- What is a Battery Management System?

- Role in Electric Vehicles

- Components of a BMS

- Functions and Features

- Battery Protection Mechanisms

- Cell Monitoring

- Temperature Management

- Charging/Discharging Control

- SOC and SOH Estimation

- Challenges in BMS Design

- Conclusion

What Is a Battery Management System?

A Battery Management System (BMS) is the electronic brain of an EV battery pack monitoring, protecting, balancing, and communicating data to ensure safe and optimized performance. It tracks voltages, currents, and temperatures at the cell and pack levels, detects abnormal conditions, and actively controls charging/discharging protocols. To understand how intelligent systems enhance battery management through predictive monitoring, anomaly detection, and real-time optimization, explore Artificial Intelligence Training a hands-on course that covers machine learning, embedded AI, and smart energy control strategies for advanced EV applications. By managing these parameters in real time, the BMS safeguards the pack from thermal runaway, overcharge, undervoltage, and other critical issues.

Role in Electric Vehicles

In electric vehicle (EV) applications, the Battery Management System (BMS) serves multiple essential functions that are critical for both safety and performance. One of its primary roles is safety and protection, it actively monitors the battery’s condition and will disconnect or limit operations when it detects issues such as over-voltage, under-voltage, over-current, or unsafe temperatures. This proactive approach safeguards the battery and the vehicle from potential hazards. To explore how such innovations are creating new roles and reshaping the automotive industry, explore Career Opportunities in EV a comprehensive guide that highlights emerging job roles, required skills, and the future scope of professionals in the electric vehicle sector. Additionally, the BMS enhances performance and longevity by regulating charge and discharge processes while balancing individual cells within the battery pack. This regulation not only extends the battery’s cycle life but also minimizes degradation over time. Moreover, the BMS contributes to efficiency and thermal control by managing cooling and heating systems to maintain optimal operating temperatures.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

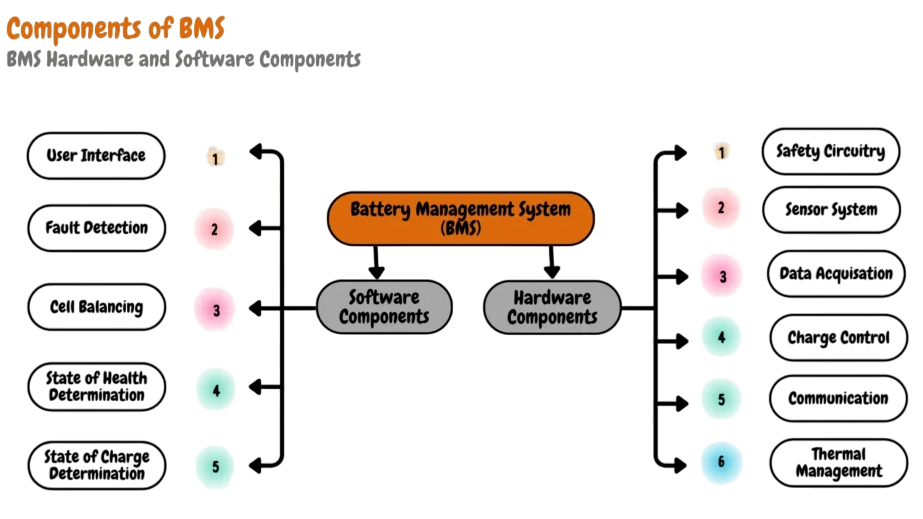

Components of a BMS

A robust BMS comprises several key hardware modules and subsystems. To explore how these systems integrate with charging infrastructure and support the growth of sustainable mobility, explore EV Charging Stations a detailed guide that highlights charging hubs, connectivity, efficiency, and their critical role in powering the future of electric vehicles.

- Cell Monitoring Units: Measure individual cell voltages, currents, and temperatures via ADC or digital sensors deployed throughout the pack.

- Battery Control Unit (BCU): The central processor responsible for computations (SoC, SoH, balancing control), decision-making, and interfacing with vehicle systems.

