- Overview of BLDC Motor Operation

- Role of Magnetic Fields

- Stator and Rotor Function

- Commutation Process

- Hall Sensors and Control

- Sensorless Operation

- Torque Production

- PWM and Controllers

- Summary

Overview of BLDC Motor Operation

Because of their great efficiency, dependability, and precise control, brushless DC (BLDC) motors are utilised in a wide range of applications, from computer peripherals to electric vehicles. In contrast to conventional brushed DC motors, BLDC motors rely on electronic controllers to control current flow in the stator windings rather than brushes. A BLDC motor operates on the basis of the interaction between the permanent magnets in the rotor and the electromagnetic field of the stator, which is often optimized through Artificial Intelligence Training to enhance performance, improve efficiency, and enable adaptive control based on real-time data analysis. A spinning magnetic field is produced when current passes through the stator windings in a predetermined order. The rotor spins as a result of this field’s interaction with the rotor magnets, which produces torque. The motor can rotate smoothly and effectively by precisely timing the current switching (commutation). For applications demanding precise speed control, high torque, and long operating life, it is essentially essential to comprehend the working principle of BLDC motors.

Role of Magnetic Fields

Brushless DC (BLDC) motors rely on magnetic fields to function. To produce motion, these motors rely on the interaction of the stator and rotor magnetic fields. Permanent magnets are found in the rotor of a BLDC motor, whilst electromagnets make up the stator.

- When electric current is applied to the stator windings, the revolving magnetic field created by the stator interacts with the magnetic field created by the rotor’s permanent magnets.

- The electromagnetic field of the stator and the magnetic field of the rotor interact to produce a force that turns the rotor. The timing of current flow through the stator windings, or commutation, determines the rotor’s rotation direction and speed.

- The motor may achieve great efficiency, accurate control, and smooth spinning by carefully regulating the magnetic fields in the stator and rotor, with the Steering Geometry playing a crucial role in optimizing the alignment and movement, ensuring precise control and minimizing friction during operation.

For BLDC motors to generate torque, magnetic fields are also necessary. The force between the rotor’s magnets and the stator’s revolving magnetic field produces the torque. The motor’s torque output increases with the strength of the magnetic field interaction. In conclusion, magnetic fields are essential to the overall performance and efficiency of a BLDC motor because they generate the force required for spinning.

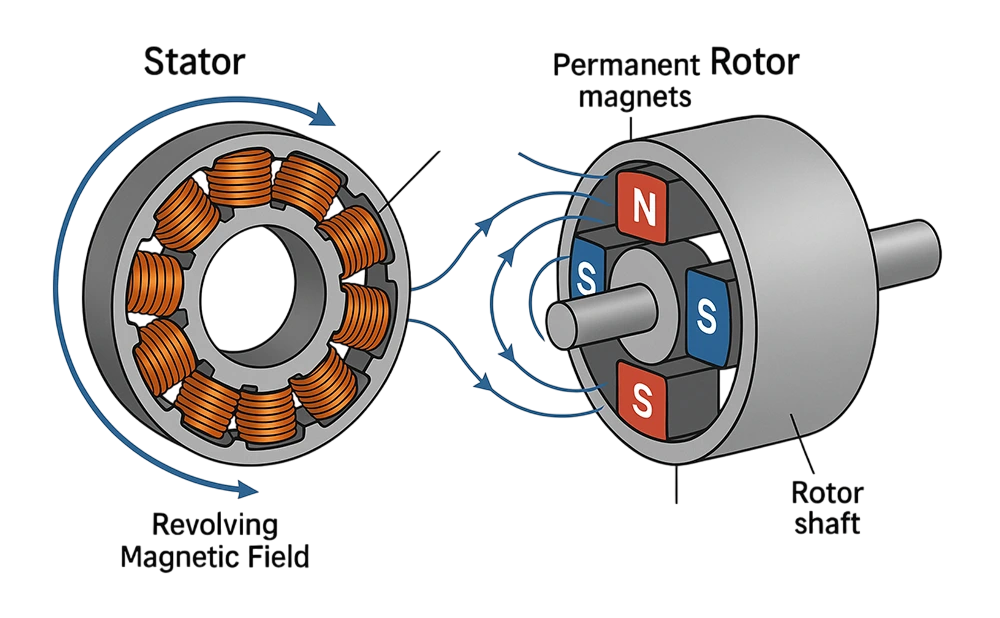

Stator and Rotor Function

The stator and rotor are the two main parts of a BLDC (Brushless DC) motor that cooperate to transform electrical energy into mechanical energy.

Stator Function:

The motor’s stator, which is its stationary component, is primarily responsible for creating a revolving magnetic field. Direct current (DC) that passes through the coils is used to power the stator windings. Usually made up of copper windings and laminated iron cores, the stator produces a magnetic field when current passes through these windings. A continuous spinning magnetic field is produced by the stator’s numerous phases, often three. The rotor must be driven by this revolving magnetic field in order to produce motion, with the power for this process often supplied by an EV Battery which provides the necessary energy for the motor’s operation in electric vehicles. An electronic controller successively energises the stator’s windings in a predetermined order to guarantee that the magnetic field rotates at a steady speed and gives the rotor constant torque

Conversely, the motor’s rotating component is called the rotor. Depending on the motor’s design, it is typically composed of either electromagnets or permanent magnets. The rotor’s job is to rotate in reaction to the stator’s magnetic field. The rotor of BLDC motors is usually made to have a low moment of inertia, which enables it to accelerate and decelerate rapidly, offering superior performance for applications needing precise control and quick reaction times.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Commutation Process

A BLDC (Brushless DC) motor’s commutation process is crucial to maintaining the rotor’s continuous rotation. In contrast to conventional brushed DC motors, which switch the current to the motor windings using mechanical brushes and a commutator, BLDC motors employ electronic commutation. A controller that controls the timing of current passage via the stator windings performs this electrical commutation.

