- Electric Vehicles Regulate Motor Speed

- Importance of Speed Control in Electric Vehicles

- Open-loop vs. Closed-loop Speed Control

- Throttle Control Mechanism

- Pulse Width Modulation (PWM) Control

- Vector Control(VC)

- Field oriented control foc

- Voltage Control Method

- Direct Torque Control (DTC)

- Sensorless Speed Control

- Comparison of Methods

- Emerging Techniques and AI Integration

- Industry Trends and Future Outlook

- Conclusion

Electric Vehicles Regulate Motor Speed

Speed control in electric vehicles (EVs) is crucial for their performance and efficiency. Unlike traditional internal combustion engine (ICE) vehicles, which use mechanical throttles and multi-speed gearboxes, EVs control speed entirely through Artificial Intelligence Training electronic systems. These systems manage the flow of electric energy from the battery to the motor by adjusting voltage, current, and frequency. This results in smooth torque delivery and acceleration, improved efficiency, and better adaptability to various driving conditions. Speed control also plays a role in regenerative braking, where kinetic energy converts back into electrical energy during deceleration, enhancing overall energy use. As electric mobility becomes more common, effective motor control techniques are essential for achieving a balance between performance, range, and driver comfort.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Importance of Speed Control in Electric Vehicles

Speed control directly affects many performance aspects of an EV, including energy consumption, battery life, thermal stability, and passenger comfort. In simpler terms, a well-controlled motor leads to a well-behaved vehicle.

- Energy Efficiency: Efficient speed regulation ensures power is delivered only when needed, preventing wasteful energy loss.

- Safety Features: Enables hill start assist, traction control, and torque vectoring for improved safety and drivability.

- Component Longevity: Precise speed control reduces wear on bearings, tires, and transmission couplers.

- Regenerative Braking: Recovers energy during controlled deceleration and feeds it back into the battery.

- Range Extension: Energy recovery can extend driving range by up to 10–15%, depending on driving conditions.

- Sustainability Impact: Advanced speed control methods enhance both performance and cost-effectiveness in EV operation.

Open-loop vs. Closed-loop Speed Control

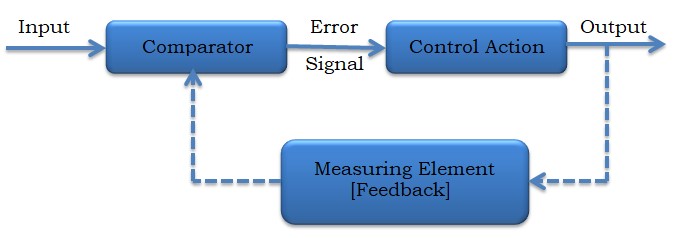

Speed control strategies can be divided into open-loop and closed-loop systems, based on their use of feedback to correct deviations.

- Open-Loop Control: Operates without feedback. The bldc foc controller sends preset signals to the motor based on input commands, like throttle position, without verifying actual motor speed.

- Advantages: Simple, affordable, and easy to implement.

- Limitations: Sensitive to external factors such as load changes, road gradient, or temperature. Common in low-power applications like electric scooters and fans.

- Closed-Loop Control: Continuously monitors actual motor speed using sensors like Hall sensors or encoders.

- Real-Time Adjustment: Compares measured speed with desired reference and adjusts current or voltage to minimize error.

- Benefits: Delivers high accuracy, stability, and responsiveness. Essential for modern EVs to maintain consistent performance under varying conditions.

In summary, open-loop systems are simple but limited, while closed-loop systems are intelligent, adaptable, and crucial for high-performance electric vehicles.

Throttle Control Mechanism

The throttle control mechanism in EVs replaces the mechanical linkage used in gasoline engines with an electronic system. The driver’s accelerator pedal connects to a position sensor, often a Hall-effect sensor or a potentiometer, which translates pedal movement into an electrical signal.

- Motor bldc foc controller: Processes the signal and determines how much current to send to the motor based on pedal position.

- Torque and Speed: Higher pedal input results in more current, increasing torque and vehicle speed.

- Regenerative Braking: When the pedal is released, the motor reverses to act as a generator, recovering energy.

- One-Pedal Driving: Some EVs, like Tesla models, use regenerative braking to slow the vehicle without brake input.

- System Responsiveness: Smooth coordination between throttle input and motor control enhances driving experience and efficiency.

- Duty Cycle: A higher duty cycle means more power and greater speed.

- Efficiency: Transistors act as ideal switches, minimizing power loss due to heat.

- Torque Stability: PWM reduces voltage ripples and maintains smooth torque delivery, even at low speeds.

- Inverter Integration: PWM control is used in nearly all EV motor bldc foc controller as part of inverter operation.

- Advanced Control: When paired with Field-Oriented Control (FOC), PWM ensures precise, low-noise, and efficient speed regulation.

- Transformation Method: field oriented control (FOC) transforms three-phase AC motor currents into a rotating reference frame using Clarke and Park transformations.

- d-axis Current: Regulates magnetic flux.

- q-axis Current: Controls torque.

- Torque and Flux Separation: Enables AC motors to behave like DC motors with precise torque control.

- Smoother Torque: Delivers minimal ripple and improved ride quality.

- Dynamic Response: Enhances acceleration and responsiveness.

- Efficiency and Noise: Improves energy efficiency and reduces operational noise.

- Low-Speed Performance: Offers better control and stability at low speeds.

- DC Motor Emulation: Vector control enables AC motors to behave like DC motors, simplifying control logic.

