- Introduction to Just-in-Time (JIT)

- What Is Just-in-Time (JIT) in Inventory Management?

- How Exactly Treat Mean by Just-in-Time?

- History of Just-in-Time Manufacturing

- Components associated with JIT

- Steps in Cycle of Continuous Improvement for JIT Inventory

- What are the Tools of just–in -time?

- Features of Just in Time Inventory System

- How might Just-In-Time (JIT) JIT be applied effectively?

- Advantage Just-In-Time Systems

- Precautions

- Conclusion

- Without a moment to spare assembling was an idea acquainted with the United States by the Ford engine organization. It deals with an interest pull premise, despite until recently utilizing procedures, which chipped away at a creation push premise.

- To expand further, without a moment to spare assembling (casually alluded to as JIT creation frameworks), real orders direct what ought to be made, so the specific amount is delivered at the specific time that is required.

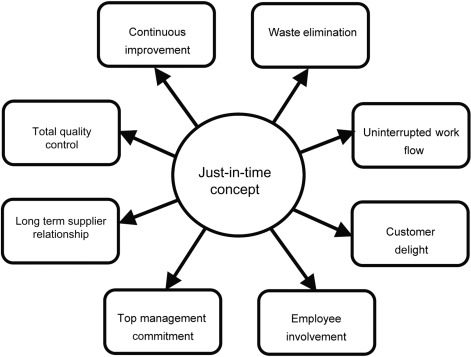

- In the nick of time producing goes connected at the hip with ideas like Kanban, persistent improvement, and all-out quality administration (TQM). In the nick of time creation requires complicated preparation as far as acquisition arrangements and the assembling system assuming its execution is to be a triumph.

- Profoundly progressed innovative emotionally supportive networks give the essential back-up that Just-in-time fabricating requests with creation planning programming and electronic information trade being the most pursued.

- There are a bigger number of benefits than drawbacks to rehearsing JIT if you have a demonstrated, dependable inventory network and exact interest arranging.

- JIT has likely dangers on the off chance that you don’t have exact and as often as possible refreshed deals estimates.

- Before executing JIT, ensure your stock framework works with JIT stock administration.

- JIT stock administration guarantees that stock shows up as it is required for the creation or to satisfy customer need, yet no sooner. The objective is to kill waste and increment the productivity of your activities. Since the principle objective is regularly quality and not the most minimal value, JIT requires long-haul contracts with solid providers.

- JIT’s known as a lean administration process. In JIT, all pieces of any creation or administration framework, especially individuals, are interconnected. They illuminate one another and are commonly reliant upon producing effective results. This present practice’s starting point comes from Kaizen, a Japanese expression signifying “improve.” Originating in Japan, the business reasoning looks to persistently further develop activities and include all representatives, from sequential construction system laborers to the CEO. Like JIT, the objective is to lessen squander and work on quality.

- It’s obscure precisely when Japanese makers started taking on JIT producing rehearses, however, it is sure that they were set off by the financial environment of the post-World War II period. Following the conflict, Japan missed the mark on money to back huge clusters, enormous stock creation strategies utilized by other created nations. They additionally had high joblessness and an absence of plentiful normal assets.

- To make due, they needed to “incline out” their cycles. They constructed more modest processing plants, which zeroed in on rapidly transforming modest quantities of unrefined components into limited quantities of actual items. Handling more modest clusters permitted the makers to decrease monetary danger while easing back producing manageable degrees of working capital. The framework that they utilized came to be known as without a moment to spare assembling, advocated in Western media as the Toyota Production System.

- Housekeeping – actual association and discipline

- End of imperfections

- Arrangement decrease and adaptable changeover draws near

- Little part estimates

- Uniform plant load – evening out as a control system

- Adjusted stream – effectively overseeing stream by restricting clump sizes

- Expertise expansion – multi-practical laborers

- Control by perceivability – utilizing visual devices to further develop correspondence

- Planning for process

- Smoothing out the development of materials

- Cell producing

- Pull framework

- Kanban

- The primary focal point of JIT is to distinguish and address the obstructions in the creative interaction. It shows the secret issues of stock. The superb goal of JIT is to build the stock turnover and lessen the holding and all associated costs.

