- Introduction to Total productive maintenance

- Top administration and unwavering quality specialists

- Deal with gear upkeep that endeavors to accomplish wonderful creation

- Advantages of Total Productive Maintenance (TPM)

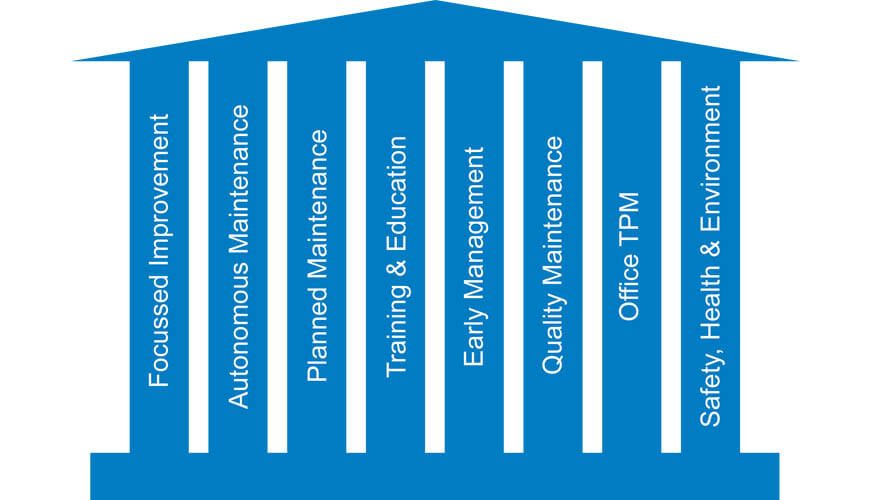

- The 8 Pillars of Total Productive Maintenance (TPM)

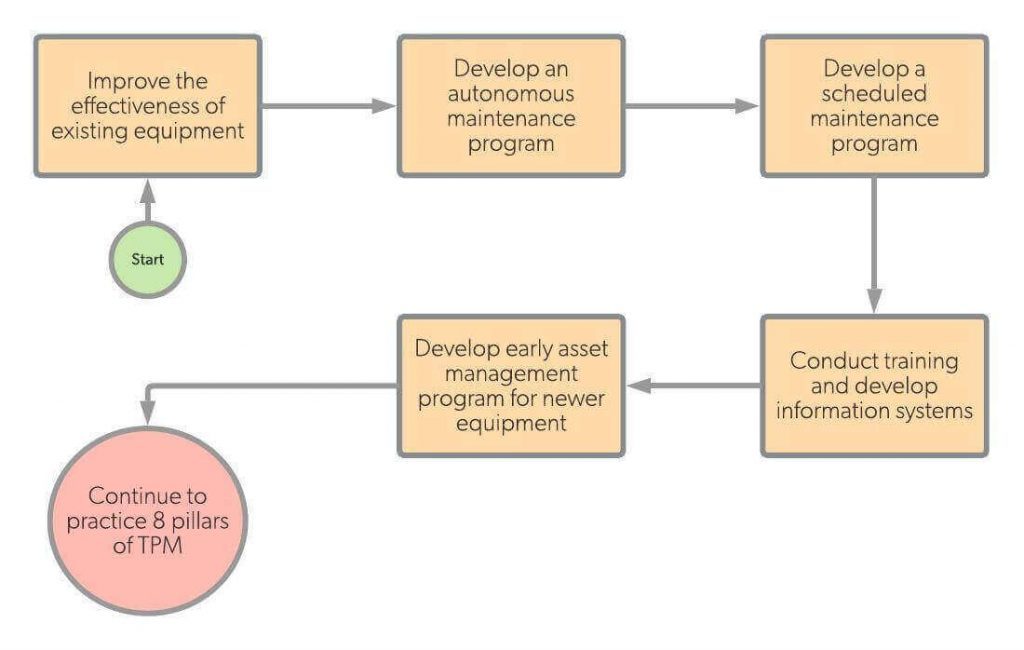

- Instructions to Implement Total Productive Maintenance (TPM)

