- Introduction to Supply Chain Management

- Core Components of a Supply Chain

- Why Supply Chain Management Is Crucial in Today’s Economy

- Cost Efficiency and Profitability

- Enhancing Customer Satisfaction

- Technology’s Role in Modern Supply Chains

- Challenges in Supply Chain Management

- The Future of Supply Chain Management

Introduction to Supply Chain Management

Supply Chain Management (SCM) is a critical function that oversees the seamless flow of goods, services, information, and finances from the initial supplier to the final customer. It involves every stage of production, from sourcing raw materials to delivering finished products. The importance of supply chain management lies in its ability to improve efficiency, reduce costs, enhance customer satisfaction, and build resilience against market disruptions. In today’s global economy, SCM is more than just logistics; it is a strategic tool that aligns operations with business goals. Modern logistics and supply chain management practices leverage technology, data analytics, and process optimization to ensure timely deliveries and responsive service. To excel in this dynamic field, professionals often pursue PMP Training, which equips them with project management skills essential for planning, execution, and continuous improvement in supply chain operations. One transformative innovation in this space is the importance of blockchain in supply chain, which offers enhanced transparency, traceability, and security. Blockchain helps track product origin, verify authenticity, and streamline documentation, especially in industries like pharmaceuticals, agriculture, and luxury goods. With businesses increasingly facing complex challenges such as geopolitical tensions, demand fluctuations, and sustainability concerns, effective supply chain management becomes essential. Companies that invest in agile and tech-enabled supply chains gain a competitive edge, reduce waste, and drive long-term profitability while meeting the evolving expectations of customers and regulators alike.

Are You Interested in Learning More About PMP? Sign Up For Our PMP Certification Training Today!

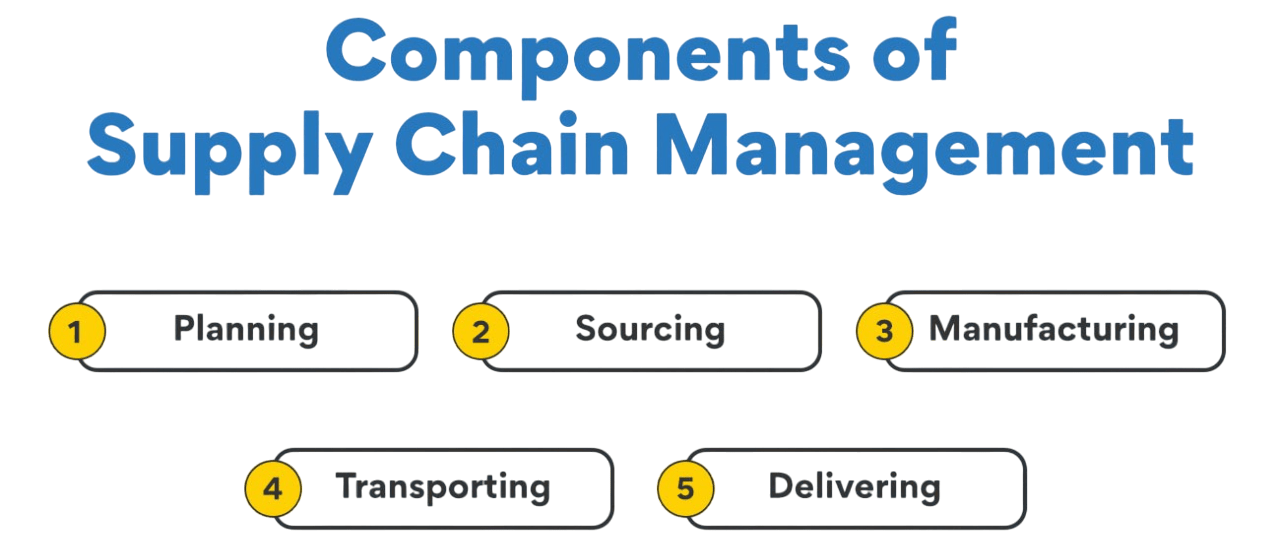

Core Components of a Supply Chain

- Supply Chain Planning: This involves forecasting demand, aligning inventory levels, and designing workflows to meet business goals. Accurate planning ensures timely production and delivery, reducing stockouts and excess inventory.

- Supplier Management: Building strong relationships with reliable suppliers is crucial. This component focuses on selecting, evaluating, and collaborating with suppliers to ensure quality, consistency, and long-term value. Applying Managerial Economics Concepts helps professionals make informed decisions on supplier selection, cost analysis, and value optimization to enhance overall supply chain efficiency.

