- Electric Vehicle Components

- Electric Motor

- Battery Pack

- Battery Management System

- Power Electronics (Inverter, Converter)

- Charging Port and Onboard Charger

- Transmission System

- Thermal Management System

- Controller and Embedded Software

- Regenerative Braking System

- Emerging Innovations in Components

- Conclusion

Electric Vehicle Components

The design and integration of Electric Vehicle Components form the foundation of modern EV architecture, ensuring optimal performance, safety, and sustainability. These Electric Vehicle Components work cohesively to deliver zero-emission mobility, combining advanced electrical systems, efficient motors, and intelligent control units. To explore how intelligent systems integrate these components for optimized performance, predictive diagnostics, and sustainable mobility, explore Artificial Intelligence Training a hands-on course that covers embedded AI, machine learning, and smart control strategies for next-generation EV technologies. As technology continues to evolve, understanding these components becomes essential for innovation and progress in the electric mobility sector.

Electric Motor

The electric motor acts as the core of an electric vehicle (EV). It plays an important role in converting electrical energy into mechanical energy to move the vehicle forward. Different types of electric motors are used in EVs. Each type offers distinct advantages suited to various performance needs. Brushless DC (BLDC) motors are known for their high efficiency, compact design, and low maintenance, making them a popular choice for many applications. To understand how motor selection aligns with energy storage, charging cycles, and overall vehicle performance, explore Electric Vehicle Battery Guide a comprehensive resource that explains battery chemistries, capacity planning, lifecycle management, and the critical role of batteries in powering efficient electric mobility. On the other hand, Permanent Magnet Synchronous Motors (PMSM) are great for providing high torque density and quick responsiveness. This makes them particularly popular in luxury and performance-oriented electric vehicles. For commercial or high-load EVs, Induction Motors are often used because of their durability and cost-effectiveness. They provide a dependable option for heavy-duty tasks. Additionally, Switched Reluctance Motors (SRM) are recognized for their strong construction and ability to work without permanent magnets. This makes them a versatile solution for various engineering issues. The efficiency of these motors is vital because it directly affects the vehicle’s overall range and performance. They also enable regenerative braking, which improves energy efficiency and adds to the driving range, highlighting the innovative technology behind modern electric vehicles.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Battery Pack

The battery pack is the EV’s energy reservoir. Lithium-ion batteries dominate the market due to their high energy density and long life cycle. A battery pack comprises hundreds or thousands of individual cells grouped into modules. To understand how such precision in design parallels the alignment and handling dynamics of vehicles, explore What is Steering Geometry a comprehensive guide that explains caster, camber, toe angles, and their critical role in ensuring stability, efficiency, and safety in both conventional and electric vehicles.

- Energy Density: Determines how much energy the battery stores per unit mass or volume.

- Voltage and Capacity: Affect acceleration, range, and peak power.

- Form Factors: Cylindrical (e.g., 2170 or 4680), pouch, and prismatic cells.

- Safety Mechanisms: Include insulation, pressure vents, thermal sensors, and fire barriers.

Designing for optimal thermal and structural integrity is crucial to ensure performance and durability across various environmental conditions.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

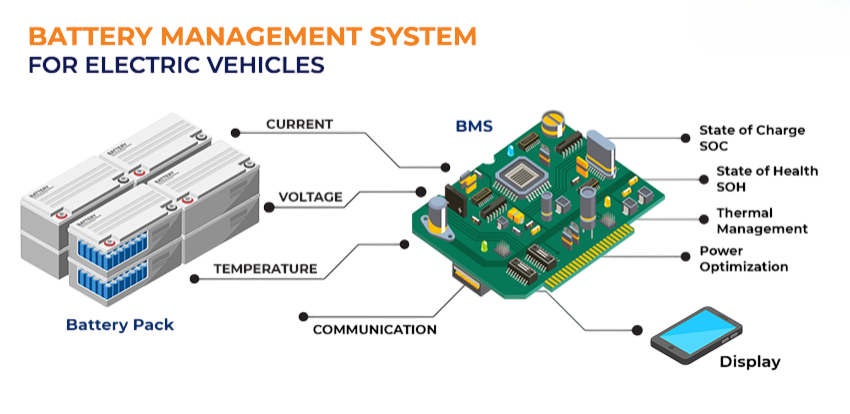

Battery Management System

The BMS is the brain of the battery pack. It continuously monitors and regulates battery performance. Its core functions include balancing cell voltages, protecting against overcharging or deep discharging, and ensuring thermal stability. To visualize how these systems are represented in design schematics and technical illustrations, explore Electric Vehicle Drawing a comprehensive guide that explains EV circuit diagrams, battery management layouts, motor connections, and the graphical representations engineers use to design and optimize electric vehicles.

