You are at the proper place if you are getting ready for an Oracle Fusion SCM interview. We’ll go over some frequently requested Oracle Fusion SCM interview questions today, which will give you more self-assurance. It combines end-to-end business processes while taking into account how modern organizations’ supply chains are developing. Consequently, in order to be considered for various business Oracle Fusion SCM job roles, Oracle Fusion SCM specialists must answer interview questions about Oracle Fusion SCM. To assist prospective corporate Oracle Fusion SCM professionals, the following discussion provides an overview of several Oracle Fusion SCM interview question types.

1. What is Oracle Fusion SCM?

Ans:

Oracle Fusion SCM is a comprehensive suite of cloud-based applications designed to manage and optimize the entire supply chain lifecycle. It encompasses various modules, providing end-to-end solutions for procurement, order fulfilment, inventory management, product lifecycle, and more.

2. How does Oracle Fusion SCM differ from traditional SCM systems?

Ans:

Oracle Fusion SCM stands out from traditional SCM systems by offering a cloud-based, integrated, scalable solution. It promotes real-time collaboration, ensuring stakeholders across the supply chain have access to the latest information, enhancing agility and responsiveness to market changes.

3. What modules are included in Oracle Fusion SCM?

Ans:

Oracle Fusion SCM includes essential modules such as Procurement, Order Management, Inventory Management, Product Lifecycle Management, and Manufacturing. Each module addresses specific aspects of the supply chain, providing a holistic approach to SCM.

4. Explain Procurement in Oracle Fusion SCM.

Ans:

Procurement in Oracle Fusion SCM streamlines the entire procurement process, automating tasks from requisition to purchase order creation. It facilitates supplier management and contract negotiations and ensures compliance, promoting efficient and cost-effective procurement practices.

5. How does Oracle Fusion SCM handle Order Management?

Ans:

Oracle Fusion SCM’s Order Management module orchestrates the entire order lifecycle. It encompasses order to capture, pricing, and fulfilment, ensuring accurate and timely order processing. This module enhances customer satisfaction by providing real-time visibility into order status and delivery.

6. Describe Oracle Fusion SCM’s approach to Inventory Management.

Ans:

Oracle Fusion SCM’s Inventory Management module optimizes inventory levels, tracks stock movements, and offers real-time visibility. It enables organizations to maintain optimal stock. Levels minimize carrying costs and respond quickly to changes in demand, ultimately improving operational efficiency.

7.What is Product Lifecycle Management (PLM) in Oracle Fusion SCM?

Ans:

Oracle Fusion SCM’s PLM module manages the complete product lifecycle, from conceptualization to disposal. It includes tools for product data management, change control, and compliance tracking, ensuring organizations efficiently bring high-quality products to market.

8. How does Oracle Fusion SCM support collaborative decision-making?

Ans:

Oracle Fusion SCM facilitates collaborative decision-making by providing real-time visibility into supply chain processes. This enables stakeholders to share information, anticipate potential issues, and make informed decisions, fostering a collaborative and responsive supply chain environment.

9. Explain the concept of Demand Planning in Oracle Fusion SCM.

Ans:

Demand Planning in Oracle Fusion SCM involves forecasting and aligning customer demand with inventory levels. This module uses advanced analytics and historical data to enhance accuracy, helping organizations optimize their supply chain based on anticipated demand patterns.

10. What role does Manufacturing play in Oracle Fusion SCM?

Ans:

Oracle Fusion SCM’s Manufacturing module supports diverse manufacturing processes, offering work order management, routing, and quality control features. It ensures efficient production processes, improved resource utilization, and adherence to quality standards.

11. How does Oracle Fusion SCM handle integration with other Oracle Cloud modules?

Ans:

Oracle Fusion SCM seamlessly integrates with other Oracle Cloud modules, such as Finance and HCM. This integration provides a unified view of an organization’s operations, promoting consistency and accuracy in financial and human resource management.

12. What are the key benefits of using Oracle Fusion SCM?

Ans:

The key benefits of Oracle Fusion SCM include improved visibility, streamlined processes, increased collaboration, cost reduction, and the ability to adapt rapidly to changing market conditions. It empowers organizations to make data-driven decisions and enhances overall supply chain performance.

13. How does Oracle Fusion SCM address compliance and regulatory requirements?

Ans:

Oracle Fusion SCM incorporates features to monitor and ensure compliance with regulatory requirements. It includes tools for tracking product safety, environmental standards, and other industry-specific regulations, promoting adherence to legal and ethical standards.

14. Explain the concept of Work Execution in Oracle Fusion SCM.

Ans:

Work Execution in Oracle Fusion SCM involves the management and execution of tasks related to supply chain operations. This includes work orders, task lists, and resource management, ensuring efficient and coordinated execution of operational activities.

