- Electric Vehicle Powertrain: An Overview

- Powertrain Overview

- Electric Motor Integration

- Battery Pack Role

- Power Electronics (Inverter/Controller)

- Transmission Systems

- Regenerative Braking

- Thermal Management

- Efficiency and Range

- Vehicle Dynamics Integration

- Design Challenges

- Powertrain Testing

- Emerging Technologies

- Conclusion

Electric Vehicle Powertrain: An Overview

Electric vehicles (EVs) have changed the automotive industry by offering cleaner and more efficient alternatives to traditional internal combustion engine (ICE) vehicles. At the core of an EV is its powertrain, which converts electrical energy into mechanical motion. This article provides a clear overview of the electric powertrain, covering critical parts, design challenges, emerging technologies, and how it integrates with vehicle dynamics.

Powertrain Overview

The powertrain of an electric vehicle consists of various components that work together to transfer power from the battery to the wheels. Unlike traditional vehicles, which use an engine, transmission, and exhaust systems, EV powertrains are more streamlined. Key components include the electric motor, battery pack, power electronics (inverter and controller), transmission systems, and regenerative braking mechanisms. The purpose of the powertrain is to maximize efficiency, performance, and reliability while reducing energy losses. By converting electrical energy from the battery into mechanical power to drive the wheels, the powertrain shapes the vehicle’s driving characteristics and range.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Electric Motor Integration

The electric motor is the center of the EV powertrain. It converts electrical energy into mechanical torque, propelling the vehicle. Various types of motors are used, including brushless DC motors (BLDC), induction motors, and permanent magnet synchronous motors (PMSM). Each type has its advantages and trade-offs regarding efficiency, cost, and power density. Integrating the motor into the vehicle’s chassis requires careful mechanical and electrical design. Motors can be mounted centrally with a driveshaft or directly in the wheel for better torque vectoring and improved dynamics. In-wheel motors simplify mechanical design by removing traditional drivetrain parts but present challenges, such as unsprung mass and thermal management. The motor’s control system adjusts torque and speed based on driver inputs and vehicle conditions, ensuring smooth acceleration, regenerative braking, and efficient operation.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Battery Pack Role

The battery pack stores energy in an EV and is arguably the most important part determining range and performance. Modern EVs use lithium-ion batteries because of their high energy density, reliability, and long lifespan.

- Cell Configuration: Battery packs consist of hundreds to thousands of individual cells arranged in series and parallel to achieve the necessary voltage and capacity.

- Battery Management System (BMS): Monitors cell voltages, temperatures, and health to ensure safe and optimal operation.

- Capacity and Range: Battery capacity directly affects the vehicle’s driving range.

- Power Delivery: Influences acceleration and overall performance.

- Cooling Systems: Advanced cooling systems keep battery temperatures within safe limits, extending battery life and efficiency.

- Controller Functions: Manages power flow and operational modes such as driving, regenerative braking, and idle states.

- Sensor Integration: Processes inputs from sensors and the accelerator pedal to optimize performance and energy efficiency.

- Semiconductor Advances: Silicon carbide (SiC) and gallium nitride (GaN) transistors improve inverter efficiency and thermal performance.

- Multi-Speed Gearboxes: Used in high-performance EVs to improve acceleration, top speed, and driving efficiency.

- Differential Gears: Distribute torque to the drive wheels, enhancing traction and handling.

- NVH Considerations: Transmission integration must address noise, vibration, and harshness for a smooth and quiet ride.

- Motor Reversal: During braking, the electric motor runs in reverse, acting as a generator.

- Power Electronics: Manage the transition smoothly, balancing braking force between regenerative and friction systems.

- Safety and Stability: Ensures controlled

- Cooling Methods: EV powertrains use liquid cooling, air cooling, or phase-change materials to manage temperatures.

- Battery Cooling: Battery packs often include cooling channels or heat pipes to evenly distribute thermal loads and prevent hotspots.

- Electronics and Motor Cooling: Dedicated systems handle heat from electrical losses in power electronics and motors.

- System Efficiency: Advanced thermal management extends component lifespan and improves overall efficiency.

- Motor Design: Impacts how effectively electrical energy is converted into mechanical output.

- Inverter Performance: Determines how efficiently DC power is transformed and managed for motor operation.

- Drivetrain Losses: Mechanical inefficiencies can reduce overall energy transfer to the wheels.

- Auxiliary Systems: Climate control and other subsystems consume energy and affect total efficiency.