- All out Productive Maintenance 5 stages

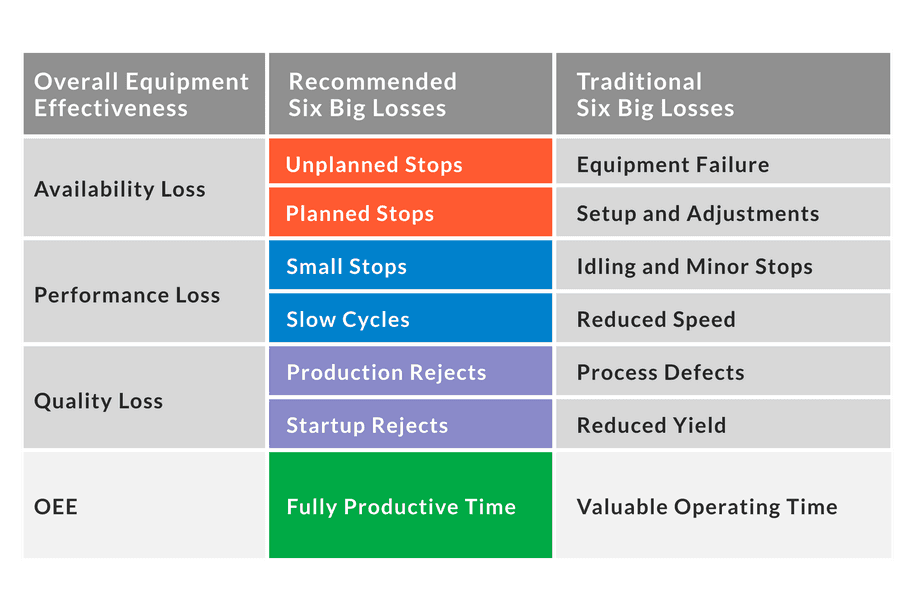

- Top 5 Loss Chart

- What might be said about The Remaining Four TPM Pillars?

- Conclusion

- No Breakdowns

- No Small Stops or Slow Running

- No Defects

- Likewise it esteems a protected workplace:

- Find out About Vorne XL

- Standard Ad

- What’s the most straightforward to get to the next level? Choosing hardware that is least demanding to further develop allows you the opportunity for quick and positive outcomes; notwithstanding, it doesn’t test the TPM cycle as unequivocally as the other two choices.

- Where’s the bottleneck? Picking gear in view of where creation is plainly being held up gives you a prompt expansion in absolute result and gives speedy restitution. The drawback is that utilizing this gear as a pilot implies you’re involving a basic resource for instance and hazard its opportunity being disconnected longer than you would like.

- What’s the most dangerous? Fixing gear that gives administrators the absolute most difficulty will be generally welcomed, fortifying help for the TPM program. Nonetheless, this doesn’t give you as much prompt recompense as the past methodology, and it could be trying to acquire a speedy come about because of sorting out a perplexing issue, prompting lack of engagement.

- On the off chance that this is your first time carrying out a TPM program, your most ideal decision is ordinarily the primary methodology – the least demanding hardware to move along. Assuming you have some or broad involvement in absolute useful support, you might decide to address the bottleneck. This is on the grounds that you can fabricate brief stock or stock, ensuring vacation can be endured, which limits hazard.

- Incorporate representatives across all parts of your business (administrators, support staff, supervisors and organization) in the pilot choice cycle. It’s smart to utilize a visual like a venture board where you can present advancement for all on see.

- You might have seen the execution interaction refuted four of the eight support points: quality administration, early hardware the executives, security and TPM in organization. Things being what they are, when would it be a good idea for you to present these exercises? They ought to be established depending on the situation. How about we investigate a few models.

