- Introduction to Supply Chain Digital Transformation

- Drivers of Digital Transformation in Supply Chain

- Key Technologies Enabling Digital Supply Chains

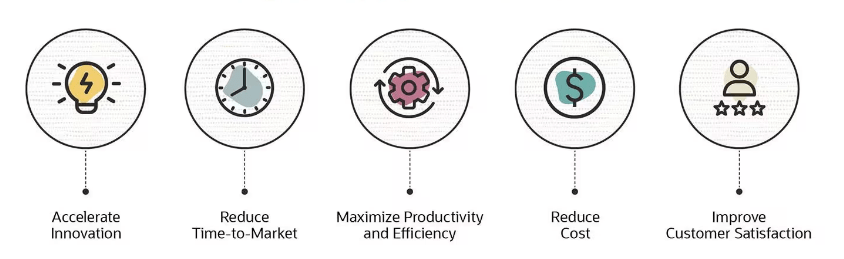

- Benefits of Digital Transformation in Supply Chain

- Challenges in Implementing Digital Transformation

- Step-by-Step Approach to Digital Transformation in Supply Chain

- Case Study Successful Digital Transformation in Supply Chain

- Future Trends in Supply Chain Digital Transformation

Introduction to Supply Chain Digital Transformation

Supply chain digital transformation refers to the comprehensive integration of advanced digital technologies into all aspects of the supply chain, including procurement, manufacturing, logistics, warehousing, and distribution. It represents a fundamental shift in how supply chains function by utilizing tools such as artificial intelligence, the Internet of Things, blockchain, cloud computing, and advanced analytics. These technologies enable automation, real-time visibility, predictive insights, and data-driven decision-making throughout the supply chain. As global markets become more interconnected and customer expectations continue to evolve, the need for agile, responsive, and transparent supply chains has increased significantly. Digital transformation allows organizations to respond quickly to disruptions, reduce operational costs, improve productivity, and enhance overall service levels. It also provides end-to-end visibility, which is essential for managing risk, optimizing inventory, meeting compliance requirements, and can be further enhanced through PMP Training. However, digital transformation is not just a matter of adopting new technology. It is a strategic and cultural evolution. Success depends on rethinking existing workflows, upskilling employees, fostering innovation, and ensuring that digital initiatives align with the organization’s broader goals. It often involves integrating traditional systems with modern platforms and requires collaboration across various departments. In addition to operational benefits, digital transformation supports sustainability by improving the efficiency of resource use, minimizing waste, and enabling circular supply chain practices. It also enhances resilience by developing systems that can adapt to global disruptions such as pandemics, natural disasters, or geopolitical challenges. In summary, supply chain digital transformation is critical for organizations that aim to stay competitive in a fast-paced, ever-changing business environment. Those that embrace digital innovation are better positioned to unlock new opportunities, drive long-term growth, and deliver superior customer value.

Interested in Obtaining Your PMP Certificate? View The PMP Certification Training Offered By ACTE Right Now!

Drivers of Digital Transformation in Supply Chain

Several key factors are driving digital transformation in supply chain management. One of the primary drivers is the growing demand from customers for faster deliveries, greater transparency, and personalized experiences. In today’s competitive environment, consumers expect real-time updates, flexible delivery options, and tailored products, which require supply chains to become more agile, responsive, and customer-centric. Meeting these expectations is only possible through the integration of digital technologies that enhance speed, visibility, and adaptability. Another significant factor in the discussion of Business Analyst vs Financial Analyst is the increasing frequency and severity of global disruptions. The COVID-19 pandemic exposed critical vulnerabilities in supply chains across the world, including dependence on limited suppliers, lack of real-time information, and insufficient contingency planning. These challenges prompted companies to invest in digital tools that improve visibility, enable predictive analytics, and support more resilient and flexible operations. The rapid growth of e-commerce is also reshaping supply chain priorities. Online shopping has placed immense pressure on logistics, order fulfillment, and inventory management systems. To meet rising demand and maintain efficiency, businesses are adopting automation, robotics, and digital tracking systems that streamline processes and improve accuracy. Technological advancements have further accelerated digital transformation. Innovations such as cloud computing, artificial intelligence, machine learning, and the Internet of Things have become more accessible and cost-effective, enabling companies of all sizes to digitize their supply chain operations.

These tools not only boost efficiency but also provide valuable data for strategic decision-making. Finally, the need to reduce costs and meet sustainability goals is encouraging companies to optimize their supply chains. Digital solutions help minimize waste, reduce energy consumption, and improve resource allocation, aligning operations with environmental and financial objectives. In summary, customer expectations, global challenges, technological progress, and sustainability goals are collectively fueling the digital transformation of supply chains.

