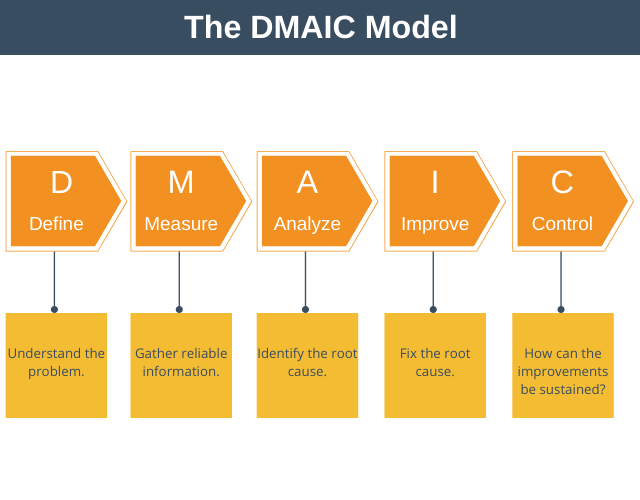

DMAIC (an acronym for Define, Measure, Analyze, Improve and Control) (pronounced də-MAY-ick) refers to a data-driven improvement cycle used for improving, optimizing and stabilizing business processes and designs.

- What is DMAIC

- Why the DMAIC Process?

- The Five Phases of DMAIC

- Benefits of DMAIC: Why It’s Needed

- There are number one methodologies in Six Sigma

- Conclusion

What is DMAIC

When we inspect the definition of DMAIC, it’s miles a 5-segment method for enhancing a huge sort of organizational processes, whether or not it’s software program development, manufacturing, or a few different manners. While it’s related to Six Sigma, this method also can be implemented to lean and different manner-development strategies. DMAIC is a statistics-pushed hassle-fixing approach designed to pick out and deal with inefficiencies in a manner, which improves its effects and makes those upgrades greater predictable.

- There are obvious inefficiencies and defects withinside the present manner.

- There is ability to lessen variables which include lead instances or different flaws at the same time as enhancing variables like productiveness or value savings.

- The circumstance is assessable, and the effects may be understood correctly thru quantifiable means.

- After you’ve got got evaluated the above elements, you may conclusively decide in case your manner can gain from imposing DMAIC.

Why the DMAIC Process?

Before we dive into the primary manner, there’s one extra step that a few agencies appoint which will parent out whether or not DMAIC is the proper technique to resolve their issues. This step is called “Recognize”.

The cause why this step is crucial, no matter now no longer being officially part of DMAIC, is that DMAIC can not be implemented to all situations. There are precise situations wherein this approach may be the proper match for manner development. Recognizing the proper situations and selecting the proper hassle to resolve are key to expertise whether or not DMAIC is the proper device for you.

How do you compare the ones situations? Here are 3 essential elements to consider:

- Identify the possibilities with excessive ability for development

- Outline the scope of the mission

- Create a cost move map (VSM) to report each step withinside the manner

- Develop a voice of the client table (VOCT) to pinpoint the client needs

- Identify all stakeholders

- Estimate mission effect and completion

- Identify and report enterprise opportunity

- Draw out different associated processes

- Develop the statistics series strategies for use to degree success

- Recognize input, processes, and output indicators

- Collect and take a look at present day nation statistics

- Outline the failure modes and results evaluation

- Implement manner functionality evaluation

- The use of visible control gear which include manipulate charts, bar charts, and run charts etc. assist you to obtain higher effects at this degree

- Performing a whole root purpose evaluation (RCA), which covers a vast variety of strategies and methodologies, which includes alternate evaluation, activities and causal thing evaluation, and the Kepner-Tregoe

- Problem Solving and Decision Making model.

- Doing failure mode and results evaluation (FMEA) to pick out all feasible hassle areas, inefficiencies, flaws, defects, and shortcomings.

- Getting a visible illustration of the versions inside a given manner the use of a multi-vari chart.

