- Introduction to Supply Chain Management Objectives

- Enhancing Customer Satisfaction

- Reducing Operational Costs

- Improving Supply Chain Efficiency and Responsiveness

- Ensuring Quality and Compliance

- Building Supply Chain Resilience

- Supporting Sustainability and Corporate Responsibility

- Fostering Collaboration and Innovation

Introduction to Supply Chain Management Objectives

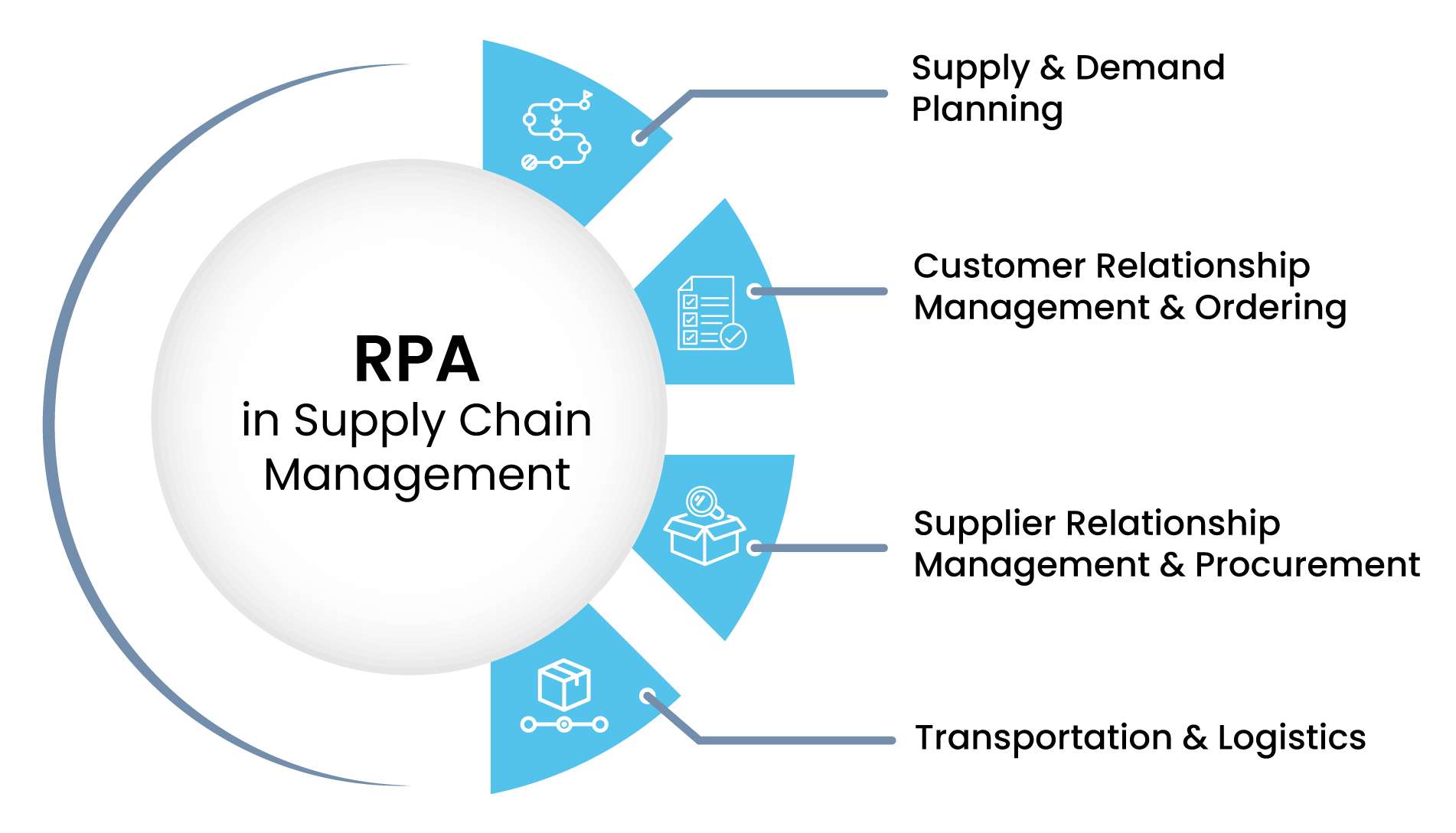

Supply chain management plays a critical role in ensuring that products and services move efficiently from suppliers to customers. At its core, the Objectives of Supply Chain Management include reducing costs, enhancing customer satisfaction, improving operational efficiency, and fostering collaboration across the supply network. In today’s dynamic global environment, organizations are increasingly focusing on supply chain resilience strategies to prepare for and respond to unexpected disruptions such as geopolitical shifts, natural disasters, and pandemics. These strategies emphasize flexibility, risk mitigation, and proactive planning to maintain continuity and minimize losses. For instance, diversification of suppliers, investment in digital technologies, and scenario planning are vital components that help firms remain agile under pressure. Additionally, PMP Training equips supply chain professionals with project management skills that enhance their ability to implement these strategies effectively and respond to disruptions with confidence. In German-speaking markets, the term Supply Chain Resilience Deutsch highlights a growing emphasis on strengthening supply chains through localized sourcing, digital transformation, and regulatory compliance. Building a resilient supply chain not only aligns with strategic business goals but also safeguards long-term profitability and brand reputation. As global supply networks become more interconnected, achieving the objectives of supply chain management requires a balanced approach that integrates resilience, efficiency, and adaptability, making supply chains not just faster and cheaper, but smarter and stronger as well.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