- Quality upkeep ought to be acquainted with the TPM cycle when huge issues about quality are being raised by clients or representatives. The best an ideal opportunity to utilize early hardware the board is when new gear is in the plan stage or is being introduced. Security, wellbeing, and climate ought to constantly be at the very front of any interaction or program plan. Use it couple with the five-venture execution process.

- TPM in an organization ought to be tended to before you carry out the last form of your arranged support plan. Issues in organization like work request delays, handling issues and part acquisition significantly postpone the remainder of the creation cycle.

- Supporting the Improvement Achieved with Total Productive Maintenance (TPM). Carrying out an all out useful upkeep program offers moderately momentary achievement. The stunt is supporting that accomplishment over the long haul.

- This beginnings with the representatives. In the event that representatives become tied up with the TPM program, imagine the better eventual fate of the organization and can perceive how this superior future advantages them, it can make a strong feeling of cohesiveness. Remunerating accomplishments is a superb method for reinforcing the laid out cohesiveness among representatives.

- One more method for accomplishing economical improvement with your TPM program is by having drawing in, dynamic administration. This shows the significance of the program through words as well as activities. Drawing in authority keeps workers from slipping once again into old propensities and inhales new energy into the interaction consistently.

- At last, don’t neglect kaizen. Consistent improvement assists your TPM with programing adjust to changing conditions and holds the program back from becoming flat and workers from becoming unengaged.

Introduction to Total productive maintenance

Under the absolute useful upkeep theory, everybody from high level administration to gear administrators ought to take an interest in support. In any case, how? Every individual from an association can contribute in their own particular manner:

Top administration and unwavering quality specialists

The board ought to be associated with TPM by advancing it as a corporate approach. Dependability designs likewise should be involved, as they can decipher the upkeep information put away in an association’s CMMS to track down pertinent measurements and create business experiences.

Administrators

Administrators are the proprietors of an office’s resources, meaning they need to assume liability for the everyday upkeep of their machines. This incorporates the cleaning and customary grease vital for gear wellbeing. Administrators are likewise expected to track down early indications of gear weakening and report them, as well as decide ways of further developing hardware activity.

Support chiefs and specialists

Upkeep directors and experts are relied upon to prepare and uphold administrators to meet their objectives and perform further developed preventive support exercises. They are additionally expected to assume liability for development exercises that will affect the key presentation pointers (KPIs) set out by unwavering quality architects. Peruse more with regards to who is truly answerable for upkeep, and how to use a CMMS to get to TPM.

Deal with gear upkeep that endeavors to accomplish wonderful creation:

No Accidents

TPM stresses proactive and protection upkeep to boost the functional proficiency of gear. It obscures the qualification between the jobs of creation and support by putting a solid accentuation on engaging administrators to assist with keeping up with their gear. The execution of a TPM program makes a common obligation regarding hardware that empowers more prominent inclusion by plant floor laborers. In the right climate this can be extremely successful in further developing usefulness (expanding up time, diminishing process durations, and disposing of imperfections).

Customary TPM PILLARS

The customary way to deal with TPM was created during the 1960s and comprises of 5S as an establishment and eight supporting exercises (some of the time alluded to as points of support).

Chart of TPM with 5S Foundation and eight supporting support points.

The customary TPM model comprises of a 5S establishment (Sort, Set all together, Shine, Standardize, and Sustain) and eight supporting support points.

The 5S Foundation

The objective of 5S is to establish a workplace that is perfect and efficient. It comprises of five components:

Sort: dispense with whatever isn’t really required in the workspace

Fix: sort out the excess things

Sparkle: clean and review the workspace

Normalize: make principles for playing out the over three exercises

Support: guarantee the guidelines are routinely applied

It ought to be sensibly instinctive the way in which 5S makes an establishment for well-running gear. For instance, in a perfect and efficient workplace, apparatuses and parts are a lot more straightforward to find, and it is a lot simpler to recognize arising issues, for example, liquid releases, material spills, metal shavings from unforeseen wear, hairline breaks in components, and so forth.

