- What is SAP EWM?

- How is SAP EWM unique from Drain WM?

- Elements of SAP EWM

- SAP EWM Architecture

- EWM Association Construction

- SAP EWM Configuration Records

- SAP EWM Designing Chronicles

- Key Warehousing Cycles in SAP EWM Plan

- Conclusion

- SAP EWM represents SAP Expanded Stockroom The board. It is utilized for dealing with the distribution center stock and supporting the stock development handling. It empowers the organization to control its approaching and active cycles of the Stockroom just as the developments of the merchandise in the Distribution Center. A portion of the significant cycles in the Stockroom is approaching and active materials, satisfying client orders, merchandise receipt and products issue and appropriation of products. On the off chance that an organization isn’t putting away any merchandise, then, at that point, stockroom the board isn’t needed. The inbound interaction incorporates the capacity of the merchandise at the Stockroom and their area, while the outbound cycle incorporates the pickup of products. The materials are put away in the capacity container at the Stockroom, and we can discover its current area.

- A stockroom the board framework controls the developments of merchandise utilizing SAP EWM. SAP EWM makes it conceivable to successfully screen the nature of the merchandise, dealing with the basic capacities and the conveyance of the products. It likewise offers the instruments for checking the stockroom exercises. Extra elements of the Distribution center like making a group number, chronic number, seller the board stock, esteem added administrations and asset streamlining can likewise be made due. SAP stockroom the executives is not quite the same as Stock administration. Stock administration manages the number of products at the capacity area, and the actual area isn’t known, while the distribution center administration is centered around the development of merchandise, observing the actual area of products that are recorded with specific reports.

- Stockroom the board offers vigorous and improved elements for dealing with the fundamental exercises of the Distribution center. SAP EWM is equivalent to Distribution center administration. It offers highlights like picking, RF system, set aside, distribution center design, and numerous other adaptable choices for dealing with the stockroom capacities. New components like assets, movement regions, work focuses, work the executives that are not accessible in WM can be made in SAP EWM.

- SAP EWM offers a vigorous answer for an association for overseeing stockroom capacities. It additionally upholds every one of the cycles of the production network and planned operations.

- The distribution center exercises like picking, posting of products, dealing with the capacity receptacle, and getting the merchandise can be overseen by SAP EWM.

- It helps in setting an alarm for the altered information preceding getting the merchandise from the EWM to the ERP framework, switching or revising the receipt of products from the EWM to the ERP framework, and an inbound conveyance division from the EWM to ERP framework.

- Dealing with units that contain different items can be deconsolidated before being put away in different capacity areas.

- Capacity ideas can be resolved to utilize opening for items and naturally improve the course of action of products distribution centers.

- It empowers us to perform executable assignments like work bundles, including the errands connected with the Distribution center that should be performed by the representatives of the Stockroom as a feature of the stockroom exercises.

- It helps us in overseeing and following vehicles and other transportation units from yard registration to the yard look at alongside the developments and different undertakings in the yard.

- SAP EWM likewise covers the capacity and treatment of risky substances and their vehicle as per SAP Ecological Wellbeing and Security EHS guidelines. In SAP EWM, work times and assets can be arranged viably, and this permits us to make our Stockroom compelling by adequately overseeing secret weapon the board errands.

- The distribution center cockpit can be utilized in SAP EWM for showing stockroom key figures graphically and for assessing or observing the exercises through characterized outline types.

- Cross-docking is utilized for performing transportation of taking care of units through different conveyance communities or stockrooms until they arrive at the last area inside the Distribution center.

