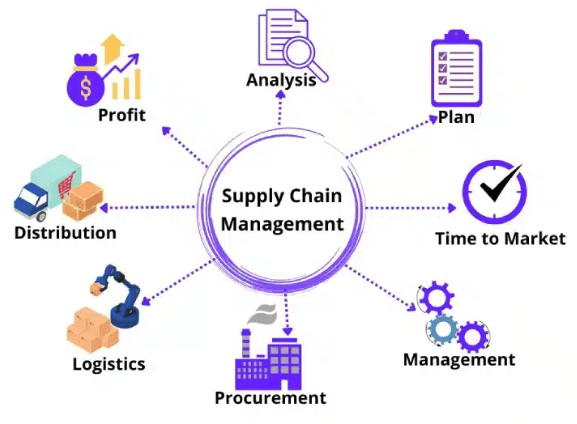

Supply Chain Management (SCM) focuses on coordinating and optimizing the movement of goods, information, and finances from suppliers to customers. It includes key activities such as procurement, production, logistics, and inventory management. By efficiently managing these processes, organizations can boost efficiency, lower costs, and enhance customer satisfaction. SCM also entails demand forecasting and adapting to market fluctuations, making it essential for sustaining a competitive edge in today’s fast-paced business landscape.

1. What is the Ultimate Objective of Supply Chain Management?

Ans:

Value for customers, cost minimization, and efficiency maximization are the ultimate goals of supply chain management. It ensures the delivery of products and services on time to fulfill customer demands. SCM focuses on improving collaboration among all stakeholders, such as suppliers, manufacturers, and retailers. SCM aims to enhance performance in the supply chain by optimizing processes and resources. This will result in increased profitability and loyalty from customers.

2. What is supply chain management?

Ans:

Supply chain management (SCM) manages the flow of goods, services, and information from the first supplier to the final customer. It integrates and orchestrates all activities related to sourcing, procurement, production, and distribution to maximize efficiency and minimize costs while enhancing customer satisfaction. SCM will effectively provide products at the right place, time, and quantity to ensure proper delivery. It also drives policies and strategies regarding supply chain customers and suppliers.

3. What Is Affreightment?

Ans:

Affreightment is a contract between a shipper and the carrier in a shipping contract where the responsible party, payment, and liability settle the transportation conditions of goods. The affreightment can be overland, air, or sea transport. The term helps determine the contractual obligations of the parties involved in shipping. It is widely used in logistics and maritime law. It is an important concept that shapes international trade.

4. What Do Supply Chains Involve?

Ans:

- Supply chain management encompasses several elements, including sourcing, procurement, production, logistics, and distribution.

- Other important elements are inventory management, demand forecasting, and supplier relationship management. SCM requires coordination among all the diverse marketing, finance, and operations functions.

- Enhancing technology is basically about visibility and communication along the supply chain. Performance measurement and risk management are also crucial factors in optimizing supply chain processes. Together, these factors ensure the free flow of goods and information.

5. What are Compliance Labels?

Ans:

- Compliance labels are marks or ratings that test a product’s compliance with certain regulatory and industry standards.

- Such labels prove that commodities are safe, environmentally friendly, or even meet quality requirements. Compliance labels may include safety certifications, environmental labels, and industry standards.

- They increase transparency and assure consumers that they are following regulations. Proper documentation of accuracy and tests is required to achieve such labels.

- In other words, compliance labels are important for market access and consumer safety.

6. What is the role of logistics in supply chain management?

Ans:

Logistics is essential to managing the supply chain since it coordinates the movement and storage of goods and materials. It encompasses transportation, warehousing, inventory management, and order fulfillment. The right logistics will ensure products are delivered to the customers on time in the required condition. It also encompasses route optimization and design to reduce costs and maximize efficiency. Logistics brings together various activities into supply chain management.

7. Why is Logistics Important?

Ans:

Logistics ensures the transportation of goods and services in the supply chain without hassle. This affects the satisfaction of the customers through delivery and availability times. Proper logistics management helps to decrease operational costs and improve inventory control, which maximizes the utility of the available resources. More than this, it facilitates a quick response to market requirements and changes. Logistics has also contributed enormously to competitive advantage through the best utilization strategies, including transportation and distribution.

8. What are the Differences Between Supply Chain Management and Logistics?

Ans:

| Feature | Supply Chain Management (SCM) | Logistics |

|---|---|---|

| Definition | Encompasses the entire flow of goods and services from suppliers to customers. | Focuses specifically on the transportation and storage of goods. |

| Scope | Involves multiple functions, including procurement, production, and distribution. | Primarily concerned with the movement and storage of products. |

| Objectives | Aims to optimize the entire supply chain for efficiency and customer satisfaction. | Aims to ensure timely delivery and cost-effectiveness in transportation. |

| Activities | Includes planning, sourcing, production, and logistics. | Involves warehousing, inventory management, and transportation. |

| Perspective | Strategic, considering long-term relationships and processes across the supply chain. | Tactical, focusing on the operational aspects of moving goods. |

9. What does Logistics Do?

Ans:

- Major logistics activities include transportation, warehousing, inventory, order processing, and distribution.

