- Introduction to Supply Chain Management

- Key Components of Supply Chain

- Importance of Supply Chain Management

- Supply Chain Strategies and Models

- Technology in Supply Chain Management

- Challenges in Supply Chain Management

- Future Trends in Supply Chain Management

- Conclusion

Introduction to Supply Chain Management

In today’s globalized and highly competitive market, supply chain management, often referred to as SCM, has become a critical function for businesses aiming to achieve operational excellence and stay ahead of their competitors. At its core, supply chain management involves the coordination and oversight of all activities related to sourcing raw materials, procuring necessary goods and services, converting these inputs into finished products, and managing logistics to deliver those products to end customers. SCM integrates supply and demand management both within individual companies and across multiple organizations, ensuring a seamless flow of materials, information, and finances along the supply chain. The supply chain itself is a complex network that connects a variety of entities, including suppliers who provide raw materials, manufacturers that convert these materials into finished goods, warehouses and distribution centers that store and manage inventory, and retailers who ultimately sell products to consumers, all of which can be effectively managed with PMP Training. This interconnected system is fundamental to the production and delivery process, enabling companies to ensure that the right products reach the right places at the right times. Effective supply chain management is vital for optimizing operational efficiency, reducing unnecessary costs, improving product quality, and increasing the speed of delivery. Moreover, well-managed supply chains significantly enhance customer satisfaction by reliably meeting demand and maintaining product availability. These benefits collectively drive profitability and create a competitive advantage for businesses operating in increasingly demanding markets. As companies face growing pressure to be agile and responsive, supply chain management remains the backbone that supports these goals. In summary, SCM is a strategic discipline that not only enables businesses to operate more efficiently but also empowers them to respond effectively to market changes, customer needs, and global challenges.

Do You Want to Learn More About PMP? Get Info From Our PMP Certification Training Today!

Key Components of Supply Chain

Understanding the fundamental components of the supply chain is essential to grasp how it operates as a cohesive system. A supply chain is made up of several key elements that work together to ensure the smooth flow of goods, information, and finances from the initial supplier all the way to the end customer. These components include sourcing and procurement, manufacturing, logistics, distribution, and customer service. Each plays a vital role in delivering products efficiently and effectively. One critical but often overlooked component is reverse logistics, which involves managing the movement of products back from customers to suppliers or manufacturers a process that can be better optimized by applying Managerial Economics Concepts to reduce costs and improve decision-making efficiency. This process handles the return of defective, damaged, or excess products for purposes such as repair, recycling, refurbishment, or disposal. Reverse logistics is increasingly important as companies seek to reduce waste and promote sustainability while maintaining customer satisfaction. Efficient management of returns helps organizations recover value from returned goods and reduce environmental impact by minimizing landfill waste. It also supports warranty management and helps comply with regulatory requirements related to product disposal and recycling. By integrating reverse logistics with traditional forward supply chain activities, companies can create a more circular and sustainable supply chain. This integration requires coordination across multiple departments, including customer service, warehousing, transportation, and procurement.

Modern technologies like tracking systems and data analytics enhance visibility and efficiency in managing returns. In summary, understanding all components of the supply chain, including reverse logistics, provides a comprehensive view of how products move through the system. Each element contributes to meeting customer demand, optimizing costs, and supporting sustainability goals. Recognizing the importance of reverse logistics ensures companies can manage the entire product lifecycle responsibly and effectively.

Importance of Supply Chain Management

- Strategic Business Function: Supply Chain Management (SCM) is no longer just about transporting goods; it plays a central role in aligning supply operations with overall business strategy, efficiency, and responsiveness.

- Customer Satisfaction and Service: Efficient SCM ensures that products are delivered on time, in the right quantity, and in good condition. A reliable supply chain directly impacts customer satisfaction, loyalty, and repeat business.

- Cost Efficiency and Profitability: Well-managed supply chains optimize inventory, reduce waste, and improve logistics, resulting in lower operational costs and higher profit margins.

- Risk Mitigation: SCM helps identify and mitigate risks such as supplier disruptions, geopolitical issues, and natural disasters. A resilient supply chain protects against interruptions and maintains business continuity by leveraging insights from the Nature Of Managerial Economics Important for proactive planning and strategic decision-making.

