- What is Electric Motors

- BLDC Motor Overview

- Construction and Components

- Sensor and Sensorless Types

- Difference from Brushed Motors

- Operation Basics

- Efficiency and Reliability

- Merits of BLDC

- Control Mechanisms

- Application Areas

- Limitations

- Summary

What is Electric Motors

Electric motors are at the heart of modern motion and automation. From electric vehicles to drones, fans, and hard drives, they convert electrical energy into mechanical motion. Among the many motor types, the Brushless DC Motor (BLDC) stands out for its efficiency, precision, and durability. Unlike traditional brushed motors, BLDC motors eliminate mechanical commutation and brushes, resulting in less maintenance, higher performance, and longer life, which can be further enhanced with Artificial Intelligence Training for optimized control and predictive maintenance. This article explores the fundamentals of BLDC motors, their construction, operation, advantages, control methods, applications, and emerging trends in technology and market growth. Electric motors are electromechanical devices that convert electrical energy into mechanical energy using the interaction between magnetic fields. They are essential components in automation, transportation, industrial machinery, and consumer electronics.

BLDC Motor Overview

A Brushless DC Motor (BLDC) is a synchronous motor powered by direct current through an electronic controller instead of mechanical commutation. The rotor of a BLDC motor contains permanent magnets, while the stator has windings that generate a rotating magnetic field. Unlike brushed motors, which use carbon brushes to switch current direction, BLDC motors rely on an electronic speed controller (ESC) that performs the commutation electronically, following the Working Principle of BLDC Motors for efficient operation. This allows for precise control over speed and torque, along with enhanced reliability. BLDC motors are sometimes referred to as electronically commutated motors (ECM) because of their digital switching nature.

Construction and Components

The stator and rotor are the two primary components of a BLDC motor. When current flows through the stator’s armature windings, which are composed of laminated steel cores, a rotating magnetic field is produced. Depending on the application, the windings are usually placed in either a Delta (Δ) or Star (Y) form. Permanent magnets composed of ferrite or neodymium-iron-boron (NdFeB) are found in the rotor.

These magnets can be integrated within for high-torque applications, such as in electric cars, or surface-mounted for low-inertia applications, which can be further supported by innovations like Battery Swapping in EV for enhanced convenience and efficiency. The electronic controller switches the current in the stator windings after receiving feedback from Hall effect sensors or encoders that measure the rotor’s position. Back-EMF signals are employed for this purpose in sensorless motors. Using pulse width modulation (PWM) to control the voltage and guarantee smooth performance, the controller controls the motor’s speed, torque, braking, and direction.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Sensor and Sensorless Types

BLDC motors are classified into two main types based on rotor position detection:

- Sensored BLDC Motors

- Use Hall effect sensors or encoders for rotor position feedback.

- Offer precise control, especially at low speeds or under variable load conditions.

- Common in applications like robotics, EVs, and CNC machines. Sensorless BLDC Motors

- Use back-EMF detection to estimate rotor position, eliminating the need for physical sensors, a method commonly applied in EV Projects and Systems for cost-effective and reliable motor control.

- Are simpler, cheaper, and more compact, but less accurate at very low speeds.

- Common in fans, drones, and pumps where exact position accuracy isn’t critical.

Both types rely on sophisticated controllers, but sensorless motors are more popular for lightweight and cost-sensitive designs.

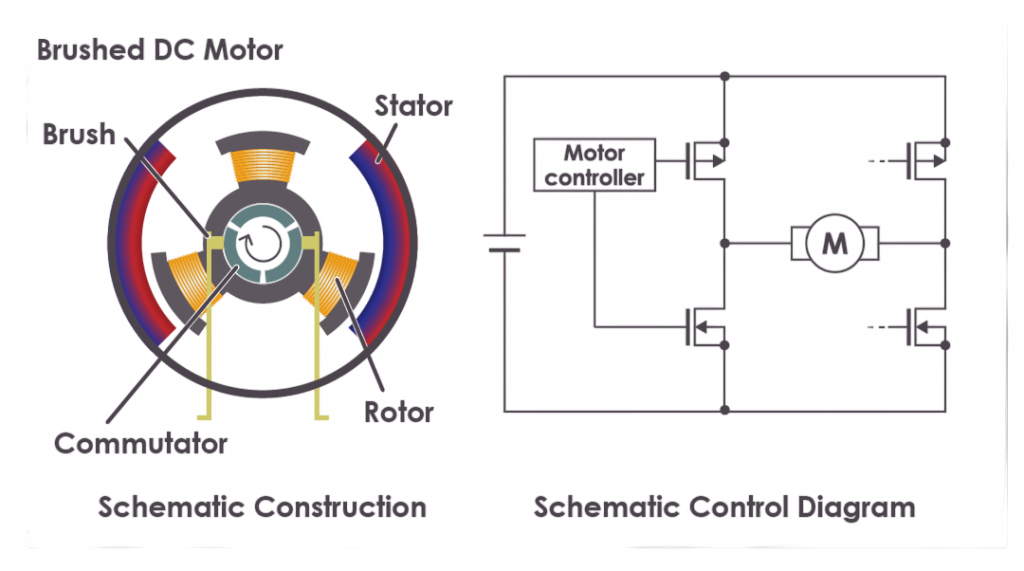

Difference from Brushed Motors

The fundamental distinction between brushed and brushless DC motors lies in the commutation method: how the current direction in the windings is switched to keep the motor spinning.

| Aspect | Brushed DC Motor | Brushless DC Motor (BLDC) |

|---|---|---|

| Commutation | Mechanical (via brushes and commutator) | Electronic (via ESC) |

| Maintenance | Requires frequent brush replacement | Virtually maintenance-free |

| Efficiency | 75–80% | 85–90% |

| Speed Control | Simple voltage variation | Requires electronic control |

| Noise | Moderate to high due to brush friction | Very low |

| Lifespan | Shorter (brush wear) | Longer |

| Applications | Toys, low-cost tools | Drones, EVs, industrial robots |

Thus, BLDC motors offer better reliability, energy efficiency, and performance key reasons why industries have transitioned from brushed to brushless technology.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Operation Basics

The operation of a BLDC motor is based on electromagnetic interaction. The controller sequentially energizes the stator windings to produce a rotating magnetic field, which interacts with the rotor’s magnetic poles, generating torque and motion.

