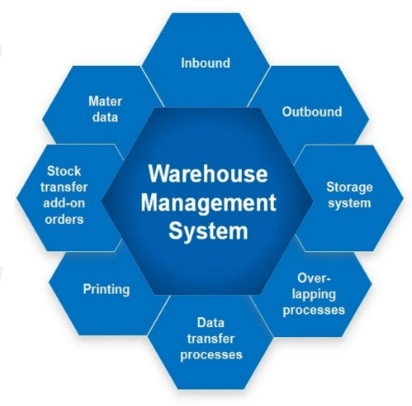

SAP created SAP Extended Warehouse Management (SAP EWM), a sophisticated software system designed to handle the intricate problems associated with contemporary warehouse and distribution management. With the help of its many features and capabilities, businesses can effectively manage their inventory, optimise warehousing operations, and improve the efficiency of their whole supply chain.

1.What is SAP WM?

Ans:

The SAP Warehouse Management system (WM) provides flexible, automated support in the processing of all goods movements and in managing stocks in the warehouse complex.

2.What is the Transfer Requirement?

Ans:

Requirement (TR) is the document used to request the movement of the materials within a warehouse complex. It serves as the basis for creating stock transfer orders and for triggering actual physical movement of goods within the warehouse.

3.What is the Transfer Order?

Ans:

A Transfer Order (TO) is the document used to manage and control the movement of materials within the warehouse. It represents the detailed instructions for moving a goods from one location to another, whether it’s picking goods for outbound delivery, moving goods within a warehouse, or replenishing stock.

4. What basis TO will get generated?

Ans:

Transfer Orders (TOs) in the SAP Warehouse Management (WM) can be generated based on the various triggers and criteria within the system. The generation of a TO is determined by a specific business scenario and operational needs.

5.Which one system generates first, TR or TO?

Ans:

Transfer Orders (TOs) are typically generated based on the Transfer Requirements (TRs). Transfer Requirements serve as planning documents indicating the need to move materials within the warehouse.

6. What level release strategies get defined?

Ans:

AP release strategies are used in the various modules, such as Materials Management (MM), Sales and Distribution (SD), and Purchase Orders, to control the release of documents for the further processing.

7.What are the transactions available to create a transfer order for moving partial stocks within warehouse number?

Ans:

a) LT01

b) LT10

Two transactions are available to create the transfer order for moving partial stocks within warehouse number:-Create Transfer Order without a Source Object (transaction code LT01)-Create a Transfer Order from Stock List (transaction code LT10)

8.What are the Different stock types and storage types in WM?

Ans:

Stock Types are: Unrestricted, Blocked

Quality Storage Types: Rack Open Shelf Damage.

9.What are different Movement Types ?

Ans:

- 101 – GR Receipts

- 102 – GR PO reverse

- 601 – GI delivery

- 602 – Cancel GI delivery

- 651 – Sales return

- 909 – GR Amendment Excess

10.what are the different types of picking and put away strategies ?

Ans:

Picking-FIFO– To sale an oldest material first- LIFO – To sale latest material first

Put away: Next to empty bin, addition to existing stock, mixed storage, fixed storage, open storage.

11.Why should one create the Second TO in WM?

Ans:

Second TO has to be created at a delivery level to move the stock from an intermediate storage type to the Goods issue (delivery) area for loading the stock into the vehicle.

12.What does configure the automatic TO creation at all document levels?

Ans:

The automatic creation of Transfer Orders (TOs) is generally based on the Transfer Requirements (TRs) rather than at document level. Transfer Requirements serve as the basis for creating the Transfer Orders.

13.Where do you configure the strategies for Put away and Picking?

Ans:

SPRO-> Logistics Execution-> Warehouse Management -> Strategies -> Define a Put away Strategies and Logistics Execution-> Warehouse Management -> Strategies -> Define a Stock Removal Strategies

14.Explain Warehouse Structure?