As indicated by Aberdeen Research, the normal hourly expense of vacation across all organizations is $260,000, and it is by all accounts rising. This figure is up from the 2014 information of $164,000. This is particularly unsettling since essentially all modern and assembling creation is achieved utilizing machines, making it generally subject to those machines working constantly.

Anyway, what might you do for cure this issue? All out useful upkeep (TPM) is the method involved with utilizing machines, gear, representatives and supporting cycles to keep up with and work on the trustworthiness of creation and the nature of frameworks. Set forth plainly, it’s the most common way of getting workers engaged with keeping up with their own gear while underlining proactive and preventive support methods. Complete useful upkeep takes a stab at wonderful creation. That is:

1. No breakdowns

2. No stops or running gradually

3. No deformities

4. No mishaps

Since the objective of all out useful upkeep is to further develop efficiency by diminishing personal time, executing a TPM program can significantly affect your general gear adequacy (OEE) after some time. To do this, preventive upkeep ought to continuously be more important than anything else to everybody. For instance, running machines with the mentality of “we’ll fix it when it breaks” isn’t a choice with absolute useful upkeep. A TPM program disposes of this outlook and transforms it into one of putting apparatus at the center focal point of an activity and amplifying its accessibility.

Further developing OEE through TPM is regularly finished by shaping little, multidisciplinary groups to address center regions, for example, preventive and independent support, preparing representatives who work apparatus, and the security and normalization of work processes. All out useful upkeep centers around the proficient and powerful utilization of the method for creation, meaning all divisions ought to be involved. These little groups cooperate to expand efficiency and diminishing personal time through gear dependability.

Advantages of Total Productive Maintenance (TPM)

Going from responsive to prescient upkeep is probably the greatest benefit of executing a TPM program. Responsive upkeep or “firefighting” is expensive, as you’re paying for hardware fixes as well as managing the expense of impromptu vacation. We should investigate a portion of the immediate and backhanded advantages that outcome from complete useful support.

The 8 Pillars of Total Productive Maintenance (TPM)

Customary complete useful support was created by Seiichi Nakajima of Japan. The consequences of his work regarding the matter prompted the TPM interaction in the last part of the 1960s and mid 1970s. Nippon Denso (presently Denso), an organization that made parts for Toyota, was one of the main associations to carry out a TPM program. This brought about a globally acknowledged benchmark for how to carry out TPM. Fusing lean assembling methods, TPM is based on eight support points in view of the 5-S framework. The 5-S framework is a hierarchical strategy based around five Japanese words and their importance.

Seiri (sort out): dispensing with the mess from the work area

Seiton (deliberateness): guarantee request by following “a spot for everything and all things where they ought to be”

Seiso (neatness): clean the work area and keep it that way

Seiketsu (normalize): normalize all work processes, making them steady

Shitsuke (maintain): continually supporting the initial four stages

The eight mainstays of absolute useful upkeep center around proactive and preventive methods to assist with further developing hardware unwavering quality. The eight points of support are: independent upkeep; centered improvement (kaizen); arranged support; quality administration; early gear the board; preparing and training; wellbeing, wellbeing and climate; and TPM in the organization. We should separate every point of support beneath.

Independent support: Autonomous upkeep implies guaranteeing your administrators are completely prepared on routine upkeep like cleaning, greasing up and reviewing, as well as putting that obligation exclusively in their grasp. This gives machine administrators a sensation of responsibility for hardware and expands their insight into the specific piece of gear. It additionally ensures the hardware is in every case spotless and greased up, distinguishes issues before they become disappointments, and opens up upkeep staff for more significant level errands. Executing independent upkeep includes cleaning the machine to a “benchmark” standard that the administrator should keep up with. This remembers preparing the administrator for specialized abilities for leading a normal examination in view of the machine’s manual. When prepared, the administrator sets their own independent examination plan. Normalization guarantees everybody follows similar methodology and cycles.