- Battery Disconnect Unit (BDU) / Contactor: High-current switches (e.g., MOSFETs or relays) used to isolate the battery under fault conditions.

- Balancing Circuits: Can be passive (resistive bleed) or active (energy transfer) balancing sub-circuits used to equalize cell voltages.

- Thermal Management Sensors & Actuators: Temperature probes and cooling units like fans or liquid loops controlled by the BMS.

- Communication Interfaces: CAN, LIN, and emerging wireless protocols enabling data exchange with vehicle systems and external devices.

These components ensure that a BMS can monitor, analyze, protect, and communicate effectively in a demanding automotive environment.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Functions and Features

Battery Protection Mechanisms:

- Prevent over-charge, over-discharge, over-current, ground fault, and temperature extremes via disconnects or controlled shutdowns.

- Use pre-charge circuits to limit inrush currents into capacitors.

- Enforce cutoffs calibrated to cell chemistry and aging.

Cell and Pack Monitoring:

- Individual cell voltages (min/max detection)

- Pack-current flows using shunts or Hall sensors

- Multiple temperature readings (cell-level, coolant)

- Monitoring of cooling effectiveness and contactor states

Temperature Management:

- Passive systems use natural cooling (air ducts) for low-cost operation.

- Active systems employ fans or liquid loops, managed via control logic to regulate energy vs cooling needs.

- Advanced setups use predictive controls (MPC, AI) for energy-efficient thermal regulation.

Charging & Discharging Control:

- Manages acceptable currents and voltages during charge/discharge cycles.

- Coordinates regenerative braking energy harvesting and thermal control.

- Implements pre-charge protection and avoids cold-weather overcharging.

SoC, SoH, SoP, SoSa Estimation:

- SoC: uses coulomb counting (charge-in/out) and voltage integration.

- SoH: tracks capacity fade via comparisons of current vs original values.

- SoP: estimates available power based on current battery status.

- SoSa: signals whether the battery is safe to operate.

- Algorithms vary from simplistic lookup tables to AI-driven models.

Balancing (Equalization):

- Passive balancing expends excess energy as heat via resistive bleeders.

- Active balancing transfers charge between cells using capacitors, inductors, or DC-DC converters improving efficiency but increasing complexity.

System Communication:

- Utilizes CAN-bus (standard in automotive), LIN, and emerging wireless solutions for inter-module coordination.

- Communicates status and diagnostics to the vehicle control unit and user display.

Battery Protection Mechanisms

In addition to basic electrical protections, several advanced safety measures are implemented to safeguard battery packs. Over-voltage and under-voltage thresholds are carefully set for each cell and the overall pack to prevent damage during extreme conditions. Furthermore, over-current protection is vital, as it prevents thermal or mechanical damage by cutting off excess current when necessary. Critical temperatures trigger thermal cutoffs, ensuring that the battery remains within safe operating limits. To explore how intelligent systems strengthen these protections through predictive monitoring, anomaly detection, and adaptive control, explore Artificial Intelligence Training a hands-on course that covers embedded AI, smart diagnostics, and real-time safety algorithms for advanced EV battery systems. Ground-fault detection adds another layer of safety by isolating packs from chassis leakages, thereby preventing potential hazards. Additionally, inrush current precharge limits are established to mitigate transient spikes during operation. All these protections are actively enforced through a combination of switches and automatic intervention logic, ensuring safety under any condition and providing peace of mind for users.

