- Introduction to Supply Chain Management Features

- Integration of Key Business Processes

- Customer-Centric Approach

- Coordination and Collaboration Among Partners

- End-to-End Supply Chain Visibility

- Demand-Driven Planning and Execution

- Focus on Continuous Improvement and Agility

- Conclusion

Introduction to Supply Chain Management Features

Supply Chain Management (SCM) involves the comprehensive planning, coordination, and oversight of all activities related to sourcing raw materials, procuring goods and services, converting inputs into finished products, and managing logistics to ensure timely delivery to end customers. It is a multifaceted discipline that integrates both strategic and operational elements across various organizational boundaries. The core features of SCM reflect the complexity and interconnectivity of modern business operations. These include demand forecasting, inventory management, supplier relationship management, production planning, logistics coordination, and performance monitoring. Together, these elements, when guided by PMP Training, work to align the efforts of manufacturers, suppliers, distributors, and retailers toward common business objectives. A key feature of SCM is its emphasis on cross-functional and cross-organizational integration. Effective supply chain management requires seamless communication and collaboration among diverse stakeholders, often spanning multiple countries and time zones. Technology plays a central role in facilitating this integration. Advanced systems such as Enterprise Resource Planning (ERP), Transportation Management Systems (TMS), and real-time data analytics platforms enable end-to-end visibility and more informed decision-making. The benefits of a well-managed supply chain are significant. Organizations can reduce operational costs through efficient resource allocation, minimize waste, improve delivery performance, and enhance customer satisfaction. Additionally, agile supply chains can quickly adapt to changes in consumer demand, supply disruptions, and evolving market conditions. In today’s volatile and competitive global environment, these capabilities are critical. Recognizing and leveraging the essential features of supply chain management allows businesses to build systems that are not only efficient but also resilient. Such supply chains are better equipped to navigate uncertainty, seize new opportunities, and maintain a competitive edge in dynamic markets.

To Earn Your PMP Certification, Gain Insights From Leading Blockchain Experts And Advance Your Career With ACTE’s PMP Certification Training Today!

Integration of Key Business Processes

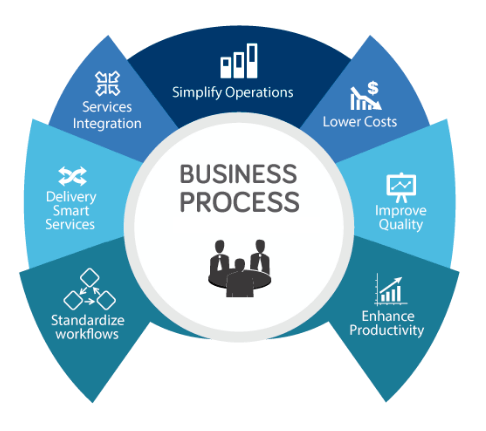

One of the most fundamental and defining features of Supply Chain Management (SCM) is the integration of all major business processes that contribute to the flow of goods, services, and information across the entire supply network. This integration extends across procurement, manufacturing, warehousing, transportation, and distribution functions, connecting various departments within an organization as well as external partners such as suppliers, logistics providers, and customers. Rather than operating in isolated functional silos, SCM fosters collaboration and coordination across the supply chain, enabling a more unified and strategic approach to operations, much like the principles emphasized in What is Sprint Planning. By aligning these processes, organizations can reduce duplication of efforts, eliminate inefficiencies, and optimize the use of critical resources. For example, real-time communication between procurement and production ensures that materials are ordered in sync with manufacturing schedules, avoiding both shortages and excess inventory. Similarly, coordination between warehousing and transportation leads to smoother delivery operations and reduced lead times. Integrated supply chain processes also enable businesses to respond more effectively to market changes and customer demands. With better visibility into each stage of the supply chain, decision-makers can anticipate potential disruptions, manage risks proactively, and adjust plans as needed. This enhances the agility and resilience of the supply chain. Moreover, process integration improves communication and data flow among all stakeholders.

It reduces delays, minimizes misunderstandings, and fosters a collaborative culture focused on shared goals such as customer satisfaction, cost efficiency, and sustainability. As supply chains become increasingly complex and global, the ability to integrate processes effectively becomes a critical success factor. Ultimately, integration is what transforms a collection of individual functions into a cohesive, high-performing supply chain.

Customer-Centric Approach

- Shift from Internal Focus to Customer-Centricity: Unlike traditional supply chains that prioritized internal efficiencies, modern supply chain management (SCM) centers around fulfilling customer needs and expectations.