- Supplier Risk Management: Identifying and mitigating risks associated with suppliers such as delays, quality issues, or geopolitical disruptions helps prevent bottlenecks and ensures business continuity.

A supply chain is made up of several interconnected components that work together to ensure the efficient production and delivery of goods and services. Understanding these core components of a supply chain is essential for maintaining smooth operations, reducing costs, and responding effectively to market changes. Below are six key components that form the backbone of a successful supply chain:

- Logistics Management: This covers the transportation, warehousing, and distribution of goods. Efficient logistics management reduces delivery times, minimizes costs, and improves customer satisfaction.

- Cold Chain Logistics: For temperature-sensitive goods like food and pharmaceuticals, cold chain logistics ensures that products are stored and transported under controlled temperatures, maintaining safety and quality.

- Information Flow & Technology Integration: Modern supply chains rely on real-time data and integrated systems to enable visibility, tracking, and decision-making across the entire network.

Why Supply Chain Management Is Crucial in Today’s Economy

In today’s fast-paced and interconnected global economy, Supply Chain Management (SCM) plays a pivotal role in determining the success and sustainability of businesses across all industries. The importance of supply chain management has grown significantly as companies face increasing pressure to deliver products faster, cheaper, and with greater transparency. SCM ensures the smooth movement of goods, services, and information from suppliers to consumers, optimizing resources and minimizing delays or disruptions. Understanding What is Human Resource Management is also essential, as effective supply chains rely heavily on skilled personnel, team coordination, and strategic workforce planning to achieve operational excellence. Moreover, logistics and supply chain management contribute directly to customer satisfaction by ensuring timely delivery, accurate order fulfillment, and efficient returns processing. In an era where trust and traceability are paramount, the importance of blockchain in supply chain is also becoming more evident. Blockchain technology enhances transparency, reduces fraud, and improves traceability by providing secure, real-time records of transactions across the supply chain. This is particularly critical for industries like food, pharmaceuticals, and electronics, where product authenticity and safety are vital. Additionally, the ability to anticipate and adapt to global events such as pandemics, geopolitical shifts, or natural disasters makes effective SCM an essential competitive advantage. Businesses that invest in resilient and tech-driven supply chain systems are better equipped to navigate uncertainties, meet customer expectations, and thrive in an increasingly demanding market landscape.

To Explore PMP in Depth, Check Out Our Comprehensive PMP Certification Training To Gain Insights From Our Experts!

Cost Efficiency and Profitability

- Supply Chain Planning: Accurate forecasting and demand planning help prevent overproduction or stock shortages, reducing unnecessary holding costs and ensuring optimal inventory levels.

- Supplier Management:Building strategic partnerships with reliable suppliers leads to better pricing, quality assurance, and reduced procurement costs, which directly impact profitability. Professionals with PMP Training can effectively manage these supplier relationships and procurement projects, ensuring alignment with business objectives and sustained value creation.

- Supplier Risk Management: Proactively identifying and mitigating supplier-related risks such as delays or non-compliance avoids costly disruptions and protects operational continuity.

Achieving cost efficiency and profitability is a top priority for every business, and effective supply chain management plays a vital role in reaching these goals. By optimizing operations and minimizing waste across the supply chain, companies can reduce expenses while maintaining high service standards. Below are six ways supply chain strategies contribute to cost savings and increased profits:

- Logistics Management: Streamlined transportation, optimized routes, and efficient warehousing reduce fuel costs, lower transit times, and improve order accuracy, all contributing to lower operational costs.

- Cold Chain Logistics: In industries like food and pharmaceuticals, maintaining strict temperature control reduces spoilage and product loss, improving margin preservation and customer trust.

- Process Automation and Technology: Integrating automation tools and real-time data analytics within the supply chain enhances decision-making, increases productivity, and reduces human error, ultimately boosting overall profitability.

Enhancing Customer Satisfaction

Enhancing customer satisfaction has become a key competitive advantage in today’s marketplace, and a well-structured supply chain plays a vital role in achieving it. The importance of supply chain management lies in its ability to deliver products accurately, on time, and in perfect condition factors that directly impact the customer experience. From procurement to final delivery, every component of logistics and supply chain management must operate efficiently to meet customer expectations. Timely order fulfillment, transparent tracking, and responsive service are now baseline standards, and any disruptions can significantly affect brand loyalty. By understanding the Scope of Management Accounting, businesses can better analyze operational costs, forecast demand, and allocate resources efficiently to maintain seamless supply chain performance and enhance customer satisfaction. The importance of blockchain in supply chain has grown as consumers demand greater visibility into the origin and journey of their purchases. Blockchain ensures transparency, traceability, and trust by recording every transaction in a secure and immutable system. This is especially crucial for industries like food, fashion, and healthcare, where product authenticity and ethical sourcing matter deeply to consumers. A responsive and agile supply chain can also quickly adapt to changing customer demands, offer personalized service, and handle returns smoothly. Ultimately, by aligning supply chain operations with customer needs, businesses not only improve satisfaction but also build long-term loyalty and a strong reputation in the market.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Technology’s Role in Modern Supply Chains

