- Introduction to Supply Chain Analytics

- Importance of Analytics in Supply Chain Management

- Key Components of Supply Chain Analytics

- Types of Analytics Used in Supply Chains

- Tools and Technologies for Supply Chain Analytics

- Benefits of Implementing Supply Chain Analytics

- Challenges in Supply Chain Analytics Adoption

- Conclusion

Introduction to Supply Chain Analytics

Supply Chain Analytics refers to the systematic collection, analysis, and interpretation of data related to all aspects of supply chain operations. Its primary purpose is to improve decision-making and optimize the overall performance of the supply chain. By leveraging advanced analytical techniques such as big data analytics, machine learning, and predictive modeling, companies can transform large volumes of raw data into meaningful and actionable insights. These insights help organizations better understand their supply chain processes, uncover hidden inefficiencies, and make data-driven decisions that enhance efficiency and reduce costs. One of the key benefits of supply chain analytics is increased visibility. By analyzing data from multiple sources including suppliers, production facilities, warehouses, and transportation networks organizations gain a comprehensive view of their entire supply chain. This transparency enables quicker identification of bottlenecks, delays, or disruptions, allowing for faster corrective actions with the support of PMP Training. Analytics also plays a vital role in demand forecasting by using historical data and market trends to predict future customer needs more accurately. Improved demand forecasts help companies optimize inventory levels, reduce stockouts, and minimize excess inventory. Risk management is another important application of supply chain analytics. By identifying potential risks such as supplier failures, geopolitical issues, or natural disasters, businesses can develop contingency plans and improve supply chain resilience. Additionally, analytics supports continuous improvement by measuring key performance indicators (KPIs) and benchmarking against industry standards. As global supply chains grow more complex due to globalization, increasing customer expectations, and technological advancements, supply chain analytics has become an essential tool. Organizations that effectively utilize analytics can increase agility, improve operational efficiency, and maintain a competitive edge in the market. In today’s data-driven world, supply chain analytics is no longer a luxury but a critical necessity for sustainable business success.

Do You Want to Learn More About PMP? Get Info From Our PMP Certification Training Today!

Importance of Analytics in Supply Chain Management

In today’s fast-paced and constantly evolving market environment, traditional supply chain management methods often struggle to keep up with rapid changes and growing customer expectations. These conventional approaches tend to be reactive, responding to problems only after they occur. Supply chain analytics, however, empowers organizations to shift toward proactive and data-driven decision-making. By analyzing real-time and historical data, businesses can anticipate potential disruptions before they happen, allowing them to take preventive measures that minimize operational risks and avoid costly delays. One of the significant advantages of supply chain analytics is its ability to optimize inventory management in Projects in Business Environments. With accurate demand forecasting and deeper insights into sales trends, companies can maintain optimal stock levels, reducing excess inventory and associated holding costs while preventing stockouts that can harm customer satisfaction. This leads to more efficient use of capital and improved service levels, enabling businesses to deliver products to customers more reliably and quickly. Analytics also plays a critical role in identifying cost-saving opportunities across the supply chain. By pinpointing inefficiencies, waste, or underutilized resources, companies can streamline processes and reduce operational expenses. Moreover, sustainability has become a key focus for many organizations, and supply chain analytics supports these efforts by uncovering areas where waste can be minimized, energy consumption reduced, and sustainable sourcing practices enhanced.

Beyond internal benefits, supply chain analytics fosters greater transparency and collaboration among partners, such as suppliers, logistics providers, and distributors. This improved visibility strengthens alignment between supply and demand, ensuring that all parties work together toward common goals. Ultimately, companies that effectively leverage supply chain analytics gain a competitive edge through improved agility, efficiency, and resilience in a challenging and dynamic marketplace.

Key Components of Supply Chain Analytics

- Data Collection: Gathering data from multiple sources such as suppliers, production lines, logistics, and sales systems is fundamental. Accurate and timely data forms the basis for meaningful analysis.

- Data Integration: Combining diverse datasets from different departments and partners into a unified system ensures consistency and allows comprehensive analysis across the entire supply chain.

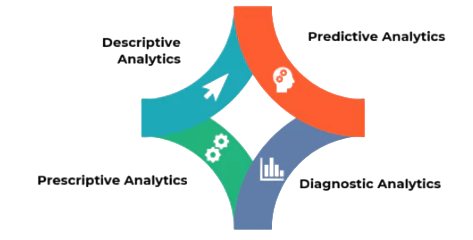

- Descriptive Analytics: This component focuses on understanding past and current supply chain performance by analyzing historical data to identify trends, patterns, and inefficiencies, which is essential for achieving What is Business Agility.

