- Introduction to Supply Chain Strategy

- Importance of a Robust Supply Chain Strategy

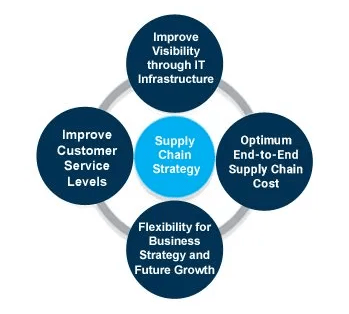

- Key Components of an Effective Supply Chain Strategy

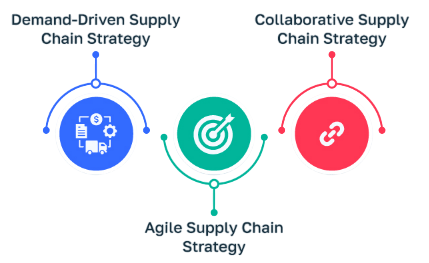

- Types of Supply Chain Strategies

- Steps to Develop a Successful Supply Chain Strategy

- Benefits of a Well-Defined Supply Chain Strategy

- Challenges in Implementing Supply Chain Strategies

- Conclusion

Introduction to Supply Chain Strategy

A Supply Chain Strategy is a long-term plan that outlines how a company’s supply chain will support and contribute to its overall business objectives. This strategy involves making critical decisions related to sourcing of raw materials, production processes, logistics operations, inventory management, and distribution channels. The goal is to create a supply chain that delivers a competitive advantage by efficiently meeting customer needs while minimizing costs and risks. A well-crafted supply chain strategy ensures that the capabilities of the supply chain are aligned with customer demands, current market conditions, and the broader goals of the organization. It requires a deep understanding of the company’s products, customer expectations, supplier base, and competitive landscape, which can be enhanced through PMP Training. By integrating these factors, businesses can design supply chains that are agile, resilient, and capable of adapting to changes in demand or disruptions in supply. In today’s globalized markets, where competition is intense and market conditions evolve rapidly, having a clear and actionable supply chain strategy is more important than ever. It helps companies achieve operational excellence by streamlining processes, reducing waste, and improving coordination across the supply chain. Furthermore, an effective strategy supports cost efficiency through better negotiation with suppliers, optimized inventory levels, and efficient logistics planning. Customer satisfaction is also a key focus of a strong supply chain strategy. Ensuring that products are delivered on time, in the right quantities, and at the right quality level helps build customer loyalty and strengthens the company’s brand reputation. Ultimately, the supply chain strategy acts as a roadmap guiding decisions and investments to ensure the supply chain contributes positively to the company’s long-term success in a competitive and dynamic environment.

Would You Like to Know More About PMP? Sign Up For Our PMP Certification Training Now!

Importance of a Robust Supply Chain Strategy

The supply chain is the backbone of any business that deals with physical goods. It connects every stage of production and distribution, ensuring that products move smoothly from suppliers to customers. Without a solid supply chain strategy, companies face numerous risks including inefficiencies, increased operational costs, missed delivery deadlines, and ultimately a poor customer experience. These issues can damage a company’s reputation and reduce profitability. Therefore, having a robust supply chain strategy is essential to overcome these challenges and create value, much like the differences between Agile vs Waterfall. A well-designed supply chain strategy allows companies to optimize the use of resources such as materials, labor, and transportation. This optimization reduces waste and lowers costs while maintaining high service levels. Additionally, it helps mitigate risks by identifying potential disruptions and creating contingency plans. Flexibility is another important benefit, as a strong strategy enables businesses to quickly adapt to changing market conditions, such as shifts in demand, supplier issues, or new regulations. Furthermore, a comprehensive supply chain strategy supports innovation by encouraging the adoption of new technologies and processes that improve efficiency and customer satisfaction. It also promotes sustainability by incorporating environmentally friendly practices such as reducing emissions and minimizing waste. Scalability is equally important because it allows the supply chain to grow in alignment with the business, supporting expansion into new markets or product lines.

By coordinating complex global supply networks and streamlining communication among partners, a clear supply chain strategy ensures smooth operations even during disruptions. Instead of being viewed as a cost center, the supply chain becomes a key source of competitive advantage that drives growth, customer loyalty, and long-term success in a highly competitive marketplace.