- Meeting Customer Requirements: The primary goal is to deliver products that meet customer demands regarding availability, quality, cost, and delivery speed, ensuring a superior overall experience.

- Customer-Driven Planning and Execution: Supply chain decisions from sourcing to distribution are guided by customer demand patterns to better align operations with real market needs, reflecting principles found in What is Total Productive Maintenance.

- Understanding Customer Preferences: Companies invest in gathering data and insights to comprehend customer preferences, enabling tailored product offerings and more responsive service.

- Demand Anticipation: Modern SCM incorporates forecasting and predictive analytics to anticipate changes in customer demand, helping avoid stockouts or overstocks.

- Designing for Customer Experience: Supply chains are designed to enhance customer satisfaction by reducing lead times, improving product quality, and ensuring reliable delivery.

- Competitive Advantage through Loyalty: A customer-centric supply chain builds trust, satisfaction, and loyalty, differentiating companies in competitive markets and driving long-term success.

- Extensive Coordination: Supply chain management (SCM) involves extensive coordination not only within a company but also with external partners like suppliers, distributors, and logistics providers.

- Synchronizing Activities: This cooperation is vital to synchronize activities across the supply chain, ensuring that production, inventory, and delivery processes work seamlessly together.

- Information Sharing: Sharing timely and accurate information among all parties, supported by PMP Training, helps reduce uncertainties and enables faster problem-solving when issues arise.

- Building Trust: Collaborative relationships build trust between partners, which lowers risks related to supply disruptions, delays, and quality problems.

- Collaborative Techniques: Techniques like Collaborative Planning, Forecasting, and Replenishment (CPFR) highlight the importance of joint efforts in improving demand forecasting and inventory management.

- Transparent Communication: Transparent communication channels enable all stakeholders to align their objectives, making coordination more effective and improving overall supply chain performance.

- Aligned Incentives: Aligning incentives and shared goals across the supply chain ensures that every partner works toward optimizing the flow of products and information, benefiting the entire network.

- Responsiveness to Actual Demand: A key feature of supply chain management (SCM) is responding to real customer demand rather than relying only on forecasts or push-based methods.

- Demand-Driven Adjustments: Supply chains adjust procurement, production, and distribution activities based on real-time sales data and market signals, enabling more accurate alignment with customer needs.

- Reduced Inventory Levels: By reacting directly to actual demand, companies can keep inventory at lower levels, which reduces holding costs and the risk of obsolete stock.

- Minimized Waste: Aligning supply closely with demand helps minimize overproduction and waste, contributing to more sustainable and cost-effective operations, which illustrates Why is Retrospection Needed.

- Key Techniques: Just-in-Time (JIT), Lean manufacturing, and agile supply chain management are examples of approaches that support demand-driven operations by improving efficiency and responsiveness.

- Enhanced Flexibility: Demand-driven SCM enables companies to quickly adapt to changing market conditions and customer preferences, improving overall supply chain agility.

- Efficient Resource Allocation: This approach ensures that resources such as labor, materials, and production capacity are used efficiently, matching supply with fluctuating market demands without excess.

Interested in Obtaining Your PMP Certificate? View The PMP Certification Training Offered By ACTE Right Now!

Coordination and Collaboration Among Partners

End-to-End Supply Chain Visibility

Visibility across the entire supply chain is a critical feature of effective Supply Chain Management (SCM). It refers to the ability to monitor and track all aspects of the supply chain in real time, including inventory levels, production status, shipment movements, and fluctuating demand signals. This end-to-end transparency enables organizations to have a clear view of their operations from the point of origin to the final customer, allowing for faster and more informed decision-making. With high visibility, companies can identify potential disruptions, bottlenecks, or inefficiencies early, and take corrective actions before they escalate into larger issues. Supply chain visibility is made possible by a range of advanced technologies. Radio Frequency Identification (RFID) and Internet of Things (IoT) devices provide granular, real-time data about the location and condition of goods in transit or storage, similar to how Agile teams rely on data in What are Agile Metrics. Cloud-based platforms offer centralized access to this data, enabling different supply chain partners to share and view information simultaneously. Additionally, analytics tools process vast volumes of data to uncover trends, monitor performance metrics, and generate predictive insights. Enhanced visibility not only improves coordination across departments and partner organizations but also significantly reduces uncertainty. When all stakeholders have access to accurate and timely data, it becomes easier to align supply with actual demand, manage inventory more effectively, and reduce lead times. This contributes to higher service levels, increased customer satisfaction, and lower operational costs. In today’s dynamic and fast-paced business environment, supply chain visibility is no longer optional it is essential for building agile, responsive, and resilient supply chains that can adapt to rapid changes and maintain a competitive advantage.