- Commutation Types:

- Current Switching: A spinning magnetic field is produced by sequentially energising the stator windings. The rotor rotates because its magnets are drawn to these poles.

- Controller Role: The motor’s controller uses sensorless techniques like back EMF or Hall effect sensors to track the rotor’s location. In order to guarantee steady spinning, it then alternates the stator’s current at specific times.

- Timing and Sequence: To keep the rotor moving smoothly and continuously, the current is switched in a particular sequence (6-step or 12-step) depending on the rotor’s position. This method is key to improving the Future of the EV where advancements in motor control and battery efficiency will enable longer range, faster charging, and more responsive driving experiences.

- Sustaining Rotation: Effective and smooth rotation is made possible by the commutation process, which guarantees that the rotor is constantly drawn in the direction of the rotating magnetic field. Commutation Types:

- Sensor-based commutation: This technique uses sensors, such as Hall effect sensors, to measure the position of the rotor and provide feedback to the controller, which modifies the current flow in response.

- Sensorless Commutation: This technique uses the electromotive force (EMF) produced by the rotor’s rotation to determine its position. This is frequently employed in applications where it is intended to reduce the number of sensor components.

Making ensuring the rotor is always in sync with the revolving magnetic field produced by the stator is the aim of the commutation process in both situations. When the rotor and stator fields are misaligned, proper commutation guarantees that the motor runs smoothly, efficiently, and without major losses.

Hall Sensors and Control

Hall sensors, which provide real-time feedback on the rotor’s location, are essential to the operation of BLDC motors. These sensors enable for accurate regulation of the current flow in the stator windings by detecting the magnetic field of the rotor’s permanent magnets and transmitting this information to the motor’s controller. This guarantees smooth motor running and appropriate commutation.

How Hall Sensors Work:Hall sensors are placed in fixed positions on the stator and detect the presence of the magnetic field from the rotor’s permanent magnets as they pass by. When a magnet from the rotor comes near the sensor, the sensor generates a voltage signal, which is sent to the motor controller. This process can be further enhanced with Artificial Intelligence Training allowing the system to predict and optimize motor performance by analyzing sensor data and adjusting control strategies in real-time.

- Hall Sensor Benefits:

- Accurate Position Feedback: They enable accurate commutation by giving exact information about the rotor’s position.

- Increased Efficiency: The motor operates more smoothly and efficiently when current switching is timed correctly.

- Simpler Control: Without the need for intricate sensorless algorithms, Hall sensors facilitate the implementation of accurate and dependable motor control.

In summary, Hall sensors are crucial for the precise control of BLDC motors, providing the necessary feedback for accurate rotor position tracking and efficient commutation.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Sensorless Operation

By using the motor’s back electromotive force (EMF) to estimate rotor position, sensorless operation in BLDC motors does away with the necessity for physical position sensors like Hall sensors or encoders. By eliminating possible areas of failure, this method improves dependability, lowers costs, and simplifies motor design, offering a significant advantage in the EV vs Fuel Vehicle debate, where electric vehicles benefit from fewer moving parts, reduced maintenance needs, and overall higher reliability compared to traditional internal combustion engines. However, because the back EMF signal is weak and more difficult to detect, it can be difficult to execute at low speeds. Despite these difficulties, sensorless operation is extensively employed in applications where cost, compactness, and durability are important considerations, such as drones, electric cars, and HVAC systems.

Torque Production

The interaction of the stator and rotor magnetic fields produces torque in BLDC (Brushless DC) motors. A revolving magnetic field produced by current flowing through the stator windings interacts with the rotor’s permanent magnets. This magnetic contact exerts a force that generates torque. The strength of the magnetic field, the current flowing to the windings, and the number of poles in the motor all affect how much torque is generated.

Because there are no brushes to create wear or friction, torque creation in BLDC motors is more efficient, leading to better power output and smoother operation, which is especially beneficial across various Types of Electric Vehicle such as battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and two-wheeled electric vehicles, all of which rely on efficient, low-maintenance motors for optimal performance. Because the torque and winding current are directly correlated. For applications needing high torque or changing speeds, precise control is possible since the torque is directly proportional to the current in the windings.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

PWM and Controllers

One important method for regulating the torque and speed of BLDC motors is pulse width modulation, or PWM. PWM is used by the motor controller in a BLDC system to control the voltage applied to the motor windings. The controller modifies the average voltage applied to the motor, which in turn regulates the motor’s speed, by altering the duty cycle of the PWM signal. This is a key aspect of the Electric Vehicle Working Principle where efficient power management and precise control of the motor’s speed and torque are essential for maximizing the performance, range, and energy efficiency of electric vehicles.In contrast to a lower duty cycle, which lowers power and slows the motor down, a higher duty cycle gives the motor more power, increasing its speed and torque.

Summary

With benefits including increased efficiency, a longer lifespan, reduced maintenance, and accurate speed control, brushless DC (BLDC) motors have become a very dependable and effective substitute for conventional brushed motors. Their increasing use in a variety of fields, including robotics, industrial automation, and electric vehicles, highlights their performance advantages and adaptability, which are further amplified through Artificial Intelligence Training AI allows these systems to learn from data, predict behaviors, and optimize performance in dynamic environments. BLDC motors are predicted to become more and more important in high-performance, energy-efficient systems as technology develops, spurring innovation in a variety of sectors.