Key Technologies Enabling Digital Supply Chains

- Internet of Things (IoT): Devices like sensors and RFID tags provide real-time tracking of goods and assets across the supply chain. This visibility improves inventory management, reduces losses, and enhances decision-making.

- Artificial Intelligence (AI): AI analyzes large datasets to predict demand, optimize routes, and automate decision-making. Machine learning models help identify patterns, forecast disruptions, and enhance supply chain resilience.

- Blockchain Technology: It enhances transparency, traceability, and security in supply chains by providing a tamper-proof record of product provenance and movement, which is especially relevant when considering the question Can Business Analyst be a Project Manager?

- Cloud Computing: Cloud platforms enable scalable data storage and processing power, facilitating collaboration across supply chain partners. Cloud-based systems support real-time data sharing and integration of diverse supply chain functions.

- Advanced Analytics and Big Data: Big data analytics processes massive volumes of structured and unstructured data to extract actionable insights. This supports demand forecasting, risk management, and performance optimization.

- Robotics and Automation: Automation technologies like robotic process automation (RPA) and autonomous vehicles streamline warehouse operations and logistics. They increase speed, accuracy, and efficiency while reducing human error.

- Digital Twins: Digital twins create virtual replicas of physical supply chain components or processes. They allow simulation, monitoring, and optimization of supply chain activities in a risk-free digital environment.

- Enhanced Visibility: Digital tools provide real-time data tracking across the supply chain, enabling companies to monitor inventory, shipments, and operations closely, reducing delays and errors.

- Improved Efficiency: Automation and AI streamline repetitive tasks such as order processing, demand forecasting, and inventory management, saving time and reducing operational costs, especially when combined with PMP Training.

- Better Decision-Making: Advanced analytics offer actionable insights from large datasets, helping managers make informed decisions about procurement, production, and distribution strategies.

- Increased Agility: Digital transformation enables supply chains to quickly adapt to changes such as market demand shifts, supplier disruptions, or logistical challenges, enhancing overall resilience.

- Cost Reduction: Through process optimization, waste minimization, and efficient resource utilization, digital supply chains lower costs related to storage, transportation, and labor.

- Enhanced Customer Experience: Faster delivery, improved order accuracy, and transparent tracking systems increase customer satisfaction and trust.

- Sustainability: Digital technologies help monitor environmental impact by optimizing routes, reducing waste, and enabling more sustainable sourcing and manufacturing practices.

- Assess Current State: Begin by evaluating your existing supply chain processes, technologies, and pain points. Identify areas needing improvement and opportunities for digital adoption.

- Define Clear Objectives: Set specific, measurable goals aligned with business priorities such as improving visibility, reducing costs, or enhancing customer satisfaction.

- Develop a Digital Strategy: Create a comprehensive roadmap that outlines the technologies to be adopted, integration plans, and timelines, which can influence the Project Manager Salary in India .

- Invest in Key Technologies: Select appropriate technologies like IoT, AI, cloud computing, or blockchain based on your needs. Prioritize scalable and flexible solutions that can evolve.

- Pilot and Test Solutions: Implement pilot projects in limited areas to validate technology effectiveness, gather feedback, and fine-tune processes before full-scale deployment.

- Train and Engage Workforce: Provide training and support to employees to ensure smooth adoption. Encourage a culture of innovation and continuous improvement throughout the organization.

- Monitor, Analyze, and Optimize: Continuously track key performance indicators (KPIs) to measure progress. Use analytics to identify bottlenecks, optimize operations, and adjust strategies as needed.

To Earn Your PMP Certification, Gain Insights From Leading Blockchain Experts And Advance Your Career With ACTE’s PMP Certification Training Today!