Ans:

A warehouse structure refers to a physical and logical layout of a warehouse facility, including arrangement of storage areas, aisles, racks, bins, and other elements necessary for an efficient storage, handling, and movement of goods.

15.Does a single warehouse could be configured for more than one company code?

Ans:

A single warehouse can be configured to serve the multiple company codes. This approach is particularly common in the large organisations or those with complex warehouse management needs where centralising a warehouse operations can lead to efficiency and a cost-saving benefits.

16. What documents are created during GR entry in the WM Process?

Ans:

Documents are created during GR entry un VM process:

- PO

- Inbound Delivery

- Transfer Requirement

- Shipment and TO

17.Where is the control to confirm TO for Put away and Picking?

Ans:

Control to confirm the TO for Put away and Picking can be configured at a Warehouse, Storage types and Movement types levels. confirmation of Transfer Orders (TOs) for put away and picking is controlled through the various configurations and settings.

18.What does Stock Uploading happen at which Module MM or WM at rollout in xyz client?

Ans:

Decision of whether stock uploading will happen in Materials Management (MM) module or the Warehouse Management (WM) module during rollout of an SAP implementation depends on a specific requirements and business processes of the client, in this case, XYZ client.

19.What is the importance of Quant numbers?

Ans:

Whenever the GR system generates a one Quant number based on the combination of the Material, Batch, and Bin. The outbound delivery plant for each item is defined in the order.

20. What is the highest priority outbound delivery plant in descending priority order?

Ans:

Outbound delivery plant defined in the Customer material information master record, outbound delivery plant defined in the ship-to party master record, Outbound delivery plant defined in the material master.

21.What happens when no storage location for picking is specified in the order item?

Ans:

The system determines a storage location when it creates outbound delivery and copies it into a delivery item. The storage location entered in the order item is used in outbound delivery.

22. What basis does a Transfer Order get generated?

Ans:

A Transfer Order is generated based on the Transfer Requirements, which, in turn, are created based on the movements in the Inventory Management (IM) module or the other relevant documents.

23. What is the difference between Storage Units and Handling Units?

Ans:

Storage Unit: A container used to store or transport the materials within the warehouse.

Handling Unit: A combination of materials and packaging, used for efficient handling and tracking during the goods movement.

24. What are the different types of picking and putting away strategies and explaining justifications.

Ans:

Picking Strategies:

- FIFO (First In, First Out) – To sell the oldest material first, ensuring an inventory turnover.

- LIFO (Last In, First Out) – To sell the latest material first, suitable for perishable items or specific business requirements.

Putaway Strategies:

- Next Empty Bin – Maximises warehouse space utilisation.

- Addition to Existing Stock – Optimizes space by filling the partially empty bins.

25. What are the Interim Storage Types in SAP WM?

Ans:

Interim Storage Types are the temporary storage areas used during the goods movements for goods receipt, goods issue, posting changes, and physical inventory differences.

26. Why is Storage Unit activation mandatory?

Ans:

The activation of storage units is not mandatory; it depends on specific warehouse processes and the requirements of organisation. Storage unit management in SAP WM allows to group materials or products into logical units for handling and storage within a warehouse.

27. What level release strategies are defined in SAP WM?

Ans:

Release strategies are configured at a warehouse level in the SAP WM. Warehouse Management (WM), release strategies are typically not defined at warehouse level.

28.How does the system create any dynamic storage bins during the Goods Receipt (GR)?

Ans:

Yes, the system can create dynamic storage bins during Goods Receipt (GR), especially when using the Purchase Order or other related documents.

