- EV Batteries: Driving the Future

- Battery Chemistry Types

- Lithium-ion Batteries

- Solid-State Batteries

- Battery Modules and Packs

- Energy Density

- Charging Cycles and Lifespan

- Safety and Thermal Management

- Recycling and Disposal

- Cost and Supply Chain

- Innovations in Battery Tech

- Future Outlook

EV Batteries: Driving the Future

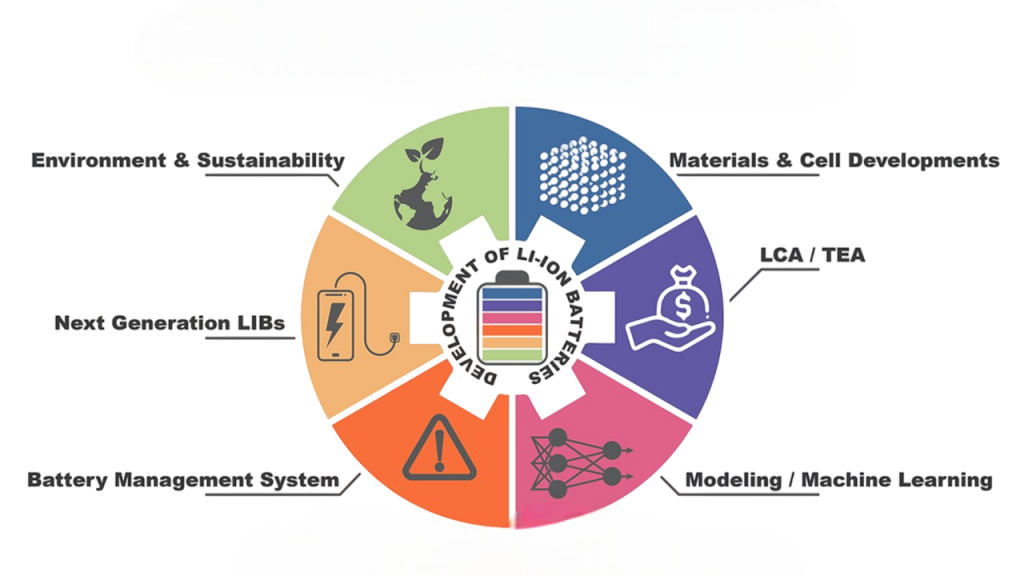

Electric vehicle (EV) batteries are the heart of modern electric transportation, responsible for storing and delivering the energy that powers electric motors. These batteries must provide high energy density, fast charging capabilities, long life spans, and enhanced safety, all while being cost-effective, environmentally sustainable, and optimized through Artificial Intelligence Training. With the global shift towards clean mobility, EV battery technology has evolved rapidly, making them one of the most researched and innovated components in the automotive industry. EV battery technology has emerged as a key component of automotive industry innovation and research as the globe moves faster towards greener mobility options. EV batteries are becoming smarter, more efficient, and more sustainable power sources for the next generation of mobility thanks to ongoing developments in materials, design, and production.

Battery Chemistry Types

The performance and characteristics of EV batteries largely depend on their chemical composition. Various chemistries offer trade-offs between energy density, cost, longevity, safety, and environmental impact, especially when comparing EV vs Fuel Vehicle . The most common types include:

- Lithium-Ion (Li-ion): Dominant in today’s EVs due to high energy density and relatively long life.

- Nickel-Metal Hydride (NiMH): Previously used in hybrid vehicles, now largely phased out in EVs.

- Solid-State: Next-generation technology offering improved energy density and safety.

- Lithium Iron Phosphate (LFP): Lower energy density but excellent thermal stability and life cycle.

- Lithium Nickel Manganese Cobalt Oxide (NMC) and Lithium Nickel Cobalt Aluminum Oxide (NCA): Widely used in high-performance EVs.

Lithium-Ion Batteries

The most popular energy storage technology in electric cars nowadays is lithium-ion batteries. By transferring lithium ions between a positive electrode (cathode) and a negative electrode (anode) via an electrolyte, they enable the battery to effectively store and deliver electrical energy.