Benefits of Digital Transformation in Supply Chain

Challenges in Implementing Digital Transformation

Despite the numerous benefits that digital transformation brings to supply chain management, it also presents several significant challenges. One major obstacle is the presence of legacy systems and outdated infrastructure, which are often incompatible with new digital technologies. This incompatibility can require costly upgrades or complete overhauls, creating financial and operational burdens for organizations. Many companies struggle with integrating these new solutions smoothly into their existing technology environments. Another challenge arises from data silos that exist across different departments and among supply chain partners. When data is isolated and not shared effectively, it prevents organizations from conducting integrated data analysis and gaining a holistic view of their supply chain operations, highlighting the importance of the Phases of Project Management. This fragmentation limits the ability to make informed decisions and fully leverage the benefits of digital tools. Workforce resistance also plays a critical role in slowing down digital transformation efforts. Employees may fear job loss due to automation or feel unprepared because of a lack of necessary digital skills. This resistance can result in low adoption rates and hinder the overall success of transformation initiatives. To address this, organizations need to invest in training and change management programs. Furthermore, increased digital connectivity exposes supply chains to higher cybersecurity risks. Protecting sensitive data and maintaining secure systems require robust cybersecurity strategies and continuous monitoring, adding another layer of complexity to digital transformation. Finally, some companies are hesitant to invest in digital transformation because of unclear returns on investment or concerns about short-term disruptions during the transition period. These uncertainties can make decision-makers cautious and delay progress. In conclusion, overcoming these challenges requires effective change management, clear alignment of digital strategies with business objectives, and a commitment to investing in both technology and people.

Are You Considering Pursuing a Master’s Degree in PMP? Enroll in the PMP Master Program Training Course Today!

Step-by-Step Approach to Digital Transformation in Supply Chain

Case Study Successful Digital Transformation in Supply Chain

A leading global retailer was facing significant challenges with inventory management and supply chain visibility, which led to frequent stockouts, lost sales opportunities, and high inventory carrying costs. These issues affected the company’s profitability and customer satisfaction. To address these problems, the retailer decided to undertake a comprehensive digital transformation of its supply chain operations. The transformation began with the deployment of Internet of Things (IoT) sensors across its warehouses and transportation fleets. These sensors continuously monitored inventory levels, environmental conditions, and shipment locations, providing real-time data throughout the supply chain. Alongside this, the company integrated artificial intelligence (AI)-based demand forecasting tools. These advanced algorithms analyzed historical sales data, market trends, and external factors to predict demand more accurately and optimize inventory replenishment, shedding light on Why Do Scrum Masters Get Paid so Much for their expertise in managing complex workflows. To support seamless data sharing and coordination, the retailer adopted a cloud-based supply chain platform. This platform connected suppliers, logistics providers, and internal teams on a single system, enhancing collaboration and visibility. Recognizing that technology alone was not enough, the company invested heavily in training its employees on the new digital tools. They also established cross-functional teams responsible for overseeing the implementation, troubleshooting issues, and ensuring alignment across departments. The results of this digital transformation were impressive. Inventory holding costs decreased by 25%, freeing up capital and reducing waste. On-time delivery rates improved by 30%, enhancing customer satisfaction and supplier relationships. Real-time transparency became available to customers and suppliers alike, boosting trust and collaboration. Additionally, the retailer gained the ability to respond more quickly to changing market trends and supply chain disruptions, increasing its overall competitiveness in a fast-moving industry. This case demonstrates how strategic adoption of digital technologies, combined with employee engagement and process redesign, can drive substantial improvements in supply chain performance.

Preparing for a PMP Job? Have a Look at Our Blog on PMP Interview Questions and Answers To Ace Your Interview!

Future Trends in Supply Chain Digital Transformation

Looking ahead, supply chain digital transformation will increasingly rely on AI-powered autonomous systems to achieve end-to-end automation. Self-driving trucks are expected to transform logistics by reducing transportation costs, improving delivery speed, and increasing safety through consistent and precise operation without human error. In addition, robotic warehouses will manage inventory, packing, and sorting tasks with higher efficiency and accuracy, reducing manual labor and operational delays. Edge computing will be an important part of this change by enabling data processing to happen closer to where the data is generated, such as sensors in trucks or warehouses, instead of relying only on centralized cloud servers. This will reduce delays in data processing, allowing for faster real-time decisions that respond immediately to changing conditions like traffic issues or sudden demand increases, supported by PMP Training. Advanced analytics will continue to improve the ability to predict future demand, supply risks, and market trends. By analyzing large amounts of past and current data, these tools will help companies make proactive decisions to adjust operations and avoid disruptions before they affect customers. Sustainability will remain a key priority in digital transformation efforts. Digital technologies will track carbon emissions across the supply chain and support circular economy initiatives such as recycling and reusing materials to lower environmental impact. This focus responds to increasing regulations and customer expectations for responsible business practices. Furthermore, blockchain technology will be used more widely to improve trust and traceability in global supply chains. Its secure, decentralized ledger will increase transparency in sourcing, manufacturing, and delivery processes, reducing fraud and improving compliance. Together, these trends will create supply chains that are smarter, more resilient, and more sustainable, helping businesses succeed in an evolving and competitive marketplace.