29. Differentiate stock comparison between IM and WM?

Ans:

| Aspect | Inventory Management (IM) | Warehouse Management (WM) | |

| FocusFocus |

controlling replenishment, stock accuracy, and total inventory levels |

overseeing the transportation, tracking, and storage of merchandise in a warehouse. | |

| Scope | encompass several locations or storage spaces inside an organisation. | mostly concentrates on overseeing the administration of a particular warehouse or distribution facility | |

| Software Systems | frequently coupled with systems for enterprise resource planning (ERP). | Usually either connected or standalone from warehouse management systems (WMS). | |

| Objectives |

Maintain sufficient supply levels and guard against shortages or surplus |

Streamline warehouse operations to complete orders more quickly, store inventory more effectively, and track it accurately. |

30. What does Posting Change?

Ans:

A posting trade generally refers to the bookkeeping alternative – a change in facts – about selected material. For most posting adjustments, which includes the converting a batch wide variety or freeing a blocked inventory, the goods themselves remain inside equal bodily area.

31.What are the Reasons for Making Posting Changes Posting adjustments ?

Ans:

- Releasing stock from the inspection into to be had inventory

- Converting blocked inventory to the inspection inventory

- Designating available fabric as an inspection stock

- Changing the Material Number

- Splitting available substances into the two or greater batches

32. Where does find the exact whereabouts of material quantity in the warehouse?

Ans:

Storage bins

- In Warehouse Management, Storage bins are the master data created either from the application menu or in Customizing.

- Based on this master data stock overview in Warehouse Management shows the exact whereabouts of a material quantity in the warehouse.

33. What are the requirements for Purchase order items that are included when inbound delivery is created?

Ans:

When an inbound delivery is created in the SAP Materials Management (MM), it typically relates to the purchase order or a scheduling agreement. The requirement for purchase order items when an inbound delivery is created includes the several key aspects:

- Reference Document.

- Material and Quantity.

- Delivery Date.

- Delivery Quantity.

34. What is the system Landscape at XYZ client?

Ans:

Specific client information, systems, or configurations, including the details about system landscape of any particular client such as “XYZ client.” System landscapes in SAP can vary greatly depending on specific needs and requirements of the organization.

35. Explain Handling Units (HUs) in SAP WM.

Ans:

Handling Units (HUs) are the packaging units used to group materials for storage, transportation, and handling purposes. HUs can include the multiple items and are managed as a single entity within the warehouse.

36.What is the purpose of the Picking Strategy in SAP WM?

Ans:

A Picking Strategy determines how items are selected from a warehouse for outbound deliveries. Different picking strategies, FIFO (First-In-First-Out) and LIFO (Last-In-First-Out), optimise a picking process based on specific criteria.

37. How does handle stock differences in SAP WM?

Ans:

Stock differences in SAP WM can be handled through the inventory adjustments, physical inventory counts, and reconciliation processes. SAP provides the functionalities to investigate, adjust, and resolve stock discrepancies.

38. Explain Batches and Serial Numbers in SAP WM.

Ans:

Batches are groups of the materials produced or procured under the same conditions, while Serial Numbers uniquely identify the individual items.

39. What is Cross-Docking in SAP WM?

Ans:

Cross-Docking is the logistics strategy where incoming goods are immediately transferred to the outbound destinations without being stored in the warehouse. It optimises order fulfilment by reducing the storage time and costs.

40. Explain the Difference Between Lean WM and Decentralised WM.

Ans:

Lean WM is a simplified version of the WM designed for basic warehousing tasks and is suitable for smaller warehouses. Decentralised WM is the standalone WM system integrated with the SAP ERP and is suitable for complex warehouse structures and high-volume environments.

41. How does one configure and use “Interleaving” in SAP WM?

Ans:

Interleaving is the feature in SAP WM that allows for the interleaving of different materials within the same storage bin. It optimises space utilisation and facilitates efficient picking. Configuration involves the setting up bin types, storage types, and storage section control.

42. What is “Batch Determination” in SAP WM, and how does it work?

Ans:

Batch determination is the process of selecting an appropriate batch of a material for goods movement. It considers criteria like shelf life, material properties, and availability. Batch determination is important for quality control and traceability.

43. Explain Physical Inventory in SAP WM.

Ans:

Physical Inventory in the SAP WM involves the process of counting and verifying actual stock quantities in the warehouse bins and comparing them with the system’s recorded quantities. It ensures data accuracy and helps in identifying discrepancies.