The high energy density of lithium-ion batteries, which allows cars to go farther between charges, is one of their primary benefits. Additionally, they are lighter than other battery kinds, which improves the efficiency of the vehicle as a whole, aligning with the Electric Vehicle Working Principle. Furthermore, lithium-ion batteries have a comparatively long lifespan typically more than a thousand charge-discharge cycles and facilitate quick charging. But there are some disadvantages to these batteries as well. They are vulnerable to thermal runaway, which, if left unchecked, can result in overheating or even fire. Lithium-ion batteries generally deteriorate over time, losing efficiency and capacity. They are extremely costly to create due to the high cost of raw ingredients, especially cobalt and nickel.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Solid-State Batteries

Solid-state batteries are an emerging technology that replaces the liquid electrolyte with a solid one, enhancing safety and performance as a key component of Electric Vehicle Parts. This innovation promises several benefits over conventional lithium-ion batteries:

- Benefits:

- Higher energy density.

- Enhanced safety due to non-flammable solid electrolyte.

- Longer lifespan with less degradation.

- Faster charging potential. Challenges:

- High manufacturing costs.

- Difficulties in mass production.

- Temperature sensitivity and material interface issues.

Several companies and research institutions are investing heavily in making solid-state batteries commercially viable within the next decade.

Battery Modules and Packs

Batteries for electric vehicles (EVs) are constructed using a modular design in which individual cells are grouped into modules, which are then put together to form larger battery packs. The battery system is simpler to cool, maintain, and modify for various car types thanks to this layered design. The cells, the tiniest units that store energy, are at the centre. These cells are the basic components of the battery and come in a variety of configurations, most often cylindrical, prismatic, or pouch-shaped, forming an essential part of Types of Electric Vehicle. These cells come together to form a module, which aids in managing and organising the performance of several cells at once. Ultimately, the battery pack the entire system that powers the car is made up of a number of modules. In addition to the modules, the pack incorporates safety features, cooling systems, and control electronics that monitor and manage battery performance. Scalability and safety are improved by this modular design. If an issue occurs, it can frequently be limited to a single module or section, minimising widespread failure and making replacement or maintenance easier.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Energy Density

Energy density is a critical parameter for EV batteries as it determines how much energy a battery can store relative to its weight (gravimetric) or volume (volumetric).

- Gravimetric Energy Density: Influences vehicle weight and range.

- Volumetric Energy Density: Important for space optimization in vehicle design.

Improvements in energy density lead directly to longer driving ranges without increasing battery size or weight, which is crucial for consumer adoption of a Hybrid Electric Vehicle.