15. How does Oracle Fusion SCM utilize Artificial Intelligence (AI) and Machine Learning (ML)?

Ans:

Oracle Fusion SCM leverages AI and ML to provide predictive analytics, demand forecasting, and intelligent automation. These technologies enhance decision-making, optimize supply chain processes, and enable proactive responses to market dynamics.

16. Describe the role of Supplier Qualification Management in Oracle Fusion SCM

Ans:

Supplier Qualification Management in Oracle Fusion SCM ensures suppliers meet specific criteria and standards. It includes features for evaluating and managing supplier performance, certifications, and compliance, promoting strong and reliable supplier relationships.

17. How does Oracle Fusion SCM handle transportation management?

Ans:

Oracle Fusion SCM’s Transportation Management module optimizes the planning and execution of Transportation activities. It includes route optimization, carrier management, and real-time tracking, ensuring efficient and cost-effective transportation operations.

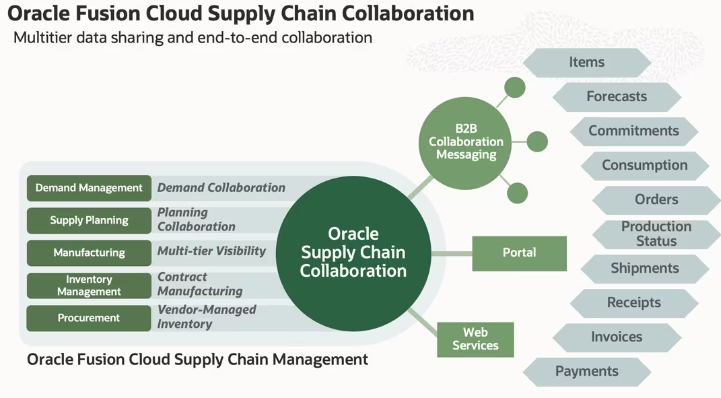

18. Explain the concept of Supply Chain Collaboration in Oracle Fusion SCM.

Ans:

Supply Chain Collaboration in Oracle Fusion SCM focuses on facilitating communication and collaboration among supply chain partners. It ensures that stakeholders have access to relevant information, fostering a collaborative environment that enhances overall supply chain efficiency.

19. How does Oracle Fusion SCM support global supply chain operations?

Ans:

Oracle Fusion SCM provides features to support global supply chain operations, including multi-language and multi-currency capabilities. It also ensures compliance with international trade regulations, facilitating smooth and compliant global supply chain management.

20. What role does Reporting and Analytics play in Oracle Fusion SCM?

Ans:

Reporting and Analytics in Oracle Fusion SCM offer robust tools for generating reports, dashboards, and analytics. Users can gain insights into key performance indicators (KPIs), monitor trends, and continually make data-driven decisions to improve supply chain performance.

21.Explain the concept of a Mobile Supply Chain in Oracle Fusion SCM.

Ans:

Mobile Supply Chain in Oracle Fusion SCM enables users to access supply chain information and perform tasks on mobile devices. This enhances flexibility, allowing users to stay connected to the supply chain and make informed decisions while on the move.

22. How does Oracle Fusion SCM address sustainability in the supply chain?

Ans:

Oracle Fusion SCM includes features to monitor and improve sustainability in the supply chain, such as tracking carbon emissions and promoting eco-friendly practices. It also ensures compliance with environmental regulations, contributing to a more sustainable supply chain.

23. Describe the integration capabilities of Oracle Fusion SCM with third-party systems.

Ans:

Oracle Fusion SCM supports seamless integration with third-party systems through APIs. This capability allows organizations to connect their supply chain processes with other enterprise applications, promoting interoperability and data consistency.

24. What role does Predictive Maintenance play in Oracle Fusion SCM?

Ans:

Predictive Maintenance in Oracle Fusion SCM involves using data analytics and AI to predict when equipment or assets will require Maintenance. This proactive approach helps minimize downtime, optimize maintenance schedules, and ensure the reliability of critical assets.

25. How does Oracle Fusion SCM handle product traceability and recall management?

Ans:

Oracle Fusion SCM provides robust capabilities for product traceability, allowing organizations to trace products through the entire supply chain. In the event of a recall, it facilitates quick and accurate identification of affected products, minimizing potential risks and ensuring consumer safety.

26. Explain the concept of Demand Sensing in Oracle Fusion SCM.

Ans:

Demand Sensing in Oracle Fusion SCM utilizes real-time data and analytics to sense changes in customer demand. This enables organizations to adapt quickly to fluctuations in market demand, optimize inventory levels, and align their supply chain strategies with evolving customer needs.

27. How does Oracle Fusion SCM address the challenges of supply chain disruptions?

Ans:

Oracle Fusion SCM includes features for risk management, scenario planning, and real-time visibility. These capabilities allow organizations to proactively identify and mitigate potential disruptions, ensuring resilience and continuity in facing unforeseen challenges.

28. Describe the role of Blockchain in Oracle Fusion SCM.

Ans:

Oracle Fusion SCM leverages Blockchain technology to enhance transparency, traceability, and security in the supply chain. It provides an immutable ledger for recording and verifying transactions, reducing fraud risk, and ensuring supply chain data integrity.