Want to Pursue a PMP Master’s Degree? Enroll For PMP Master Program Training Course Today!

Demand-Driven Planning and Execution

Focus on Continuous Improvement and Agility

Supply chains operate in increasingly dynamic and unpredictable environments shaped by market volatility, rapid technological advancements, geopolitical shifts, and evolving customer expectations. In this context, one of the most prominent features of Supply Chain Management (SCM) is the emphasis on continuous improvement. This approach involves a persistent focus on measuring performance, optimizing processes, and fostering innovation to enhance efficiency, responsiveness, and resilience. Rather than viewing operations as static, modern supply chains are designed to evolve continuously in response to both internal and external changes. A critical component of continuous improvement is the regular assessment of key performance indicators (KPIs), which is relevant when comparing the Project Life Cycle vs Product Life Cycle. Metrics such as order accuracy, inventory turnover, lead time, and customer service levels provide actionable insights into the health of the supply chain. By analyzing these metrics, organizations can identify inefficiencies, set performance targets, and track progress over time. Continuous improvement also involves adopting lean principles which aim to eliminate waste, streamline workflows, and maximize value for the customer. Equally important is the development of supply chain agility which is the ability to quickly adapt to disruptions and respond to new opportunities. Agile supply chains can pivot strategies, shift sourcing models, or reallocate resources in real time. This agility is supported by a culture of learning, collaboration, and adaptability within supply chain teams. Employees are encouraged to challenge the status quo, explore new technologies, and implement best practices. Through continuous improvement, companies not only boost operational efficiency but also strengthen their ability to withstand disruptions and maintain a competitive edge. In today’s fast-paced environment, this mindset is essential for long-term success and sustainability in supply chain operations.

Preparing for a PMP Job? Have a Look at Our Blog on PMP Interview Questions and Answers To Ace Your Interview!

Conclusion

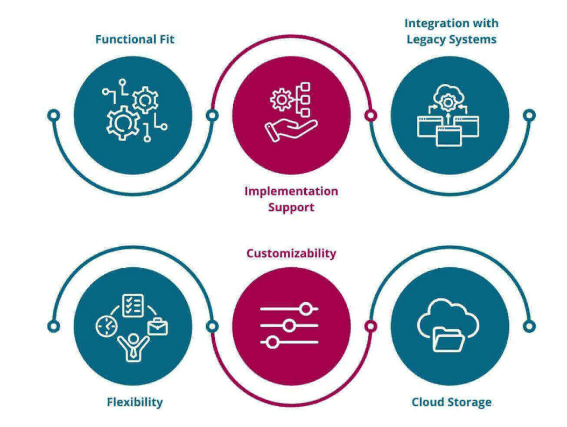

The features of supply chain management reflect its evolution from a basic logistics function into a comprehensive and strategic discipline that is essential for achieving business success. Over time, supply chain management has expanded to encompass a wide range of interconnected processes and capabilities. Key features such as integration, customer-centricity, collaboration, visibility, demand-driven processes, continuous improvement, and technological enablement collectively define what makes supply chain management effective in today’s complex business environment. Integration refers to the seamless coordination of all activities related to sourcing, production, and distribution, breaking down traditional barriers between departments and organizations. Customer-centricity, emphasized in PMP Training, places the customer at the heart of supply chain decisions, ensuring that products and services are delivered in a way that maximizes satisfaction and loyalty. Collaboration emphasizes the importance of strong partnerships among suppliers, manufacturers, distributors, and retailers to enhance efficiency and innovation. Visibility across the supply chain enables real-time tracking and transparency, allowing companies to quickly identify issues and respond to changing conditions. Demand-driven processes ensure that supply chain activities are closely aligned with actual customer demand rather than forecasts alone, reducing waste and improving responsiveness. Continuous improvement focuses on ongoing performance measurement, process optimization, and the adoption of best practices to build resilience and agility. Technological enablement plays a critical role by providing advanced tools such as analytics, artificial intelligence, Internet of Things devices, and cloud platforms. These technologies support better decision-making, increase automation, and enhance communication across the supply chain. By embracing and strengthening these features, companies can build supply chains that are cost-efficient, agile, and customer-focused. This ultimately creates lasting competitive advantages and drives sustainable business growth in today’s global markets. Understanding these features is the foundation for mastering supply chain management.