Centered improvement: Focused improvement is based around the Japanese expression “kaizen,” signifying “improvement.” In assembling, kaizen requires further developing capacities and cycles persistently. Centered improvement views at the interaction in general and conceptualizes thoughts for how to further develop it. Getting little groups in the mentality of proactively cooperating to execute ordinary, gradual enhancements to processes relating to gear activity is key for TPM. Expanding colleagues takes into account the ID of repeating issues through cross-practical conceptualizing. It likewise joins input from across the organization so groups can perceive what cycles mean for various offices. Also, engaged improvement expands proficiency by diminishing item absconds and the quantity of cycles while upgrading wellbeing by examining the dangers of every individual activity. At long last, engaged improvement guarantees enhancements are normalized, making them repeatable and supportable.

Arranged support: Planned upkeep includes concentrating on measurements like disappointment rates and recorded vacation and afterward booking upkeep undertakings based around these anticipated or estimated disappointment rates or personal time periods. As such, since there is a particular opportunity to perform upkeep on gear, you can plan support around when the hardware is inactive or creating at low limit, seldom intruding on creation. Furthermore, arranged support takes into account stock development for when booked upkeep happens. Since you’ll realize when each piece of hardware is planned for upkeep exercises, having this stock development guarantees any diminishing underway because of support is alleviated. Adopting this proactive strategy enormously diminishes how much spontaneous personal time by taking into consideration most upkeep to be anticipated times when apparatus isn’t booked for creation. It likewise allows you to design stock all the more completely by enabling you to more readily control parts that are inclined to wear and disappointment. Different advantages remember a continuous diminishing for breakdowns prompting uptime and a decrease in capital interests in hardware since it is being utilized to its greatest potential.

Quality support: All the upkeep arranging and planning on the planet is supportive of nothing on the off chance that the nature of the upkeep being performed is insufficient. The quality support point of support centers around working plan mistake location and avoidance into the creation cycle. It does this by utilizing underlying driver investigation (explicitly the “5 Whys”) to distinguish and take out repeating wellsprings of imperfections. By proactively recognizing the wellspring of mistakes or deformities, processes become more dependable, delivering items with the right determinations the initial time. Conceivably the greatest advantage of value support is it keeps abandoned items from dropping down the line, which could prompt a ton of revise. With designated quality upkeep, quality issues are tended to, and long-lasting countermeasures are set up, limiting or totally disposing of imperfections and personal time connected with absconded items.

Early hardware the board: The TPM mainstay of early gear the executives takes the down to earth information and in general comprehension of assembling gear obtained through absolute useful support and uses it to work on the plan of new gear. Planning hardware with the contribution of individuals who use it most permits providers to further develop practicality and the manner by which the machine works in ongoing plans. While examining the plan of gear, it’s vital to discuss things like the simplicity of cleaning and grease, openness of parts, ergonomically putting controls in a way that is agreeable for the administrator, how changeovers happen and wellbeing highlights. Adopting this strategy builds effectiveness significantly more on the grounds that new gear as of now meets the ideal details and has less startup issues, consequently arriving at arranged execution levels faster.

Preparing and schooling: Lack of information about gear can wreck a TPM program. Preparing and schooling applies to administrators, chiefs and support faculty. They are expected to guarantee everybody is in total agreement with the TPM interaction and to address any information holes so TPM objectives are feasible. This is the place where administrators master abilities to proactively keep up with gear and distinguish arising issues. The support group figures out how to carry out a proactive and preventive upkeep timetable, and directors become knowledgeable in TPM standards, representative turn of events and training. Utilizing apparatuses like single-point illustrations posted on or approach hardware can additionally assist with preparing administrators on working strategies.

Wellbeing, wellbeing and climate: Maintaining a protected work space implies representatives can play out their errands in a protected spot without wellbeing gambles. It’s vital to create a climate that makes creation more effective, however it ought not be at the gamble of a representative’s security and wellbeing. To accomplish this, any arrangements presented in the TPM cycle ought to constantly think about wellbeing, wellbeing and the climate. Beside the conspicuous advantages, when representatives come to work in a protected climate every day, their demeanor will in general be better, since they don’t need to stress over this huge viewpoint. This can expand usefulness in a recognizable way. Considering wellbeing ought to be particularly common during the early hardware the executives phase of the TPM interaction.

