- Electric Vehicle Controller

- Types of EV Controllers

- Control Algorithms

- Hardware Components

- Motor Control Logic

- Speed and Torque Regulation

- Regenerative Braking Support

- Communication with BMS

- Fault Detection

- Controller Programming

- Safety Features

- Advancements in Controller Design

- Conclusion

Electric Vehicle Controller

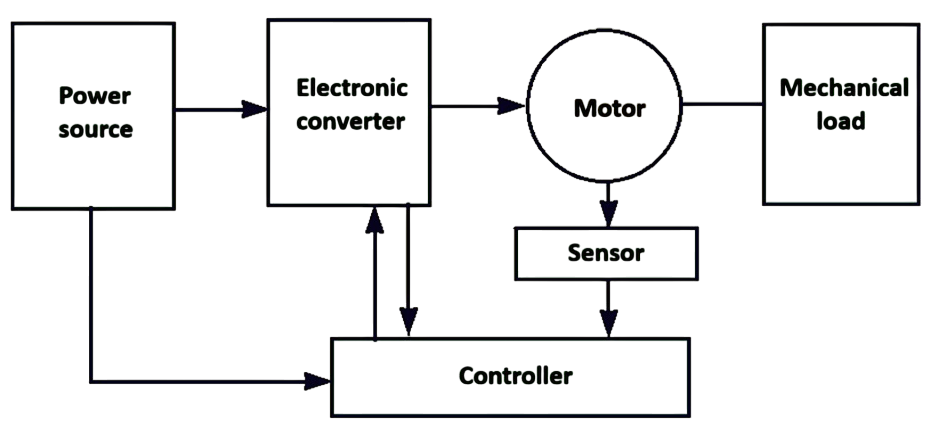

Electric Vehicle Controllers are vital components that manage and regulate power delivery from the battery to the motor. They act as the brain of the electric propulsion system, interpreting driver inputs such as acceleration and braking, and translating them into precise electrical signals to control the motor. To understand how intelligent systems refine this translation for smoother, safer, and more responsive driving, explore Artificial Intelligence Training a hands-on course that covers embedded control, machine learning, and real-time signal processing for next-gen automotive applications. Without a controller, there would be no mechanism to coordinate these signals, leading to inefficient or even unsafe operation. These controllers ensure that the EV operates smoothly, efficiently, and safely under various driving conditions. As electric mobility advances, the complexity and intelligence of controllers have also increased, incorporating software algorithms, real-time data processing, and communication with other subsystems.

Types of EV Controllers

EV controllers can be broadly categorized based on their function and motor compatibility. To explore how these controllers integrate into larger fleet operations, ensuring efficiency, safety, and optimized performance, explore What is EV Fleet Management a comprehensive guide that explains fleet monitoring, controller roles, maintenance strategies, and the technologies driving scalable electric mobility solutions. AC motor controllers are designed for asynchronous and synchronous motors and are widely used due to their efficiency and regenerative capabilities.

DC motor controllers, although simpler, are gradually becoming obsolete due to limitations in control precision and efficiency. Brushed DC controllers are cost-effective but require frequent maintenance. Brushless DC (BLDC) controllers, in contrast, are more durable and offer better control over motor speed and torque. Additionally, traction motor controllers, inverter controllers, and dual motor controllers serve specific configurations and performance requirements in electric cars, bikes, and commercial EVs.

Ready to Get Certified in Artificial Intelligence? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Control Algorithms

- Control algorithms are the heart of EV controllers, ensuring optimal performance by dynamically adjusting voltage and current to the motor. To explore how these intelligent systems are shaping next-generation mobility and driving innovation in sustainable transport, explore Future of the Electric Vehicle a comprehensive guide that highlights advancements in control strategies, battery technologies, charging ecosystems, and the evolving role of EVs in global transportation.

- Common control strategies include Pulse Width Modulation (PWM), which regulates power output through high-frequency switching, and Vector Control (Field-Oriented Control or FOC), which provides precise control over torque and speed by controlling the magnetic field in the motor.

- Direct Torque Control (DTC) offers an alternative that directly manages torque and flux without modulation, leading to faster dynamic response. Adaptive and model-predictive control algorithms are also being implemented in advanced systems to enhance performance under variable load and road conditions. These algorithms enable seamless acceleration, smooth torque delivery, and energy-efficient operation, ensuring better driving experience and range management.

