- The Power Behind Electric Vehicles: Understanding EV Motors

- DC Brushed Motors

- Brushless DC Motors (BLDC)

- Permanent Magnet Synchronous Motors (PMSM)

- Induction Motors

- Switched Reluctance Motors (SRM)

- Comparison of Motor Types

- Motor Selection Criteria

- Efficiency and Performance

- Cost and Maintenance

- Real-World Applications

- Future Trends in Motor Tech

- Conclusion

The Power Behind Electric Vehicles: Understanding EV Motors

Electric vehicles (EVs) are changing transportation by providing cleaner, more efficient options compared to internal combustion engines (ICEs). At the center of every EV is its electric motor, which turns electrical energy into mechanical motion. The type of motor affects an EV’s performance, energy efficiency, cost, and suitability for different applications. Factors like power density, torque characteristics, efficiency, cooling needs, and control complexity influence the choice of motor. With rapid improvements in materials, electronics, and control systems, Artificial Intelligence Training various motor types are now used across many EV categories, from scooters to electric trucks.

DC Brushed Motors

DC brushed motors are some of the oldest electric motors and have been in use since the early days of electrification. They use a commutator and brushes to allow electrical current to reach the rotating armature of the Artificial Intelligence Training.

- Working Principle: A brushed DC motor operates by applying voltage to the armature winding, creating a magnetic field. The interaction between this field and the stator’s magnetic field produces torque. The commutator changes the current direction, which keeps the rotation going.

- Pros: Simple control

- Pros: Low initial cost

- Pros: Easy to understand and maintain

- Cons: High wear and tear (brush and commutator)

- Cons: Low efficiency

- Cons: Limited lifespan

- EV Use: These motors were used in early EVs and electric bicycles but are now mostly replaced due to maintenance issues.

This summarizes the key aspects of brushed DC motors, including their operation, advantages, limitations, and historical use in electric vehicles.

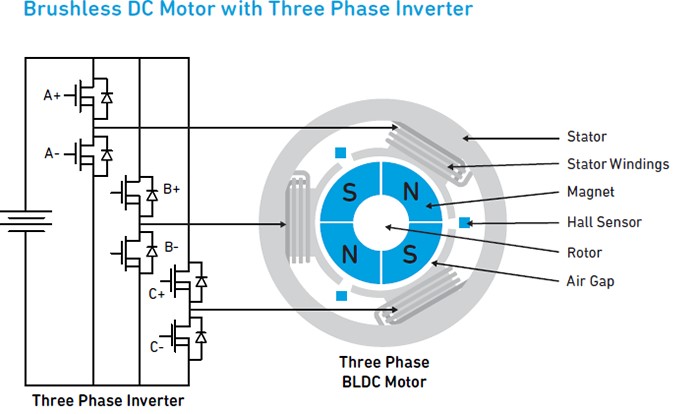

Brushless DC Motors (BLDC)

BLDC motors are a modern version of brushed motors that provide better efficiency, longer life, and higher battery power density. They replace brushes with an electronic controller that switches the current.

- Working Principle: BLDC motors have permanent magnets on the rotor and three-phase windings on the stator. Electronic sensors detect the rotor’s position, and the controller switches the current to generate a rotating magnetic field that drives the rotor.

- Pros: High efficiency (85–90%)

- Pros: Longer lifespan (no brush wear)

- Pros: Good torque-to-weight ratio

- Pros: Precise control

- Cons: Higher initial cost

- Cons: Requires a sophisticated controller

- EV Use: They are widely used in two-wheelers, e-bikes, drones, and small passenger EVs.

This highlights the advantages and applications of BLDC types of motors in electric vehicles, showing why they are preferred in modern electric vehicles.

Permanent Magnet Synchronous Motors (PMSM)

PMSMs are high-performance motors that use permanent magnets in the rotor and offer better torque and battery power density compared to other types.

- Working Principle: Like BLDC motors, PMSMs produce torque through interaction between the rotating magnetic field of the stator and the constant magnetic field of the rotor. However, the back-EMF (electromotive force) waveform in PMSMs is sinusoidal instead of trapezoidal.