- Transportation management will involve selecting the modes of transport and finding the best routes to reduce cost and delivery time. Warehousing encompasses the storage of products and inventory management, ensuring orders are executed efficiently.

- Inventory management is highly related to maintaining appropriate stock levels to meet customer orders while avoiding overstocking. Other logistics activities include packaging and labeling of the product for shipment.

10. Define Advance Shipping Notice.

Ans:

- An Advance Shipping Notice, or ASN, is a communication the supplier sends to the customer before shipment. The notice includes detailed information about the shipment’s contents and quantity and when they should be expected.

- ASNs enable receiving departments to receive the products in a much more efficient order processing manner. Furthermore, they can help improve inventory management by maintaining the stock level before receiving the product.

- Using ASNs minimizes order-less errors and promotes proper communication between suppliers and customers. Generally, ASNs have made the supply chain more streamlined and efficient.

11. What are the key components of the supply chain?

Ans:

A supply chain can be broadly classified into four main segments: sourcing, production, logistics, and distribution. Sourcing is the process of procuring raw materials or inputs and parts from the vendor. The production represents the steps of transforming these materials into the final product. Logistics include transportation and warehousing. Distribution is defined as delivering products to customers or retailers. Together, these parts ensure that the flow of goods from their origin to the destination is smooth.

12. How does stock management impact the efficiency of the supply chain?

Ans:

This implies that inventory management influences the supply chain’s efficiency. Inventory controls the inventory levels so customers get their desires without surplus. It minimizes carrying costs and prevents stockout; hence, customers have products they want when they want them. It also improves the speed of order fulfillment, which increases customer satisfaction. Optimizing an inventory turnover-free capital for other kinds of investments. An accurate set of inventory data is also useful in bettering demand forecasting.

13. Why is there a need for demand forecasting in a supply chain?

Ans:

- Demand forecasting is vital in supply chain management as it forecasts the future demand for products in the market.

- Correct forecasting allows organizations to work effectively on their production, inventory levels, and procurement strategies.

- By knowing ahead of time the fluctuations in demand, companies can avoid stockouts and excess inventories.

- Demand forecasting also provides information for pricing strategies and marketing initiatives. This pre-informed approach improves a supply chain’s overall response and agility.

14. What’s the role of suppliers in the supply chain?

Ans:

- Suppliers are integral parts of a supply chain, as they are indispensable in delivering the required raw materials and components in production.

- They make quality inputs available on time, which is closely related to the efficiency of the entire manufacturing process and ultimately affects the product’s quality.

- Effective supplier relationships would thus support smoother communication and collaboration, which could be easier to facilitate.

- Suppliers also exert influence over costs by keeping pricing lower than the absolute minimum; this can compensate for benefits at the bottom line.

15. How is technology changing the way supplies are managed?

Ans:

Technology is changing the aspects of supply chain management to make the process more transparent, efficient, and responsive. For instance, enterprise resource planning systems use advanced software solutions that arrange things and share information accordingly. Automation technologies continue to advance processes, reduce manual work, and lessen errors. Analytics tools also improve decision-making through real-time facts and predictive modeling.

16. What are the problems in supply chain management?

Ans:

Some common challenges in supply chain management include variability in demand, disruptions that affect supply chains, and complexity associated with managing different inventories. Demand variability will produce a situation with stockout or excess inventory. Supply chain disruptions arise due to natural disasters, geopolitical issues, and global pandemics that affect delivery schedules. Complex interactions with various suppliers are time-consuming.

17. What impact does globalization have on supply chain operations?

Ans:

- Globalization impacts the supply chain operation through wider market opening and competition intensification.

- Due to globalization, companies can source from a more diversified array of suppliers at a lower cost. However, this also carries with it further complexities, like increased lead times and transportation costs.

- The management of international rules, tariffs, and customs attracts extreme attention. Cultural differences affect supplier relationships and communication.

18. What is the importance of supplier relationship management?

Ans:

- Supplier Relationship Management (SRM) can be very important in developing collaboration and enhancing communication between an organization and its suppliers.

- Strong relationships with suppliers result in quality, reliability, and innovation. Effective SRM facilitates good negotiation results in terms of favorable pricing and terms.

- Effective SRM helps identify risks and respond efficiently to issues. Strategic partnerships improve the overall performance and resilience of supply chain management and eventually lead to long-term business success.

19. How do supply chain disruptions impact businesses?

Ans:

Supply chain disruptions severely affect the business operations of the business enterprise since it will start causing delays in production and delivery. With these disruptions, the companies will pay more than they should because of the rush order delivery or sourcing of material from another provider. Consumers are only satisfied if the product is scalable or delivered too slowly. More probable is the total loss of reputation and consumer confidence, which might also be irreversible.

20. How does data analytics help in supply chain decisions?

Ans:

Data analytics plays a critical facilitator role in decision-making in supply chains by providing actionable insights based on large volumes of information. It helps organizations detect trends and predict demand, thus optimizing inventory levels. This is why data analytics can be a means of improving the process’ overall efficiency and even cutting costs for companies. It gives better visibility on the supply chain, allowing stakeholders to become much more collaborative.

21. What are the supply chain models?

Ans:

- There are four varied types of supply chain models: the efficient supply chain model, the responsive supply chain model, the agile supply chain model, and the hybrid supply chain model.

