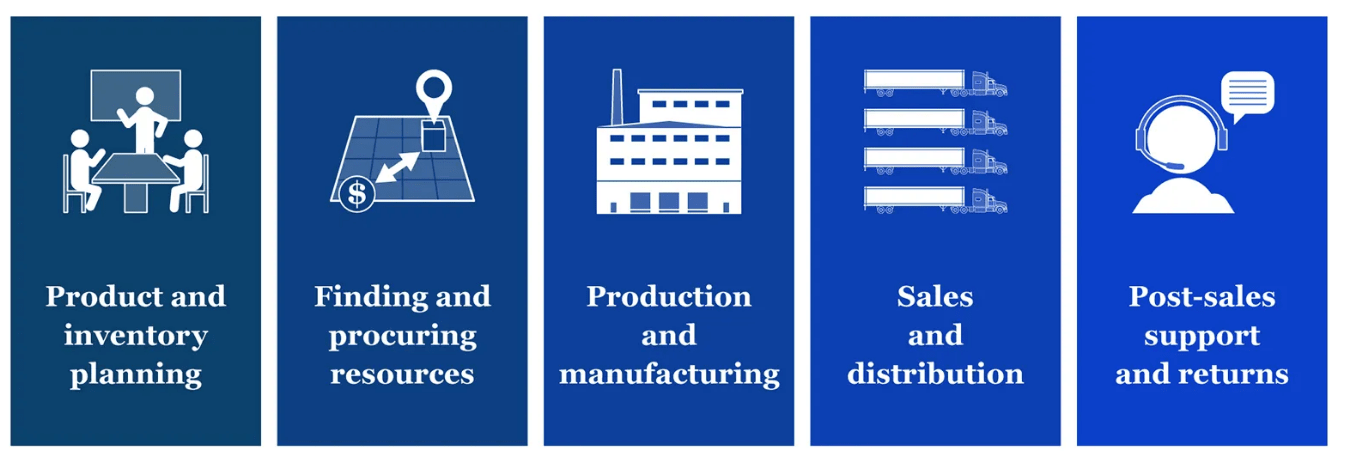

Supply Chain Management (SCM) involves the coordination and management of all processes required to source, procure, produce, and deliver goods and services to customers. It covers a wide range of activities, including supplier selection, production planning, inventory control, transportation, warehousing, and customer service. Over the years, SCM has evolved from a narrow focus on logistics and inventory control to a comprehensive, integrated discipline that is now seen as a core driver of business strategy and competitive advantage. In the early stages, supply chain practices were largely reactive and operational, centered around fulfilling orders and managing stock levels. As manufacturing and distribution networks expanded, especially in the late 20th century, the need for better coordination among suppliers, manufacturers, and distributors became apparent. This led to the development of more structured supply chain processes and the introduction of enterprise resource planning (ERP) systems to support integration and data sharing, further strengthened by PMP Training. The rise of globalization further transformed supply chain management by introducing complex, multi-tiered networks that span continents. Companies began to source materials and manufacture products across different countries to reduce costs and increase efficiency. This global reach brought new challenges such as longer lead times, geopolitical risks, and the need for greater visibility. In recent years, technology has become a major force shaping the future of SCM. Digital tools such as supply chain analytics, artificial intelligence, blockchain, and the Internet of Things have enhanced real-time decision-making, risk management, and operational agility. At the same time, customer expectations for speed, transparency, and sustainability have pushed companies to rethink how they design and manage their supply chains. This blog explores the historical evolution of supply chain management and highlights the trends that are influencing how companies build smarter, more responsive, and resilient supply chains today.

Interested in Obtaining Your PMP Certificate? View The PMP Certification Training Offered By ACTE Right Now!

Early History and Traditional Supply Chains

In ancient times, supply chain management in its earliest form began to take shape through the development of long-distance trade routes. One of the most well-known examples is the Silk Road, which connected regions across Asia, the Middle East, and Europe. These routes allowed merchants to exchange goods such as silk, spices, precious metals, and textiles. While these early trade networks laid the groundwork for global commerce, supply chains during this period remained largely fragmented, localized, and uncoordinated. The traditional supply chain in ancient and pre-industrial societies focused primarily on the basic movement of raw materials and finished products, much like the linear approach of Agile vs Waterfall methodologies. Procurement and transportation processes were rudimentary, often carried out by individual traders, small merchant groups, or local craftsmen. Most production was done on a local scale, within villages or small city-states, and was highly dependent on manual labor. Goods were often produced to meet immediate needs rather than to stockpile for future demand, and inventory was managed informally or manually without standardized systems. There was little to no strategic coordination among the different participants in these early supply chains. Communication between buyers and suppliers was limited and slow, typically relying on face-to-face meetings, messengers, or handwritten correspondence. Transactions were based on trust and repeated interactions rather than formal contracts or shared data.