- Voltage and Temperature Monitoring: Detects abnormal cell behavior.

- Cell Balancing: Ensures uniform charging and discharging across cells.

- Charge State Estimation: Calculates State of Charge (SOC) and State of Health (SOH).

- Fault Detection and Alerts: Prevents conditions like thermal runaway and overcurrent.

- Data Logging and Diagnostics: For remote monitoring and predictive maintenance.

Advanced BMS platforms support wireless communication and real-time integration with vehicle ECUs.

Power Electronics (Inverter, Converter)

Power electronics play an important role in managing and controlling energy flow in many applications, especially in electric vehicles. The inverter is a key part of these systems. It converts direct current (DC) from the battery into alternating current (AC) needed by the motor. Modern inverters use materials like silicon carbide (SiC) or gallium nitride (GaN) to improve efficiency and performance. To explore how intelligent systems optimize inverter design, enhance energy conversion, and support real-time performance monitoring, explore Artificial Intelligence Training a hands-on course that covers embedded AI, predictive modeling, and smart control strategies for advanced EV power electronics. Another important component is the DC-DC converter, which reduces high-voltage DC to lower voltages, such as 12V or 48V. This lower voltage powers auxiliary systems like lights, windshield wipers, and infotainment units. The onboard charger (OBC) is also essential. It changes AC power from the electrical grid into regulated DC to charge the vehicle’s battery. For these power electronic systems to work well, they must meet standards for compactness, effective cooling, and electromagnetic compatibility (EMC). This ensures they operate smoothly within the vehicle’s environment.

Charging Port and Onboard Charger

The charging interface is a key part that connects electric vehicles (EVs) to power sources. Charging options for EVs fall into three main levels. Level 1 charging runs on a 120V AC supply. This is the simplest form of charging and typically uses a standard home socket, but it is also the slowest option. Level 2 charging uses a 240V AC connection. It works well in both homes and workplaces and provides a quicker charging experience. To explore how evolving charging technologies, infrastructure, and innovations are shaping tomorrow’s mobility, explore Future of the Electric Vehicle a comprehensive guide that highlights advancements in charging systems, battery innovations, autonomous integration, and the global trends driving the next era of sustainable transportation. The fastest option is Level 3 charging, also known as DC Fast Charging. This can be found at public charging stations and delivers power levels from 50 kW to over 350 kW, which cuts down on charging times significantly. The onboard charger (OBC) is crucial in this scenario, as it manages the charging rates while ensuring electrical safety and grid compatibility. Notably, advanced onboard chargers can support bidirectional power flow. This allows for vehicle-to-grid (V2G) and vehicle-to-home (V2H) functions, increasing the usefulness of electric vehicles in today’s energy systems.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Transmission System

Unlike ICE vehicles, EVs often utilize simplified single-speed transmissions due to the electric motor’s broad torque band. Components include the motor, inverter, transmission, and battery pack, all working together to deliver smooth and efficient performance. To explore how these components integrate with rapid energy replenishment solutions, explore Battery Swapping EV Technology a comprehensive guide that explains modular battery packs, swapping stations, infrastructure design, and the role of this technology in reducing downtime and enhancing EV adoption.

- Reduction Gearbox: Converts motor RPM to optimal wheel torque.

- Differential: Balances wheel rotation during cornering.

- Axles and CV Joints: Deliver power smoothly to wheels.

In performance EVs like Porsche Taycan, multi-speed transmissions are used for improved top-speed efficiency.

Thermal Management System

Maintaining optimal temperature is crucial for EV efficiency, safety, and battery life. EVs utilize integrated thermal management systems to regulate heat during charging, discharging, and operation. To understand how these thermal controls integrate with monitoring, protection, and energy optimization, explore Battery Management System a comprehensive guide that explains cell balancing, voltage and current monitoring, fault detection, and the critical role of BMS in ensuring reliable electric vehicle performance.

- Liquid Cooling Loops: Circulate coolant around battery cells, inverter, and motor.

- Heat Pumps: Improve energy efficiency in HVAC and battery heating.

- PTC Heaters: Provide rapid cabin heating in cold climates.