TPM in organization: A decent TPM program is just comparable to the amount of its parts. Absolute useful support should look past the plant floor by tending to and disposing of areas of waste in managerial capacities. This implies supporting creation by further developing things like request handling, obtainment and planning. Regulatory capacities are frequently the initial phase in the whole assembling process, so it’s significant they are smoothed out and squander free. For instance, in the event that request handling techniques become more smoothed out, material gets to the plant floor speedier and with less mistakes, disposing of expected vacation while missing parts are found.

Instructions to Implement Total Productive Maintenance (TPM)

Since you have a comprehension of the establishment (5-S framework) and points of support on which the TPM interaction is constructed, we should investigate how to carry out a TPM program. This is for the most part done in five stages: recognizing a pilot region, reestablishing gear to prime working condition, estimating OEE, tending to and lessening significant misfortunes, and carrying out arranged upkeep.

All out Productive Maintenance 5 stages

Stage 1: Identify a Pilot Area

Utilizing a pilot region to start execution helps acquire acknowledgment from staff when they see the advantages that emerge from the interaction. While picking gear for a pilot region, think about these three inquiries:

Stage 2: Restore Equipment to Prime Operating Condition

The idea of reestablishing hardware to prime working condition rotates around the 5-S framework and independent support. To start with, TPM members ought to figure out how to consistently hold hardware to its unique condition utilizing the 5-S framework: put together, tidiness, organization, normalize and support. This may include:

a) Shooting the region and present status of the gear and afterward presenting them on your undertaking board.

b) Clearing the region by eliminating unused apparatuses, flotsam and jetsam and whatever can be viewed as waste.

c) Sorting out the devices and parts you use routinely (a shadow board with instrument traces is a famous choice).

d) Cleaning the gear and the encompassing region completely.

e) Shooting the enhancements of the hardware and encompassing region and afterward presenting on the task board.

f) Making a normalized 5-S work interaction to keep up with the coherence of this cycle.

g) Examining the cycle with reducing recurrence (first every day, then, at that point, week after week, and so on) to guarantee the 5-S process is being followed (update the interaction to keep it current and important).

Whenever you’ve laid out a benchmark condition of the hardware, you can carry out the independent upkeep program via preparing administrators on the best way to clean gear while examining it for wear and anomalies. Making an independent upkeep program likewise implies fostering a normalized method for cleaning, examine and grease up hardware accurately. Things to address during the arranging time frame for the independent upkeep program include:

1) Recognizing and archiving assessment focuses, including parts that suffer wear.

2) Expanding perceivability where conceivable to assist with examination while the machine is running (supplanting dark monitoring with straightforward watching).

3) For and obviously naming set focuses with their relating settings (the vast majority set marks with settings straightforwardly on the gear).

4) Recognizing all grease focuses and booking upkeep during changeovers or arranged vacation (consider putting challenging to-get to oil focuses that require halting the machine outwardly of the gear).

5) Preparing administrators to make them mindful of any arising or possible issues so they can report them to the line manager.

6) Making an independent upkeep agenda for all administrator controlled undertakings.

7) Reviewing the cycle with reducing recurrence to guarantee the agenda is being followed.

Stage 3: Measure OEE

1. Stage three expects you to follow OEE for the objective hardware, either physically or utilizing mechanized programming (as long as it incorporates code following for spontaneous stoppage time). For subtleties on the most proficient method to work out OEE physically, reference Reliable Plant’s article on OEE. Routinely estimating OEE gives you an information driven affirmation on whether your TPM program is working and allows you to follow progress over the long run.

2. Since the greatest misfortunes with respect to gear are the consequence of spontaneous personal time, it’s critical to classify each impromptu stoppage occasion. This gives you a more precise gander at where a stoppage is happening. Incorporate an “obscure” or “unallocated” stoppage time classification for obscure causes.

