- Introduction to Supply Chain Management

- Definition and Scope of Supply Chain Management

- The Objectives of Supply Chain Management

- Key Functions within Supply Chain Management

- Importance of Supply Chain Management in Business

- Types of Supply Chains

- Technologies Shaping Supply Chain Management

- Future Trends in Supply Chain Management

Introduction to Supply Chain Management

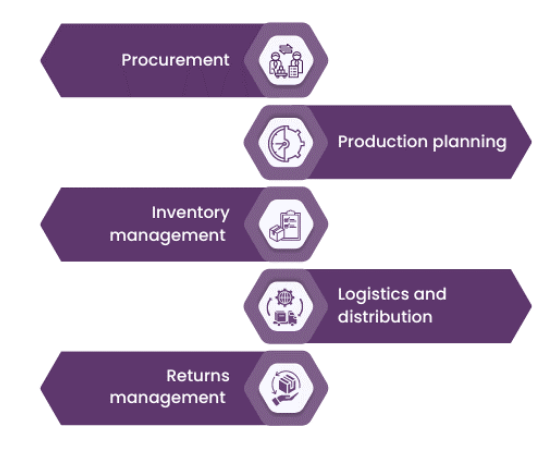

Supply Chain Management (SCM) is a critical discipline that serves as the backbone of operations for nearly every business involved in producing or delivering goods and services. In the modern, globalized economy where markets move rapidly and competition is intense, SCM plays a vital role in ensuring that products flow smoothly and efficiently from raw material suppliers to manufacturers, then through distribution channels, and ultimately reach the end customers. This flow involves not only the physical movement of goods but also the management of related information and financial transactions. Effective SCM coordinates these complex activities to optimize the entire supply chain, balancing cost, speed, quality, and customer satisfaction. The scope of SCM is broad, and with the support of PMP Training, it encompasses procurement of raw materials, production planning, inventory management, transportation, warehousing, and demand forecasting. Each of these functions must be carefully aligned and integrated to avoid delays, excess inventory, or stockouts. Moreover, SCM requires close collaboration among various stakeholders, including suppliers, manufacturers, distributors, retailers, and logistics providers. This collaboration is crucial to respond quickly to market changes, meet customer expectations, and maintain a competitive advantage. The significance of SCM extends beyond operational efficiency. It directly impacts a company’s profitability, customer loyalty, and ability to innovate. With supply chains becoming increasingly complex due to factors like globalization, technological advancements, and changing consumer behaviors, mastering SCM is more important than ever. It empowers businesses to reduce costs, improve service levels, increase agility, and build resilience against disruptions. This blog will explore the key concepts, broad scope, and vital importance of supply chain management in driving business success in today’s dynamic environment.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Definition and Scope of Supply Chain Management