- An efficient supply chain focuses on achieving lower costs through economies of scale. A responsive supply chain focuses on flexibility and speed to respond to increasingly changing customer desires.

- Agile supply chains combine efficiency and responsiveness. They can quickly respond to market changes.

- Hybrid supply chains combine different strategies to balance between cost and service levels. Each model serves specific business needs and market environments.

22. What are the impacts of sustainability on supply chain practices?

Ans:

- Sustainability impacts supply chain practices with both environmental considerations and social responsibility toward methods applied by organizations.

- Companies have been strongly focused on waste reduction, lowering carbon footprints, and sourcing ethically produced materials. Energy efficiency and waste reductions in sustainable practices also generate cost savings.

- Increased consumer consciousness about sustainability issues requires businesses to resonate with the same value system. Pressure from the regulatory system also compels companies and suppliers to adopt sustainable practices within the supply chain.

23. What is just-in-time inventory?

Ans:

Just-in-time (JIT) inventory is a kind of inventory management technique where the receipt of goods occurs at the production stage only when they are needed. This effectively reduces the cost of holding inventory and captures cash flows. The accuracy of demand forecasting and supplier relations is essential to ensure on-time supply. This technique minimizes overproduction and excess idle inventories. The critical disadvantage of JIT is that it requires the most cautious planning and coordination.

24. How does regulation affect supply chain management?

Ans:

Regulations influence supply chain management through legal compulsions to abide by certain laws, ensuring safety, environmental protection, and labor policies. Thus, regulations can decide on the source, transportation methods, and product quality standards. Non-compliance can result in legal issues and a loss of reputation for your brand. Companies must be aware of how the laws are constantly changingchanging and align the supply chain operations accordingly with those changes.

25. What are the benefits of supply chain management software?

Ans:

- In contrast, supply chain management software offers many benefits concerning visibility and coordination within the supply chain.

- For instance, it can be applied to tracking inventory and shipments in real-time, making decisions promptly. Routine tasks can then be automated to reduce manual errors and speed things up.

- The software can support data analytics, which enables the identification of trends and, based on the knowledge gained, operation optimization.

- Its main benefits include the ability of relevant stakeholders to work together as much as possible because it smooths communication and information sharing.

26. Why is customer relationship management important to supply chains?

Ans:

- CRM is important to supply chains because it helps strengthen relationships with customers, ultimately improving customer satisfaction and loyalty.

- Good CRM systems allow an organization to source customer data and analyze it to tailor better services or products. By understanding customer needs and preferences, businesses will improve demand forecasting and inventory management.

- Strong customer relationships further provide collaboration and information exchange opportunities, leading to improved operational efficiency.

27. How do reverse logistics operations function?

Ans:

Reverse logistics involves returning goods to the manufacturer or the distribution center for returns, repair, recycling, or disposal. Such processes include managing returns, refurbishing products, and recycling materials. Reverse logistics aids in effective customer return management, making it easy to return the product and settle funds or exchanges at the appropriate time. It improves sustainability as recycling reduces the extra removed portions of waste, which may again be reused.

28. What are key supply chain management performance indicators (KPIs)?

Ans:

Key performance indicators or KPIs are measurable values that evaluate the effectiveness and efficiency of supply chain operations. Some of the most common KPIs include order fulfillment rates, inventory turnover, lead times, and transportation costs. These indicators show where improvements are required and enable companies to track progress toward strategic objectives. KPIs can also be used for benchmarking to the industry average or for comparison with competitors.

29. What is your role in this regard, considering risk management about supply chain strategy?

Ans:

- Risk management is an integral part of a strategy within the supply chain, as it identifies, assesses, and mitigates disruptions that could affect operations.

- Thus, effective risk management would consider vulnerabilities such as less reliable suppliers, geopolitical issues, and natural disasters.

- Further, preparing contingency plans and diversifying suppliers can lessen risks. Continuous monitoring and evaluation of risks allow organizations to respond quickly to growing threats.

- Proactive risk management increases resilience and stability in the supply chain. Managing risks in the supply chain is an integral aspect of ultimate success.

30. Why is logistics network design important?

Ans:

- Logistics network design is important because it dictates how goods are transported and stored within the supply chain.

- A well-designed logistics network maximizes transportation routes, cuts down on cost, and achieves faster delivery. An effective logistics network also optimizes inventory management by strategically situating the warehouses and distribution centers.

- It allows for a network design considering all these factors: customer demand, geographical locations, and modes of transportation. A good logistical network can scale and be flexible; it keeps pace with the changing dynamic in the marketplace.

31. How does transport mode choice affect supply chain efficiency?

Ans:

Transport mode selection has quite a great impact on supply chain efficiency, which goes along with speed, cost, and reliability of delivery. The ways of transportation vary greatly: by air, by sea, by road, and by rail. For instance, air delivers fast but at a price; sea transport delivers in bulk at a lower cost but very slow. The mode choice affects the inventory because more rapid modes are less likely to require inventory, and transport mode influences the supply chain’s carbon footprint.