3. It’s suggested that you accumulate information for at least two weeks to get an exact portrayal of the spontaneous stoppage time and a reasonable image of what little pauses and slow cycles mean for creation. The following is a worked on illustration of a main 5 misfortune diagram. Every misfortune is classified and is in slipping request from the misfortune that makes the most vacation the misfortune that causes the least.

Top 5 Loss Chart

Stage 4: Address/Reduce Major Losses

Whenever you have an information driven preview of where your top misfortunes are, it’s an ideal opportunity to address them. This progression utilizes the recently talked about mainstay of centered improvement or kaizen. To do this, set up a cross-practical group of administrators, upkeep faculty and managers that can analyze the OEE information utilizing underlying driver investigation and recognize the primary cause(s) of the misfortunes. Your group’s interaction may look something like this:

Select a misfortune in view of OEE and stoppage time information. This should be the greatest wellspring of impromptu stoppage time. Investigate the manifestations of the problem(s). Gather point by point data on indications like perceptions, actual proof and visual proof. Utilizing a fishbone outline to follow manifestations and record data which.

Stage 5: Implement Planned Maintenance

1. The last advance of the TPM execution process is the combination of proactive upkeep methods into your program. This includes working off the third mainstay of arranged support. Pick what parts ought to get proactive support by seeing three elements: wear parts, parts that fizzle and emphasize focuses. Distinguishing emphasize focuses is frequently finished by utilizing infrared thermography and vibration investigation.

2. Then, utilize proactive upkeep spans. These spans are yet to be determined and can be refreshed on a case by case basis. For wear and anticipated disappointment based parts, lay out the current wear level and afterward a standard substitution stretch. Once these are not entirely set in stone, you can make a proactive substitution timetable of all wear-and disappointment inclined parts. While doing this, utilization “run time” rather than “schedule time.” Finally, foster a normalized interaction for making work orders in view of the arranged upkeep plan.

3. You can enhance upkeep stretches by planning an input framework. Things like log sheets for each wear-and disappointment inclined part where administrators can record substitution data and part condition at the hour of substitution will be critical. Also, direct month to month arranged support reviews to check the upkeep plan is being followed and the part logs are being stayed up with the latest. Survey the logs’ data to check whether acclimations to the support plan should be made.

What might be said about The Remaining Four TPM Pillars?

Absolute Productive Maintenance: A Case Study

1. Previously, American enterprises have been hesitant to execute complete useful support into their present cycles. Truth be told, a study done by the Manufacturing Research Center showed that main 27% of respondents said TPM was an ebb and flow business drive, however just 6% said they were completely executing it. Also, just 5% of respondents said TPM was their plant’s way to deal with support and dependability.

2. Notwithstanding this indifference, plants all over the planet are receiving huge rewards from making absolute useful upkeep the focal point of their support endeavors. A review distributed in the International Journal of Innovative Science, Engineering and Technology observed that, in a limited scale polymer organization, the OEE esteem before TPM execution was 75%. After a TPM program was executed, OEE improved to 85 percent, and a superior quality rate was accomplished. The concentrate additionally uncovered how benefit expanded by 12%, as breakdown and support costs dropped pointedly (80 and 20 percent) while work proficiency expanded. Numerous other substantial and theoretical advantages were likewise revealed because of executing a TPM program.

3. One of the most talked about contextual investigations for TPM execution is that of Latin American blending organization Cervecería Cuauhtémoc Moctezuma, producers of six brew brands including Tecate, Dos Equis and Sol. This article spreads out the organization’s TPM achievement exhaustively, showing how to complete useful support works out in a certifiable situation.

Conclusion

Today, with expanding rivalry and intense business sectors, TPM might choose the achievement or the disappointment of an organization. TPM has been a demonstrated program for a long time and associations, particularly into assembling, can embrace this system with no gamble.