- The controller’s hardware consists of power electronics, microcontrollers, sensors, and protective circuits. Power transistors like IGBTs or MOSFETs handle high current flow and are crucial for PWM switching. The microcontroller unit (MCU) or digital signal processor (DSP) processes sensor data and runs control algorithms in real-time. Current and voltage sensors, temperature sensors, and position encoders provide feedback that guides control decisions.

- Heat sinks and cooling systems are used to manage thermal loads, while protective circuits ensure operation within safe parameters. Advanced controllers also include communication modules like CAN bus transceivers, which facilitate data exchange with other subsystems. Integration of these components ensures the EV controller can deliver efficient, reliable, and safe motor control.

- EV controllers regulate speed and torque to ensure responsive yet smooth driving. Speed is typically controlled using feedback from the motor’s encoder, allowing the controller to compare actual speed to the target and adjust current accordingly. Torque control is achieved by modulating current amplitude based on load demand.

- Using FOC or DTC, the controller can isolate and manipulate torque-producing and magnetizing currents separately, enabling highly efficient torque regulation. This precise control is crucial for applications like hill starts, overtaking, or navigating traffic. The result is not only improved vehicle control and comfort but also energy savings and extended battery life.

- EV controllers are programmable units that can be customized for various vehicle types, performance profiles, and motor technologies. Engineers use dedicated software tools to configure control parameters such as acceleration curves, torque limits, and regenerative braking strength. Programming is done using embedded code, often in C/C++, and may involve tuning PID loops or implementing complex control strategies.

- Some platforms support auto-code generation from simulation environments like MATLAB/Simulink. Programmable controllers enable manufacturers to deploy one hardware model across multiple vehicle models with software variations, reducing costs. They also allow updates and refinements post-production, making them adaptable to new algorithms, battery chemistries, and regulations.

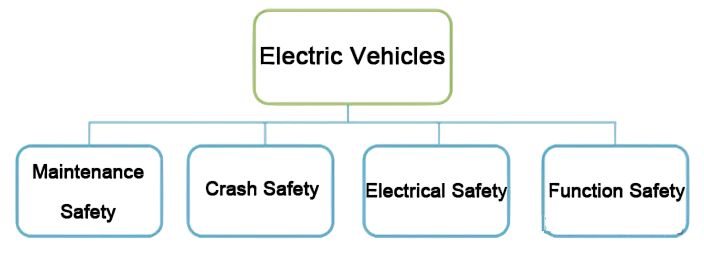

- Safety is a top priority in EV controller design. Controllers are equipped with redundant systems, fail-safe protocols, and emergency shutdown capabilities to protect passengers and equipment. To understand how these safety mechanisms are represented in technical schematics and design layouts, explore Learn Electric Vehicle Drawing a comprehensive guide that illustrates EV components, controller architecture, wiring diagrams, and the visual logic behind safe and efficient electric vehicle design. Thermal protection ensures the controller reduces or stops operation when overheating is detected. Overcurrent protection safeguards against short circuits and component damage.

- Speed limits and torque boundaries prevent dangerous driving scenarios, especially in consumer-grade electric scooters or bikes. Safety compliance standards like ISO 26262 (functional safety) guide the development of automotive-grade controllers. Additionally, controllers often support secure boot, encryption, and tamper detection to protect against cyber threats. Integrated safety enhances consumer trust and regulatory acceptance of EV technology.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Hardware Components

Motor Control Logic

Motor control logic interprets driver inputs (accelerator, brake) and converts them into motor commands. For example, when the accelerator is pressed, the controller determines the required torque and modulates voltage accordingly. To understand how intelligent systems enhance this decision-making process for smoother and more efficient propulsion, explore Artificial Intelligence Training a hands-on course that covers embedded control, machine learning, and real-time signal processing for advanced automotive applications. During deceleration, it may activate regenerative braking or reduce torque. The logic takes into account parameters like vehicle load, incline, and battery state-of-charge to optimize motor output. Controllers also manage motor startup, ensuring a smooth ramp-up of speed, and handle transitions between different driving modes such as eco, sport, or cruise control. In multi-motor EVs, the logic coordinates torque distribution to each motor for balanced traction and performance.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Speed and Torque Regulation