- Sustainability and Environmental Impact: Modern supply chains prioritize sustainability by lowering carbon emissions, minimizing waste, and adopting ethical sourcing practices.

- Regulatory Compliance: SCM ensures that businesses comply with global trade laws, labor standards, and environmental regulations. Staying compliant avoids fines, legal issues, and reputational damage.

- Enhanced Brand Reputation: Consumers are increasingly loyal to brands that demonstrate social and environmental responsibility throughout their supply chains.

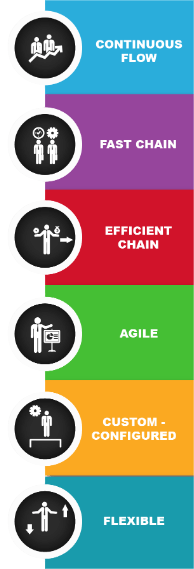

- Lean Supply Chain Strategy: This approach focuses on minimizing waste and maximizing efficiency. It is best suited for stable and predictable markets where demand is consistent, helping reduce inventory and operational costs.

- Agile Supply Chain Strategy: An agile strategy emphasizes flexibility and responsiveness. It is ideal for industries with high demand variability or customized products, allowing quick reactions to market changes and customer needs.

- Hybrid (Leagile) Supply Chain Strategy: Lean methods are applied upstream in production to maintain efficiency, while agile practices are used downstream to handle demand fluctuations and ensure rapid delivery, all supported by PMP Training.

- Outsourcing and Offshoring: Many companies outsource supply chain activities or move production to countries with lower labor costs to reduce expenses. While cost-effective, this strategy can introduce risks such as reduced control, quality issues, and supply disruptions.

- Demand-Driven Supply Chain: This strategy focuses on responding to actual customer demand rather than forecasts. It uses real-time data to guide inventory and production decisions, improving alignment with market needs.

- Digital Supply Chain Strategy: Incorporating digital technologies such as IoT, AI, and blockchain, this strategy enhances visibility, accuracy, and responsiveness across the supply chain network.

- Sustainable Supply Chain Strategy: Sustainability is now a core strategy. Companies adopt eco-friendly practices, such as ethical sourcing, emissions reduction, and waste minimization, to meet regulatory requirements and customer expectations.

- Data Management and Integration: Modern supply chains generate vast amounts of data from multiple sources, including suppliers, logistics providers, and customers.

- Demand Forecasting and Planning: Accurate forecasting remains a challenge due to unpredictable market conditions, changing customer preferences, and global events. Addressing these challenges also involves understanding What is Human Resource Management, as effective talent planning and workforce alignment play a crucial role in enhancing forecasting accuracy and organizational adaptability.

- Cost vs. Sustainability Balance: Balancing cost-efficiency with environmental and social responsibility is a persistent challenge.

- Global Disruptions and Geopolitical Risks: Supply chains are increasingly exposed to geopolitical tensions, trade restrictions, and natural disasters.

- Supplier Reliability and Risk Management: Dependence on global suppliers adds complexity and risk.

- Technology Integration and Cybersecurity: While digital tools offer efficiency, integrating new technologies into existing systems can be difficult.

- Regulatory Compliance: Navigating complex and ever-changing international trade laws, labor regulations, and environmental standards requires constant monitoring.

Would You Like to Know More About PMP? Sign Up For Our PMP Certification Training Now!