Key Components of an Effective Supply Chain Strategy

- Strategic Supplier Selection: Carefully choosing suppliers based on their ability to deliver high-quality materials, cost-effectively and reliably, is crucial to maintaining a strong supply chain.

- Cost-Effectiveness: Balancing quality with competitive pricing ensures that procurement contributes to overall cost savings without sacrificing product standards.

- Reliability: Evaluating suppliers’ track records for timely delivery and consistent performance helps reduce disruptions and maintain smooth operations, similar to the comparison between Jira vs Trello.

- Sustainability Considerations: Integrating environmental and social responsibility criteria into supplier evaluation supports ethical sourcing and long-term viability.

- Vulnerability Identification: Assessing potential risks such as supplier dependency, geopolitical factors, or natural disasters helps companies recognize weak points in the supply chain.

- Contingency Planning: Developing backup plans, including alternative suppliers and flexible logistics, ensures readiness to respond swiftly to unexpected disruptions.

- Sustainable Operations: Embedding sustainability into supply chain practices not only reduces environmental impact but also enhances brand reputation and meets growing stakeholder expectations.

- Procurement: This function manages the sourcing and purchasing of raw materials and components needed for production, ensuring quality and timely supply.

- Production: Responsible for manufacturing and assembling products, production ensures that goods are created efficiently and meet required specifications.

- Inventory Management: With the help of PMP Training, stock levels are controlled to balance meeting customer demand while minimizing holding costs and reducing excess inventory.

- Warehousing: Focuses on the proper storage, handling, and safeguarding of products within distribution centers, ensuring goods are ready for timely dispatch.

- Sustainability Integration: Supply chains increasingly incorporate environmental goals, aiming to minimize waste, reduce carbon emissions, and use resources efficiently.

- Balancing Performance and Sustainability: Efforts to improve sustainability are aligned with maintaining or enhancing supply chain speed, quality, and cost-effectiveness.

- Long-Term Competitive Advantage: By combining responsiveness with sustainability, companies build resilient supply chains that satisfy customers and meet regulatory and societal expectations.

- Optimized Resource Allocation: Efficiently using materials, labor, and technology ensures that supply chain operations run smoothly while minimizing waste and unnecessary expenses.

- Process Improvements: Continuous enhancements in workflows, automation, and logistics reduce bottlenecks and increase productivity, leading to lower operational costs.

- Cost Reduction: Together, optimized resource use and improved processes help companies cut expenses, improving profitability without sacrificing quality or service levels.

- Differentiated Capabilities: Developing unique supply chain strengths, such as faster delivery, customization, or sustainability practices, enables companies to stand out in competitive markets.

- Market Leadership: Superior supply chain capabilities contribute to building brand reputation, attracting customers, and securing long-term business growth, which are topics covered in What are Scrum Ceremonies.

- Regulatory Compliance: Adhering to laws and industry standards prevents costly fines, legal issues, and supply chain disruptions caused by non-compliance.

- Environmental Responsibility: Meeting environmental regulations and adopting green practices enhances corporate reputation and appeals to eco-conscious consumers, supporting sustainable business success.

Do You Want to Learn More About PMP? Get Info From Our PMP Certification Training Today!

Types of Supply Chain Strategies

Steps to Develop a Successful Supply Chain Strategy

Aligning supply chain goals with the overall business vision, market positioning, and customer needs is fundamental to creating a cohesive and effective supply chain strategy. This alignment ensures that every activity within the supply chain contributes directly to the company’s broader objectives, whether those relate to growth, cost leadership, innovation, or customer satisfaction. By understanding the market positioning, businesses can tailor their supply chain approaches to support differentiation or cost efficiency depending on their competitive strategy. Likewise, keeping customer needs at the center of supply chain planning helps companies deliver products and services that meet or exceed expectations, thereby building loyalty and enhancing brand reputation. To support these strategic goals, it is essential to implement appropriate technology solutions such as Enterprise Resource Planning (ERP) systems, Supply Chain Management (SCM) software, and advanced analytics platforms, reflecting the Key Values and Principles Behind the Agile Manifesto. ERP systems integrate core business processes and provide a unified source of data that improves decision-making across departments. SCM software offers specialized tools to manage procurement, production, inventory, and logistics with greater accuracy and efficiency. Analytics platforms enable the analysis of large volumes of data to uncover trends, forecast demand, identify inefficiencies, and optimize resource allocation. Together, these technologies create a powerful foundation for executing supply chain strategies effectively. Continuous assessment of supply chain performance is critical to maintaining alignment with strategic goals. Businesses must regularly monitor key performance indicators and operational metrics to identify areas for improvement. As market conditions evolve, customer preferences shift, and new challenges arise, companies need to adapt their supply chain strategies accordingly. This flexibility allows organizations to stay competitive, respond to disruptions, and capitalize on emerging opportunities. By aligning goals, leveraging technology, and embracing continuous improvement, businesses can build supply chains that drive sustainable success and deliver measurable value.