- No Brush Contact Losses: Mechanical friction is eliminated.

- Optimized Magnetic Circuit: Permanent magnets reduce I²R losses.

- Better Heat Dissipation: Heat is generated mainly in the stator, which is easier to cool than a rotor.

- Commutation Control: Determines which stator coils to energize based on rotor position.

- Speed Regulation: Adjusts PWM signals to control motor speed proportionally to the desired value.

- Torque Control: Controls the amount of current flowing into the motor to adjust torque output.

- Trapezoidal Control: Simpler and widely used for general applications; uses six-step commutation with Hall sensors, making it a reliable method for controlling Electric Vehicle Parts like motors and actuators.

- Sinusoidal (or Field-Oriented Control – FOC): Provides smoother torque and higher efficiency; commonly used in advanced EVs and drones.

- Higher Initial Cost: Permanent magnets and electronic controllers increase cost compared to simple DC motors.

- Complex Control: Requires a dedicated controller for commutation and speed control, increasing system complexity, which is particularly important in applications like Hybrid Electric Vehicle systems for optimized performance.

- Magnet Demagnetization: Permanent magnets can lose strength under high temperatures or improper handling.

- EMI and Noise Issues: High-frequency switching in controllers can cause electromagnetic interference.

- Sensor Dependency: In sensored motors, sensor failure can disrupt motor operation.

Commutation Process: The process of energizing the windings is called electronic commutation, replacing the mechanical commutator found in brushed motors. In a 3-phase BLDC motor, the windings are energized in a six-step sequence (also called trapezoidal commutation), a process that can be optimized with Artificial Intelligence Training for more efficient and adaptive motor control. At any given time, two windings are powered while one remains unpowered, allowing continuous torque generation.

Back EMF: As the rotor spins, it induces a back electromotive force (back EMF) in the stator windings. The controller uses this feedback to synchronize switching patterns and maintain rotation efficiency.

Efficiency and Reliability

The efficiency of BLDC motors stems from their ability to minimize energy losses:

In terms of reliability, the electronic commutation ensures consistent performance without degradation over time, making BLDC motors a key factor in the ongoing debate of EV vs Fuel Vehicle performance and longevity. BLDC motors can operate 24/7 in demanding environments, provided they have proper cooling and controller protection. Their mean time between failures (MTBF) is significantly higher than brushed motors, making them suitable for critical systems like aerospace controls, robotics, and EVs.

Merits of BLDC Motors

BLDC motors are becoming more and more used in a variety of applications due to their many benefits. High efficiency is one of their main advantages; because of their optimised magnetic design and lack of brush friction, they may reach efficiencies beyond 90%. Additionally, because permanent magnets enable powerful torque generation in a small motor size, BLDC motors offer a high torque-to-weight ratio. Additionally, they have improved speed-torque characteristics because of electronic commutation, which keeps the speed constant despite changes in load.

Other noteworthy benefits include smooth operation and low noise because they don’t have brushes, which makes them perfect for quiet settings, aligning with the Electric Vehicle Working Principle for efficient and silent performance. Additionally, this results in less wear and a longer operational life. Additionally, precise control of speed, torque, and position is made possible by electronic commutation, which is essential for applications in robotics and electric vehicles (EVs). Finally, compared to conventional brushed motors, BLDC motors require far less maintenance due to their strong dynamic response, which allows for rapid acceleration and deceleration.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Control Mechanisms

Controlling a BLDC motor requires an electronic controller or ESC (Electronic Speed Controller). The controller performs several key functions:

Two common control methods are:

FOC uses vector control algorithms to precisely align current with magnetic fields, reducing torque ripple and improving dynamic performance.

Application Areas

Because of their great versatility, BLDC motors are used in many different industries. They are utilised in electric and hybrid cars, power steering systems, cooling fans, pumps, and air conditioning compressors. They are essential to industrial automation, including motion control in manufacturing facilities, robots, servo systems, CNC machines, conveyors, and factory automation, and are also crucial in various Types of Electric Vehicle for precise motor control. Hard drives, DVD players, computer fans, and home appliances including air conditioners, washing machines, and vacuum cleaners are examples of consumer electronics that use BLDC motors. BLDC motors are used in the aerospace and defence industries for satellite mechanisms, aircraft actuators, drones, UAVs, and precise servo drives.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Limitations

Despite their advantages, BLDC motors have certain limitations:

However, advancements in power electronics, microcontrollers, and cost-effective magnet manufacturing are rapidly mitigating these drawbacks.

Summary

The Brushless DC (BLDC) motor is a technological evolution that has transformed how electrical energy is converted into motion. Its high efficiency, precise control, and low maintenance make it an indispensable part of modern engineering from electric cars and drones to factory robots and home appliances. As innovations in magnet materials, control algorithms, and semiconductor technology continue to evolve, BLDC motors, enhanced by Artificial Intelligence Training will play a pivotal role in enabling a cleaner, smarter, and more connected world. Their future is bright, defined by integration with AI-based controllers, IoT-enabled systems, and next-generation electric mobility.