32. What is supply chain resilience?

Ans:

Supply chain resilience is the ability of a supply chain to anticipate, respond to, and recover from disruptions. This concept refers to approaches that strengthen flexibility and stability in managing such challenges as natural disasters, geopolitical matters, or market fluctuations. Resilience building involves supplier diversification, maintaining safety stock, and investing in risk management practices. Companies with resilient supply chains can better withstand shocks and maintain business continuity.

33. To what extent do cultural differences impact international supply chains?

Ans:

- Cultural differences significantly influence international supply chains, as communication, negotiation, and business practices differ across cultures.

- Different attitudes toward time, hierarchy, and relationships may result in misunderstanding or friction.

- For example, direct communication differs across cultures, with some preferring directness and others using indirectness.

- Moreover, local customs and regulations may impact the selection of suppliers and the form of partnerships. Cultural specificities should be known and practiced to collaborate appropriately.

34. What are the best practices related to warehouse operations?

Ans:

- Optimize layout and space utilization with maximum workflow efficiency. Installing inventory management systems can be tracked in real-time and allow accurate inventory levels.

- There is mandatory scheduled training for all employees that ensures they are aware of the safety procedures and operational practices.

- Automation technologies include using a barcode scanner and conveyor systems to streamline processes, reduce errors, and achieve great precision. Regular audits maintain the accuracy of the inventory and standards of operation.

35. How can blockchain technology contribute to improving the transparency of the supply chain?

Ans:

Blockchain technology contributes to making the supply chain transparent by using a distributed ledger of transactions that cannot be changed. Thus, it ensures that all parties involved in the supply chain may trace the movement of products in real-time, and risks of fraud and error are relatively low. Smart contracts automate transactions, thus ensuring compliance and accountability on all sides.

36. What is the procurement function in the supply chain?

Ans:

This includes identifying supplies, negotiating contracts, and managing supplier relationships that guarantee quality and cost-effectiveness. The right procurement strategies lead to lower costs and better supply chain efficiency. Procurement also influences inventory management, deciding when and how much to order. Implementing other supply chain functions should ensure procurement is aligned with the overall business objective.

37. How do tariffs and trade policies affect supply chains?

Ans:

- How tariffs and trade policies influence supply chains: “Tariffs and trade policies affect supply chains because they impact the price and availability of crossing borders into a foreign country.

- The imposition of tariffs increases the cost of importing materials, forcing companies to revisit their sourcing strategy.

- Trade policies also determine which countries can have free-trade status with others, so suppliers’ choices and logistics decisions are impacted. These tariff modifications can change the market’s dynamics and demand quick changes from firms and companies.

38. How does automation affect the process involved in the supply chain?

Ans:

This can make them highly efficient, reduce labor costs, and increase the degree of accuracy. Processes like robotics, artificial intelligence, and automated inventory management systems streamline the processes and minimize human errors. Therefore, they enhance the speed of order processing and fulfillment for better customer service. However, they call for a high investment and loads of maintenance on a periodic basis. This is also accompanied by workforce implications that require re-skilling and training.

39. How might companies measure their supply chains’ performance?

Ans:

Several supply chain KPIs, such as order fulfillment rates, inventory turnover, and delivery lead times, can be measured. Measuring those factors provides insights into efficiency, responsiveness, and cost-effectiveness. Trends and differences in such data indicate where changes are needed, and they support other strategic decisions about making those changes. Benchmarking against industry standards will make companies judge their performance based on comparison with rivals.

40. What is the role of inventory turnover in supply chain efficiency?

Ans:

- Inventory turnover refers to the number of turns that inventory is sold and replaced within a given time period; it determines the period that can be considered efficient in inventory management.

- A high turnover rate reflects good sales and inventory control. Often, turning over stock minimizes holding costs and waste.

- A better turnover rate increases an organization’s capability to meet customer demand within optimum stock levels. Low turnover rates may indicate a problem with overstocking or poor sales performance.

41. How would season affect the supply chain planning?

Ans:

- Seasonal fluctuation greatly influences supply chain planning, as the change in seasons affects demand variability.

- Consumer demand tends to shoot up during peak seasons, so an organization needs to provide for the inventory requirements and longer lead times. Thus, they need to predict the changes needed to keep adequate stocks and delivery.

- It would also need to adjust the level of staffing and logistics capacity. Failure to plan seasonality sometimes leads to stockouts or excess inventory. Proactive planning keeps throughput efficiency and customer satisfaction intact during fluctuating demand periods.

42. What are the benefits of third-party logistics providers?

Ans:

Third-party logistics providers offer various benefits, such as cost savings with economies of scale. They come equipped with expertise in logistics management, which allows organizations to free up their core business activities. Flexible solutions can be supported if seasonal fluctuation is necessary, along with other changing requirements. Access to advanced technology and systems can also increase supply chain visibility and efficiency.

43. What are the benefits of cross-docking in a supply chain?

Ans:

Cross-docking increases efficiency in supply chains by allowing less storage time and faster product flow. It is a process in which incoming shipments are directly unloaded to outbound transportation with minimal handling. In this case, cross-docking reduces a firm’s dependence on warehousing, lowering holding costs on inventory and shortening delivery times. Additionally, cross-docking improves coordination with suppliers and distributors, thus promoting faster response to market demands.

44. How does supply chain management contribute to customer satisfaction?

Ans:

- Supply chain management directly determines customer satisfaction. On-time delivery and product availability show that timely delivery means the availability of goods at the desired time.