44.Explain Slotting in SAP WM.

Ans:

Slotting in SAP WM involves optimising the placement of goods within the warehouse. It considers the factors like picking frequency, storage conditions, and material characteristics to determine the most efficient storage locations for items.

45. What is the Transportation Planning Point (TPP) in SAP WM?

Ans:

A Transportation Planning Point is the organisational unit in SAP used for transportation planning and execution. It determines shipping point and route for outbound deliveries and is crucial for integrating SAP WM with logistics and transportation modules.

46. Explain Stock Removal Strategies in SAP WM.

Ans:

Stock removal strategies define how the materials are picked from storage bins during the outbound processes. Strategies include the picking based on the nearest bin, fixed bin, or specific picking sequence defined by a system.

47. What is a Warehouse Activity Monitor (WAM) in SAP WM?

Ans:

The Warehouse Activity Monitor provides real-time visibility into warehouse operations. It displays the key performance indicators (KPIs) and metrics, allowing supervisors to monitor efficiency of the warehouse tasks and processes.

48.What is Dynamic Cycle Counting in SAP WM?

Ans:

Dynamic Cycle Counting is an inventory management strategy where items are counted continuously and frequently, often using the random sampling methods. It helps to maintain accurate inventory levels without need for extensive, time-consuming physical inventories.

49.What are Radio Frequency (RF) devices in SAP WM, and how does it benefit warehouse operations?

Ans:

RF devices are the handheld or mobile devices used by a warehouse operator to interact with the SAP WM system. They improve the accuracy and efficiency by enabling real-time data entry, task execution, and communication within the warehouse.

50. How does Cross-Docking differ from a Flow-Through Distribution in SAP WM?

Ans:

Cross-Docking involves a direct transfer of goods from inbound to outbound without storage. Flow-Through Distribution, on other hand, temporarily stores the inbound goods but quickly moves them out for the order fulfilment.

51.What are the benefits of using ABC Analysis in SAP WM for inventory management?

Ans:

ABC Analysis categorises inventory items into the classes (A, B, and C) based on their value and importance. It helps to prioritise inventory management efforts, ensuring that high-value items receive more attention.

52. Explain the difference between Putaway and Picking in SAP WM.

Ans:

Putaway involves storing materials in a warehouse, ensuring they are in the right bins. Picking, on other hand, is the process of retrieving the materials from storage bins for order fulfilment or other purposes.

53.How does it manage high-bay storage in SAP WM?

Ans:

High-bay storage involves all the racks for storing goods. SAP WM allows configuring this type of storage, but it requires a consideration of equipment like stacker cranes and additional safety measures due to height of storage.

54. Explain Load Carrier in SAP WM.

Ans:

A Load Carrier is the vehicle or container used for transporting goods within a warehouse. In SAP WM, it can be assigned to the specific warehouse tasks, making it simpler to manage the movement of materials.

55. Explain Yard Management in SAP WM.

Ans:

Yard Management in SAP WM involves managing the storage and movement of trailers or containers in the yard area outside the warehouse. It optimises the allocation of the resources and improves overall efficiency of warehouse operations.

56. Explain Wave Management in SAP WM.?

Ans:

Wave Management in SAP WM involves the grouping and optimising warehouse tasks (like picking orders) into waves. It helps in streamlining order processing, increasing a picking efficiency, and reducing the travel time within the warehouse

57. Explain integration points between SAP WM and other SAP modules like SAP MM and SAP SD.

Ans:

SAP WM integrates with SAP MM for procurement and inventory management and with the SAP SD for sales and distribution processes. WM receives the goods from MM (goods receipt) and supplies goods to MM (goods issue).

58. How to handle serialisation and serialisation management in SAP WM?

Ans:

Serialisation involves assigning unique serial numbers to individual items. In SAP WM, this is managed by using Handling Units (HUs). Serialization Management allows for the unique identification of items and efficient tracking throughout the supply chain.

