- Foundations of Semiconductors

- Overview of IGBT

- Overview of MOSFET

- Structural Differences

- Switching Characteristics

- Frequency Performance

- Heat Dissipation

- Use Cases in EVs

- Cost Considerations

- Summary of Key Differences

- Voltage/Current Ratings

- Conclusion

Foundations of Semiconductors

Semiconductors are the backbone of modern electronics, enabling the operation of devices ranging from smartphones and computers to electric vehicles and renewable energy systems. These materials, typically silicon-based, have electrical conductivity that lies between conductors (like copper) and insulators (like glass), which makes them ideal for controlling electrical current flow. Semiconductors can be precisely engineered to act as switches, amplifiers, or rectifiers, which forms the foundation of digital and analog electronics, and plays a crucial role in Artificial Intelligence Training and modern computing systems. With the rise of power electronics, semiconductors play an increasingly crucial role in converting and controlling electric power efficiently. Two of the most important semiconductor devices used in power electronics are Insulated Gate Bipolar Transistors (IGBTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs). These devices control high voltages and currents with high efficiency and fast switching capabilities, making them vital in electric vehicles (EVs), renewable energy inverters, and industrial motor drives.

Overview of IGBT

The Insulated Gate Bipolar Transistor (IGBT) is a semiconductor device designed to handle high voltage and current levels with relatively low losses. It combines the high input impedance and fast switching of a MOSFET with the high current and low saturation voltage capability of a bipolar junction transistor (BJT). The IGBT is a voltage-controlled device widely used in medium to high-power applications, including various Types of Electric Vehicle systems, where switching speeds do not need to be extremely high. IGBTs are especially popular in industrial applications such as motor drives, induction heating, and electric vehicle inverters due to their ability to efficiently switch large power loads with moderate switching frequencies (typically below 20 kHz). They feature a gate terminal insulated from the main current-carrying channel, which makes them easy to drive with low power input signals.

Overview of MOSFET

Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) are another essential type of semiconductor switch widely used in power electronics. Unlike IGBTs, MOSFETs are majority carrier devices, relying primarily on electrons or holes without involving minority carrier injection, which contributes to their extremely fast switching speed and high frequency performance.

MOSFETs are voltage-driven devices with a gate insulated by a thin oxide layer, giving them high input impedance and low gate drive power requirements, making them ideal for applications in Hybrid Electric Vehicle systems. These characteristics make MOSFETs highly suitable for low to medium voltage applications, typically up to 250 volts, although advancements in technology have increased this limit. MOSFETs excel in applications requiring high switching frequencies (up to hundreds of kHz or even MHz), such as power supplies, DC-DC converters, and radio frequency amplifiers.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

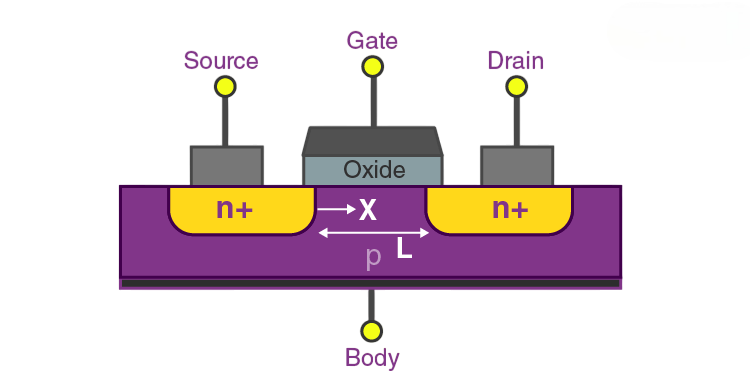

Structural Differences

The fundamental difference between IGBTs and MOSFETs lies in their internal structure and carrier mechanisms. An IGBT is a four-layer device (PNPN) that combines features of BJTs and MOSFETs. The device has an insulated gate like a MOSFET but conducts through a bipolar transistor action, allowing for high current densities. Conversely, a MOSFET is a three-layer device with a source, drain, and gate structure, commonly used in applications found in the Electric Vehicles List . The gate is insulated from the channel by a thin oxide layer, and conduction is due to majority carriers (electrons in N-channel MOSFETs or holes in P-channel MOSFETs). This structural simplicity allows faster switching but limits voltage and current handling compared to IGBTs. In practical terms, the bipolar conduction in IGBTs results in lower conduction losses at high voltages, while MOSFETs have inherently faster switching capabilities due to unipolar conduction.

Switching Characteristics

Switching characteristics are critical in determining the suitability of IGBTs and MOSFETs for different applications. MOSFETs generally exhibit faster switching times, often in the range of nanoseconds, due to the absence of minority carrier charge storage. This rapid switching ability reduces switching losses and allows MOSFETs to operate efficiently at high frequencies.

- IGBTs, on the other hand, have slower switching speeds because of the charge storage effect inherent in their bipolar conduction.

- When an IGBT turns off, stored minority carriers, relevant to EV’s Advantages and Disadvantages , must be removed, causing a tail current and switching losses.

- This phenomenon limits the switching frequency of IGBTs, typically to a few tens of kHz, though newer devices have improved in this regard.

- Since typical IGBT switching frequencies are only a few tens of kilohertz, they are more appropriate for medium-frequency, high-power applications like electric car inverters, motor drives, and induction heating.

In conclusion, IGBTs perform exceptionally well in high-power, high-voltage applications where efficiency and thermal management are more important than switching frequency, whereas MOSFETs predominate in high-frequency, low-voltage systems where switching speed is crucial.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Frequency Performance

Frequency performance is a decisive factor when selecting between IGBTs and MOSFETs. MOSFETs support switching frequencies up to several hundred kHz or even into the MHz range, making them ideal for switching power supplies, RF amplifiers, and digital circuits.