In today’s dynamic and highly competitive environment, technology plays a transformative role in shaping modern supply chains, driving efficiency, visibility, and adaptability across operations. From real-time tracking to predictive analytics, businesses are leveraging digital tools to streamline every aspect of their supply networks. In logistics management, technologies like GPS, RFID, and route optimization software enhance delivery accuracy and reduce transportation costs. For cold chain logistics, IoT sensors and automated monitoring systems ensure temperature-sensitive goods are stored and transported under optimal conditions, preventing spoilage and improving compliance. Understanding What is Leadership And Its Importances is critical in this context, as strong leadership ensures accountability, quick decision-making, and effective coordination among teams to manage risks and maintain cold chain integrity. Supplier risk management has also evolved, with AI and risk assessment tools helping companies identify vulnerabilities in their supply base and take proactive measures to mitigate disruptions. Meanwhile, advanced supply chain planning platforms use data analytics and machine learning to forecast demand more accurately and align resources accordingly. Additionally, digital supplier management systems enable better communication, performance tracking, and collaboration with vendors, leading to improved reliability and cost-effectiveness. These technological advancements not only enhance operational efficiency but also offer businesses the agility to respond to sudden changes in demand, geopolitical risks, and environmental factors. Embracing innovation across supply chain functions is no longer optional it’s essential for resilience, sustainability, and long-term profitability.

Challenges in Supply Chain Management

Supply Chain Management (SCM) faces numerous challenges in today’s fast-evolving global landscape, making it more complex than ever for businesses to operate efficiently and meet customer expectations. The importance of supply chain management becomes evident when disruptions such as pandemics, geopolitical tensions, raw material shortages, or labor constraints impact production and delivery timelines. These challenges can lead to increased costs, missed deadlines, and reduced customer satisfaction. Additionally, global supply chains often lack transparency, making it difficult to trace goods, verify authenticity, or respond quickly to issues. By applying the Functions of Management Accounting organizations can gain better control through cost tracking, performance measurement, and strategic planning, enabling more informed decisions and improved supply chain visibility. This is where the importance of blockchain in supply chain becomes critical. Blockchain technology provides secure, transparent, and tamper-proof tracking of goods, helping businesses enhance traceability, combat fraud, and streamline compliance. On the operational side, inefficiencies in logistics and supply chain management, such as poor coordination, outdated infrastructure, and inadequate inventory control, continue to hamper performance. Moreover, rapid changes in consumer demand and sustainability requirements are forcing companies to adapt their supply chains in real-time. To remain competitive, organizations must overcome these hurdles by investing in advanced technologies, building stronger partnerships, and creating more agile, resilient supply chain strategies that can weather disruption and deliver consistent value to both the business and its customers.

Preparing for a PMP Job Interview? Check Out Our Blog on PMP Interview Questions and Answers

The Future of Supply Chain Management

The future of supply chain management is being shaped by rapid technological advancements, shifting consumer expectations, and the growing need for resilience and sustainability. As global markets become more interconnected and complex, companies are rethinking traditional models and adopting more agile, data-driven approaches. Logistics management is evolving with the integration of automation, AI, and real-time tracking, which enhances delivery efficiency and reduces costs. In sectors like pharmaceuticals and food, cold chain logistics is becoming increasingly vital, with IoT-enabled monitoring systems ensuring temperature-sensitive products remain compliant and safe throughout the supply journey. Professionals with PMP Training are better equipped to manage these complex logistics projects, ensuring efficiency, regulatory compliance, and risk mitigation across the supply chain. At the strategic level, supply chain planning is being driven by predictive analytics and machine learning, enabling businesses to anticipate demand shifts and align operations proactively. Effective supplier management will be more collaborative, focusing on building long-term partnerships and enhancing communication through digital platforms. Meanwhile, supplier risk management will be critical, as companies face unpredictable disruptions due to geopolitical, environmental, or market-related factors. Future-ready supply chains will prioritize flexibility, transparency, and sustainability, leveraging digital tools to gain end-to-end visibility and respond quickly to changes. As businesses continue to adapt, the supply chain will move from a cost center to a strategic driver of innovation, growth, and customer satisfaction.