Charging Cycles and Lifespan

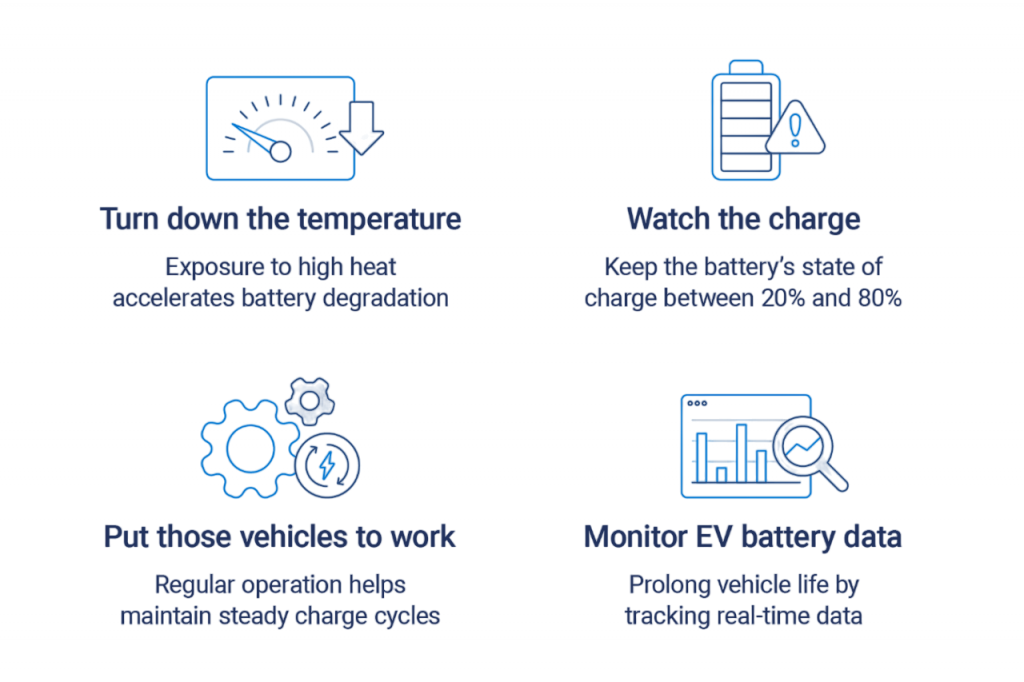

One full battery discharge and recharge is referred to as a charging cycle. One important indicator of a battery’s lifespan is how many of these cycles it can go through before suffering a noticeable loss of capacity. Long battery life is crucial for sustainability, economic effectiveness, and performance in electric cars.

Under normal circumstances, modern lithium-ion batteries can provide between 1,000 and 1,500 charge cycles, or eight to ten years of regular vehicle use, with performance further optimized through Artificial Intelligence Training. Battery Management Systems (BMS) continuously monitor and control variables like temperature, voltage, and charging rates to further improve durability and guarantee the battery runs within safe and effective bounds.

Safety and Thermal Management

Battery safety is paramount, especially given the potential for overheating and thermal runaway in high-energy systems. Electric Vehicles List incorporate multiple layers of safety:

- Safety Features:

- Battery Management System (BMS): Monitors voltage, temperature, and current.

- Thermal Management Systems: Include liquid cooling or air cooling.

- Crash Protection: Reinforced housing to shield from impacts.

- Fire Suppression Systems: Activated in case of a short circuit or fire.

Proper thermal regulation ensures consistent performance and prevents overheating, which can lead to degradation or safety incidents.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Recycling and Disposal

The handling of end-of-life batteries has grown to be a significant industrial and environmental concern as the use of electric cars continues to increase. Reusing and recycling EV batteries properly lessens their negative effects on the environment and their reliance on raw resources like nickel, cobalt, and lithium. To build a circular and sustainable battery environment, effective recycling technologies must be developed, considering the role of Types of Motors in Electric Vehicles in overall efficiency and longevity. When their capacity falls below what is needed for vehicle use, many EV batteries find second-life uses in addition to recycling. These recycled batteries can be utilised in stationary energy storage systems, like those that store solar energy or balance the grid. Additionally, they can supply data centres and other vital infrastructure with backup power.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Cost and Supply Chain

Battery cost is one of the largest contributors to the overall cost of an EV, highlighting the growing significance of Career Opportunities in EV for professionals across the industry. While prices have dropped significantly over the past decade from over $1000/kWh to under $130/kWh the industry aims to achieve sub-$100/kWh pricing for true mass-market affordability.

- Cost Influencers:

- Raw material prices (lithium, cobalt, nickel).

- Manufacturing scale and efficiency.

- Technology improvements (e.g., 4680 cells).

- Supply chain disruptions. Supply Chain Challenges:

- Geopolitical issues affecting mining regions.

- Ethical concerns around cobalt mining.

- Dependency on specific countries for rare materials.

Efforts to localize battery supply chains and develop alternative chemistries (like LFP) are addressing these issues.

Innovations in Battery Tech

Ongoing research and development in battery technology aim to enhance performance, safety, and cost-efficiency. Notable innovations include:

- Silicon Anodes: Higher energy density compared to graphite.

- Cobalt-Free Chemistries: Reduce reliance on controversial materials.

- Battery-as-a-Service (BaaS): Subscription models for battery usage.

- AI-Driven BMS: Advanced monitoring and predictive analytics.

- 3D-Printed Electrodes: Improve structure and conductivity.

These breakthroughs are shaping the next generation of EV batteries and paving the way for broader adoption.

Summary

EV batteries are transforming transportation, offering cleaner, more efficient alternatives to internal combustion engines. With rapid advancements in chemistry, design, safety, lifecycle management, and Artificial Intelligence Training these power systems are becoming more accessible and reliable. As we move into a future defined by sustainability and technology, EV battery innovation will remain a cornerstone of progress. EV batteries, which provide greener and more effective substitutes for internal combustion engines, are revolutionising transportation. These power systems are becoming more dependable and affordable thanks to quick developments in chemistry, design, safety, and lifecycle management. EV battery innovation will continue to be a key component of advancement as we transition into a future characterised by sustainability and technology.