- Better SCM ensures the right products are in the right place at the right time. Effective inventory management ensures a higher service level and responsiveness to customer requirements.

- Collaboration among the partners within the supply chain fosters openness and dependability, therefore directly leading to better customers.

45. In what way can supply chain collaboration provide a competitive advantage?

Ans:

- Supply chain collaboration can provide a competitive advantage by strengthening relationships and enhancing overall efficiency among the partners.

- This sharing of information and resources can effectively help them in demand forecasting and inventory management. Collaborative efforts develop innovations in processes and products that are more responsive to changes in markets.

- Also, it leads to aligned goals among the stakeholders, reducing costs and enhancing service levels.

- This synergy allows organizations to adapt rapidly to disruptions and capitalize on opportunities.

46. What are the trends reshaping the future of supply chain management?

Ans:

The bigger trends involve greater digitalization and automation-from analytics enabled by more advanced artificial intelligence and Internet of Things integration-to real-time decisions. Sustainability is finally center stage, compelling companies to become more environmentally friendly. In addition, attention to supply chain resilience decreases disruption risks. The increased focus lies on cooperative models since businesses shift towards relationship improvement.

47. How does transportation management affect the general performance of a supply chain?

Ans:

Transportation management greatly influences the overall performance of the supply chain; it may pertain to speed of delivery, cost, or reliability. A managed transportation system optimizes routes and schedules, reduces transit time and expenses, and promotes visibility into the shipment status for advance decision-making. It ensures that a customer is appropriately satisfied by offering timely delivery. One also tends to reduce their carbon footprint compared to other traditional modes of transportation.

48. What are some of the effective supply chain optimization strategies?

Ans:

- Effective strategies in supply chain optimization include data analytics to guide decision-making and process automation to enhance efficiency.

- Just-in-time inventory practices reduce costs associated with holding products and assure their availability for sale. Collaboration among supply chain partners improves communication and resource sharing.

- Organizations can apply continuous improvement methodologies such as Lean and Six Sigma to identify and eliminate waste. Periodic monitoring through KPIs ensures the operation aligns with the organization’s goals.

49. How do environmental considerations affect decisions regarding supply chains?

Ans:

- Environmental concerns have impacted decisions related to supply chains, creating a call for organizations to become more environmentally friendly and reduce their ecological footprint.

- Suppliers are increasingly assessed based on their environmental performance as this helps in responsible sourcing.

- Transport modes are also often evaluated for carbon intensities, and other factors tend to favor options with a lesser carbon intensity.

- Regulatory compliance, as far as environmental standards are concerned, also impacts operational strategies.

50. What are the challenges of managing multi-channel supply chains?

Ans:

The multi-channel supply chain is hard to manage and coordinate, especially regarding inventory across different channels and customer consistency. Advanced logistics demand addressing online and offline sales would be in a very good position if effective strategies could be applied in managing the inventory. Visibility and real-time tracking become challenging across different channels. Systems and processes need to be integrated to operate effectively.

51. How does lead time affect supply chain performance?

Ans:

Lead time has a significant implication on the performance of a supply chain because it affects both inventory levels and customer satisfaction. Holding costs build up with increases in lead times as more inventory holds, but potential stockouts and lost sales rise with higher lead times. Reduced lead times positively affect responsiveness to market conditions. It means that businesses would adapt to changes in the market earlier on. Effective management of lead times is likely to result in increased planning accuracy and reduce waste.

52. What are the supply chain’s core demand forecasting techniques?

Ans:

- Organizations can accurately forecast demand using past sales data, market trends, and statistical models.

- Still, input from the sales, marketing, and supply chain teams through collaborative forecasting helps in achieving better precision.

- Sophisticated analytics and machine learning enable the detection of patterns and sharpening predictions.

- Forecasts should be updated in real-time to account for seasonal fluctuations and market shifts. Specialized software packages dedicated to demand forecasting help speed up this process.

53. What is the task of a supply chain manager?

Ans:

- A supply chain manager manages and coordinates all the activities of a supply chain to become efficient and effective.

- It comprises managing supplier relations, optimum inventory control, and developing logistics operations.

- Supply chain managers collect information that will help in assessing performance improvement areas.

- Furthermore, supply chain managers coordinate and link most other departments to harmonize the business’s objectives with the activities occurring in the supply chain.

54. How does inventory classification-ABC analysis improve inventory management?

Ans:

ABC analysis improves inventory management by classifying it into three classes where items fall according to value and importance. Class A items present a low volume of inventory but hold the bulk of their value and must, therefore, be closely monitored. Class B items are of middle value and Class C items are low-value ones and thus of least importance. This classification helps firms use their resources most productively because much effort goes into the high-impact items.

55. What are the stages in the order execution cycle?

Ans:

Order fulfillment involves key stages, including placing, processing, picking, packing, and shipping. Customers place their orders through channels that reach the system for processing. Items are then picked from the inventory based on the details of the placed order. After being picked, items are packed securely and ready for shipping. The orders are shipped to the customers normally with the option of tracking information. Timely deliveries and satisfactory responses to customers are achievable this way.