- Predictive Analytics: Using statistical models and machine learning, predictive analytics forecasts future events such as demand fluctuations, supply risks, and potential disruptions, enabling proactive decision-making.

- Prescriptive Analytics: Going beyond predictions, prescriptive analytics recommends optimal actions to improve supply chain outcomes, such as inventory adjustments, route optimization, or supplier selection.

- Visualization Tools: Dashboards and interactive reports help stakeholders easily interpret complex data and monitor key performance indicators (KPIs) in real time, facilitating quicker responses.

- Performance Measurement: Continuous tracking of metrics like delivery times, order accuracy, and cost efficiency allows organizations to assess effectiveness and drive continuous improvement.

- Descriptive Analytics: Focuses on analyzing historical data to understand what has happened in the supply chain. It helps identify trends, patterns, and bottlenecks by summarizing past performance.

- Diagnostic Analytics: Goes deeper than descriptive analytics to explain why certain events occurred. This type investigates root causes of problems such as delays or quality issues, helping pinpoint areas for improvement with the guidance of PMP Training.

- Predictive Analytics: Uses statistical models and machine learning algorithms to forecast future supply chain events like demand changes, potential disruptions, or inventory shortages. It enables proactive planning.

- Prescriptive Analytics: Recommends specific actions based on predictive insights. For example, it can suggest optimal inventory levels, supplier choices, or transportation routes to improve efficiency and reduce costs.

- Cognitive Analytics: Incorporates artificial intelligence and natural language processing to interpret unstructured data (e.g., emails, social media) and provide deeper insights, supporting more informed decisions.

- Real-Time Analytics: Processes data as it is generated to provide immediate insights and enable quick responses to operational issues, such as rerouting shipments or adjusting production schedules.

- Big Data Analytics: Handles vast and complex datasets from various sources across the supply chain, uncovering hidden patterns and correlations that traditional analytics might miss, driving innovation and competitive advantage.

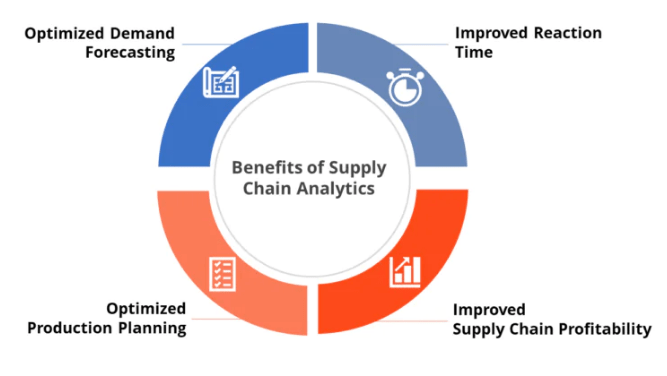

- Improved Demand Forecasting: Analytics help predict customer demand more accurately, reducing overstock and stockouts, which leads to better inventory management.

- Enhanced Operational Efficiency: By identifying bottlenecks and inefficiencies, analytics enable companies to optimize processes such as production scheduling and transportation routes.

- Cost Reduction: Data-driven insights help minimize unnecessary expenses by optimizing inventory levels, reducing waste, and improving supplier negotiations, raising the question Can Business Analyst be a Project Manager?

- Risk Management: Analytics identify potential risks like supplier failures or logistics disruptions early, allowing companies to develop contingency plans and maintain continuity.

- Better Decision-Making: Access to comprehensive, real-time data supports informed decisions at every stage of the supply chain, from procurement to delivery.

- Increased Customer Satisfaction: Improved accuracy in order fulfillment and faster response times contribute to higher customer satisfaction and loyalty.

- Competitive Advantage: Companies leveraging supply chain analytics can innovate faster, adapt to market changes swiftly, and outperform competitors through data-driven strategies.

Would You Like to Know More About PMP? Sign Up For Our PMP Certification Training Now!