59. Explain Warehouse Order Creation Rules (Put away and Picking Strategies) in SAP WM.

Ans:

Warehouse Order Creation Rules determine how the transfer orders are created for putaway and picking. Putaway strategies define how the materials are placed in the warehouse, while picking strategies determine the order in which materials are picked.

60. What are the different types of storage bins in SAP WM?

Ans:

Storage bins in SAP WM can be fixed, bulk, picking, or quants. Fixed bins are the assigned specific materials, bulk bins store large quantities, picking bins are used for an order picking, and quants represent actual physical stock of materials in the bin.

61. Explain Advanced Production Integration (PP-PI) in SAP WM.?

Ans:

Advanced Production Integration (PP-PI) in the SAP WM enables seamless integration between the production and warehouse processes.

62. How is the storage and management of hazardous materials in SAP WM?

Ans:

Hazardous materials are managed using the specific storage types and storage bins that comply with the safety regulations. Special handling procedures, labelling, and storage segregation are implemented to ensure safe storage and handling.

63. Explain Decentralised Warehouse Management in SAP S/4HANA.?

Ans:

Decentralised Warehouse Management in the SAP S/4HANA allows individual warehouses or distribution centres to operate independently while being integrated into the central SAP system. It provides flexibility in managing various warehouse operations at different locations.

64. How does one optimise warehouse operations using Warehouse Performance Management (WPM) in SAP WM?

Ans:

Warehouse Performance Management (WPM) in SAP WM involves analysing key performance indicators (KPIs) such as order picking efficiency, inventory turnover, and resource utilisation.

65. Explain Physical Inventory in SAP WM.

Ans:

- Physical Inventory in SAP WM involves the periodic counting of materials.

- Cycle counting is a process of counting specific materials on a regular basis, ensuring continuous accuracy.

- A Continuous inventory verification involves real-time monitoring of the stock levels, detecting discrepancies, and triggering immediate corrective actions.

66. Describe the process with implementing RF (Radio Frequency) technology in SAP WM.

Ans:

With implementing RF technology, covering areas are RF device configuration, barcode scanning, real-time data exchange, and the impact of the RF technology on accuracy, speed, and the overall warehouse efficiency.

67. What is SAP WM used for?

Ans:

The SAP Warehouse Management system (WMS) provides the flexible, automated support in processing all the goods movements and in managing stocks in your warehouse complex.

68. How does link material and warehouse in SAP?

Ans:

Enter the material number, industry sector code, and material type and choose Select View. Choose the Warehouse Management and any relevant additional views and choose Org. levels.

69. Which is better, SAP MM or SD?

Ans:

Both the modules SAP SD and SAP MM are equally good or bad .SAP SD stands for the sales and distribution on other hands SAP MM stands for material management, SAP MM is closely linked with the other modules of SAP like SD, FICO etc.

70.What are the Advantages of Sap Wm?

Ans:

Improved Efficiency:

- Optimised Processes

- Task Automation

Enhanced Accuracy:

- Real-time Data

- Barcode Scanning

71. What are the disadvantages of Sap Wm?

Ans:

Complex Implementation:

- Challenge

- Impact

High Initial Cost:

- Challenge

- Impact

72. What does SAP warehouse management do?

Ans:

The SAP warehouse management system is an ERP software that integrates all functions of a warehouse and streamlines them making it simpler and more effective to run the facility and ensure that they are able to stay on top of everything and ensure that everything is in the rightful place.

73. What does Functions of SAP Warehouse Management

Ans:

It is able to manage structures of the warehouse no matter how complex they are.

- SAP WM is able to monitor a movement of stock and process differences.

- Allows for an easy management of potentially hazardous material.

- SAP WM is able to make the use of bar code scanners hence making an entire process of inventory much easier.