Supply Chain Strategies and Models

Technology in Supply Chain Management

Technology plays a transformative role in modern supply chains by providing powerful tools that improve visibility, coordination, and decision-making across all stages of the supply chain. As supply chains become increasingly complex and global, technology helps companies manage operations more efficiently and respond quickly to changes or disruptions. Among the key technologies revolutionizing supply chain management are Transportation Management Systems (TMS) and blockchain. A Transportation Management System is software designed to plan, execute, and optimize the movement of goods across various transportation modes such as trucking, shipping, rail, and air. Implementing such systems effectively often requires strong organizational direction, which highlights What is Leadership And Its Importance in driving adoption, streamlining processes, and ensuring cross-functional collaboration. TMS enables companies to schedule shipments, select the most efficient routes, manage carriers, and track deliveries in real-time. By improving delivery times and reducing transportation costs, TMS contributes directly to enhanced customer satisfaction and lower overall logistics expenses. It also provides valuable analytics that help businesses identify bottlenecks and make better strategic decisions. Blockchain technology, on the other hand, offers a high level of transparency and security within supply chains by creating immutable digital records of transactions. Each transaction or movement of goods is recorded in a decentralized ledger that cannot be altered retroactively. This level of transparency fosters trust among supply chain partners by allowing all parties to verify the authenticity, origin, and status of products at any point in the supply chain. Blockchain is particularly useful in industries where provenance and compliance are critical, such as pharmaceuticals, food, and luxury goods. It also helps reduce fraud, errors, and administrative costs by automating contract execution through smart contracts. Together, TMS and blockchain represent just two examples of how technology empowers supply chains to become more agile, transparent, and efficient. These innovations enable companies to gain competitive advantages in today’s fast-paced global market.

Gain Your Master’s Certification in PMP by Enrolling in Our PMP Master Program Training Course.

Challenges in Supply Chain Management

Future Trends in Supply Chain Management

The supply chain landscape is evolving rapidly as it adapts to technological innovations and shifting market dynamics. Advances in digital technologies are transforming how companies plan, operate, and optimize their supply chains. One major trend is the growing use of advanced analytics and artificial intelligence, which enhance key functions such as demand forecasting, supplier risk assessment, and inventory optimization. These tools enable businesses to analyze vast amounts of data quickly and accurately, allowing for better predictions of customer demand, identification of potential disruptions, and smarter inventory management. As a result, companies can reduce stockouts, lower excess inventory costs, and respond more effectively to market changes. Another significant trend is the increasing interconnectedness of supply chains. Organizations are moving toward greater integration and data sharing among suppliers, manufacturers, logistics providers, and customers a shift that aligns closely with the need to Learn Objectives of Management Accounting, such as cost control, performance evaluation, and informed decision-making through accurate financial insights. This seamless flow of information helps improve operational efficiency and build resilience against unexpected events such as natural disasters, geopolitical shifts, or pandemics. By sharing real-time data, all stakeholders can collaborate more closely to anticipate problems, adjust plans, and maintain service levels. Additionally, supply chains are becoming more agile and adaptive, enabled by technologies like cloud computing, the Internet of Things (IoT), and blockchain. These innovations provide greater visibility and transparency, allowing companies to track products throughout their journey and verify authenticity and compliance. Sustainability is also gaining prominence, with supply chains incorporating greener practices and ethical sourcing to meet customer expectations and regulatory requirements. In summary, the future of supply chains will be defined by smart technologies, interconnected networks, and a focus on agility and sustainability. Companies that embrace these trends will be better positioned to compete in a fast-changing global marketplace.

Are You Preparing for PMP Jobs? Check Out ACTE’s PMP Interview Questions and Answers to Boost Your Preparation!

Conclusion

Supply chain management is a vital discipline that influences every aspect of business performance, playing a crucial role in determining a company’s success or failure. It encompasses all activities involved in sourcing raw materials, managing procurement, overseeing production processes, and delivering finished products efficiently and reliably to customers. When supply chain management is effective, it leads to significant cost savings by optimizing resources, reducing waste, and improving operational efficiencies. Additionally, it enhances customer satisfaction by ensuring products are available when and where customers need them, maintaining quality standards and timely delivery. These factors collectively contribute to creating a strong competitive advantage in increasingly crowded markets, especially when guided by PMP Training. In today’s world, supply chain management has become more complex due to the forces of globalization, rapid technological innovation, and growing sustainability concerns. Global supply chains span multiple countries and regions, exposing businesses to challenges such as geopolitical risks, trade regulations, and diverse cultural expectations. At the same time, emerging technologies such as artificial intelligence, data analytics, Internet of Things devices, and blockchain are transforming how companies manage their supply chains. These technologies enable greater visibility, faster decision-making, and improved collaboration among supply chain partners. Companies that invest in advanced SCM practices and technologies will be better positioned to navigate these challenges and seize new opportunities. Understanding and mastering supply chain management is no longer optional; it is essential for businesses aiming to thrive in today’s fast-paced, interconnected economy.