Regenerative Braking Support

Regenerative braking allows EVs to recover energy during deceleration and feed it back into the battery. The controller manages this by switching the motor into generator mode when braking is detected. To explore how this regenerative process integrates with propulsion systems and enhances overall efficiency, explore EV Powertrain a comprehensive guide that explains the components, working principles, and innovations driving modern electric vehicle performance. It determines the appropriate level of regeneration based on factors like battery capacity, motor speed, and vehicle deceleration rate. Regenerative braking reduces wear on mechanical brakes and improves overall energy efficiency. Advanced controllers support blended braking, which combines regenerative and mechanical braking seamlessly to maintain stability and comfort. Some systems allow customization of regen levels, offering drivers the choice between aggressive or mild regenerative effects.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Communication with BMS (Battery Management System)

The inverter plays one of the key roles in an electric vehicle. It interfaces between the battery and the electric motor. In more detail, the inverter converts direct current (DC) power stored in the battery to the alternating current (AC) power required by the electric motor. To explore how this conversion process integrates with charging systems and supports efficient energy transfer, explore Electric Vehicle Charging a comprehensive guide that explains charging methods, inverter functionality, grid interaction, and innovations driving the future of EV infrastructure. The vehicle propulsion system will then use the converted power. The inverter does this by advanced electronic switching to rapidly reverse the direction of flow of the DC to form an AC. The motor and the inverter are tightly linked together, where the former’s power delivery affects the vehicle’s acceleration and the overall driving experience. Beyond simply providing power to the motor, the inverter performs another vital function during regenerative braking. When the driver applies the brakes, or when the vehicle is coasting downhill, the electric motor can act as a generator, converting kinetic energy back into electrical energy. In this mode, the motor produces AC power, which must be converted back into DC power to recharge the battery. The inverter handles this reverse conversion, efficiently channeling the AC electricity from the motor back into the battery for storage and future use

Fault Detection

Fault detection mechanisms in EV controllers are essential for diagnosing and responding to electrical, mechanical, and communication issues. The controller monitors all subsystems and parameters such as motor current, inverter temperature, sensor inputs, and communication signals. To understand how this central unit ensures seamless coordination, safety, and efficiency across the entire drivetrain, explore Electric Vehicle Working Principle a comprehensive guide that explains its architecture, functions, integration with other components, and its critical role in modern EV performance. If anomalies like overcurrent, undervoltage, overheating, or encoder failure are detected, the controller triggers predefined safety actions such as reducing power, shutting down the motor, or alerting the driver. Advanced systems utilize self-diagnostic algorithms and log fault codes for service technicians. Some controllers even support over-the-air (OTA) diagnostics and firmware updates, reducing downtime and improving serviceability. Reliable fault detection minimizes the risk of accidents and protects critical components.

Controller Programming

Safety Features

Advancements in Controller Design

The landscape of EV controller technology is evolving rapidly. Modern controllers incorporate AI-based adaptive algorithms that learn from driving patterns to optimize energy consumption and performance. Integration with vehicle-to-grid (V2G) systems enables intelligent energy management between EVs and the power grid. To explore how these innovations are being applied in real-world scenarios and shaping the future of sustainable mobility, explore Top Electric Vehicle Projects a comprehensive guide that highlights pioneering EV initiatives, V2G applications, charging infrastructure advancements, and the technologies driving smarter energy ecosystems. SiC (Silicon Carbide) and GaN (Gallium Nitride) transistors are replacing traditional silicon-based components, improving switching efficiency and reducing size and heat generation. Controllers are becoming increasingly modular, with plug-and-play support for multiple motor and battery configurations. Enhanced connectivity features, such as OTA updates, real-time telemetry, and app-based customization, provide greater control and user engagement. Manufacturers are also integrating controllers and inverters into compact power modules, reducing cost and complexity. These advancements are essential to support emerging EV applications like autonomous vehicles, high-performance electric trucks, and smart fleets. As EV adoption grows, controllers will play a pivotal role in achieving the industry’s goals for sustainability, performance, and reliability.

Conclusion

Electric Vehicle controllers are the intelligent core of modern electric mobility, ensuring precise, safe, and efficient motor operation. From managing power delivery to interfacing with batteries and handling regenerative braking, these units integrate hardware, software, and intelligence into a compact system. To understand how AI enhances this integration for smarter, more responsive EV performance, explore Artificial Intelligence Training a hands-on course covering embedded systems, machine learning, and real-time control strategies for next-generation electric mobility. With advancements in AI, semiconductor materials, and safety protocols, EV controllers are evolving to meet the demands of next-generation transportation. Understanding the intricacies of EV controllers is essential for engineers, manufacturers, and enthusiasts striving to shape a cleaner and smarter automotive future.