- Range Optimization: Reducing energy losses increases driving range per

- Torque Vectoring: Advanced control algorithms distribute power independently to each wheel to improve handling and cornering.

- All-Wheel Drive Optimization: Torque vectoring is especially beneficial in all-wheel-drive EVs for enhanced control.

- System Integration: The powertrain interacts with traction control, stability control, and ABS systems to maintain vehicle control.

- Safety Response: These systems work together during rapid acceleration or emergency braking to ensure stability and safety.

- Weight Management: Battery packs add considerable weight, requiring lightweight materials and compact designs to keep vehicle efficiency.

- Thermal Issues: Managing heat in closely packed electrical components is essential to prevent performance decline or failure.

- Cost: High-quality batteries and power electronics can increase vehicle prices, challenging manufacturers to balance performance and affordability.

- Reliability and Durability: EV powertrains must endure harsh operating conditions and provide long service life similar to traditional vehicles.

- Packaging Constraints: Fitting all components into existing vehicle platforms while ensuring interior space and safety standards requires innovative engineering.

- Efficiency Curves: Tests measure how effectively the powertrain converts energy across different load conditions.

- Thermal Behavior: Evaluates heat management in tightly packed electrical components to prevent failure.

- Noise and Vibration: Assesses acoustic comfort and mechanical stability during operation.

- Regenerative Braking: Verifies energy recovery performance under various driving scenarios.

- Real-World Simulations: Confirms the powertrain’s ability to handle diverse operating conditions.

- Accelerated Life Testing: Predicts component longevity under stress and extended use.

- SIL and HIL Testing: Validates control algorithms before deployment using software and hardware simulations.

- Solid-State Batteries: These offer higher energy density, faster charging, and improved safety compared to lithium-ion cells.

- Wide Bandgap Semiconductors: SiC and GaN are improving inverter efficiency and lowering cooling needs.

- Integrated Motor Drive Units: These combine motor, inverter, and gearbox into compact, efficient modules.

- Wireless Charging: This allows easy and continuous charging without physical connectors.

- Artificial Intelligence: AI enhances predictive maintenance, optimizes energy management, and improves vehicle control systems.

- Hydrogen Fuel Cell Integration: This offers extended range options and fast refueling capabilities in hybrid powertrains.

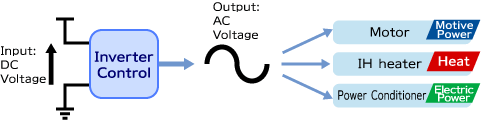

Power Electronics (Inverter/Controller)

Power electronics connect the battery and electric motor. The inverter converts the DC voltage from the battery into AC voltage for the motor, controlling frequency and amplitude to manage motor speed and torque.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Transmission Systems

Unlike traditional ICE vehicles, most EVs have a simplified transmission system. Many use a single-speed reduction gearbox because electric motors provide a wide torque band, making multi-speed transmissions unnecessary.

Regenerative Braking

Regenerative braking is a key feature of EVs. It captures kinetic energy during deceleration and converts it back into electrical energy to recharge the battery. This process extends driving range and reduces wear on mechanical brake parts.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Thermal Management

Thermal management is vital for maintaining optimal operating temperatures for the battery, motor, and power electronics. Effective heat dissipation ensures reliability, performance, and safety.

Efficiency and Range

Efficiency is an important measure in electric powertrain design. It reflects how well the system converts stored electrical energy into mechanical power and, ultimately, vehicle motion.

Vehicle Dynamics Integration

Integrating the powertrain with the vehicle’s dynamics involves balancing performance, safety, and comfort. Torque delivery must be carefully managed to prevent wheel slip and ensure stability under various road conditions.

Design Challenges

Designing an electric powertrain comes with unique challenges:

Powertrain Testing

Testing is crucial to verify the performance, durability, and safety of the EV powertrain. This includes bench testing individual components (motors, inverters, batteries) and system-level testing on dynamometers and test tracks.

Emerging Technologies

The future of electric powertrains will be shaped by emerging technologies:

Conclusion

The electric vehicle powertrain is a complex system that integrates various technologies to deliver clean, efficient, and high-performance mobility solutions. From electric motors and battery packs to power electronics and regenerative braking, every component plays a vital role in the vehicle’s function and efficiency. Ongoing innovation in battery technology, thermal management, and control systems will continue to improve EV range, reliability, and affordability. As these technologies evolve, electric powertrains will become more common, driving the automotive industry toward a more sustainable future.