Information sharing was minimal, and there was no visibility into upstream or downstream processes. The primary focus during this era was ensuring the availability of goods, with little attention paid to efficiency, cost control, or integrated planning. While these early supply chains lacked the sophistication of modern systems, they laid the essential foundation for trade, economic development, and the future evolution of supply chain management practices.

The Impact of Industrial Revolution on Supply Chains

- Mechanization and Mass Production: The Industrial Revolution introduced mechanization, enabling mass production techniques that significantly increased manufacturing capacity.

- Expansion of Supply Chains: Factories began sourcing raw materials from wider geographical areas and distributing finished products to larger, more diverse markets.

- Advancements in Transportation: The development of railroads and steamships revolutionized the movement of goods, allowing faster and more reliable transportation over long distances, similar to how teams choose between Jira vs Trello for efficient project management.

- Improved Communication: Telegraph systems facilitated quicker communication between suppliers, manufacturers, and distributors, enhancing coordination across the supply chain.

- Linear and Siloed Processes: Despite these advancements, supply chains remained mostly linear, with limited visibility and coordination between different stages such as sourcing, production, and distribution.

- Growing Inventory Levels: Increased production capacity and less integrated planning led to higher inventory levels, often resulting in inefficiencies and increased costs.

- Foundations for Modern Supply Chains: Although still rudimentary, this period marked the beginning of more organized supply chain functions, laying the groundwork for future innovations and integrated management.

- Focus on Efficiency and Cost Reduction: In the mid-20th century, companies prioritized improving operational efficiency and minimizing costs across their supply chains.

- Emergence of Operations Research and Management Science: The development of these analytical fields provided tools and models for optimizing inventory control, production scheduling, and resource allocation, all of which are integral components covered in PMP Training.

- Just-In-Time (JIT) Manufacturing: Introduced by Toyota in the 1970s, JIT revolutionized inventory management by reducing stock levels, minimizing waste, and promoting lean production practices.

- Supply Chain Management as a Discipline: During the 1980s and 1990s, Supply Chain Management (SCM) emerged as a distinct field, focusing on the coordination and integration of all supply chain activities.

- Cross-Functional Coordination: SCM emphasized collaboration between procurement, production, and logistics departments to improve overall supply chain performance.

- Supplier Partnerships: Firms began building closer relationships with suppliers to improve quality, reliability, and cost-effectiveness through long-term collaboration.

- Demand Forecasting and Responsiveness: Advances in forecasting techniques helped companies better predict customer demand, enabling more agile and cost-efficient supply chains.

- Expansion of Global Supply Chains: Since the late 20th century, globalization has extended supply chains across international borders, creating intricate global networks.

- Outsourcing and Sourcing: Companies increasingly outsource manufacturing to lower-cost countries and source raw materials from around the world to optimize costs and efficiency.

- Access to International Markets: Global supply chains enable firms to serve diverse markets worldwide, increasing product variety and customer reach, much like how What are Scrum Ceremonies help teams coordinate and deliver value efficiently.

- New Challenges Introduced: Global operations bring challenges such as longer lead times, higher risks, regulatory compliance complexities, and geopolitical uncertainties.

- Balancing Efficiency and Resilience: Supply chain managers must find a balance between minimizing costs and maintaining supply chain resilience and flexibility to respond to disruptions.

- Digital Tools and Risk Management: The complexity of global supply chains has driven widespread adoption of digital technologies and risk management strategies to improve visibility and responsiveness.

- Impact of Trade Agreements and Finance: International trade agreements and supply chain finance solutions have influenced global supply chain management practices, facilitating smoother cross-border transactions and funding.

To Earn Your PMP Certification, Gain Insights From Leading Blockchain Experts And Advance Your Career With ACTE’s PMP Certification Training Today!