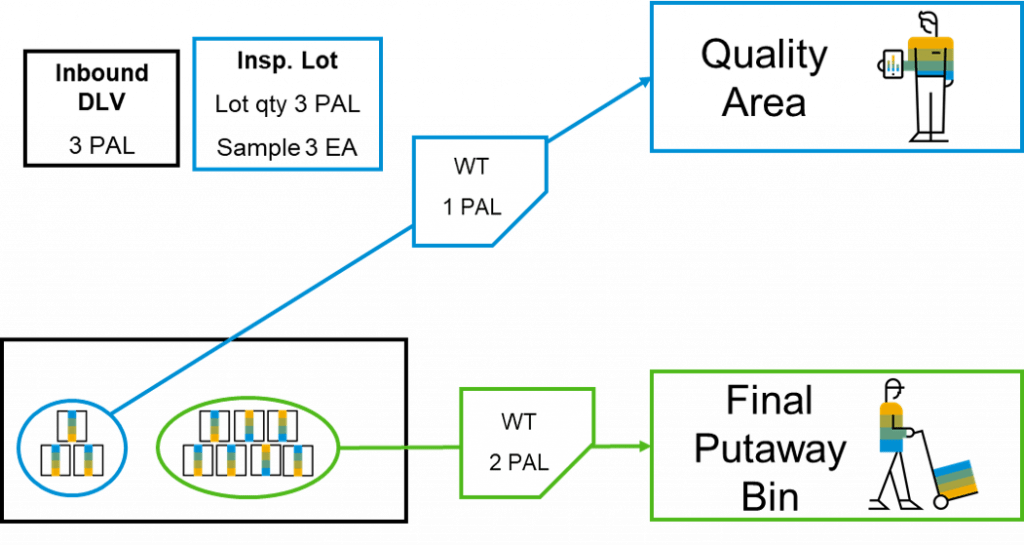

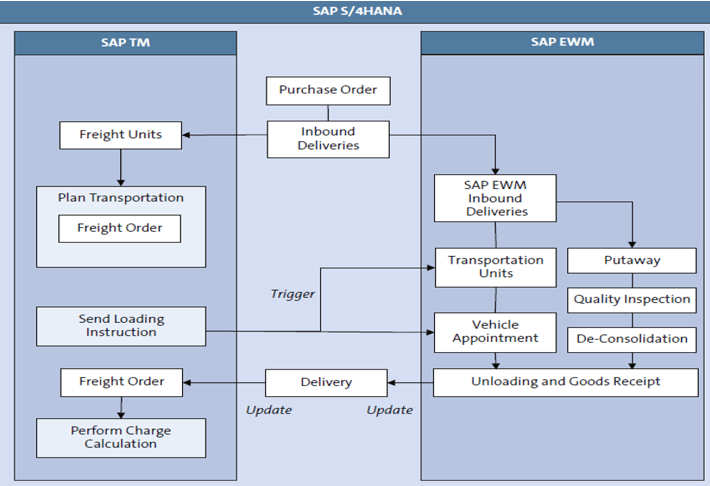

- The inbound cycle begins with the creation of an inbound transport produced using the ASN/purchase demand in the SAP ERP structure. The structure concludes the SAP EWM designing for express settings, for instance, the stockroom collaboration type, and makes the ID (inbound movement) in EWM using the post-dealing with a framework (PPF).

- The product got will then, be placed into the limit type/storing holder in the dispersion community by making the stockroom task include inbound transport in EWM.

What is SAP EWM?

How is SAP EWM unique from Drain WM?

Elements of SAP EWM:

A portion of the significant elements of SAP EW are:

SAP EWM Architecture:

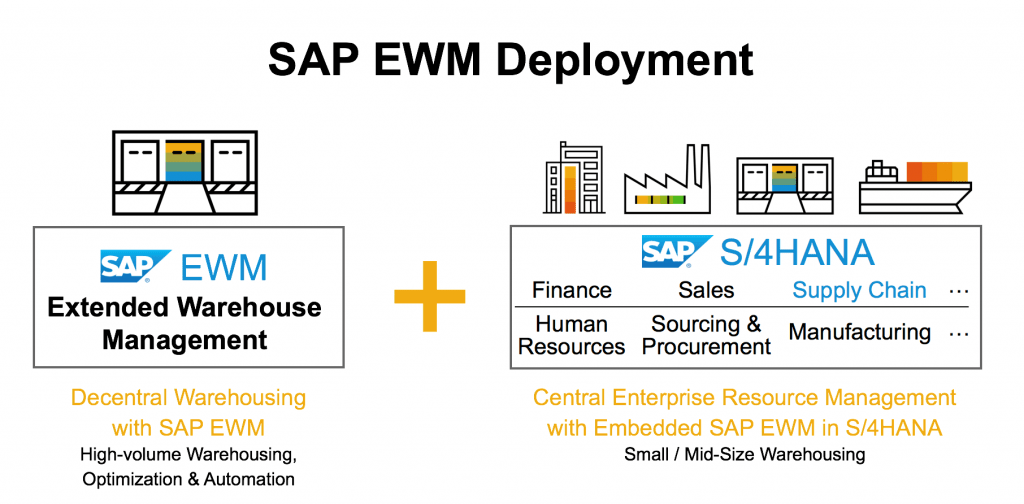

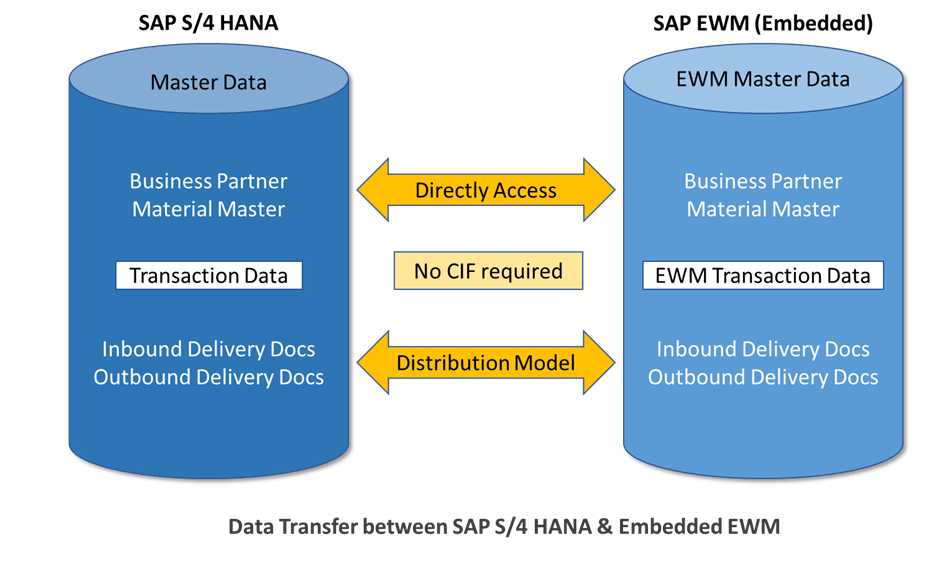

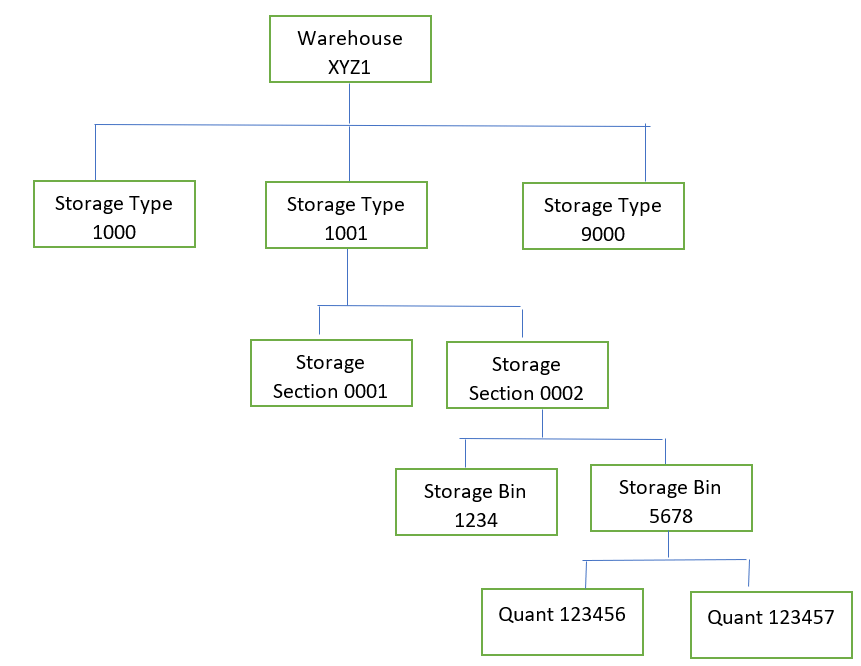

SAP EWM is viewed as an independent application that might be utilized in any of the warehousing conditions. The essential elements of EWM are dealing with the stock at the capacity receptacle level, deciding the capacity canister for the approaching and active merchandise, and pressing the items when transporting them to the clients. SAP EWM has two adaptations. One of them has a decentralized design; it arrives in an alternate box and needs a connection point like Center Connection point CIF for trading ace information between the EWM and the ERP. Nonetheless, with S/4 HANA, ECC and EWM are implanted into a solitary framework, and there is no necessity for CIF.