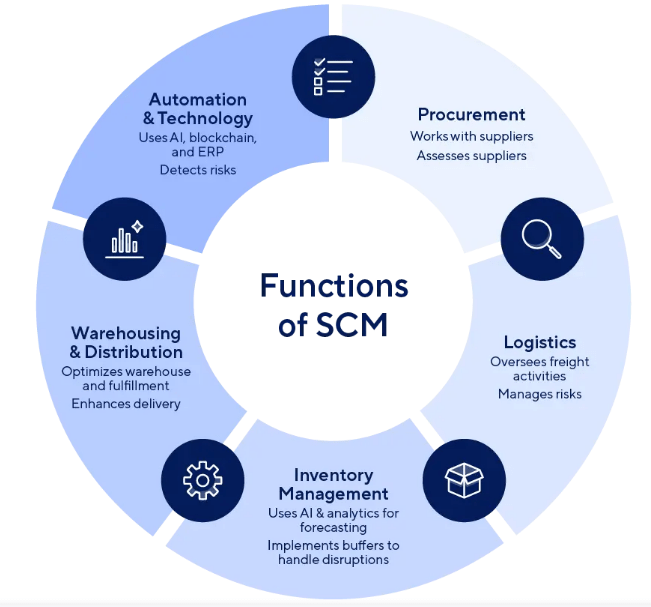

Supply Chain Management (SCM) is broadly defined as the comprehensive process of designing, planning, executing, controlling, and monitoring all activities involved in the supply chain. The primary objective of SCM is to create net value for the organization by building a competitive infrastructure, leveraging global logistics capabilities, synchronizing supply with customer demand, and measuring overall performance on a global scale. This strategic discipline aims to streamline the entire flow of goods, information, and finances from the initial supplier all the way to the end customer, ensuring that each step adds value while minimizing costs and inefficiencies. SCM covers a wide range of functions that are essential for effective operations, especially in the context of Projects in Business Environments. Procurement involves sourcing and acquiring raw materials and components from suppliers, while production focuses on transforming these inputs into finished goods. Inventory management ensures optimal stock levels are maintained to meet demand without excessive holding costs. Logistics oversees the transportation and warehousing of products, making sure goods are delivered safely, on time, and at the lowest possible cost. Customer service completes the cycle by ensuring that customer needs and expectations are met or exceeded. A key feature of SCM is its integrative nature. It brings together various entities, suppliers, manufacturers, warehouses, transportation providers, retailers, and customers into a unified and coordinated system. This integration breaks down traditional functional silos, promotes collaboration, and enhances communication across all parties involved.

By connecting these components seamlessly, SCM enables organizations to respond rapidly to market changes, optimize resource use, and build resilient supply chains capable of adapting to disruptions. Overall, SCM is a vital discipline that combines strategic planning and operational excellence to drive competitive advantage and business success in today’s interconnected and fast-moving global economy.

The Objectives of Supply Chain Management

- Cost Reduction: One of the main goals of supply chain management (SCM) is to reduce overall costs by optimizing procurement, production, transportation, and inventory management.

- Improved Service Levels: SCM aims to enhance customer service by ensuring products are available when and where customers need them, improving reliability and satisfaction.

- Increased Operational Efficiency: Streamlining processes and eliminating waste across the supply chain increases efficiency and productivity, benefiting all stakeholders, which is a key aspect of What is Business Agility.

- Competitive Advantage: Effective SCM helps organizations differentiate themselves in the market by delivering superior value through faster, cheaper, and higher-quality service.

- Balancing Supply and Demand: SCM works to align supply closely with customer demand to avoid shortages and overstocks, maintaining equilibrium throughout the supply chain.

- Accelerated Product Flow: Reducing delays in production and distribution speeds up the movement of goods, enabling quicker response to market changes and customer needs.

- Sustainability and Alignment: By integrating business processes and technology across partners, SCM fosters sustainable practices and ensures the right product is delivered at the right time, place, and cost.

- Procurement: This function manages the sourcing and purchasing of raw materials and components needed for production, ensuring quality and timely supply.

- Production: Responsible for manufacturing and assembling products, production ensures that goods are created efficiently and meet required specifications.

- Inventory Management: PMP Training helps control stock levels to balance meeting customer demand while minimizing holding costs and reducing excess inventory.

- Warehousing: Focuses on the proper storage, handling, and safeguarding of products within distribution centers, ensuring goods are ready for timely dispatch.

- Transportation: Manages the physical movement of goods throughout the supply chain network, selecting appropriate modes and routes to optimize delivery speed and cost.

- Demand Planning: Involves forecasting customer needs using historical data and market trends to guide production and inventory decisions.

- Customer Service: Handles order processing, fulfillment, and after-sales support, ensuring customers receive products accurately and promptly while addressing any issues.

- Industry Variation: Supply chains differ depending on the industry, product characteristics, and specific customer requirements, requiring customized management approaches.

- Direct Supply Chain: This type features a simple flow where goods move directly from supplier to manufacturer and then to the customer, suitable for straightforward products.

- Complex Supply Chain: Involves multiple suppliers, manufacturers, distributors, and intermediaries, creating a more intricate network with increased coordination needs, raising the question: Can Business Analyst be a Project Manager?

- Global Supply Chain: Operates across multiple countries and regions, dealing with challenges like customs regulations, tariffs, longer lead times, and geopolitical risks.

- Service Supply Chain: Unlike product-focused chains, service supply chains manage the delivery of intangible services, such as maintenance, consulting, or customer support.

- Tailored Strategies: Understanding the type of supply chain helps businesses develop specific SCM strategies that address unique challenges and opportunities of each model.

