- Tesla’s EV Battery Technology

- Tesla Battery Packs

- Lithium-Ion Chemistry Used

- 4680 Cells

- Battery Management System (BMS)

- Thermal Management System

- Charging Technologies

- Battery Safety

- Gigafactory Production

- Second Life Batteries

- Sustainability Focus

- Tesla’s Future Battery Plans

- Conclusion

Tesla’s EV Battery Technology

Tesla has changed electric mobility with its innovative battery systems that set the standard for range, performance, and sustainability in its vehicles. From the first Roadster to the Model S Plaid and Cybertruck, Tesla’s batteries have evolved over time. They have improved energy density, charging speed, and thermal management. With Artificial Intelligence Training a vertically integrated approach that covers raw materials, cell design, software, and large-scale production, Tesla consistently improves performance while lowering costs. Beyond cars, its scalable battery systems seek to speed up the global movement toward sustainable energy for homes and the grid.

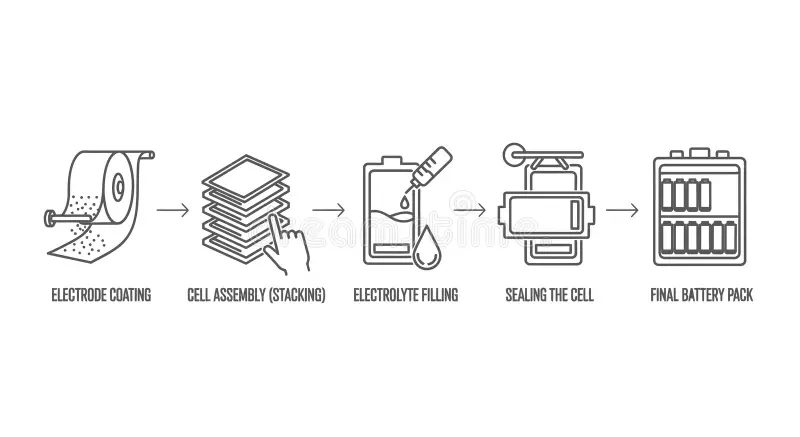

Tesla Battery Packs

Tesla’s battery packs form the base for its EVs. Each pack consists of thousands of small cylindrical cells, similar to AA EV batteries but much better at storing energy. These cells are organized into modules, and then combined into a complete battery pack inside a protective casing.

- Battery System: The pack isn’t just an Tesla sustainable energy solutions storage unit; it is a complex component that includes the Battery Management System (BMS), thermal control systems, and strong structures for crash safety.

- Placement: The flat, underfloor position of the pack lowers the center of gravity, improving vehicle stability, handling, and passenger safety.

- Model S and Model X: Use large-capacity packs over 100 kWh, aimed at maximum range and performance.

- Model 3 and Model Y: Feature medium-capacity packs (60–82 kWh), focused on efficiency and affordability.

- Cybertruck and Semi: Use next-generation pack designs based on 4680 cells for greater energy output and structural integration.

Each pack is carefully designed to strike a balance among weight, cost, and performance, showcasing Tesla’s ability to adjust its battery design for different needs ranging from high-speed sedans to heavy-duty trucks.

Lithium-Ion Chemistry Used

Tesla’s success relies partly on its control of lithium-ion battery chemistry. This chemistry affects how much energy can be stored, how fast it charges, and its lifespan. Instead of using one type, Tesla applies various chemistries, each improved for specific uses and markets.

- Nickel Cobalt Aluminum (NCA): Mainly used in Model S and Model X cars, this chemistry offers one of the highest energy densities available, allowing for excellent range and acceleration.

- Nickel Manganese Cobalt (NMC): Used in Model 3 and Model Y vehicles made in China. NMC ensures better thermal stability and longer life cycles, ideal for the mass-market.

- Lithium Iron Phosphate (LFP): Found in standard range models and energy storage products like Powerwall and Megapack. LFP cells do not contain cobalt, are cost-effective, and durable but have slightly lower energy density.

By strategically using these chemistries, Tesla manages supply chain risks, decreases reliance on scarce materials like cobalt, and stays flexible to optimize for range, cost, and lifespan.

4680 Cells

A key moment in Tesla’s battery evolution was the introduction of the 4680 cell, named for its size 46 mm in diameter and 80 mm in length. Unveiled at Tesla’s 2020 Battery Day, the 4680 represents a significant advance in cell design and production efficiency.