EWM Association Construction:

For actuating the stockroom the board in the ERP framework, the plant, and the capacity area of that plant should be connected with the suitable distribution center number that will be then appointed to the EWM distribution center number. Following are the primary components of the EWM stockroom that should be set up in the EWM framework.

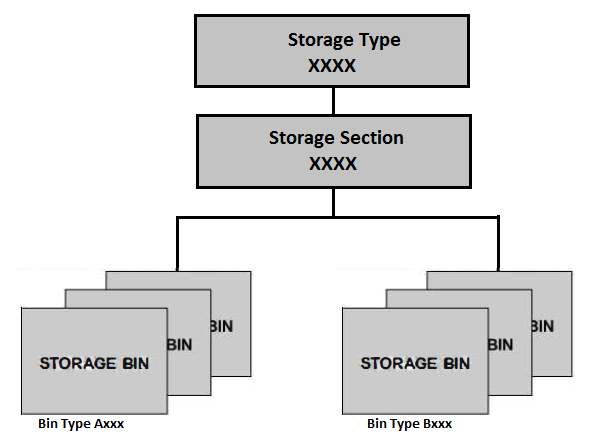

Capacity type: The capacity type is the other division in the SAP EWM. It alludes to the extra room or office, space required, specialized attributes in the Distribution Center. A specific job ought to be arranged for the capacity type as indicated by its use. Following are the different jobs of the capacity type:

Standard stockpiling type: It is the stockroom region wherein the items are put away.

Recognizable proof Point: It is a moderate region wherein the items are marked put briefly positioned for a specific reason.

Pick Point: It is the point in the distribution center from where the pressing and picking exercises are performed.

Recognizable proof and Pick point: It is the point that is utilized as both the pick point just as the ID point.

Organizing Region bunch: various arranging regions are gathered as organizing region gatherings.

Work focus: It is a spot where exceptional cycles like quality, counting, deconsolidation, and so forth, are completed.

Entryway: It is where the truck comes to stack or dump.

Capacity area: The capacity type is then separated into capacity areas as per its properties. It is additionally joined with different containers with comparable traits like light, weighty, slow, quick, and so forth The capacity segment in EWM can be utilized alternatively.

Capacity receptacles: It is the littlest addressable unit of room in the Stockroom, and it portrays the precise area inside the Distribution center where an item might be put away. It’s remarkable, all things considered. Each capacity receptacle has a sort of container connected with its properties.

Quant: It is the presence or load of a specific item with comparable qualities in the asset, stockpiling canister, and transport unit. The various clumps inside an item are the diverse quants. Quants might be made or taken out exclusively by the framework by the developments.

Action region: Stockroom exercises, like picking, putaway, and actual stock, are done at action regions. The active region is made out of at least one stockpiling receptacle appointed. As indicated by the movement, a similar stockpiling container might be dispensed to more than one active region. For each action, the dispensed receptacles are arranged by the movement area. This makes it conceivable to enhance the grouping of stockroom errands relying upon the capacity canisters task to an active region.

Arranging Regions: Before stacking or In the wake of dumping, the material might be put away in the meantime stockpiling alluded to as organizing region. An arranging region indicates a capacity part of the capacity type under the job “D”. You want to set up the action that is done in the arranging region, which is, characterized assuming it is approaching or active or both. We additionally have the choice of appointing a stacking rule. Inside the capacity segment, we might have at least one canisters which are additionally alluded to as organizing coves for this sort of capacity.

Entryway: A distribution center entryway might be utilized on approaching and active shipments. The entryway where the shipment began is refreshed inside the conveyance. Vehicles and transport units advance toward the entryways of the Distribution center, where they load or dump merchandise. The entryway might be utilized as a yard canister or organizing region.