Cell Monitoring

Accurate battery operations rely on several foundational tasks that ensure efficient performance and reliability. First and foremost, voltages are monitored through either multiplexing techniques or direct-sensing integrated circuits (ICs), providing critical insights into the battery’s status. To explore how these monitoring methods integrate with advanced energy systems and drive innovations in sustainable mobility, explore Battery Technology a comprehensive guide that highlights Tesla’s innovations, voltage management strategies, efficiency improvements, and the future of energy storage in electric vehicles. Additionally, temperatures are assessed at strategic points within the battery pack, which is essential for maintaining optimal operating conditions. Current flows are measured using shunts, allowing for precise tracking of energy usage and performance. The computations of State of Charge (SoC) and State of Health (SoH) leverage advanced methods such as money coulomb counting and impedance models, which enhance the accuracy of performance evaluations. The integration of high-resolution data from these measurements not only facilitates early anomaly detection but also promotes optimal energy management, ultimately contributing to the longevity and efficiency of battery operations.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Temperature Management

BMS Temperature Control focuses on maintaining optimal thermal conditions to ensure safety, efficiency, and extended battery life. To explore how these thermal management strategies integrate with advanced energy systems and shape the future of sustainable mobility, explore EV Battery Technology a comprehensive guide that highlights cooling methods, temperature sensors, performance optimization, and innovations driving electric vehicle advancements.

- Actuating active cooling fans or liquid-cooled loops.

- Prioritizing targeted zones during high-load or fast-charging events.

- Utilizing predictive algorithms (e.g., Model Predictive Control) to balance battery health and energy.

- Maintaining battery within safe ideal range (usually 20–40 °C for Li-ion cells).

Thermal regulation extends battery life and ensures consistent performance.

Charging/Discharging Control

BMS regulates charging to:

- Prevent excess voltage or current.

- Sync with regenerative braking to capture energy efficiently.

- Stabilize charge cutoffs to preserve cell health.

- Handle pre-charge processes to protect high-voltage components.

During discharge, it ensures currents remain within thermal and electrochemical limits.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

SoC and SoH Estimation

To estimate SoC:

- Coulomb counting measures current integration over time.

- Voltage-based look-up tables map voltage to charge.

- Impedance and model-based techniques use electrical models to adapt to conditions.

SoH estimation involves:

- Comparing current capacity to baseline reference using cycle tests or modeling.

- Employing AI/ML methods to detect early degradation trends.

Key challenges include sensor drift, temperature effects, and cumulative error in SoC predictions. To explore how these issues are addressed through advanced engineering, monitoring systems, and innovative design principles, explore Electric Vehicle Technology a comprehensive guide that explains EV working principles, efficiency improvements, and the future of sustainable transportation.

Challenges in BMS Design

Key challenges in BMS design and deployment include ensuring safety, scalability, and seamless integration with charging infrastructure. To explore how industry leaders are addressing these challenges and driving innovation in sustainable mobility, explore List of Electric Vehicle Companies a comprehensive guide that highlights top EV manufacturers, their strategies, and contributions to the future of electric transportation in India.

- State Estimation Error: Accurate SoC/SoH remains elusive due to nonlinear battery behavior.

- Thermal Non-uniformity: Difficult to evenly manage temperature in large packs.

- Scalability & Modularity: Designing hardware/serviceable battery stacks is complex.

- Wireless Security & Standards: Reliability concerns around interference and cybersecurity.

- Cost Constraints: High-accuracy sensors and software increase BOM cost.

- Certification and Safety: Meeting standards across global regions demands extensive validation.

Conclusion

The Battery Management System is the pivotal component ensuring the safety, reliability, and efficiency of EV batteries. It integrates multi-faceted hardware and software systems to monitor electrical and thermal states, manage energy flow, balance cell performance, and communicate with the rest of the vehicle platform. To explore how intelligent systems optimize these integrations through predictive analytics, adaptive control, and real-time communication, explore Artificial Intelligence Training a hands-on course that covers embedded AI, energy management algorithms, and system-level optimization for advanced EV platforms. While modern BMS designs are already sophisticated, their evolution is accelerating, from AI-driven diagnostics to wireless sensing, from enhanced cybersecurity to modular, easily serviceable architectures. As EV adoption scales globally, the sophistication and expectations from BMS platforms will only intensify making design expertise in this domain both critical and valuable. A strong understanding of BMS principles is essential for EV engineers, system designers, and anyone involved with the future of energy storage systems.