- Higher Energy Density: The larger size allows more active material per cell, providing up to five times the energy and six times the power of older cells.

- Structural Integration: These cells fit directly into the vehicle’s chassis in a “structural battery pack” design, which removes unnecessary parts, reduces weight, and enhances strength.

- Lower Cost: The simpler design and innovative dry-electrode production cut costs per kilowatt-hour by more than 50%.

- Faster charging system and Better Thermal Performance: The tabless design improves heat dissipation and allows higher current, enabling quicker charging and discharging cycles.

The 4680 cell marks the next step for Tesla and will be crucial for future models like the Cybertruck, Semi, and the next-generation Model Y vehicles.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Battery Management System (BMS)

Tesla’s Battery Management System serves as the control center for the battery pack. It constantly monitors voltage, temperature, current, and internal resistance of each cell group to ensure top performance and safety.

- Cell Balancing: Maintains equal charge levels in each cell to avoid overcharging or underutilization.

- State of Charge (SOC) Estimation: Provides accurate energy readings to improve range predictions.

- State of Health (SOH) Monitoring: Tracks battery wear over time, predicting when maintenance or replacement is needed.

- Thermal Regulation: Works with the cooling system to keep temperatures balanced.

- Fault Detection and Protection: Quickly responds to problems such as short circuits or overvoltage, disconnecting the system if necessary.

Tesla’s BMS software is continuously updated over-the-air (OTA), enhancing efficiency and extending battery life even after years of use.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Thermal Management System

Keeping the battery at the right temperature is vital for safety and longevity. Tesla uses a liquid cooling and heating system that keeps every cell within its ideal temperature range.

- Coolant Channels: Thin channels run alongside cells that distribute a glycol-based coolant.

- Pumps and Valves: Adjusts flow based on load and environmental changes.

- Heat Exchanger: Moves excess heat to or from the vehicle’s HVAC system, improving energy efficiency.

This system operates effectively in all environments from the freezing temperatures of Alaska to the extreme heat of Nevada, ensuring reliable performance and preventing thermal runaway.

Charging Technologies

Tesla’s charging system network is among the most extensive and efficient Artificial Intelligence Training globally. It relies on three main components to support fast and convenient energy replenishment.

- Superchargers: Tesla’s fast-charging network delivers up to 250 kW of power, adding up to 200 miles of range in just 15–20 minutes. With thousands of stations worldwide, it alleviates “range anxiety” for long trips.

- Home Charging (Wall Connector): Offers easy overnight charging systemat up to 11.5 kW. Users wake up to a fully charged vehicle, reducing the need for public charging.

- V3 Supercharging: New power electronics and liquid-cooled cables significantly cut charging system times compared to earlier models.

- Regenerative Braking: Captures energy during deceleration and converts it back into electrical energy stored in the battery. This system can enhance driving efficiency and range by up to 20%.

Tesla’s charging and energy recovery systems work together to maximize range, convenience, and overall vehicle efficiency.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Battery Safety

Safety is central to Tesla’s battery design. The company includes multiple layers of protection, combining hardware and software safeguards.

- Cell Isolation: Fire-resistant barriers between cells to control any potential thermal runaway.

- Crash Protection: Strong pack enclosures integrated into the vehicle’s body to absorb impact energy.

- Automatic Disconnects: High-voltage circuits are isolated immediately in the event of a collision to prevent electric shock.

- Software Oversight: Continuous monitoring through the BMS and vehicle systems ensures early detection of issues.

Tesla’s safety measures have been rigorously tested, and its EVs consistently receive high safety ratings from regulatory agencies worldwide.

Gigafactory Production

Tesla’s Gigafactories are essential to its energy and automotive operations. These large facilities combine cell production, module assembly, and pack integration in one place, greatly lowering costs and carbon emissions.

- Gigafactory Nevada (USA): Produces 2170 cells and packs for Model 3 and Y, as well as energy storage products.

- Gigafactory Berlin (Germany): Focuses on 4680 cell production for European markets.

- Gigafactory Texas (USA): Supports production of Cybertruck, Semi, and next-generation vehicles.

- Gigafactory Shanghai (China): Manufactures LFP-based packs to meet regional needs.

Gigafactories exemplify Tesla’s strategy of vertical integration and global scalability. They secure supply chains and enable rapid Tesla battery innovation from laboratory to large-scale manufacturing.