Work focus: The Work Place is an actual unit in a stockroom with the accompanying exercises: Pressing, quality investigation, counting, VAS, Deconsolidation, and so forth Each work community will be doled out to the capacity type, stockpiling container, and distribution center number.

Store network unit: A physical or a hierarchical unit utilized in the calculated cycle for specific business quality, for example, a transportation office or merchandise receipt office.

Overseer: Each distribution center number should likewise be allocated to a colleague following up in the interest of the caretaker. Overseers are the individuals who store, oversee or handle stock for another colleague without title move. The caretaker holds just the genuine ownership of the stock, while the proprietor holds lawful belonging.

Accessibility bunch: The EWM framework will utilize the accessibility gathering to recognize the kinds of stock and where the ERP framework is put away. We might have different sorts of stock in EWM for a capacity place in ERP. The EWM distinguishes the ERP stockpiling area for the accessibility bunch. Nonetheless, the blend should be interesting for each Distribution center.

Distribution center Cycle Type: The action or the development of each interaction like products receipt, posting Change, giving merchandise in the Stockroom are constrained by the Stockroom interaction type. A stockroom cycle type is appointed to each distribution center assignment record and diversely affects making stockroom undertakings.

SAP EWM Configuration Records:

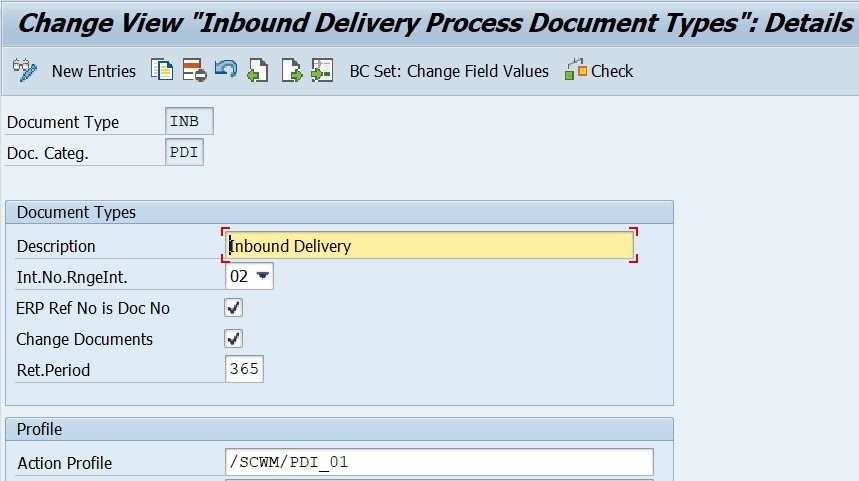

Inbound movement notice: The Supplier’s Transportation Notice is taken care of in the Inbound Movement Cautioning (IDN). It contains all procedures data associated with the coming movement process and is normally made with an oncoming message and was used as the reference file for making Inbound Transport.

Inbound movement (Stockroom Requesting): It incorporates all of the data expected to trigger and screen the full inbound transport process thusly made after the incitation of the Inbound Movement Notice.

Outbound Movement Sales: It incorporates all determined data relevant to the outbound transport process and is thusly made by the coming messages and goes comparably a sort of viewpoint chronicle for the arrangement of an outbound transport demand.

Outbound transport demand (dispersion focus requesting): It contains all of the essential data to trigger and track the entire outbound movement process and is normally made after the activation of the outbound movement interest.

Posting Change: It is a report with all of the data expected to complete the EWM posting change process. It triggers the EWM coming about to the trade posting report posted in the ERP.

Warehouse Requesting: It is a report that licenses stockroom exercises to be dealt with for a particular thing that joins Putaway, Picking, Stock Trade, Posting Change, dismissing. Following are the kind of dissemination focus requests made by the system: Posting Change, outbound movement, inbound transport, inside stock trade.

Stockroom Task: It is a document used to do improvements of items which are physical or reasonable, that joins picking, packaging, putaway, show change, etc A stockroom task fuses every one of the important information about an organized advancement of product: what ought to be moved, how much ought to be moved, from where it ought to be moved to where. Warehousing tasks are required for Picking, Inside advancements, Putaway, Posting changes, Product issue postings, and Items receipt postings.