Enhancing Customer Satisfaction

- Implement Cold Chain Logistics: For perishable goods like pharmaceuticals and food, maintaining product integrity through cold chain logistics ensures freshness and safety, directly improving customer trust and satisfaction.

- Adopt a Sustainable Supply Chain: Consumers today value environmental responsibility. Integrating eco-friendly practices such as reducing emissions, optimizing packaging, and ethical sourcing supports long-term customer loyalty. Applying Managerial Economics Concepts helps businesses evaluate the cost-effectiveness and long-term benefits of these sustainable strategies, ensuring alignment with both market demand and profitability goals.

- Leverage Oracle SCM for Visibility: Using advanced tools like Oracle SCM helps businesses gain real-time visibility into inventory, demand forecasting, and supplier performance, enabling quicker responses to customer needs.

Enhancing customer satisfaction is a core goal of any successful business, and in supply chain management, it involves aligning operations, technology, and strategy to meet or exceed customer expectations. Whether it’s timely delivery, product quality, or service transparency, companies must adopt advanced tools and practices to deliver consistent value. Below are six key ways to enhance customer satisfaction through effective supply chain practices:

- Strengthen Supply Chain Strategy: A well-defined supply chain strategy aligns business goals with customer expectations, ensuring resources are used efficiently to deliver consistent service.

- Use Oracle Supply Chain for Integration: Oracle Supply Chain solutions enable seamless integration across procurement, logistics, and customer service, resulting in fewer delays and better coordination.

- Improve Order Accuracy and Delivery Times: Streamlining processes and investing in automation minimizes errors, enhances delivery speed, and ultimately leads to a more satisfying customer experience.