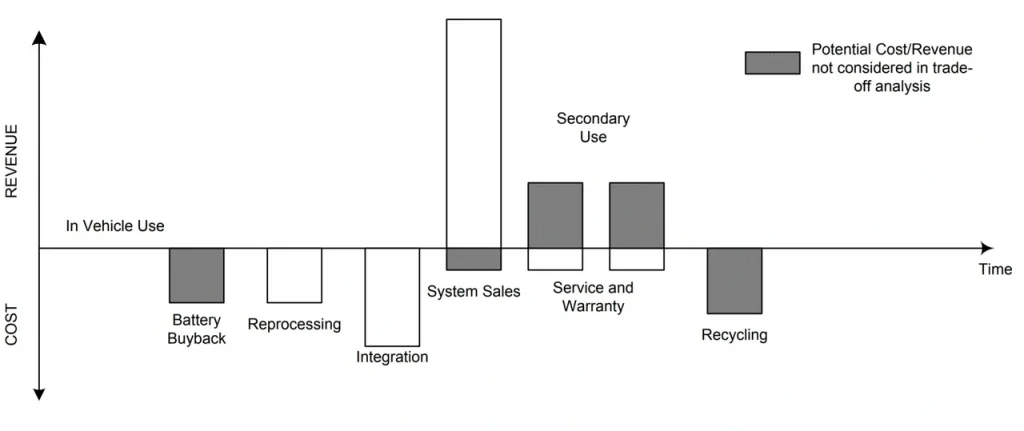

Second Life Batteries

Even after years of use in vehicles, Tesla’s batteries still hold significant energy capacity, often 70–80% of their original health. Tesla repurposes these “second-life” EV batteries for energy storage applications, prolonging their usefulness.

- Home Storage: Powerwall units that save solar energy for household use.

- Grid Stabilization: Megapacks that help balance renewable energy fluctuations and provide backup power to utilities.

- Remote Installations: Off-grid and emergency power Tesla sustainable energy solutions in isolated or disaster-prone areas.

By giving used EV batteries a second life, Tesla reduces waste, maximizes resource use, and supports a circular energy economy.

Sustainability Focus

Tesla’s mission to hasten the world’s transition to Tesla sustainable energy solutions is central to its battery strategy. The company’s sustainability efforts encompass the entire tesla battery technology lifecycle.

- Recycling Partnerships: Collaborations with companies like Redwood Materials to recover lithium, nickel, and cobalt from used cells for reuse in new batteries.

- Chemistry Tesla battery innovation: Increasing the use of cobalt-free LFP and exploring manganese-rich and silicon-based alternatives to reduce environmental and ethical issues.

- Green Manufacturing: Gigafactories are designed to run on renewable energy and minimize waste through closed-loop processes.

- Carbon Neutral Goals: Tesla aims for minimal lifecycle emissions by enhancing efficiency from material extraction to end-of-life recycling.

These initiatives not only lessen Tesla’s environmental footprint but also set new standards for the global EV industry.

Tesla’s Future Battery Plans

Tesla’s future in tesla battery technology promises to be just as exciting as its past inventions. The company is determined to explore new possibilities through long-term research and collaborations.

- Scaling 4680 Cell Production: Reaching terawatt-hour-level output to meet global vehicle and energy needs.

- Solid-State Batteries: Investigating solid electrolytes for better safety, quicker charging, and increased energy density.

- Silicon Anodes: Switching from traditional graphite to silicon to greatly boost capacity and reduce charging times.

- Cobalt-Free Cathodes: Aiming for fully cobalt-free chemistries to lower costs and eliminate supply chain challenges.

- AI-Enhanced Battery Analytics: Using machine learning to predict tesla battery technology wear, optimize charging, and extend lifespan.

As Tesla incorporates these advancements, it seeks to make electric vehicles not only equal to but better than internal combustion engines in every way possible.

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Conclusion

Tesla’s climb to the top of the EV market is linked to its expertise in tesla battery technology Artificial Intelligence Training. Through constant Tesla battery innovation from cell chemistry and pack design to production scale and sustainability Tesla has transformed the global energy landscape. Each new generation of Tesla EV batteries offers greater range, faster charging, enhanced safety, and longer life, all while minimizing environmental effects. As Gigafactories expand, new materials become available, and 4680 cells enter mass production, Tesla’s lead in technology continues to grow. Its vision reaches beyond cars to homes, power grids, and the very foundations of sustainable living. The progress in tesla battery technology tells not just of engineering achievements, but also outlines a pathway for a cleaner energy future for everyone.