29. How does Oracle Fusion SCM ensure data security and privacy?

Ans:

Oracle Fusion SCM incorporates robust security measures, including encryption, access controls, and audit trails, to ensure the confidentiality and integrity of sensitive supply chain data. This commitment to data security is critical in safeguarding against unauthorized access and data breaches.

30.Explain the concept of Continuous Improvement in Oracle Fusion SCM.

Ans:

Continuous Improvement in Oracle Fusion SCM involves a systematic approach to analyzing performance metrics, identifying areas for improvement, and implementing changes to enhance efficiency and effectiveness. It fosters a culture of ongoing optimization and innovation, ensuring that the supply chain evolves to meet changing business needs and market dynamics.

31. What is the significance of “Smart Inventory Optimization” in Oracle Fusion SCM?

Ans:

- Uses advanced analytics for predictive demand forecasting.

- Optimizes stock levels for efficient inventory management.

- Minimizes excess inventory and carrying costs.

- Enhances order fulfilment and reduces stockouts.

- Utilizes machine learning algorithms for continuous improvement.

- Improves supply chain resilience by adapting to changing demand patterns.

32. How does it ensure data accuracy and consistency across the supply chain?

Ans:

Oracle Fusion SCM employs a centralized data repository that integrates seamlessly across all modules. This ensures that information, such as product data, order details, and inventory levels, remains consistent in real time. The platform’s data validation and governance mechanisms enhance accuracy by preventing errors and discrepancies. With a unified data model, organizations can trust the integrity of their supply chain information, supporting informed decision-making.

33. Explain the role of “Supplier Collaboration” in Oracle Fusion SCM.

Ans:

Supplier Collaboration in Oracle Fusion SCM fosters a dynamic and transparent relationship between organizations and Their suppliers. It facilitates real-time communication, allowing suppliers to access and update relevant information, such as inventory levels and delivery schedules. Organizations can enhance collaboration, reduce lead times, and improve supply efficiency by providing suppliers visibility into demand forecasts and order statuses. This feature strengthens partnerships and ensures that both parties work cohesively toward common goals.

34. How does it address the complexities of managing global supply chains?

Ans:

Oracle Fusion SCM is equipped with features to handle the intricacies of global supply chains. It provides multi-language and multi-currency capabilities, supporting diverse international operations. Additionally, the platform ensures compliance with global trade regulations and standards, streamlining customs processes and reducing non-compliance risk. With real-time visibility into global operations, organizations maximize, minimize, and adapt to varying market conditions across different regions.

35. What role does “Demand Sensing” play in Oracle Fusion SCM’s approach to demand forecasting?

Ans:

Demand Sensing in Oracle Fusion SCM involves leveraging real-time data and analytics to adapt quickly to changes in customer demand. By analyzing market signals and trends, organizations ensure the accuracy of their demand forecasts. This proactive approach allows for timely adjustments to inventory levels and production schedules, ultimately reducing the impact of demand variability on the supply chain. Demand Sensing is integral to maintaining optimal stock levels and improving supply chain responsiveness.

36. How does Oracle Fusion SCM utilize analytics in inventory management?

Ans:

Oracle Fusion SCM incorporates predictive analytics to forecast future demand and optimize optimize levels. By analyzing analytical data, market trends, and other relevant factors, the platform generates accurate predictions for product demand. This information is then used to optimize levels, reducing excess inventory costs while ensuring that products are available when needed. Predictive analytics in inventory management is a critical component of Oracle Fusion SCM’s data-driven approach to enhancing supply chain efficiency.

37. Explain the “Automated Order Orchestration” concept in Oracle Fusion SCM.

Ans:

Automated Order Orchestration in Oracle Fusion SCM involves the streamlined and automatic management of customer orders from creation to fulfilment. The platform uses predefined rules and workflows to orchestrate the entire order lifecycle, from order capture to shipping. This automation minimizes intervention, reduces processing time, and ensures order accuracy. OrganizatOrganizationsove order fulfilment efficiency, enhance customer satisfaction and optimize supply chain operations by automating order orchestration.

38. What role does “Advanced Planning and Scheduling (APS)” play in Oracle Fusion SCM?

Ans:

Advanced Planning and Scheduling (APS) in Oracle Fusion SCM is a critical component that optimizes planning and scheduling processes. This feature uses sophisticated algorithms to analyze factors, including resource availability, production capacities, and demand forecasts. By generating optimal production plans, APS helps organizations minimize and reduce production costs and improve overall production efficiency. This results in enhanced agility and responsiveness to dynamic market demands.