Are You Considering Pursuing a Master’s Degree in PMP? Enroll in the PMP Master Program Training Course Today!

Benefits of a Well-Defined Supply Chain Strategy

Challenges in Implementing Supply Chain Strategies

One common challenge in implementing new supply chain strategies is employee and partner reluctance to adopt new processes or technologies. Change can create uncertainty and discomfort, especially when people are accustomed to familiar ways of working. Resistance may stem from concerns about increased workload, fear of job loss, or simply a lack of understanding of the benefits the new methods can bring. This hesitation can slow down or even derail important initiatives, limiting the organization’s ability to improve efficiency, reduce costs, or enhance customer service. Therefore, managing change effectively is a critical component of successful supply chain transformation. To overcome resistance, companies must focus on clear and consistent communication that explains why changes are necessary and how they will positively impact the organization and individuals, highlighting the differences between a Business Analyst vs Financial Analyst. Providing adequate training and support helps employees and partners gain the skills and confidence needed to embrace new technologies and workflows. Encouraging feedback and involving stakeholders in the decision-making process can increase buy-in and foster a culture of collaboration. Leadership plays a vital role in setting the tone by demonstrating commitment and addressing concerns promptly. Maintaining momentum for ongoing strategy refinement also requires dedicated commitment and resources. Supply chain environments are dynamic and continuously evolving, so strategies that worked in the past may no longer be effective. Regularly reviewing performance data, market trends, and emerging technologies enables businesses to identify opportunities for improvement. Allocating sufficient resources, including budget, personnel, and time, ensures that these adjustments can be implemented without disruption. Organizations that invest in continuous improvement position themselves to remain agile, resilient, and competitive in an ever-changing global marketplace. Ultimately, overcoming resistance and sustaining strategic focus are essential for achieving long-term success in supply chain management.

Want to Learn About PMP? Explore Our PMP Interview Questions and Answers Featuring the Most Frequently Asked Questions in Job Interviews.

Conclusion

A well-designed supply chain strategy is essential for companies to thrive in today’s complex and fast-evolving markets. It serves as a roadmap that aligns all supply chain activities with the company’s overall business goals, ensuring that every process, decision, and resource contributes directly to achieving these objectives. By doing so, the strategy drives operational excellence through improved efficiency, cost reduction, and enhanced quality. It also helps create competitive differentiation by enabling businesses to respond more quickly to customer demands, enter new markets, and innovate in their offerings. In an environment where speed and accuracy are vital, a strong supply chain strategy provides the foundation for superior performance. Managing complexity is one of the main challenges companies face when developing and implementing a supply chain strategy, which PMP Training helps address. Supply chains often involve multiple partners, diverse products, and global operations that require careful coordination and communication. Change management is another challenge, as organizations must continuously adapt to new technologies, shifting market conditions, and evolving customer expectations. Additionally, risks such as supply disruptions, geopolitical issues, and economic fluctuations can impact supply chain stability. However, companies that embrace innovation and foster collaboration among internal teams and external partners can overcome these challenges and unlock substantial value. Technological advancements play a critical role in enhancing supply chain capabilities. Tools such as artificial intelligence, advanced analytics, automation, and real-time visibility platforms enable better forecasting, decision-making, and responsiveness. As customers demand faster delivery, higher quality, and greater transparency, supply chain strategy becomes an increasingly important enabler of business success. Moreover, sustainability is gaining prominence, with companies integrating environmentally responsible practices to meet regulatory requirements and consumer expectations. In summary, a well-crafted supply chain strategy is vital for building resilience, driving growth, and ensuring long-term sustainability in today’s competitive global market.