56. How should supply chain visibility be improved?

Ans:

- Advanced technologies such as IoT and blockchain can improve supply chain visibility. Over time, they help provide real-time data on inventory levels, shipment status, and supplier performance.

- The linkage of various platforms enhances data integration, thereby making all stakeholders more transparent and communicative.

- Monitoring and reporting performance helps identify possible breakdowns and plan for alternative outcomes ahead of time.

57. What is vendor-managed inventory?

Ans:

Vendor-managed inventory, or VMI, is a supply chain system responsible for managing the customer’s inventory at his site. Under this deal, the supplier monitors inventory usage and replenishes the inventory as may be the case and beyond agreed levels. VMI enhances supplier and customer cooperation, leading to effective inventory management. It reduces stockouts and excess inventory, therefore optimizing general supply chain performance.

58. What makes supply chain integration efficient in enhancing operational efficiency?

Ans:

Supply chain integration enhances operational efficiency by encouraging smooth communication and collaboration among all parties involved. Integrating processes and systems that produce redundancy, delays, and errors in data quality reduces these. This alignment facilitates better demand forecasting and inventory management, which helps save costs. Integrated supply chains also permit faster responses to market changes and customer requirements.

59. What are the problems that face managers of global supply chains?

Ans:

Global supply chains are problematic in some ways. First, logistics can be quite complicated and complex in most cases. Another major challenge is regulatory compliance and following the rules in every country. Third, shipment coordination across several countries involves handling completely different transportation infrastructures and customs clearance rules. Fluctuating currency exchange rates may distort costs and pricing strategies.

60. How do economic factors influence the strategy in the supply chain?

Ans:

- Economic factors influence the demand chain, products, and services, affecting demand, cost, and operations.

- Economic declines, like inflation or recession, influence people’s purchasing decisions and demand for any product.

- Increased transport and material costs may force companies to look for cheaper alternatives, including logistics arrangements.

- Further, changes in trade policies and tariffs might involve changes in relationships with suppliers and sources of goods. Economic projections guide companies to make inventory levels and capacity plans.

61. Why is quality control considered important in supply chain management?

Ans:

- Quality control, as part of supply chain management, assures that the products meet the established standards and customers’ expectations.

- Quality control processes reduce defects, preventing return deliveries and ensuring higher customer satisfaction.

- Maintaining quality maintains good relationships with suppliers and customers. It also helps meet regulatory requirements and industrial standards.

- It identifies issues early, so quality control mitigates risk and reduces costs associated with rework and waste. A whole robust quality control system enhances overall supply chain performance.

62. How would companies reduce the risks of their supply chains?

Ans:

Companies can manage risk in supply chains by undertaking all-inclusive risk assessments and building contingency plans. Supplier diversification helps avoid dependence on just one supplier source and enhances flexibility. Good inventory management strategies will help them buffer against possible disruptions. There is also the aspect of investing in real-time monitoring technology to improve visibility into possible risks.

63. What are the benefits of cross-functional collaboration in supply chains?

Ans:

One of how it helps is that, in cross-functional collaboration, supply chains communicate and align well between departments like procurement logistics and marketing. This brings about more informed decision-making, thereby solving problems faster than would otherwise be the case. Shared insights and expertise bring about better efficiency in the overall innovation of the supply chain. Moreover, it promotes alignment of objectives across the functions for a more united approach with respect to better customer needs, thereby eliminating bottlenecks and inefficiencies.

64. How does lean manufacturing relate to supply chain management?

Ans:

- Lean manufacturing focuses on minimizing waste while maximizing value, which easily translates directly to the supply chain.

- Eliminating non-value-added activities enhances efficiency and reduces costs within the supply chain. Lean techniques, such as just-in-time inventory, improve responsiveness to customer demand.

- An environment of continuous improvement also fits within the goals for supply chain optimization. Effective communication and collaboration are built through lean systems, which guarantee that all stakeholders work toward common objectives.

65. How does e-commerce affect logistics in the supply chain?

Ans:

- E-commerce significantly impacts supply chain logistics, as the high demand for quicker delivery and precise order accuracy directly affects it.

- However, to keep up with this trend of shifting business activities to online shopping, agility in Logistics becomes key if the system is to manage large volumes and high volumes in short turnaround times.

- As such, online shopping has seen a surge in last-mile delivery solutions and fulfillment centers close to customers. E-commerce increases the need for robust inventory management to meet fluctuating demands.

66. How does technology enhance last-mile delivery in supply chains?

Ans:

Technology enhances last-mile delivery by route optimization and real-time tracking. Complex algorithms can determine more optimal delivery routes with low transit times and costs. Mobile apps allow buyers to track their orders. Drones and self-driving vehicles are innovative technologies that will revolutionize last-mile logistics. Another reason data analytics helps the organization is better demand forecasting, thereby proactively working on inventory management.

67. What role do training and development play in supply chain effectiveness?

Ans:

Training and development play an essential role in increasing the effectiveness of the supply chain by helping employees with skills and knowledge. Continuous learning keeps employees abreast of trends in the industry, technologies in use, and best practices. A well-trained workforce can identify inefficiency and inefficiency and develop them to improve operations. The culture of learning encourages employees to stay longer within a company.