- Dual Benefits: Combines the efficiency and durability of AC machines with the controllability of DC systems.

- Real-Time Processing: Uses high-speed DSPs or microcontrollers to compute current, voltage, and rotor position.

- Sensor Feedback: Enables immediate adjustments to match driving demands and road conditions.

- Application Scope: Ideal for EV traction systems in passenger cars, buses, and racing vehicles.

- Real-Time Estimation: The bldc foc controller calculates instantaneous torque and flux from voltage and current readings.

- Switching Strategy: Selects optimal inverter switching states to correct deviations without using modulation techniques like PWM.

- Dynamic Performance: Offers excellent torque response and minimal dependence on motor parameters.

- Simplicity: Achieves fast control without complex transformations.

- Challenges: Higher torque ripple and noise; requires precise estimation algorithms.

- Applications: Ideal for high-performance EVs and industrial systems needing rapid acceleration and accurate torque control.

- Cost and Reliability: Eliminates physical sensors, reducing hardware complexity and improving system reliability.

- Low-Speed Limitations: Accuracy may degrade during startup or low-speed operation due to weak back-EMF signals.

- Hybrid Strategy: Uses open-loop control at startup, then transitions to sensorless mode at higher speeds.

- AI Integration: Advanced algorithms enhance estimation accuracy across the full speed range.

- Application Fit: Ideal for compact EVs and two-wheelers where simplicity and cost-effectiveness are key.

- PWM Control: Efficient and cost-effective, widely used; however, it may introduce electromagnetic interference.

- FOC/Vector Control: Highly accurate and allows for smooth torque control; computationally intensive but ideal for EV traction systems.

- voltage control method: Simple and inexpensive but inefficient for variable loads.

- DTC: Provides fast response and excellent torque control, but can introduce torque ripple.

- Sensorless Control: Cost-effective and compact but may have accuracy challenges at low speeds.

- Model Predictive Control (MPC): Anticipates future system states and adjusts control inputs proactively to enhance efficiency and safety.

- Predictive Maintenance: AI identifies anomalies in torque ripple, current flow, or temperature patterns before failures occur.

- Dynamic Optimization: Controllers adapt torque and power delivery based on real-time driving conditions.

- Autonomous AI integration: Smart speed control systems align with autonomous driving technologies for next-generation EVs.

- Cloud Connectivity: Future controllers will connect with cloud systems for continuous updates, diagnostics, and performance tuning.

- Smart Control: Combines AI and adaptive algorithms to optimize torque and energy use dynamically.

- Material Innovation: SiC and GaN enable compact, efficient, and high-speed power electronics.

- Efficiency Gains: Intelligent systems improve responsiveness and reduce energy losses.

Pulse Width Modulation (PWM) Control

Pulse Width Modulation (PWM) is a common FOC method for controlling the speed of DC and some AC motors in EVs. The concept is straightforward: instead of changing voltage continuously, the bldc foc controller quickly switches the power on and off at high frequency. The ratio of “on” time to total cycle time, known as the duty cycle, determines the effective voltage and motor speed.

Field oriented control (FOC)

Field-Oriented Control (FOC), or vector control, is one of the most advanced techniques for managing AC motors, especially Permanent Magnet Synchronous Motors (PMSMs) and Induction Motors (IMs).

Thanks to these benefits, FOC method has become the standard for high-performance EV applications, offering excellent drivability, efficiency, and responsiveness

Vector Control

Vector control is another way to refer to field oriented control (FOC), but it can be seen as a broader category. This technique relies on Artificial Intelligence Training transforming the stator current vector into components aligned with the rotor flux vector, allowing for precise control over torque and speed.

Direct Torque Control (DTC)

Direct Torque Control (DTC) is a powerful method for controlling AC motors. Unlike field oriented control (FOC), which depends on current transformation and modulation, DTC manipulates motor torque and magnetic flux directly using real-time measurements.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Sensorless Speed Control

Traditional motor control relies on sensors to detect rotor position and speed. Sensorless control removes the need for these physical sensors by estimating speed and position based on electrical quantities like back electromotive force (back-EMF) or stator current measurements.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Comparison of Methods

Each speed control technique offers different advantages and limitations:

The appropriate method will depend on the EV’s purpose—high-performance vehicles may need field oriented control FOC method or DTC, while smaller or cost-sensitive applications might favor PWM control or voltage control method control.

Emerging Techniques and AI Integration

The future of speed control is in intelligent and adaptive algorithms supported by Artificial Intelligence (AI) and Machine Learning (ML). Modern controllers are now able to learn from driving behavior, traffic patterns, and environmental conditions to optimize torque and power distribution dynamically.

Industry Trends and Future Outlook

EV speed control systems are moving toward greater AI integration, software-defined architectures, and real-time cloud-based diagnostics. Advances in semiconductors, including Silicon Carbide (SiC) and Gallium Nitride (GaN) devices, are transforming power electronics, allowing for faster switching, reduced losses, and smaller hardware sizes.

Conclusion

Speed control is the hidden force that shapes an electric vehicle’s behavior—its agility, smoothness, and energy efficiency. From basic voltage control method control to sophisticated field oriented control (FOC) and Direct Torque Control systems, the evolution of motor control reflects the rapid advancement of electric mobility itself. With the arrival of artificial intelligence, predictive algorithms, and next-generation semiconductors, EV motor control is Artificial Intelligence Training set to become smarter and more responsive. The vehicles of the future will not just react; they will learn from every mile, delivering optimal performance with minimal energy use.