- Without a moment to spare technique keeps an organization from utilizing exorbitant stock and smoothens creation activities assuming a particular assignment takes surprisingly long or an imperfect part is found in the framework. This is additionally one of the principle motivations behind why the organizations (which are picked JIT) put resources into preventive support; when a section/gear separates, the whole presentation process stops.

- This idea was made relevant again by the Japanese firms, putting in a request for the material, that very day of the development of the item. The Just In Time approach takes out the prerequisite to convey voluminous inventories and brings about weighty conveying other related expenses for the producer.

- To profit from the advantages of the JIT framework, there should be an ideal synchronization between the assembling cycle and the conveyance of material. Simply In Times requires a decent comprehension of the provider and the producer as far as the amount and conveyance of the material. In case of any misconception between the maker and provider of the material, the whole presentation interaction might stop.

- One illustration of a JIT framework is a vehicle maker, a producer of vehicles that works with absolute minimum stock levels, as there is a solid dependence on the store network to convey the parts expected to make vehicles. The parts expected in the assembling of vehicles don’t show up previously or after they are required; rather, they show up just when they are required.

- Effective JIT execution completely relies upon how the producer deals with its providers. A ton of tension is applied on them, as the provider of the materials must be prepared with plentiful quality material, as the need emerges.

- Tackling central issues and whatever doesn’t enhance the item.

- Concocting frameworks to distinguish creation and united issues.

- Straightforwardness: Simple frameworks are basic and straightforward, effectively sensible and the possibilities of turning out badly are extremely low.

- An item situated designed for less time spent on materials and parts development.

- Quality control at source to guarantee each laborer is exclusively liable for the nature of their own created yield.

- Squander from item surrenders.

- Exercise in futility.

- Transportation squander.

- Stock waste.

- Squander from overproduction.

- Handling waste.

- Lessen support stock.

- Pursue zero stock

- Look for dependable providers.

- Lessen part size and increment the recurrence of orders.

- Diminish buying cost.

- Work on material dealing with.

- Heijunka

- Kanban

- Standardized Work and

- Takt Time

- Make a settled plan for getting work done.

- Layout long-haul provider-client connections.

- Make a buying theory on supporting successive little buys.

- Energize and guarantee worker discipline.

- Distinguish esteem added and non-esteem added things in shop floor exercises.

- Guarantee top administration responsibility for viability and fruitful execution.