74. What applications of sap WM?

Ans:

- Manufacturing Industry

- Retail and Distribution

- Logistics and Transportation

- Pharmaceuticals and Healthcare

- Food and Beverage

75. What do you consider before deploying a SAP warehouse management system.?

Ans:

Deploying the SAP Warehouse Management System (WMS) is a complex and critical task for any organisation. There are several factors should consider before making the decision to deploy SAP WMS:

- Business Requirements Analysis

- Integration

- Customization

- User-Friendliness

76. List out the various organisational units in Warehouse Management?

Ans:

Warehouse Number Each warehouse contains the warehouse number which is a well-known level in the warehouse management system. To map warehouse relationships, each warehouse contains the substructure.

Storage Type: There are various storage types where products are stored physically in a warehouse, including the goods receipts, goods issues, racks, and open storage.

Storage Section: It is the chunk of storage type and depicts a set of bins with the same properties.

77. What is a work centre in a warehouse?

Ans:

A work centre is the warehouse which is assigned to a physical unit and storage type to perform deconsolidation and packing and these storage types are assigned to the work centre role to identify the pick point of the warehouse.

78. What are value-added services in warehouse management?

Ans:

Value Added Services characterises the product handling to be acted in a warehouse and incorporates activities like assembling, packing, labelling, etc.

79. Differentiate difference between system-controlled and user-controlled pick, pack and pass of goods?

Ans:

System-Driven: For System driven choice, the grouping of the warehouse orders is determined according to the assigned sorted sequences in configuration settings to join the activity areas.

User-Driven: For User-driven, the sequence is physically decided during execution, which implies it should be done in a material stream framework (MFS).

80. Mention some common control fields in Replenishment?

Ans:

- Minimum stocking quantity

- Maximum stocking quantity

- Replenishment quantity

81. What is the work centre in the warehouse?

Ans:

The work centre is the storage type that also serves as a unit for packing, deconsolidation, and weighing activities in the warehouse. Its functions include pick point and pick point identification. It also aids in the quality control.

82. What is the outbound delivery system’s denial scenario?

Ans:

Once the warehouse challenge is unable to meet the amount requested, the outbound distribution request system was designed to issue a pick denial.

83. Why is it necessary to submit more than one transportation request at times?

Ans:

Once the client is configured in such a way that it must record customising changes, a customising request for the data itself, as well as during activation for customising, is required. Must enter the transport request for the data set on the first screen of the guided activity.

84. Why is delivery not always displayed when the system displays confirmation?

Ans:

The delivery numbers in the Transaction C014 can be seen in goods movement overview. This is only possible if the EVM system has not yet posted the goods movements for deliveries.

85. How does ensure the efficient dispatch of products from the warehouse?

Ans:

Ensuring efficient dispatch involves the combination of effective inventory management, clear communication with the logistics team, and regular checks on dispatch processes.

86. What are the different components of value added order in sap WM?

Ans:

Order Header Order Items Value Added Services (VAS) Work Centers Processing Steps Materials and Components Labour Resources

87. What are the different movement types?

Ans:

The system specifies SAP movement types when entering goods movement in transactions dealing with the material documents.Example: SAP movement type is the three-character key that distinguishes the different material movements, like Goods Receipt (GR), Goods Issue (GI) and Transfer Posting. Movement type 101 is for GR receipts, 102 for GR PO reverse, 601 for GR delivery, 602 for cancel GI delivery, 651 for a sales return and 909 for GR amendment excess.

88. What is the Order Header in sap WM?

Ans:

Contains the general information about Value Added Order, such as order number, creation date, and customer details.

- Order Number

- Order Type

- Order Status

- Creation Date and Time

- Requested Execution Date and Time

89. What do you Order items in sap WM?

Ans:

- Item Number

- Material Number or Product Code

- Material Description

- Quantity

- Storage Bin Information (for certain orders)

90. What does mb52 T code usage in SAP?

Ans:

Use this report to display a total stock of a material (quantity and value) at plant and storage location level. If the stocks or stock transfer stocks exist at plant level, the system totals these stocks and displays them in a column In Stock Transfer in a stock line without storage location.