- Thermal Insulation: Protects components from external thermal influences.

Modern thermal systems leverage predictive algorithms to adjust flow rates and activate subsystems dynamically.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

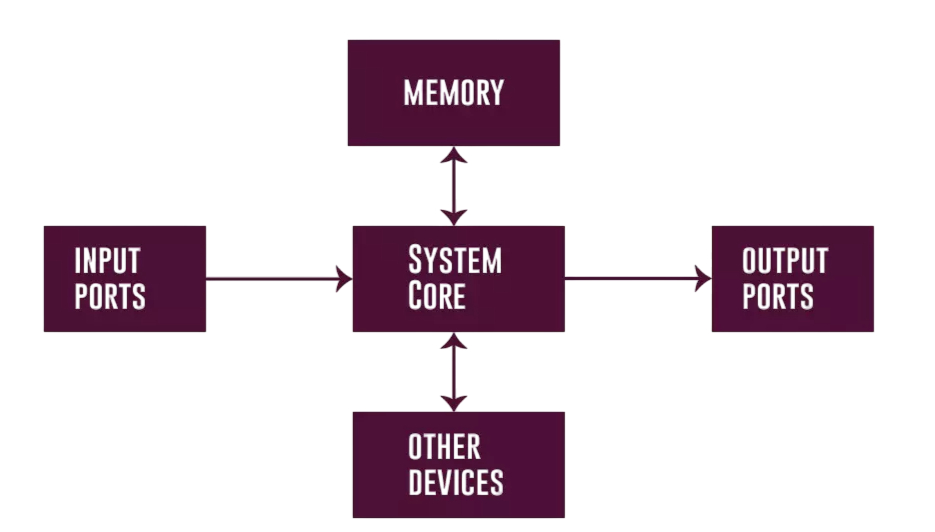

Controller and Embedded Software

Embedded software is the backbone of an electric vehicle (EV). It works across various electronic control units (ECUs) to ensure the vehicle runs well. At the center of this system is the Vehicle Control Unit (VCU).

This unit is key for powertrain control, syncing the motor, inverter, and battery for better energy management. The VCU also handles safety and diagnostics by running emergency protocols and managing faults to keep the vehicle safe. To improve the driving experience, the VCU offers adaptive drive modes. These modes adjust the vehicle’s response to match different driving styles, like eco, comfort, or sport. Another important feature of modern embedded software is Over-the-Air (OTA) updates. These updates allow for real-time software improvements and fixes without needing to access the vehicle physically.

Regenerative Braking System

Regenerative braking captures kinetic energy during deceleration and converts it into electrical energy for battery storage. Key features include:

- Energy Recovery: Up to 30% of braking energy can be recovered.

- Adjustable Regen Modes: Drivers can tune the level of braking force.

- Seamless Integration: Blends with hydraulic braking for optimal stopping.

This system reduces brake pad wear and enhances energy efficiency, especially in city driving conditions.

Emerging Innovations in Components

EV architecture is rapidly evolving with a focus on performance, sustainability, and user convenience. To understand how different propulsion systems contribute to these advancements, explore Types of Motors in Electric Vehicles a comprehensive guide that explains induction motors, BLDC motors, PMSM motors, switched reluctance motors, and their unique roles in driving efficiency, speed control, and reliability in modern EVs.

- 800V Battery Architecture: Enables ultra-fast charging and reduces cable weight.

- Wireless EV Charging: Eliminates plug-in hassle with inductive pads.

- Solid-State Batteries: Promise greater energy density and enhanced safety.

- Swappable Battery Systems: Allow quick battery replacement in fleets.

- AI-Powered Predictive Maintenance: Uses data to pre-empt failures and extend life.

- Integrated E-Axles: Combine motor, inverter, and gearbox into a single unit.

These innovations are shaping the future of mobility and driving mass EV adoption.

Conclusion

A strong understanding of Electric Vehicle Components is essential for mastering EV architecture, as each element from the motor and inverter to the battery pack and control system works in harmony to ensure performance and efficiency. To explore how intelligent systems integrate these components through predictive analytics, real-time monitoring, and adaptive control strategies, explore Artificial Intelligence Training a hands-on course that covers embedded AI, system-level optimization, and smart energy management for next-generation EV technologies. These Electric Vehicle Components not only define how energy is stored, converted, and utilized but also shape the innovation driving sustainable mobility, making them central to the future of automotive engineering.