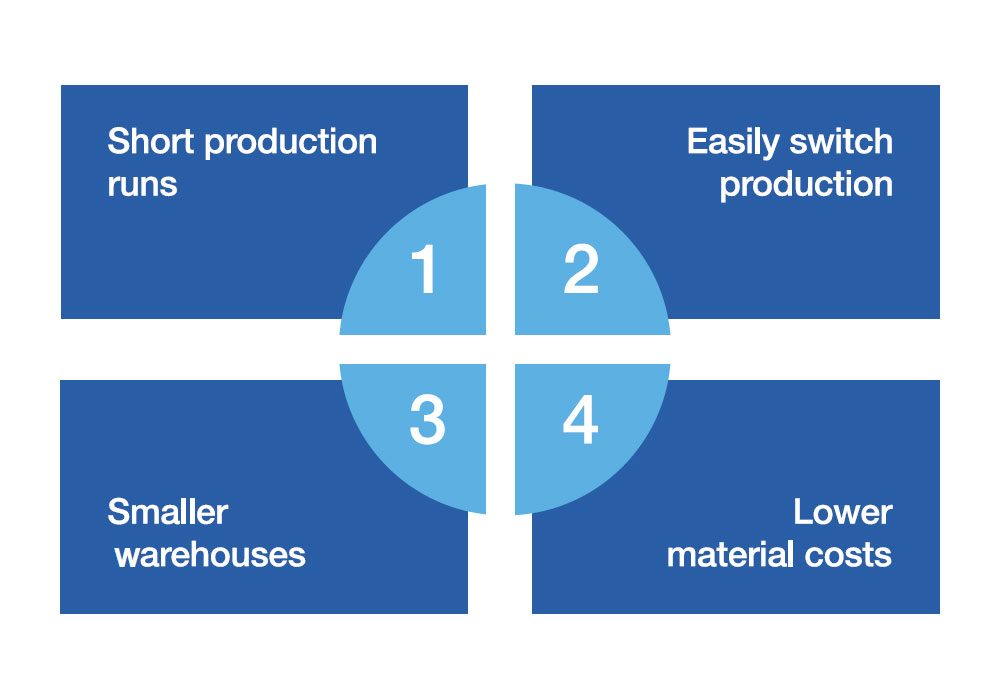

- Without a moment to spare assembling disposes of waste, as obsolete or lapsed items; don’t go into this situation by any means.

- As under this strategy, just fundamental stocks are gotten, less working capital is expected to back obtainment. Here, a base re-request level is set, and just once that imprint is reached, new stocks are requested making this a help to stock administration as well.

- Due to the previously mentioned low degree of stocks held, the association’s profit from speculation (alluded to as ROI, in administration speech) would commonly be high.

- As in the nick of time creation chips away at an interest pull premise, generally, merchandise made would be sold, and subsequently it joins changes sought after without any difficulty. This makes it particularly engaging today, where the market request is unstable and fairly flighty.

- Without a moment to spare assembling supports the ‘right first-time’ idea, so review expenses and cost of revise is limited.

- Excellent items and more noteworthy effectiveness can be gotten from following a without a moment to spare creation framework.

- Cozy connections are cultivated along the creation chain without a moment to spare assembling framework.

- Steady correspondence with the client brings about high consumer loyalty.

- Overproduction is killed when in the nick of time producing is embraced.

- Without a moment to spare assembling gives no resilience to botches, as it makes re-working undeniably challenging by and by, as stock is kept to an absolute minimum.

- There is a high dependence on providers, whose exhibition is for the most part outside the domain of the producer.

- Because there is no support for delays, creation vacation and line sitting can happen which would bear an adverse impact on funds and the harmony of the creative interaction.

- The association would not have the option to meet a surprising expansion in orders because of the way that there are no overabundance of finish products.

- Exchange costs would be moderately high as regular exchanges would be made.

- Without a moment to spare assembling might have specific hindering impacts on the climate because of the incessant conveyances that would bring about expanded utilization of transportation, which thus would consume more petroleum derivatives.

- The board purchase in and support at all levels of the association are required; assuming an in the nick of time producing framework is to be effectively embraced.

- Satisfactory assets ought to be distributed, to acquire mechanically progressed programming that is by and large required assuming a without a moment to spare framework is to be a triumph.

- Building a nearby, entrusting relationship with presumed and reliable providers will limit startling deferrals in the receipt of stock.

- In the nick of time producing can’t be embraced for the time being. It requires responsibility as far as time and acclimations to corporate culture would be expected, as it is unique to conventional creation processes.

- The plan stream process should be upgraded and designs should be re-organized, consolidated in the nick of time producing.

- Parcel sizes should be limited.

- Workstation limit ought to be adjusted whenever the situation allows.

- Preventive support ought to be completed, to limit machine breakdowns.

- Set-up times should be diminished at every possible opportunity.

- Decrease in lead times and continuous conveyances ought to be fused.

- Movement waste should be limited, so the joining of transport lines may end up being smart while carrying out an in the nick of time fabricating framework.

- Disposal of Waste.

- Regard for People.

- Absolute Quality Control.

- A Stable Schedule.

- Work with Suppliers.

Introduction to Just-in-Time (JIT):

What Is Just-in-Time (JIT) in Inventory Management?