Stockroom orders: It is a document that shows a lot of executable endeavors that a dispersion place laborer should complete at a given time. A dispersion place demand is contained in stockroom tasks. Uniting stockroom endeavors to dispersion focus demands is compelled by rules for making dissemination focus demands. Fundamental Warehousing Cycles in the SAP EWM plan:

Outbound product issue process: The Cycle begins with the creation of arrangements orders and the outbound movement in ERP that makes outbound transport demand files in EWM with PPf action. This record includes diverse data pertinent to the EWM not completely settled by the help profiles related to the outbound transport chronicle type and the movement class. It is the stockroom request report for the technique engaged with giving EWM stock. From the outbound movement demand, stockroom tasks are made for controlling the picking and other related cycles like squeezing, stacking, and sorting out.

Inbound items receipt process: Inbound cycle starts by making the inbound movement from ASN or purchase demand in SAP ERP. The structure portrays the SAP EWM plan for explicit limits, like the kind of Warehouse association, and makes the ID inside EWM through post-taking care of framework. Items will be set in the limit holder or limit type by the development of dispersion focus tasks through inbound movement in the EWM.

SAP EWM Designing Chronicles:

Inbound Transport Cautioning

Moving admonition from the supplier is saved in Inbound Transport Notice (IDN). It contains every one of the critical activities data in the inbound transport process and is made therefore by a coming message and filled in as a sort of viewpoint document to make Inbound Movement.

Inbound Transport (Stockroom Sales)

It contains all of the data required for setting off and checking the absolute inbound movement process made thusly resulting in impelling the Inbound Transport Notice.

Outbound Movement Requesting

It contains every one of the significant system’s data in the outbound transport process and is made thus by moving toward messages and is filled in as a wellspring of viewpoint report to make an outbound movement demand.

Outbound Transport Solicitation (Dispersion focus Sales)

It contains all of the data required for setting off and checking the all-out outbound movement process and is made thus following instituting the outbound transport interest.

Posting Change

This is a record containing all of the data expected to complete the posting change process in EWM. This triggers EWM due to the trade posting report posted in ERP.

Warehouse Requesting

This is a record that engages the treatment of stockroom practices for a specific thing which fuses Picking, Putaway, Posting Change, Stock Trade (inside dispersion place), Dismissing. The Structure makes the going with kind of Stockroom Sales: Inbound movement, Outbound transport demand, Posting change, Internal stock trade.

Warehouse Task

This is a record used for executing items improvements that are reasonable or physical, including pick, putaway, posting change, squeezing, etc A stockroom task contains every one of the essential information on an organized product advancement what should be moved, which sum should be moved, from where (source accumulating compartment) should the canister be moved, and to where (objective amassing repository). Dispersion focus tasks are needed for Picking, Putaway, Internal turns of events, Posting changes, Items receipt postings, and Product issue postings.

Stockroom Orders

This is a record that tends to be an executable workgroup that a stockroom delegate should perform at a specific time. The conveyance place demand involves stockroom endeavors. The social event of stockroom tasks into Warehouse demands is compelled by Stockroom Solicitation Creation Rules.

Key Warehousing Cycles in SAP EWM Plan:

Inbound Product Receipt Cycle

Outbound Items Issue Cycle

The cycle starts with Arrangements Solicitation and Outbound movement creation in ERP which makes the outbound transport demand report (ODO) in EWM through PPF action. This record contains extra EWM-relevant data that is settled considering the help profiles related to the outbound transport document type and movement characterization. This is the stockroom request record for the EWM stock issue process. From the outbound movement demand, the stockroom endeavors are made to control the picking and other related cycles like squeezing, coordinating, and stacking.

Outbound Product Issue Association

Did you like this educational exercise? Have any requests or comments? We were unable to need anything over to hear your analysis in the comments section. It’d be a significant help for us, and in a perfect world, it’s something we can address for you in the improvement of our free SAP EWM informative activities.

Conclusion:

In this instructional exercise, we have found out with regards to Drain EWM, how SAP EWM is not quite the same as WM, elements of SAP EWM, EWM’s Engineering, and so forth We truly want to believe that you found this data supportive. Assuming that you are looking for some other points connected with SAP, remember to remark on them in the remark area. We will hit you up with that subject.