39. How does Oracle Fusion SCM handle product recalls and promptly respond to quality issues?

Ans:

Oracle Fusion SCM has robust capabilities to manage product recalls and respond swiftly to quality issues. In a recall, the platform enables organized organizations to affect products throughout the supply chain quickly. This is facilitated by advanced serializaserializationk-and-trace capabilities, ensuring accuracy and efficiency in identifying impacted items. Oracle Fusion SCM helps organize organizations’ risks, protect brand reputation, and comply with regulatory requirements by providing real-time visibility and automating recall processes.

40. Explain the significance of “Real-Time Analytics” in Oracle Fusion SCM

Ans:

Real-Time Analytics in Oracle Fusion SCM provides users immediate access to critical insights and performance metrics. By leveraging real-time data, organize key performance indicators (KPIs), track supply chain activities, and make informed decisions promptly. This feature enhances visibility into operational processes, allowing stakeholders to respond swiftly to changing conditions and optimize their performance.

41. What is the role of “Collaborative Forecasting” in Oracle Fusion SCM?

Ans:

Collaborative Forecasting in Oracle Fusion SCM promotes collaboration among different stakeholders in the supply chain. It involves sharing demand forecasts and related information among internal teams, suppliers, and other relevant partners. This collaborative approach ensures that projections are more accurate and reflect collective insights. By incorporating diverse perspectives and knowledge, the organization forecasts accuracy, reduces excess inventory and enhances overall supply chain planning.

42. How does Oracle Fusion SCM handle cross-functional collaboration in supply chain operations?

Ans:

- Facilitates real-time collaboration among stakeholders.

- Integrates communication tools for seamless information sharing.

- Enables cross-functional visibility into procurement, Manufacturing, and logistics.

- Supports collaborative decision-making for rapid response to challenges.

- Enhances agility by breaking down silos in the supply chain.

- Improves overall efficiency through coordinated efforts.

43. Explain the role of “Global Order Promising” in Oracle Fusion SCM.

Ans:

Provides a unified view of available-to-promise (ATP) across the global supply chain.Considers constraints, lead times, and transportation factors. Enables accurate and real-time promise dates for customer orders. Optimizes orders, promising to meet customer expectations. Enhances customer satisfaction by ensuring reliable delivery commitments. Supports efficient allocation of inventory and resources.

44. How does Oracle Fusion SCM handle demand-driven material requirements planning (DDMRP)?

Ans:

Utilizes demand-driven principles for dynamic material planning. Focuses on actual demand signals rather than forecasts alone. Enhances agility by adjusting plans in response to real-time demand changes. Reduces excess inventory and minimizes stockouts. Supports collaborative planning with suppliers and distributors. Improves overall supply chain responsiveness and efficiency.

45. Explain the “Unified Demand Forecasting” concept in Oracle Fusion SCM.

Ans:

Integrates historical data, market trends, and external factors for accurate forecasting. Utilizes machine learning algorithms to improve forecast accuracy over time. Provides a unified forecast across all supply chain functions.Supports collaborative forecasting with critical stakeholders. Enables scenario planning for better decision-making. Enhances visibility and responsiveness to demand fluctuations.

46. What is the “Supplier Portal” role in Oracle Fusion SCM?

Ans:

- Facilitates self-service capabilities for suppliers.

- Allows suppliers to manage orders, invoices, and documentation.

- Enhances collaboration and communication with suppliers.

- Provides real-time visibility into order status and fulfilment.

- Streamlines procurement processes for both buyers and suppliers.

- Improves overall supplier relationship management.

47. How does Oracle Fusion SCM address supply chain sustainability challenges?

Ans:

Monitors and reports on environmental impact and sustainability metrics. Supports compliance with environmental regulations and standards. Enables tracking and optimization of carbon emissions. Promotes eco-friendly practices and ethical sourcing. Enhances transparency in the supply chain for sustainable decision-making. Integrates sustainability considerations into supply chain processes.

48. Describe the role of “Blockchain in Supply Chain Visibility” in Oracle Fusion SCM.

Ans:

Ensures transparency and traceability across the supply chain. Provides an immutable ledger for secure and verifiable transactions. Reduces the risk of fraud and enhances data integrity. Enables end-to-end visibility into product movements and transactions. Facilitates quicker and more accurate recalls in case of issues. Strengthens overall supply chain security and trust.

49. How does Oracle Fusion SCM support collaborative product development in the “Product Hub” module?

Ans:

Centralizes product information for consistent and accurate data. Facilitates collaboration among cross-functional teams during product development. Manages product data, specifications, and documents in a unified repository.

Enhances visibility into product lifecycles and changes. Supports compliance with regulatory requirements for product information. Improves time-to-market through efficient collaboration and information sharing.

50. What is the role of “Integrated Business Planning (IBP)” in Oracle Fusion SCM?

Ans:

Aligns strategic, financial, and operational plans for a unified approach. Enables scenario planning and what-if analysis for decision support. Integrates demand planning, supply planning, and financial planning. Enhances agility by adjusting plans in response to changing market conditions. Facilitates cross-functional collaboration in the planning process. Improves overall business performance through integrated planning.