Reducing Operational Costs

Reducing operational costs is a fundamental aspect of the Objectives of Supply Chain Management, as it directly impacts profitability, competitiveness, and long-term sustainability. Companies today are focusing on streamlining processes, optimizing resource allocation, and leveraging technology to minimize waste and improve efficiency across the supply chain. Key cost-saving initiatives include automation of routine tasks, bulk purchasing, vendor consolidation, and smarter logistics planning. In an increasingly volatile global environment, businesses are also implementing supply chain resilience strategies to reduce the financial impact of disruptions. Understanding What is Human Resource Management is equally important, as effective talent management and workforce planning play a critical role in executing these cost-saving and resilience strategies successfully. These strategies may involve building buffer stocks, diversifying supplier bases, and adopting advanced analytics to predict and respond to risks in real time. While these measures might seem to add upfront costs, they ultimately prevent more severe losses and ensure smoother operations during crises. In the European context, Supply Chain Resilience Deutsch emphasizes localized sourcing, regulatory compliance, and digital integration to not only safeguard supply networks but also control costs effectively. By focusing on resilience alongside cost reduction, organizations can strike a balance between efficiency and adaptability, reinforcing their ability to deliver value while navigating market uncertainties. Thus, reducing operational costs is not just about cutting expenses, it’s about creating a lean, responsive, and future-ready supply chain.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Improving Supply Chain Efficiency and Responsiveness

- Optimize Cold Chain Logistics: For industries like pharmaceuticals and food, efficient cold chain logistics ensure temperature-sensitive products are delivered intact, reducing waste and improving customer satisfaction.

- Adopt a Sustainable Supply Chain: A sustainable supply chain not only reduces environmental impact but also builds long-term resilience. Practices like energy-efficient transportation and ethical sourcing support both agility and cost-effectiveness. Integrating PMP Training into sustainability initiatives ensures that such projects are managed efficiently, with clear goals, timelines, and measurable outcomes.

- Leverage Oracle SCM for Real-Time Data: Using Oracle SCM tools allows companies to track inventory, orders, and shipments in real time, enabling quicker and more accurate decisions across the supply chain.

Improving supply chain efficiency and responsiveness is essential for meeting dynamic customer demands, minimizing delays, and staying competitive in today’s fast-paced market. It involves optimizing every stage from procurement to delivery through smart planning, real-time visibility, and agile decision-making. Here are key ways to enhance efficiency and responsiveness:

- Develop a Proactive Supply Chain Strategy: A clear supply chain strategy focused on risk management and demand forecasting helps organizations respond faster to market changes and disruptions.

- Integrate Oracle Supply Chain Systems: Oracle Supply Chain solutions provide end-to-end integration, improving coordination across departments and reducing communication lags.

- Invest in Automation and AI: Streamlining routine tasks through automation and leveraging AI for predictive analytics enhances speed and responsiveness, helping businesses stay ahead of disruptions.

- Diversify Supplier Base: Avoid dependency on a single supplier or region by sourcing from multiple vendors. This core part of supply chain resilience strategies minimizes risk from local disruptions.

- Invest in Risk Assessment Tools: Regularly analyze risks across the supply network and develop mitigation plans. These assessments support the overall objectives of minimizing downtime and operational loss. Understanding the Nature Of Managerial Economics helps in evaluating trade-offs, forecasting potential risks, and making informed decisions that enhance supply chain resilience.

- Strengthen Collaboration with Partners: Enhanced communication and coordination with suppliers and logistics partners improve visibility and responsiveness in times of disruption.

- Localize Supply Chains (Supply Chain Resilience Deutsch): In German markets, or Supply Chain Resilience Deutsch, local sourcing, compliance, and digital transparency are key to adapting quickly and maintaining operations.

- Build Buffer Inventory and Capacity: Strategic stockpiling and flexible manufacturing capacity provide a cushion against sudden spikes in demand or supply shortages.

- Leverage Digital Supply Chain Platforms: Tools such as real-time monitoring, AI forecasting, and digital twins enable faster response and informed decision-making, supporting stronger resilience overall.