Types of Analytics Used in Supply Chains

Tools and Technologies for Supply Chain Analytics

Supply chain analytics relies heavily on a variety of tools and technologies that enable organizations to collect, process, and analyze vast amounts of data efficiently. One of the foundational technologies is big data platforms, which can handle and store large volumes of structured and unstructured data generated from multiple sources such as suppliers, warehouses, transportation networks, and customer transactions. These platforms enable the integration of diverse data sets, creating a comprehensive view of the supply chain. Advanced analytics tools built on machine learning and artificial intelligence (AI) are increasingly essential for uncovering patterns, forecasting demand, and optimizing supply chain operations. Machine learning algorithms analyze historical data and learn from trends to predict future outcomes like inventory needs, supplier risks, and delivery timelines, demonstrating The Most Important Benefits of Blended Learning in enhancing analytical skills. AI-powered tools can also automate routine decision-making processes, improving speed and accuracy. Cloud computing platforms play a vital role in supply chain analytics by providing scalable and flexible infrastructure. Cloud-based analytics solutions enable real-time data access and collaboration among different stakeholders regardless of their geographic locations. This accessibility supports timely decision-making and fosters stronger coordination across the supply chain network. Additionally, Internet of Things (IoT) devices are transforming supply chain analytics by providing real-time data from physical assets such as sensors on trucks, warehouses, and production equipment. IoT technology allows for continuous monitoring of inventory levels, shipment conditions, and equipment status, enhancing visibility and enabling prompt responses to issues. Visualization tools and dashboards are critical for presenting complex data in an easy-to-understand format. These tools enable supply chain managers to track key performance indicators (KPIs), identify trends, and make informed decisions quickly. Together, these tools and technologies form the backbone of modern supply chain analytics, helping organizations increase efficiency, reduce costs, and enhance responsiveness in a competitive global market.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Benefits of Implementing Supply Chain Analytics

Challenges in Supply Chain Analytics Adoption

Despite the many benefits, adopting supply chain analytics presents several significant challenges that organizations must address to realize its full potential. One of the primary obstacles is data quality and availability. Supply chains generate vast amounts of data from multiple sources, but this data is often fragmented, inconsistent, or incomplete. Poor data quality can lead to inaccurate insights and misguided decisions, making it critical to invest in robust data management and integration systems. Another challenge is the complexity of supply chain networks. Supply chains often involve numerous partners across different regions and industries, each with their own systems and processes. Integrating data and analytics tools across these diverse stakeholders can be difficult, requiring collaboration and standardization that are not always easy to achieve. This complexity also makes it harder to gain end-to-end visibility, which is essential for effective analytics, underscoring Why A PMO Is Second In Line To A Project Manager in ensuring project oversight. Talent and skills gaps pose a further challenge. Many organizations lack employees with the necessary expertise in data science, machine learning, and supply chain management to effectively implement and leverage analytics solutions. Hiring or training skilled professionals can be costly and time-consuming but is crucial for driving successful analytics initiatives. Additionally, high implementation costs and unclear return on investment (ROI) can deter companies from investing in supply chain analytics. Organizations may struggle to justify the upfront expenses related to technology, infrastructure, and training without immediate or easily measurable benefits. Resistance to change within organizations also plays a role, as employees and managers may be reluctant to adopt new technologies or alter established workflows. Finally, cybersecurity risks increase with greater digitalization and data sharing across supply chains. Protecting sensitive data from breaches and ensuring compliance with data privacy regulations require strong security measures. Overcoming these challenges is essential for companies to harness the power of supply chain analytics and build more agile, efficient, and resilient operations.

Go Through These PMP Interview Questions and Answers to Excel in Your Upcoming Interview.

Conclusion

Supply chain analytics is transforming how companies manage and optimize their supply networks. By harnessing large volumes of data and applying advanced analytical techniques, organizations can gain deeper insights into their operations. These insights lead to better visibility across the supply chain, helping businesses identify inefficiencies, predict demand more accurately, manage risks, and make more informed decisions. As a result, companies can improve operational efficiency, reduce costs, and enhance customer satisfaction by ensuring timely delivery and consistent product availability. One of the key benefits of supply chain analytics is real-time monitoring. It allows organizations to track inventory levels, transportation routes, and supplier performance with precision. This capability supports quicker responses to disruptions and fosters greater coordination between departments and external partners through PMP Training. Advanced tools like predictive modeling and machine learning also help companies anticipate future challenges and opportunities, enabling them to prepare accordingly rather than react after problems occur. Despite these benefits, several challenges still hinder adoption. Many organizations struggle with poor data quality, fragmented systems, and inconsistent data standards across supply chain partners. In addition, a shortage of skilled professionals who understand both analytics and supply chain processes can slow down implementation. Integrating analytics solutions into existing operations often requires significant investment in technology and change management. However, the long-term advantages of adopting supply chain analytics far outweigh these challenges. As technologies continue to advance and become more user-friendly, analytics will become a central element of modern supply chain strategy. It will support the creation of supply chains that are not only more efficient and cost-effective but also more resilient and sustainable. Companies that invest in these capabilities today will be better prepared to adapt to changing market conditions and meet customer expectations in the future.