51. Explain how Oracle Fusion SCM ensures compliance with trade regulations in global supply chains.

Ans:

Provides tools for monitoring and adapting to changes in trade regulations. Supports compliance with customs and import/export requirements. Facilitates documentation and reporting for international shipments. Enhances visibility into global trade compliance risks. Integrates with customs management systems for streamlined processes. Reduces the risk of penalties and delays associated with non-compliance.

52. What role does “Advanced Shipment and Transportation Execution” play in Oracle Fusion SCM?

Ans:

| Aspect | Description | |

| Module | Advanced Shipment and Transportation Execution | |

| Purpose | Manages end-to-end transportation processes, optimizing shipments, and enhancing visibility. | |

| Key Features | Shipment Planning, Freight Payment and Audit, Shipment Execution, Carrier Management, Transportation Analytics | |

| Key Benefits | Cost Reduction, Improved Visibility, Enhanced Control, Streamlined Processes | |

| Integration | Oracle ERP Integration, Third-Party Systems Integration, Cloud Integration | |

| User Roles | Transportation Planner, Transportation Manager, Finance Administrator |

53. How does Oracle Fusion SCM handle returns and reverse logistics efficiently?

Ans:

Streamlines the returns process with automated return authorizations. Manages and tracks returned products for efficient reverse logistics. Facilitates product disposition and minimizes the impact on inventory. Enhances customer satisfaction through timely return processing. Supports analysis of return trends for continuous improvement. Integrates with customer service for a seamless returns experience.

54. What is the role of “Quality Management” in Oracle Fusion SCM?

Ans:

Ensures product quality through comprehensive quality control processes. Manages quality inspections, tests, and certifications. Facilitates collaboration with suppliers to maintain quality standards. Supports non-conformance management and corrective actions. Enhances visibility into quality metrics and performance. Improves overall product quality and customer satisfaction.

55. Explain the “Embedded Analytics” concept in Oracle Fusion SCM.

Ans:

Integrates analytics directly into operational workflows for real-time insights. Provides dashboards and reports for key performance indicators (KPIs). Enables data visualization and interactive analysis. Supports proactive decision-making based on data-driven insights. Enhances overall supply chain visibility and performance monitoring. Facilitates continuous improvement through actionable analytics.

56. How does Oracle Fusion SCM leverage the Internet of Things (IoT) for supply chain optimization?

Ans:

Integrates IoT sensors for real-time monitoring of assets and inventory.

Captures and analyzes data on equipment performance and conditions. Enables predictive Maintenance to reduce downtime. Improves visibility into the location and status of goods in transit. Enhances overall supply chain responsiveness through IoT insights. Supports data-driven decision-making for optimized operations.

57. Explain the role of “Risk Management” in Oracle Fusion SCM.

Ans:

Identifies and assesses potential risks in the supply chain. Supports scenario planning for risk mitigation. Enhances visibility into supply chain risks and disruptions. Facilitates proactive risk response and contingency planning. Integrates with analytics for predictive risk assessment. Ensures business continuity in the face of unforeseen challenges.

58. How does Oracle Fusion SCM ensure data security and privacy in cloud-based operations?

Ans:

Implements robust encryption protocols to secure sensitive data. Utilizes access controls and authentication mechanisms for data protection. Maintains audit trails for monitoring and tracking user activities. Adheres to industry standards and compliance requirements. Regularly updates security measures to address evolving threats. Ensures data residency and compliance with privacy regulations.

59. Describe the role of “Adaptive Intelligence” in Oracle Fusion SCM.

Ans:

Utilizes machine learning algorithms for adaptive decision-making. Provides predictive analytics for demand forecasting and planning. Adapts to changes in market conditions and customer behaviour. Enhances automation and efficiency through intelligent workflows. Supports continuous improvement through self-learning algorithms. Improves overall supply chain agility and responsiveness.

60. How does Oracle Fusion SCM facilitate real-time collaboration with suppliers and vendors?

Ans:

Provides a Supplier Portal for self-service capabilities. Enables real-time communication and document sharing. Enhances visibility into supplier performance and activities. Streamlines procurement processes for efficient collaboration. Improves supplier relationship management through shared information. Supports collaborative decision-making for mutual benefit.

61. Explain the role of “Advanced Pricing” in Oracle Fusion SCM.

Ans:

Enables dynamic pricing based on market conditions and demand. Supports complex pricing structures and discounts. Facilitates personalized pricing strategies for different customer segments. Enhances competitiveness through optimized pricing strategies. Provides real-time visibility into pricing and discounting processes. Improves overall revenue management and profitability.

62. How does Oracle Fusion SCM integrate supply chain data with external partners and systems?

Ans:

- Utilizes APIs for seamless integration with third-party systems.

- Ensures data consistency and accuracy across integrated systems.

- Facilitates real-time data exchange for improved collaboration.

- Supports standardized data formats for interoperability.

- Enhances visibility into extended supply chain networks.

- Promotes a connected and collaborative ecosystem.