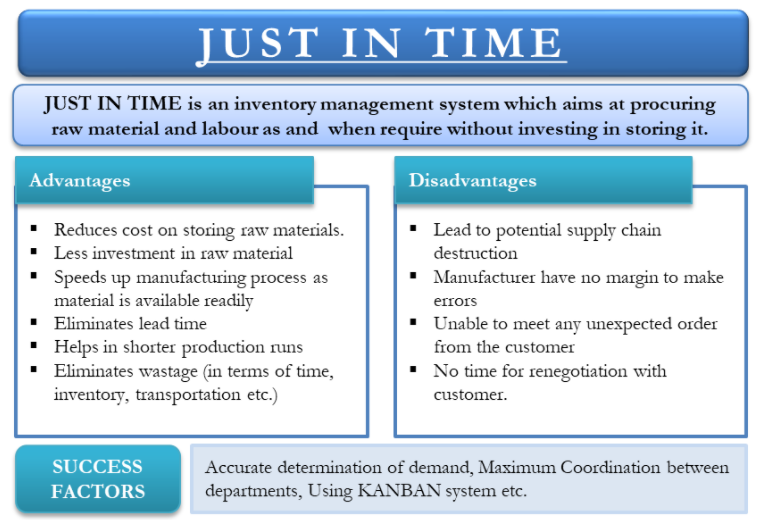

JIT is a type of stock administration that requires working intimately with providers so unrefined components show up as creation is planned to start, however no sooner. The objective is to have the base measure of stock close by to fulfill the need.

Key focal points from this tutorial:

Without a moment to spare (JIT) Inventory Management Explained:

JIT stock guarantees there is sufficient stock to deliver just what you want when you want it. The objective is to accomplish high volume creation with negligible stock available and take out squander.

How Exactly Treat Mean by Just-in-Time?

An in the nick of time (JIT) stock framework is an administration methodology that has an organization get products however close as conceivable to when they may be required. Thus, if a vehicle get together plant needs to introduce airbags, it doesn’t keep a supply of airbags on its racks yet gets them as those vehicles go onto the sequential construction system.

Types of Companies Use JIT

The JIT stock framework is well known with independent ventures and large companies the same since it improves income and decreases the capital expected to maintain the business. Retailers, eateries, on-request distributing, tech assembling, and car fabricating are instances of enterprises that have profited from without a moment to spare stock.

How Does Just-in-Time Inventory Management Work?

History of Just-in-Time Manufacturing:

JIT 101:

Supporting a JIT-producing framework requires discipline, structure, and unequivocal cycles. As well as rigorously restricting stock, the accompanying strategies are remembered for a genuine JIT framework:

Significant of JIT Concept:

Components associated with JIT:

Ceaseless Improvement:

Killing waste:

There are seven sorts of waste:

Squander minimization is one of the essential targets of the Just In Time framework. This needs powerful stock administration all through the entire production network. At first, an assembling element will try to decrease stock and upgrade activities inside its association. While trying to diminish squander ascribed to ineffectual stock administration, SIX standards comparable to JIT have been expressed by Schniededans and they are:

Steps in Cycle of Continuous Improvement for JIT Inventory:

Design: The JIT cycle starts with a survey of the fundamental assembling building blocks: item configuration, process plan, workforce, and assembling arranging. Then, at that point, plans are instituted to dispose of disturbance, limit waste and construct an adaptable framework.

Manage: – A Total Quality Management (TQM) survey guarantees there is consistent improvement all through the cycle. An administration survey characterizes laborers’ jobs and obligations, characterizes and gauges measurable quality control, settles timetables, and looks at burden and limit timetables and levels.

Pull:– Educate the group on creation and withdrawal strategies utilizing flagging techniques like Kanban. Survey part size arrangements and decrease parcel sizes.

Establish:– Vendor connections are essential to the achievement of JIT. Survey seller records. Choose favored providers, arrange contracts, talk about lead times, conveyance assumptions, and use measurements and measures. Figure out how to take advantage of them in the store network.