- IGBTs, due to their slower switching caused by charge storage effects, are limited to frequencies up to about 20 kHz, though some advanced designs push this higher.

- This frequency limitation makes IGBTs less suitable for high-frequency applications but perfectly adequate for motor drives and power inverters where switching frequencies are moderate.

However, because of its bipolar conduction nature, which incorporates both majority and minority carriers and is considered in Tesla EV Battery Tech , IGBTs perform at a modest frequency. In most situations, their switching frequency is limited to about 20 kHz due to the lengthier turn-off periods and distinctive tail current caused by the device’s stored charge during conduction. Nevertheless, switching performance has greatly increased with contemporary field-stop and trench-gate IGBT designs, enabling greater operating frequencies while preserving superior voltage and current handling capabilities.

Heat Dissipation

Effective heat dissipation is essential for maintaining the reliability and performance of power semiconductors. IGBTs typically have better heat dissipation capabilities in high-voltage and high-current scenarios because of their low conduction losses, reducing the thermal stress on the device and enhancing performance in systems used for Artificial Intelligence Training and advanced computing. MOSFETs, with their faster switching but higher conduction resistance at high voltages, often generate more heat under heavy load conditions. However, because MOSFETs operate at higher frequencies, heat sinks and thermal management strategies must be designed to cope with rapid switching losses. Both device types require proper cooling mechanisms such as heat sinks, fans, or liquid cooling to prevent thermal runaway and ensure longevity.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Use Cases in EVs

Electric vehicles (EVs) rely heavily on efficient power electronics to manage battery power and drive motors. Both IGBTs and MOSFETs find applications in EVs, but their use depends on the specific voltage, current, and switching frequency requirements. IGBTs are commonly used in the traction inverters of EVs, a key focus for those pursuing an EV Industry Career , where high voltage (often 400V to 800V) and high current are prevalent, and switching frequencies are moderate. Their ability to handle high power with relatively low losses makes them ideal for driving electric motors.

MOSFETs are typically used in lower voltage applications within EVs, such as onboard chargers, DC-DC converters, and auxiliary power units, where high switching frequencies improve efficiency and reduce size and weight. With advancing technology, wide bandgap semiconductors like SiC MOSFETs are gaining popularity in EV traction systems, offering a blend of high voltage capability and high-frequency performance.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Cost Considerations

Cost is an important factor when selecting semiconductor devices for mass-market applications. Traditional silicon MOSFETs are generally less expensive for low to medium power applications, making them attractive for consumer electronics and lower-voltage circuits. IGBTs, due to their more complex structure and higher voltage capability, are typically more expensive than MOSFETs, but their efficiency in high-power applications justifies the cost. The advent of silicon carbide (SiC) MOSFETs and gallium nitride (GaN) transistors, which is important for understanding How Regenerative Braking Works in EV , introduces higher initial costs but promises lower system costs overall through improved efficiency, reduced cooling requirements, and smaller passive components.

Summary of Key Differences

In power electronics applications, choosing the appropriate device requires an understanding of the main distinctions between IGBT and MOSFET. Both are essential for controlling switching efficiency, voltage, and current. This synopsis emphasises the main differences between them in terms of application, performance, and structure.

| Feature | IGBT | MOSFET |

|---|---|---|

| Conduction Type | Bipolar (minority & majority) | Unipolar (majority carriers) |

| Switching Speed | Moderate (microseconds) | Fast (nanoseconds) |

| Voltage Range | High (600V to several kV) | Low to medium (up to ~250V for Si, higher for SiC) |

| Current Handling | High | Moderate |

| Switching Frequency | Low to medium (up to ~20 kHz) | High (hundreds of kHz to MHz) |

| Efficiency | Better at high voltage/current | Better at high switching frequency |

| Heat Dissipation | Better for high power | Requires careful thermal management |

To sum up, MOSFETs perform well in high-frequency, low to medium-voltage systems, whereas IGBTs are best suited for high-voltage, high-current applications. Understanding these variations enables engineers to maximise modern power semiconductor designs’ performance, efficiency, and dependability.

Voltage/Current Ratings

IGBTs excel in high voltage and high current ratings, often handling voltages from 600V up to several kilovolts, with current ratings in the hundreds of amperes. This makes them suitable for industrial motor drives, grid-tied inverters, and traction applications in EVs.

- MOSFETs are more common in lower voltage ranges, typically under 250V for silicon devices, though SiC MOSFETs extend this range significantly, sometimes up to 1200V or more.

- Their current ratings are generally lower than IGBTs but adequate for many medium power applications.

- Understanding the voltage and current requirements of an application is critical in choosing the appropriate device.

In contrast, MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), which are relevant in discussions of EV vs Fuel Vehicle , are more frequently employed in low-to-medium voltage applications, usually below 250 volts for conventional silicon devices. But with to developments in wide bandgap technology, including Silicon Carbide (SiC) MOSFETs, their voltage capability has been further increased to 1200 volts or more. MOSFETs perform well in high-frequency switching situations where quick reaction and low switching losses are necessary, even though they can typically handle lower current levels than IGBTs. They are therefore perfect for electric vehicle power management circuits, onboard chargers, and DC-DC converters.

Conclusion

In conclusion, both IGBTs and MOSFETs are essential semiconductor devices with distinct characteristics tailored to specific power electronics applications, including those used in Artificial Intelligence Training and advanced computational systems. IGBTs offer superior performance in high-voltage, high-current scenarios with moderate switching frequencies, while MOSFETs excel in high-frequency, low to medium voltage environments. With ongoing advancements in semiconductor technology, especially wide bandgap materials, the boundary between these devices continues to blur, promising even greater efficiency and performance in future power electronics systems.