63. Explain the role of “Social Collaboration” in Oracle Fusion SCM.

Ans:

Integrates social collaboration tools for communication and feedback.Enables collaboration on supply chain tasks and projects. Facilitates knowledge sharing and expertise exchange among team members. Enhances transparency through social interaction within the platform. Supports real-time discussions and decision-making. Improves overall teamwork and efficiency in supply chain operations.

64. What role does “Customer Order Management” play in Oracle Fusion SCM?

Ans:

Manages the entire customer order lifecycle from creation to fulfilment.Supports order capture, pricing, and order orchestration. Enhances customer satisfaction through accurate and timely order processing. Provides real-time visibility into order status and delivery. Streamlines order management processes for efficiency. Improves overall customer experience and loyalty.

65. How does Oracle Fusion SCM handle product serialization and track-and-trace capabilities?

Ans:

Implements serial number tracking for individual product units. Ensures traceability throughout the supply chain from production to delivery. Facilitates compliance with regulatory requirements for product traceability. Enhances visibility into the movement and status of serialized products. Supports quick and accurate recalls in case of quality issues. Improves overall supply chain transparency and accountability.

66. Describe the role of “Customer Collaboration” in Oracle Fusion SCM.

Ans:

Facilitates collaboration with customers on order and delivery preferences.

Enhances communication for a better understanding of customer requirements. Supports collaborative forecasting and demand planning. Provides real-time visibility into order status and delivery schedules. Improves customer satisfaction through personalized interactions. Promotes a customer-centric approach in supply chain operations.

67. How does Oracle Fusion SCM handle the integration of sustainability metrics into supply chain decision-making?

Ans:

- Monitors and reports on environmental impact and sustainability metrics.

- Integrates sustainability considerations into product design and sourcing.

- Facilitates collaboration with suppliers for sustainable practices.

- Supports compliance with environmental regulations and standards.

- Enhances transparency in supply chain sustainability efforts.

- Improves overall corporate social responsibility and ethical practices.

68. Explain the “Multi-Enterprise Inventory Visibility” concept in Oracle Fusion SCM.

Ans:

- Provides real-time visibility into inventory across multiple enterprises.

- Enhances collaboration with suppliers, manufacturers, and distributors.

- Enables better coordination of inventory levels and replenishment.

- Reduces excess inventory and stockouts through synchronized efforts.

- Supports agile and responsive supply chain decision-making.

- Improves overall supply chain efficiency and cost-effectiveness.

69. What is the significance of “Scenario Planning” in Oracle Fusion SCM?

Ans:

Enables simulation of various supply chain scenarios for decision support. Supports what-if analysis to assess the impact of different factors. Facilitates risk assessment and mitigation planning. Enhances agility by preparing for potential disruptions. Provides insights into the consequences of various supply chain strategies. Improves overall strategic decision-making in dynamic environments.

70. How does Oracle Fusion SCM utilize “Dynamic Pricing Strategies” for better revenue management?

Ans:

Adapts pricing dynamically based on real-time market conditions. Utilizes data analytics for competitive pricing and demand forecasting. Supports personalized pricing strategies for different customer segments. Enhances overall revenue management through optimized pricing. Provides flexibility to adjust pricing strategies based on business goals. Improves competitiveness and profitability through intelligent pricing.

71. How does Oracle Fusion SCM ensure seamless integration with e-commerce platforms?

Ans:

Oracle Fusion SCM facilitates seamless integration with e-commerce platforms through robust APIs and connectors. This enables organizations to synchronize real-time product information, inventory levels, and order details between the SCM system and e-commerce platforms. Organizations can provide accurate product availability information, optimize order fulfilment processes, and enhance the overall customer experience in the rapidly evolving e-commerce landscape by ensuring a smooth data flow.

72. Explain the “Dynamic Cross-Docking” concept in Oracle Fusion SCM.

Ans:

Dynamic Cross-Docking in Oracle Fusion SCM involves optimizing the movement of goods through distribution centres without intermediate storage. The platform dynamically identifies opportunities for cross-docking based on real-time demand and inventory information. By bypassing storage and directly routing products to meet customer demand, organizations can reduce handling costs, minimize inventory holding times, and improve overall logistics efficiency. This feature is particularly beneficial in fast-paced supply chains where timely order fulfilment is crucial.

73. How does it address the challenges of managing perishable goods in the supply chain?

Ans:

Oracle Fusion SCM incorporates specialized features to address the challenges of managing perishable goods. This includes real-time monitoring of shelf life and temperature-sensitive logistics. Optimization and automated alerts for potential quality issues. Organizations can minimize waste, comply with regulatory requirements, and meet consumers’ expectations in industries such as food and pharmaceuticals by ensuring the freshness and quality of perishable products throughout the supply chain.