- Pros: High efficiency and battery power density

- Pros: Smooth torque output

- Pros: Compact size

- Pros: Superior vehicle performance at high speeds

- Cons: Expensive due to rare earth magnets

- Cons: Risk of demagnetization at high temperatures

- EV Use: PMSMs are commonly used in modern EVs like the Tesla Model 3 and Hyundai Kona, thanks to their balance of energy efficiency and power.

Also known as asynchronous motors, induction motors became popular in EVs thanks to Tesla. They do not use permanent magnets but rely on electromagnetic induction.

- Working Principle: When AC current flows through the stator, it creates a rotating magnetic field. This induces current in the rotor (usually squirrel cage), which generates torque.

- Pros: Robust and durable

- Pros: No rare earth materials

- Pros: Cheaper than PMSM

- Pros: Wide speed range

- Cons: Lower efficiency than PMSM at low loads

- Cons: Heavier and larger

- Cons: Requires complex control for high efficiency

- EV Use: Induction motors are found in the Tesla Model S, Model X, electric buses, and industrial EV applications.

This comparison highlights the strengths and trade-offs between PMSMs and induction motors in electric vehicle applications.

To Explore Artificial Intelligence in Depth, Check Out Our Comprehensive Artificial Intelligence Online Training To Gain Insights From Our Experts!

Switched Reluctance Motors (SRM)

SRMs are gaining interest because of their simple motor design, ability to tolerate high temperatures, and potential for affordable production.

- Working Principle: SRMs operate on the principle of reluctance, with the rotor aligning to the stator’s magnetic field to minimize magnetic reluctance. Unlike other types of motors in electric vehicles, the rotor has no windings or magnets, just laminated steel.

- Pros: Robust and simple motor design

- Pros: Can operate at high temperatures

- Pros: No rare earth materials

- Pros: High fault tolerance

- Cons: High torque ripple

- Cons: Acoustic noise

- Cons: Complex control system

- EV Use: SRMs are being explored for low-cost EVs, heavy-duty vehicles, and high-temperature settings. They are not yet common in passenger EVs but show promise.

This overview outlines the unique characteristics and emerging role of SRMs in electric vehicle technology.

Comparison of Motor Types

| S.No | Motor Type | Efficiency | Key Characteristics | Common Applications |

|---|---|---|---|---|

| 1 | DC Brushed | Low | High maintenance, low control complexity, low cost, low torque ripple, bulky, no magnets | Bikes |

| 2 | BLDC | High | Low maintenance, medium control complexity, medium cost, low torque ripple, compact, requires magnets | Scooters |

| 3 | PMSM | Very High | Low maintenance, high control complexity, high cost, very low torque ripple, very compact, requires magnets | Cars |

| 4 | Induction | Moderate | Low maintenance, high control complexity, medium cost, low torque ripple, heavy, no magnets | Buses |

| 5 | SRM | Moderate | Very low maintenance, very high control complexity, low cost, high torque ripple, medium size/weight, no magnets | Commercial |

Looking to Master Machine Learning? Discover the Artificial Intelligence Expert Masters Program Training Course Available at ACTE Now!

Motor Selection Criteria

Choosing the right motor for an EV involves several factors that influence vehicle performance, cost, and sustainability.

- Power Requirements: Based on vehicle weight, top speed, and acceleration.

- Torque Characteristics: Important for hill climbing and city driving.

- Efficiency: Affects driving range and energy use.

- Cost Constraints: Includes motor cost and compatibility with the controller and battery.

- Size and Weight: Impacts vehicle layout and vehicle performance.

- Thermal Management: Motors must run efficiently without overheating.

- Noise and Vibration: Important for passenger comfort.

- Availability of Raw Materials: types of motors in electric vehicles using rare earths may face supply chain issues.

Evaluating these factors helps manufacturers and engineers select the most suitable motor technology for specific EV applications.

Ready to Get Certified in Artificial Intelligence ? Explore the Program Now Artificial Intelligence Online Training Offered By ACTE Right Now!