68. What impact do weather-related conditions have on supply chains?

Ans:

- Major weather conditions can directly or indirectly influence the supply chain operation due to transportation, inventory management, and production scheduling.

- Severe storms, floods, and other extreme weather events can disrupt logistics chain schedules and shipments. Seasonal changes can influence demand patterns and should be represented in the available level of inventory.

- Supply chains must also consider and account for potential labor shortages caused by unfavorable weather conditions before the workforce is available.

- Contingency plans and monitoring of weather forecasts can reduce these impacts. Generally speaking, weather requirements play a great role in ensuring supply chain resilience.

69. Discuss the merits of just-in-case inventory.

Ans:

- A just-in-case inventory strategy offers merits since it ensures that products are available in case of unexpected spikes in demand or disruptions in supply.

- In such an event, the risks of stockouts are minimized, thus improving customer satisfaction and loyalty. It also allows firms to provide better service levels, particularly in industries experiencing variability in demand.

- Holding safety stock might also reduce the risks associated with lead time variability due to suppliers. However, this policy increases holding costs and may lead to wastage. Generally, just-in-case inventory fosters supply chain reliability operations.

70. What are the methods of applying continuous improvement to supply chain management?

Ans:

Continuous improvement practices can be applied in supply chain management through lean and Six Sigma methodologies. These methods are meant to find inefficiencies in supply chain processes and remove waste. Continuous checking of performance metrics will help identify areas for improvement. Therefore, employees’ involvement in improvement initiatives will encourage an innovation and engagement culture. Utilizing feedback loops ensures that improvements and refinements are made constantly.

71. What is the importance of ethics in supply chain management?

Ans:

Ethics are the other key aspect of supply chain management since they help create transparency, fairness, and accountability between many actors involved. Ethical practices lead to greater confidence between the suppliers, manufacturers, and consumers, thus encouraging long-term relationships. Compliance with ethical values prevents legal controversies and ruins the organizations’ reputations. On top of that, ethical sourcing and production develop corporate social responsibility and sustainability goals.

72. What is the impact of social media on supply chain operations?

Ans:

- Social media can influence supply chain operations by offering real-time customer and stakeholder feedback in real time. Such feedback may improve product development, demand forecasting, or inventory management.

- Moreover, social media allows supply chain partners to communicate and collaborate. Companies also monitor social media for brand reputation and potential issue identification.

- The increase in social media usage for marketing and promotions can also influence demand patterns, and an agile response system for the supply chain is needed. To summarize, social media is a very important tool for increasing the responsiveness and engagement of the supply chain.

73. What are agile supply chain characteristics?

Ans:

- Agility in an agile supply chain manifests itself in terms of flexibility and responsiveness to market changes. It is accommodating in responding to fluctuations in demand and supply disruptions.

- Agile supply chains use real-time data and advanced analytics in making rapid decisions. Strong collaboration among stakeholders ensures effective communication and coordination.

- Additionally, lead time is often shortened, and customer satisfaction is stressed. Generally speaking, agile supply chains increase competitive advantage in dynamic environments.

74. What do returns management processes represent in supply chains?

Ans:

Returns management processes, or reverse logistics, refer to managing returned goods by customers to the supply chain. This process usually begins with a return request, where the customer gives the reason for return. With authorization, the goods would be forwarded to some location for examination and auditing. Goods that are to be returned according to state would either be restocked, repaired, or recycled. Efficient return management helps reduce costs and increase recovery from returned products.

75. What impact does mobile technology have on supply chain management?

Ans:

Mobile technology plays an important role in improving communication and information access. Mobile devices provide entry and retrieval of real-time data and support better decision-making on-site. Mobile applications also track shipments and effectively manage inventory. Technology also enhances cooperation between partners in a supply chain by providing instant messaging and updates. Mobile technology streamlines operations and facilitates responsiveness to changes in the markets.

76. What strategies will supply chains adopt to respond to changed consumer preferences?

Ans:

- Supply chains can adapt to changes in consumer preferences by adopting adaptive production and distribution strategies. Applying data analytics would generate a lot of insight into trends and shifts in consumers’ behavior or attitudes, enabling proactive adjustment.

- It takes close coordination with the marketing and sales teams to keep on the same wavelength with customer needs and preferences. Agile inventory management makes it easy to adapt quickly to new offerings.

- Participation through various feedback channels also helps understand their needs. Supply chain responsiveness as a whole assumes great importance to competitiveness in relation to dynamic markets.

77. What are the implications of supply chain decentralization?

Ans:

- Decentralization for the supply chain means spreading decision-making and operations across multiple places or organizations.

- While decentralization may lead to better responsiveness and adaptation to the local circumstances of the market, issues such as similar quality and standards across such diversified facilities remain.

- Operation complexity and inefficiencies increase when implementing such decentralization. Communication and coordination are crucial in maintaining alignment among internal units.

78. How do companies ensure the sustainability of procurement?

Ans:

Companies can ensure sustainable sourcing by giving preference to environmentally friendly and ethical practices in a supplier selection procedure. Conducting deeper assessments of sustainability practices against suppliers’ corporate values ensures that those suppliers adhere to all the firm’s values. Long-term relationships between a company and its suppliers ensure effective collaboration on sustainability initiatives. Conducting supplier audits and implementing certifications are helpful in building accountability and transparency.