74. What is the role of “Supplier Scorecards” in Oracle Fusion SCM’s supplier management?

Ans:

Supplier Scorecards in Oracle Fusion SCM are vital in evaluating and managing supplier performance. The platform generates scorecards based on predefined key performance indicators (KPIs) and performance metrics. Organizations can make informed decisions about supplier relationships by providing a quantitative assessment of suppliers’ delivery times, quality, and other factors. This feature fosters continuous improvement and ensures suppliers align with the organization’s strategic goals and quality standards.

75.Explain the “Order Promising” concept in Oracle Fusion SCM.

Ans:

Order Promising in Oracle Fusion SCM involves providing customers with accurate and reliable delivery commitments. The platform considers inventory levels, production capabilities, and transportation constraints to determine realistic promise dates. Organizations can enhance customer satisfaction, reduce lead times, and establish a reputation for dependable and timely order fulfilment by optimizing order-promising processes.

76. How does it handle the complexities of managing serialized products in the supply chain?

Ans:

Oracle Fusion SCM excels in managing serialized products through advanced serialization and track-and-trace capabilities. Each product unit is assigned a unique serial number, enabling organizations to trace its journey throughout the supply chain. This ensures compliance with regulatory requirements, facilitates quick and accurate recalls, and enhances overall supply chain transparency. The platform’s serialization features are particularly crucial in industries where traceability and accountability are paramount.

77. What does “Document Management” play in Oracle Fusion SCM?

Ans:

Document Management in Oracle Fusion SCM involves centralized storage, retrieval, and management of various supply chain-process documents. This includes contracts, certifications, invoices, and compliance documents. By maintaining a structured repository, organizations can ensure stakeholders have easy access to relevant documents, comply with regulatory requirements, and streamline audit processes. Document Management enhances transparency and accountability in supply chain operations.

78. How does it support the integration of sustainability metrics into supply chain decision-making?

Ans:

Oracle Fusion SCM supports the integration of sustainability metrics by providing tools to monitor and report on environmental impact. The platform facilitates the incorporation of sustainability considerations into product design, sourcing, and manufacturing processes. Organizations can make informed decisions that align with sustainable practices by tracking and analyzing metrics related to carbon emissions, energy usage, and other environmental factors. This integration contributes to a more socially responsible and environmentally conscious supply chain.

79. Explain the role of “Mobile Workforce” capabilities in Oracle Fusion SCM.

Ans:

Oracle Fusion SCM’s Mobile Workforce capabilities empower users to access supply chain information and perform tasks on mobile devices. This feature enhances flexibility by allowing users to connect to the supply chain anywhere. Whether approving purchase orders, tracking shipments, or monitoring inventory levels, mobile capabilities enable on-the-go decision-making. This contributes to improved responsiveness, efficiency, and collaboration among team members, especially in industries where field operations are prevalent.

80. How does Oracle Fusion SCM integrate real-time weather data into supply chain decision-making?

Ans:

Oracle Fusion SCM can integrate real-time weather data to enhance supply chain decision-making. By considering weather conditions in demand forecasting, transportation planning, and inventory management, organizations can better anticipate and respond to potential disruptions. For example, this integration enables proactive adjustments to logistics and inventory strategies in the case of perishable goods or industries sensitive to weather patterns. This contributes to a more resilient and adaptive supply chain that can mitigate the impact of unpredictable weather events.

81. Explain the significance of “Configurable Workflows” in Oracle Fusion SCM.

Ans:

Configurable Workflows in Oracle Fusion SCM allow organizations to tailor and automate their supply chain processes according to specific business needs. This feature enables the design of customized workflows for activities such as order processing, approvals, and quality control. By configuring workflows to align with unique business requirements, organizations can streamline operations, reduce manual intervention, and ensure consistency in process execution. Configurable Workflows empower organizations to adapt supply chain processes to evolving business dynamics.

82. How does Oracle Fusion SCM integrate real-time market data into pricing strategies?

Ans:

Oracle Fusion SCM can seamlessly integrate real-time market data into pricing strategies. Organizations can dynamically adjust pricing strategies by leveraging external market data sources based on competitor pricing, demand fluctuations, and market trends. This real-time integration enables organizations to stay competitive, optimize revenue management, and respond quickly to changing market conditions. Incorporating market intelligence into pricing decisions enhances overall agility and strategic pricing capabilities.

83. What role does “Automated Compliance Monitoring” play in Oracle Fusion SCM?

Ans:

Automated Compliance Monitoring in Oracle Fusion SCM involves computerized tracking and enforcing regulatory and compliance requirements. The platform continuously monitors supply chain activities for adherence to industry-specific regulations, quality standards, and ethical practices. By automating compliance checks and alerts, organizations can reduce the risk of non-compliance, avoid penalties, and maintain high integrity in their supply chain operations. This feature is particularly crucial in industries with stringent regulatory frameworks.