Efficiency and Performance

Motor energy efficiency directly affects the range, acceleration, and energy cost of an EV. Here’s how different motors measure up:

- PMSM: Motors can exceed 95% efficiency under optimal conditions and perform well across various speeds.

- BLDC: types of motors in electric vehicles provide good low-speed torque and are efficient for city driving.

- Induction: Motors are robust under load and deliver reliable high-speed performance, though they may be less efficient at lower speeds.

- SRM: types of motors in electric vehicles are improving in efficiency thanks to better control algorithms and suit heavy-load applications.

In real-world conditions, system-level efficiency (including controller and drivetrain losses) is usually more crucial than raw motor efficiency.

Preparing for Artificial Intelligence Job Interviews? Have a Look at Our Blog on Artificial Intelligence Interview Questions and Answers To Ace Your Interview!

Cost and Maintenance

Cost considerations play a major role in selecting the right motor for electric vehicles. Here’s how different motor types compare:

- DC Brushed: Lowest initial cost, but no longer relevant for modern EVs.

- BLDC and PMSM: Higher due to electronics and magnets.

- Induction Motors: Moderate cost, but lower long-term expenses due to no magnets.

- SRM: Could be the cheapest because of its simple rotor and no magnets.

- Maintenance: BLDC, PMSM, induction, and SRM motors require less maintenance due to fewer moving parts. DC brushed motors need frequent brush replacements.

- Total Cost of Ownership (TCO): While PMSMs might be pricier upfront, their efficiency and durability often lead to lower long-term ownership costs.

Balancing initial cost, maintenance needs, and long-term efficiency helps determine the most economical motor choice for EV applications.

Real-World Applications

Different types of motors in electric vehicles are used across various EV categories based on performance, cost, and application needs.

- Passenger Cars: PMSM motors are used in Tesla Model 3, Nissan Leaf, and BMW i3. Induction motors are found in older Tesla models.

- Two-Wheelers: BLDC motors are common in scooters like Ather, Ola, and Hero Electric.

- Heavy-Duty Vehicles: SRM and induction motors are preferred in buses and trucks for their durability.

- Electric Bicycles: BLDC and DC brushed motors are small, lightweight options for e-bikes.

- Commercial Vehicles: Induction and SRM motors are suitable for rugged use with high torque requirements.

This breakdown shows how motor selection varies by EV type, balancing efficiency, cost, and operational demands.

Future Trends in Motor Tech

Emerging trends in EV motor technology are shaping the future of electric mobility with innovation and efficiency.

- Rare-Earth-Free motor design: Manufacturers are working on motors that do not rely on rare earth magnets to address costs, sustainability, and supply risks.

- Integrated Drive Units: Combining the motor, inverter, and gearbox into a single module can save space, weight, and cost, enhancing drivetrain efficiency.

- AI-Powered Motor Control: Advanced software using artificial intelligence and predictive algorithms optimizes motor performance in real-time.

- Solid-State Controllers: New power electronics (GaN/SiC) allow for faster switching, higher efficiency, and more compact motor controllers.

- Modular Motor Platforms: OEMs are creating modular electric motors that can be used across various vehicle types, speeding up production.

- In-Wheel Motors: These are not common yet but could provide better vehicle design flexibility, torque control, and space efficiency.

- SRM Optimization: Improvements in SRM control and noise reduction may make them the go-to motor for commercial EVs.

These innovations reflect the industry’s push toward smarter, more sustainable, and scalable electric vehicle solutions.

Conclusion

The electric motor is a key component that shapes the performance and experience of an EV. While older motors like DC brushed types are being phased out, modern options like BLDC, PMSM, induction, and SRM have unique advantages for specific vehicle categories and uses. With Artificial Intelligence Training growing demands for efficiency, sustainability, and cost-effectiveness, the motor landscape is evolving quickly. Innovations in motors that do not require magnets, AI-driven control systems, and integrated drive solutions promise a future where EVs become more accessible, powerful, and eco-friendly.