- Optimized Performance: By aligning supply chain design with industry and product needs, companies can improve efficiency, responsiveness, and customer satisfaction.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

Key Functions within Supply Chain Management

Importance of Supply Chain Management in Business

Effective Supply Chain Management is essential for business success in today’s competitive market. One major benefit is the reduction of operational costs. By optimizing procurement, companies can secure better prices and ensure materials are available when needed. Efficient production planning reduces downtime and waste while streamlined logistics helps transport and store goods in a cost-effective way. These improvements together lower expenses and increase profitability. In addition to cutting costs, supply chain management improves cash flow. Minimizing excess inventory frees up working capital that would otherwise be tied up in stock. Accelerating accounts receivable through better order fulfillment and invoicing also helps maintain stronger cash reserves. This financial efficiency allows businesses to invest in growth and respond to challenges more effectively, highlighting The Most Important Benefits of Blended Learning. Customer satisfaction is another important result of effective supply chain management. Delivering products on time and maintaining quality builds customer trust and loyalty. A reliable supply chain meets customer demands promptly, reducing delays and shortages. This responsiveness is especially important as consumer expectations continue to rise. Moreover, supply chain management enables companies to adapt quickly to market changes and disruptions. Whether dealing with supplier failures, sudden spikes in demand, or transportation issues, an agile supply chain can adjust to maintain operations. Additionally, modern supply chain management supports sustainability by optimizing resource use, reducing waste, and lowering carbon emissions throughout the process. Integrating sustainable practices helps businesses protect the environment, enhance their reputation, and comply with regulations. In summary, effective supply chain management drives cost savings, financial strength, customer satisfaction, agility, and sustainability, all of which are crucial for long-term business success.

Gain Your Master’s Certification in PMP by Enrolling in Our PMP Master Program Training Course.

Types of Supply Chains

Technologies Shaping Supply Chain Management

Modern Supply Chain Management (SCM) relies heavily on technology to improve visibility, efficiency, and agility throughout the entire supply chain. One of the foundational technologies is Enterprise Resource Planning (ERP) systems. These systems integrate core business functions such as procurement, production, inventory management, and finance into a unified platform. This integration ensures that information flows seamlessly across departments, allowing for better coordination and faster decision-making. In addition to ERP, specialized Supply Chain Management software plays a critical role in planning and executing supply chain activities. These platforms provide tools for demand forecasting, order management, transportation planning, and supplier collaboration. By using such software, companies can reduce errors, improve accuracy, and enhance overall supply chain performance, which explains Why A PMO Is Second In Line To A Project Manager. The Internet of Things (IoT) has introduced real-time tracking capabilities by equipping shipments, vehicles, and assets with sensors and communication devices. This enables companies to monitor the exact location and condition of goods at any given time, which reduces losses and improves customer service. Artificial Intelligence (AI) and machine learning are increasingly used to analyze large volumes of data, improving demand forecasting accuracy and supporting more informed decision-making. These technologies help identify patterns and trends that might not be visible through traditional analysis methods. Blockchain technology adds a layer of transparency and traceability by providing a secure, immutable ledger of transactions. This helps build trust among supply chain partners and ensures the authenticity of products. Automation and robotics have revolutionized warehousing and manufacturing operations by increasing speed, accuracy, and consistency. Automated systems reduce manual labor, lower costs, and improve safety. Together, these technologies are transforming traditional supply chains into highly connected and responsive digital ecosystems that can adapt quickly to changing market demands and disruptions.

Go Through These PMP Interview Questions and Answers to Excel in Your Upcoming Interview.

Future Trends in Supply Chain Management

The future of Supply Chain Management will be shaped by several important trends including increased digitization, automation, and a strong focus on sustainability. One major development is the use of autonomous vehicles and drones, which have the potential to revolutionize logistics and transportation. These technologies can improve delivery speed, reduce costs, and increase safety by minimizing human error. As these innovations mature, they will play a key role in reshaping how goods move from suppliers to customers. Advanced analytics and artificial intelligence will also be critical drivers in the future of supply chains. These technologies will enable predictive and prescriptive capabilities, allowing companies to anticipate demand changes, optimize inventory levels, and make better strategic decisions. By leveraging data and machine learning, businesses with PMP Training will be able to respond more effectively to market fluctuations and operational disruptions. Resilience will become a core focus for supply chains as companies seek to manage risks and prepare for unexpected challenges. Incorporating risk management practices and scenario planning will help organizations identify vulnerabilities and develop contingency plans. This will enable supply chains to continue operating smoothly despite disruptions caused by natural disasters, geopolitical events, or other crises. Sustainability will be integrated throughout the supply chain, with circular supply chains reducing environmental impact by promoting reuse, recycling, and waste reduction. Companies will prioritize sustainable sourcing, energy efficiency, and ethical practices to meet consumer expectations and regulatory requirements. Collaboration platforms will enhance connectivity among supply chain partners by enabling real-time communication and data sharing. This improved collaboration will foster transparency, trust, and coordinated responses to challenges. Overall, adapting to these emerging trends will be essential for businesses that want to thrive and maintain competitive advantage in an increasingly complex and evolving global marketplace.