84. Explain the “Digital Twin” concept in Oracle Fusion SCM.

Ans:

The idea of a Digital Twin in Oracle Fusion SCM involves creating a virtual replica of physical supply chain elements, such as products, processes, or assets. This digital representation allows organizations to simulate and analyze different scenarios, optimize operations, and proactively identify potential issues. Organizations gain insights into performance, conditions, and interactions by having a digital counterpart to physical elements, facilitating better decision-making, predictive Maintenance, and overall supply chain optimization.

85.How does Oracle Fusion SCM utilize “Predictive Maintenance” for equipment reliability?

Ans:

Oracle Fusion SCM employs Predictive Maintenance to forecast when equipment or assets require Maintenance. The platform can predict potential failures by analyzing historical data, performance metrics, and sensor data from equipment. This proactive approach minimizes downtime, extends the lifespan of assets, and optimizes maintenance schedules. Predictive Maintenance is especially beneficial in industries where equipment reliability is critical, contributing to cost savings and operational efficiency.

86. What role does the “Real-Time Collaboration Dashboard” play in Oracle Fusion SCM?

Ans:

The Real-Time Collaboration Dashboard in Oracle Fusion SCM provides a centralized interface for stakeholders to collaborate and monitor supply chain activities in real time. This feature aggregates critical performance indicators, alerts, and relevant data on a single dashboard, fostering collaboration and enabling quick decision-making. Whether tracking order statuses, inventory levels, or production milestones, the real-time dashboard enhances visibility, communication, and responsiveness across the supply chain.

87. Explain the “Supplier Risk Management” concept in Oracle Fusion SCM.

Ans:

Supplier Risk Management in Oracle Fusion SCM involves assessing and mitigating potential supplier risks. The platform utilizes risk assessment tools, performance metrics, and real-time data to evaluate financial stability, geopolitical considerations, and supply chain disruptions. By proactively identifying and addressing supplier-related risks, organizations can ensure continuity in the supply chain, reduce vulnerabilities, and maintain a resilient and reliable network of suppliers.

88. How does Oracle Fusion SCM support “Cross-Functional Analytics” for comprehensive insights?

Ans:

Oracle Fusion SCM supports Cross-Functional Analytics by providing integrated analytics across various supply chain functions. This approach allows organizations to gain comprehensive insights into the supply chain, from procurement to order fulfilment. Cross-functional analytics enables stakeholders to understand interdependencies, identify optimization opportunities, and make informed decisions impacting multiple supply chain areas. This holistic approach contributes to improved collaboration and performance across diverse functions.

89. What is the role of “Intelligent Automation” in Oracle Fusion SCM processes?

Ans:

Intelligent Automation in Oracle Fusion SCM involves using artificial intelligence and machine learning to automate routine and complex tasks within supply chain processes. The platform employs smart algorithms to analyze data, predict outcomes, and optimize decision-making. By automating tasks such as demand forecasting, order processing, and inventory management, organizations can achieve greater operational efficiency, reduce manual errors, and allocate resources more strategically, contributing to overall supply chain optimization.

90. Explain the significance of “Dynamic Routing Optimization” in Oracle Fusion SCM.

Ans:

Dynamic Routing Optimization in Oracle Fusion SCM involves continuously optimizing transportation routes based on real-time traffic conditions, delivery schedules, and fuel costs. The platform dynamically adjusts routes to minimize transportation costs, improve delivery times, and enhance overall logistics efficiency.

91. How does Oracle Fusion SCM handle real-time tracking of inventory movements?

Ans:

- Utilizes RFID and IoT technologies for accurate tracking.

- Provides real-time visibility into inventory levels and locations.

- Supports barcode scanning for efficient data capture.

- Enables proactive management of stock levels.

- Enhances overall supply chain responsiveness.

92.Explain the role of Oracle Fusion SCM in promoting supplier collaboration.

Ans:

Facilitates a Supplier Portal for seamless collaboration. Enables suppliers to manage orders and invoices efficiently. Enhances communication and information sharing with suppliers. Supports collaborative forecasting and demand planning. Improves supplier relationship management for mutual benefit.

93. How does Oracle Fusion SCM ensure data security in cloud-based operations?

Ans:

Implements robust encryption protocols for data protection. Utilizes access controls and authentication mechanisms. Maintains comprehensive audit trails for monitoring user activities. Adheres to industry standards and compliance requirements. Regularly updates security measures to address evolving threats.

94. Describe Oracle Fusion SCM’s approach to demand-driven material requirements planning (DDMRP).

Ans:

Focuses on actual demand signals for dynamic material planning. Utilizes advanced analytics for accurate demand forecasting. Enhances agility by adjusting plans in response to real-time changes. Reduces excess inventory and minimizes stockouts. Supports collaborative planning with suppliers and distributors.

95. How does Oracle Fusion SCM utilize predictive Maintenance for asset reliability?

Ans:

- Integrates IoT data for real-time asset monitoring.

- Utilizes AI algorithms to predict maintenance needs.

- Reduces downtime through proactive maintenance scheduling.

- Enhances overall equipment effectiveness (OEE).

- Improves asset reliability and extends equipment lifespan.