Ensuring Quality and Compliance

Ensuring quality and compliance is a critical pillar of any robust supply chain strategy, as it directly influences customer satisfaction, brand reputation, and regulatory alignment. Companies must establish strict quality control mechanisms and maintain traceability throughout the supply chain to meet both internal standards and external regulations. Technologies like Oracle SCM and Oracle Supply Chain enable real-time tracking, automated compliance checks, and integrated reporting tools that help organizations detect deviations early and respond proactively. For industries dealing with temperature-sensitive products, cold chain logistics play a vital role in preserving product integrity and meeting health and safety standards. In pharmaceuticals, food, and biotech, even minor lapses in temperature control can lead to spoilage or non-compliance, resulting in financial and reputational damage. Organizations that Learn Objectives of Management Accounting can better track, analyze, and optimize the costs associated with cold chain logistics, ensuring both regulatory compliance and financial efficiency. Moreover, building a sustainable supply chain supports not only environmental goals but also ensures compliance with evolving regulations on emissions, waste management, and ethical sourcing. Incorporating sustainability as a compliance strategy also strengthens relationships with eco-conscious customers and investors. Ultimately, ensuring quality and compliance is not just a regulatory requirement, it is a strategic necessity that supports long-term operational efficiency, reduces risk, and aligns the supply chain with broader business objectives and social responsibility goals.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Building Supply Chain Resilience

Building supply chain resilience has become a top priority for businesses facing growing uncertainties such as geopolitical tensions, natural disasters, and global pandemics. A resilient supply chain can absorb shocks, recover quickly, and continue to serve customers effectively. Aligning with the Objectives of Supply Chain Management, resilience ensures continuity, cost control, and long-term sustainability. Here are six effective ways to build a more resilient supply chain:

Supporting Sustainability and Corporate Responsibility

Supporting sustainability and corporate responsibility has become a strategic imperative in modern supply chain management, driven by growing consumer awareness, regulatory demands, and global environmental challenges. A well-executed supply chain strategy that prioritizes sustainability not only reduces environmental impact but also enhances brand reputation and stakeholder trust. Building a sustainable supply chain involves implementing eco-friendly practices such as energy-efficient transportation, ethical sourcing, waste reduction, and the use of recyclable materials. In temperature-sensitive industries, cold chain logistics must also be optimized to reduce energy consumption while maintaining product quality. Leveraging technology platforms like Oracle SCM and Oracle Supply Chain enables organizations to track and measure sustainability metrics across the entire supply network. Developing strong Financial Management Skills for Growth further empowers businesses to evaluate the cost-benefit of these technologies and sustainability initiatives, ensuring long-term profitability and efficiency. These tools help in identifying inefficiencies, improving resource allocation, and ensuring compliance with environmental regulations. Additionally, corporate responsibility extends beyond environmental concerns to include fair labor practices, community engagement, and transparent reporting. By integrating these values into supply chain operations, businesses can create long-term value for both society and shareholders. Supporting sustainability is no longer optional; it is a core element of a forward-thinking, resilient, and ethical supply chain model that prepares organizations for future challenges while contributing positively to global goals.

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

Fostering Collaboration and Innovation

Fostering collaboration and innovation within the supply chain is essential for achieving the broader Objectives of Supply Chain Management, such as cost efficiency, agility, customer satisfaction, and long-term growth. In today’s complex and rapidly changing global landscape, organizations must work closely with suppliers, logistics providers, technology partners, and even competitors to co-create value and drive continuous improvement. Collaboration enhances transparency, streamlines communication, and enables faster decision-making, while innovation introduces new processes, tools, and models that can transform traditional operations. Incorporating PMP Training into team development further strengthens project execution, ensuring collaborative and innovative efforts are aligned with strategic objectives. For instance, adopting advanced analytics, AI-powered forecasting, and shared digital platforms allows for more responsive and data-driven supply chains. These elements are also vital components of modern supply chain resilience strategies, which prioritize flexibility, adaptability, and preparedness in the face of disruptions. When stakeholders are aligned and actively engaged in innovation, they can more effectively identify vulnerabilities and build stronger networks. In European markets, Supply Chain Resilience Deutsch reflects the growing focus on localized collaboration, regulatory alignment, and digital innovation to improve performance under pressure. Ultimately, fostering a culture of collaboration and innovation empowers businesses to stay ahead of market trends, reduce risks, and continuously align their supply chain with evolving business goals and customer expectations.