Fine-tune:– Determine stock requirements, strategies, controls, and lessen stock developments.

Build:– Inform your group about the abilities and capacities it needs to finish its work and lead group schooling and strengthening meetings to instruct them.

Refine:– Reduce the number of parts and steps underway by refining, normalizing, and evaluating the whole interaction.

Review:– Define and carry out quality measures and measurements and lead an underlying driver examination of any issues. Underline upgrades and track patterns to work on each part of JIT.

What are the Tools of just–in -time?

(JIT) Depends on many lean devices, like Continuous Flow:

Features of Just in Time Inventory System:

In the nick of time stock framework has various qualities that put it aside from other stock frameworks. The following are a couple of normal ones:

More modest conveyances got all the more frequently: These conveyances can be day by day or even hourly on a case-by-case basis to keep the creation of deals process proceeding to stay aware of the interest.

Higher provider quality: Since you lack the opportunity and willpower to review products each time they show up, JIT providers are normally confirmed for quality. This implies you can believe the materials that show up will be up to the norm.

Special work game plans: JIT creation regions should be more adaptable than typical creations. This implies they are more modest and permit in-process products to be passed from each work community rapidly and productively.

Broadly educated workers: JIT representatives are frequently confirmed to chip away at various assignments inside the creation cycle. This gives them more work to do and reduces expenses to the professional at the expense of actual counts of stock.

Prompt satisfaction upon fulfillment: There is little stockpiling for finished merchandise or materials. Thusly, when you finish a decent, it is quickly put on a truck for shipment to the client.

How might Just-In-Time (JIT) JIT be applied effectively?

Advantage Just-In-Time Systems:

Following are the benefits of Adopting Just-In-Time Manufacturing Systems. In the nick of time fabricating downplays stock holding costs. The arrival of the extra room brings about better usage of room and in this manner bears a positive effect on the lease paid and on any protection expenses that would somehow be made.

Disadvantage:

Following are the impediments of Adopting Just-In-Time Manufacturing Systems:

Precautions:

Following are what to Remember When Implementing a Just-In-Time Manufacturing System:

Certification Costs:

Let’s assume you deal with a huge chain of outdoor supplies stores. You’re thinking about the effect of JIT buying for some items. Right now, you’re assessing homerun sticks. Here is some data concerning slugging stick buys:

Buying costs: The expense per polished ash is $100 for both your present buying strategy and JIT buying.

Requesting costs: The expense per request is $150 for both buying techniques.

Opportunity costs: Company the board has settled on an 8 percent required pace of profit from speculation. That 8% rate applies to any utilization of capital, including stock buys. This is the base return that the organization anticipates from the cash it has contributed. On the off chance that this return isn’t accomplished, there are reasonable better options for the organization’s money.

Normal stock: Average stock is characterized as the normal worth of stock during a specific time frame. Normal stock is (starting stock + finishing stock) ÷ 2. At present, your normal stock is 10% of yearly deals or 2,000 bats. Under JIT, your normal stock will decrease to 200 units.

Conveying costs: You additionally bring about costs for protection and capacity. Conveying costs an absolute $15 per unit.

Pre-Requisites:

Conclusion:

JIT Inventory Control is exceptionally viable and effective in disposing of waste. The interaction additionally empowers organizations to involve a greater amount of the stockroom for getting together and creating. Thusly space isn’t squandered and used rather to a most extreme limit. This likewise decreases stock expenses. JIT Inventory Control requires participation and responsibility among providers and the producer. Without an affectionate provider producer relationship and unwavering quality, JIT Inventory Control is pointless.

Although with numerous providers, makers can expect value wars and rivalry appreciating lower costs. Nonetheless, this puts unwavering quality in question. With restricted or hardly any providers as for the situation with Toyota, a nearby bond can be kept up with and unwavering quality isn’t endangered. If it is potential, organizations ought to take on JIT Inventory Control and keep up with long haul provider producer associations with trustworthy providers for the interaction to stream without a hitch.