79. What is the difference between a push versus a pull supply chain strategy?

Ans:

A push supply chain strategy produces products on forecast, pushing these products into the market based on forecasted demand. The technique tends to make more than is likely needed in situations involving incorrect demand estimation. In contrast, pull supply chains operate by customer demand, removing the products through the supply chain as required. Leaner inventory levels and an ability to respond better in case of fluctuations caused by the market can be encouraged through pull strategies.

80. How do predictive analytics improve planning for a supply chain?

Ans:

- Predictive analytics affects the planning of supply chains by using current data and algorithms. This will enable the organization to forecast future trends and demand patterns.

- The proactive strategy allows an organization to optimize its inventory levels and minimize stockouts.

- Predictive analytics also improve supplier performance evaluation and risk management by identifying which disruptions might occur.

- Analyzing different factors—from market trends to customer behavior—will better equip organizations to make appropriate decisions.

81. How is safety stock relevant to inventory management?

Ans:

- Safety stock is a form of inventory buffer that protects an organization against uncertainties like a fluctuation in demand or a disruption in supply chain resources.

- It ensures customer demand satisfaction in such unexpected events. It minimizes the incidence of stockouts, which subsequently result in lost sales and decreased customer satisfaction.

- Moreover, safety stock can support order fulfillment rates and service levels in general.

- The costs of carrying an excessive amount of safety stock are very high, calling for prudent management.

82. How are big data sources exploited to develop competitive advantage for supply chains?

Ans:

Big data enables supply chains to improve their use of advanced analytics to discover customer preferences, market trends, and operational efficiencies. Analysis of large data sets allows organizations to make decisions that optimize inventory management and production planning. Predictive analytics streamlines the process for accurate demand forecasting and reduces excess inventories and all associated costs. Real-time data monitoring will give you real-time visibility across the chain, vaccinating responses in case of any disruption.

83. How does PLM influence supply chains?

Ans:

PLM significantly influences supply chains by integrating product development, design, and manufacturing processes. Effective PLM streamlines communication between stakeholders, improving collaboration and reducing the time for products to enter the market. Regarding lifecycle product management, the organization is better equipped to optimize inventory levels and make better forecasts regarding demands.

84. What do companies do to manage suppliers’ performance?

Ans:

- Establishing clear performance metrics and key indicators (KPIs) helps manage suppliers’ performance effectively.

- Periodic review and discussion of their performances with the suppliers ensures when and where improvement can be made to uphold expectations.

- Strong supplier relationships will encourage open communication and collaboration about performance issues between the supplier and the buyer.

- Suppliers’ use of scorecards would help present a visual representation of performance data, making it easier to track progress.

85. What is the function of packaging in the supply chain efficiency?

Ans:

- Packaging is important for supply chain efficiency because it protects products during transportation and storage and minimizes damage and loss.

- Good packaging makes it easier to handle, stack, and store while saving on labor and space. It can also guarantee proper labeling and information about the product; thus, it offers excellent inventory management.

- Sustainable solutions could be approached through packaging, which would also reduce environmental impacts and costs.

- Good packaging can even ensure customers’ confidence in delivery since products will reach them in optimal conditions. Overall, packaging is part of how we can optimize operations in the supply chain.

86. How does process automation add value to supply chains?

Ans:

Process automation can add efficiency and minimize human error in many routine tasks. Operations such as inventory management, order processing, and shipment tracking are streamlined as turnaround times are faster. Further, automated systems provide real-time data and analytics so that visibility within the supply chain is heightened. This enables quicker decision-making and more responsive adjustment to changing demand.

87. Why is benchmarking essential in supply chain management?

Ans:

According to supply chain management, benchmarking is necessary because organizations need to compare their activities with industry standards or best practices. This process identifies areas for improvement and helps set realistic goals for performance enhancement. Organizations can leverage successful strategies and practices through competitors and industry leaders. Benchmarking also enhances accountability and stimulates continuous improvement initiatives in the supply chain.

88. How do customer service levels influence supply chain decisions?

Ans:

- Customer service levels exert the utmost influence on supply chain decisions, including inventory management and stock holding, distribution strategies, and production planning.

- Generally speaking, to attain a high service level, it is necessary to maintain a higher inventory stock level to satisfy customers.

- Organizations need to weigh the extra cost of maintaining a higher level of service against the benefits of increased demand, which in turn increases sales and customer loyalty.

89. What are effective ways of negotiating with suppliers?

Ans:

Effective negotiation with suppliers involves appropriate preparation, such as awareness of market conditions and supplier capabilities. Clear objectives and priorities help guide the negotiation process toward achieving mutually beneficial outcomes. Building trust and good relations leads to better communication and mutual trust. Moreover, the study of win-win situations encourages cooperation and long-term cooperation.

90. How does CPFR improve supply chains?

Ans:

CPFR improves the supply chain by encouraging collaborative cooperation between trading partners in the planning and execution processes. It has organizations share knowledge and data, thereby creating more accurate forecasts that reflect market demands. Shared planning and collaboration reduce the holding costs of inventory, thus reducing the frequency of stockouts and enhancing service levels overall. CPFR also encourages joint problem-solving among partners to become innovative and find better solutions to a challenge in the supply chain.