Emergence of Modern Supply Chain Concepts

The Role of Technology in Transforming Supply Chains

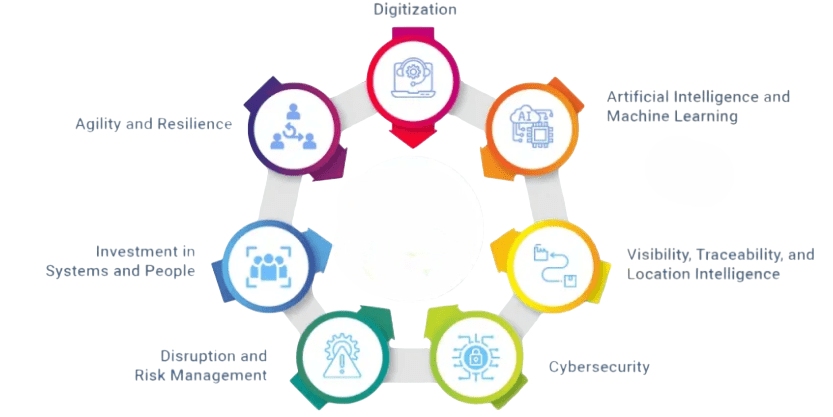

The advent of information technology has profoundly transformed supply chain management, turning it from a manual and reactive process into a proactive, data-driven function. One of the most significant advancements has been the development of Enterprise Resource Planning (ERP) systems. These platforms allow businesses to integrate real-time data across various departments such as procurement, manufacturing, finance, and logistics. By connecting operations through a centralized system, ERP enhances coordination, reduces redundancies, and improves decision-making throughout the supply chain. Tracking technologies have also advanced considerably. Barcoding systems first improved the accuracy of inventory management and streamlined warehouse operations. The introduction of Radio Frequency Identification (RFID) further enhanced tracking capabilities by allowing real-time visibility of goods in transit and in storage, reflecting the Key Values and Principles Behind the Agile Manifesto of transparency and responsiveness. This level of transparency helps reduce losses, improve inventory turnover, and support just-in-time inventory practices. The internet has accelerated the pace of supply chain transactions and opened new digital channels for interacting with customers and suppliers. E-commerce platforms enable businesses to reach global markets and fulfill orders with unprecedented speed and efficiency. As a result, customer expectations around delivery times and service levels have increased, pushing companies to innovate continuously. Advanced analytics, artificial intelligence, and machine learning have added a new layer of intelligence to supply chain management. These tools help predict customer demand, optimize transportation routes, identify supplier risks, and automate procurement decisions. Cloud computing has further enhanced collaboration by enabling supply chain partners across different regions to access shared data and work together in real time. This improves agility and responsiveness while supporting better strategic alignment. Overall, technology has redefined supply chain operations. Businesses can now operate with greater speed, precision, and flexibility, creating smarter and more resilient supply networks capable of adapting to changing market conditions.

Gain Your Master’s Certification in PMP by Enrolling in Our PMP Master Program Training Course.

Globalization and Its Effect on Supply Chain Management

The Rise of Sustainable and Ethical Supply Chains

In recent years, sustainability and ethical practices have become central priorities in supply chain management. Growing awareness among consumers, regulators, and investors has created a strong demand for transparency regarding environmental impact, labor conditions, and corporate social responsibility. As a result, organizations are rethinking how they design, operate, and monitor their supply chains to align with global sustainability goals and ethical standards. One of the key developments in this area is the adoption of green logistics. Companies are actively working to reduce their carbon emissions by optimizing transportation routes, using fuel-efficient vehicles, and shifting to alternative energy sources. Many are also redesigning packaging to reduce waste and improve recyclability. These efforts contribute to lower environmental footprints and support global efforts to combat climate change. Ethical sourcing has also gained significant importance, highlighting the different perspectives of a Business Analyst vs Financial Analyst. Businesses are expected to ensure that their suppliers adhere to labor laws, provide safe working conditions, and uphold human rights. This includes addressing issues such as child labor, unfair wages, and unsafe work environments. Audits, certifications, and partnerships with ethical sourcing organizations help verify compliance across the supply chain. The rise of circular supply chains reflects a broader commitment to sustainability. Companies are designing products and processes that emphasize reuse, recycling, and material recovery, extending product life cycles and reducing reliance on virgin resources. This circular approach not only minimizes waste but also generates economic and environmental value. Sustainability initiatives are now integrated into supplier evaluation, product development, and logistics planning. Beyond meeting regulatory requirements, companies recognize that responsible supply chain practices enhance brand reputation, build customer trust, and improve long-term business resilience. In an increasingly conscious marketplace, sustainable and ethical supply chains are becoming essential for future success.

Want to Learn About PMP? Explore Our PMP Interview Questions and Answers Featuring the Most Frequently Asked Questions in Job Interviews.

Conclusion

The evolution of supply chain management reflects the ever-changing landscape of global business and the continuous advancement of technology. What began as simple trade exchanges along ancient routes like the Silk Road has transformed into a sophisticated, interconnected system that spans continents and industries. Over time, supply chains have shifted from local, manual operations to complex, digitally enabled networks capable of real-time communication, data-driven decision-making, and end-to-end visibility. As supply chains evolved, so did their role within organizations. Once viewed primarily as a logistical or operational function, supply chain management is now recognized as a strategic driver of competitive advantage. It influences key areas such as cost efficiency, customer satisfaction, innovation, risk mitigation, and sustainability, all of which are emphasized in PMP Training. The integration of technologies like artificial intelligence, cloud computing, and advanced analytics has enabled companies to respond faster to market demands, forecast with greater accuracy, and operate more efficiently and transparently. Understanding the history and progression of supply chain management helps highlight the challenges that have been overcome and the opportunities that lie ahead. It underscores how external forces such as globalization, economic shifts, environmental concerns, and technological innovation continue to shape the discipline. Businesses must now prioritize agility, resilience, and sustainability in their supply chain strategies to remain competitive in a rapidly evolving environment. As companies look to the future, supply chain management will continue to play a critical role in enabling growth, driving innovation, and delivering value to customers. By embracing change and investing in smart, ethical, and responsive supply chain practices, organizations will be better equipped to meet the demands of an interconnected and uncertain world.