- Implementing manner manipulate

- Developing a plan for development

- Brainstorm and positioned forth answer ideas

- Develop a layout of experiments (DOE) to decide the predicted blessings of a answer

- Revise manner maps and plans in step with the statistics gathered withinside the preceding degree

- Outline a take a look at answer and plan

- Implement Kaizen activities to enhance the manner

- Inform all stakeholders approximately the answer

- Identify and report the brand new paintings standard

- Develop an excellent manipulate plan which guarantees the complete crew is operating with the identical strategies and metrics

- Confirm discount in screw ups because of the central purpose

- Use statistical manner manipulate (SPC) to reveal manner execution and pick out any troubles that arise

- Determine extra upgrades, if needed, to fulfill manner targets

- Streamline manner upgrades the use of the “Five S’s” of Lean Integrate, report, and talk the instructions learned

The Five Phases of DMAIC

The DMAIC manner follows 5 key phases, which can be meant to put the basis to your manner development, chart goals, song development, and examine effects. The 5 phases (and an evidence of each) are:

1. Define

During this segment, we choose the maximum vital and impactful possibilities for development. This segment is likewise approximately mapping the manner, focus, scope, and the closing aim in addition to expertise how the hassle influences all stakeholders. The manner to jumpstart a DMAIC cycle is through crafting the hassle statement.

The different vital steps at this degree are:

A a hit Define segment facilitates you circulate ahead with clean, well-described targets and timeline for mission completion.

2. Measure

The Measure segment is wherein baselines are drawn to evaluate the overall performance of a given manner. Without having sound benchmarks for comparison, it’s tough to song upgrades. Hence, at this degree, we:

3. Analyze

In this segment, your aim is to pick out and take a look at the underlying reasons of issues to make certain that development takes area from deep down wherein the issues stem from.

The vital steps at this degree include:

After this segment, you may be capable of seize and report all possibilities for development effectively, and your course of action will begin taking shape.

4. Improve

With the evaluation finished and the statistics in front of you, now could be the time to begin making the upgrades.

This degree consists of the subsequent activities:

The use of development control software program is useful at this degree. This facilitates to transport the manner seamlessly, obtain cross-useful collaboration and makes it less difficult for the control and bosses to comply with the development of a given DMAIC mission.

5. Control

After modifications are in area and are effectively addressing the issues to enhance your operations, it’s time to carry the manner beneath neath manipulate to make sure its long-time period effectiveness.

This is wherein you:

After the Control segment, you may quantify the whole effect of manner modifications in phrases of value discount, efficiency, excellent development, productiveness growth, and client satisfaction.

This segment maintains till new possibilities for upgrades arise, after which, the DMAIC cycle runs from begin throughout again. Starting a DMAIC manner includes time, effort, and discipline, however as soon as your crew receives the grasp of it, they may emerge as cushty with the technique.

- Business Process Improvement Methodology

- Defects according to million possibilities

- Customer focused

- Uses facts & statistics

- Quantify monetary blessings

- Structured development technique

Benefits of DMAIC: Why It’s Needed

When your employer is making an attempt to enhance a selected manner, which includes lowering the range of defects or growing normal excellent, it’s crucial to have a clean route for achieving your goals. The essential gain of the DMAIC manner is its easy however especially based technique. Without this type of structure, businesses can have a tough time monitoring what works (and why) or casting off manner modifications that don’t paintings. And without imposing powerful controls, even the high-satisfactory manner modifications won’t be well adhered to.

Since this technique is so based and calls for unique documentation, it lets in corporations to hone their technique to hassle-fixing and growth productiveness continually. Data gathered thru the manner may be used for different tasks in the identical.

Here are a few matters that ought to come for your thoughts while humans communicate approximately Six Sigma:

- DMAIC

- DFSS

There are number one methodologies in Six Sigma:

The Six Sigma DMAIC technique defined withinside the publish in advance is for making upgrades to present processes. The 2nd technique DFSS stands for Design for Six Sigma. This technique is used for brand new services and products or while the upgrades that may be made with DMAIC isn’t sufficient.

There are numerous strategies to DFSS: DMADV, IDOV, etc. The maximum famous technique to imposing DFSS is the use of DMADV (Define – Measure – Analyze – Design – Validate). More than 70% of the DFSS implementations use the DMADV technique.

DMAIC may be taken into consideration to be reactive in nature, with inside the feel that a manner already exists and is making defects. DMAIC technique is used to pick out the foundation purpose of the issues after which restore it. On the opposite hand, DFSS is usually a proactive technique. A manner does now no longer exist but and DFSS is used to surely apprehend client necessities after which increase a manner that offers excellent stages of excellent and manner overall performance. employer, presenting greater correct baselines alongside the manner.

Conclusion

The DMAIC process, a key fundamental of the six sigma methodology, is designed to create efficiencies and improve productivity. By achieving the Lean Six Sigma Green Belt certification, professionals will not only master DMAIC but also how to apply these principles to real-world situations. ACTE’s Online Lean Six Sigma Green Belt certification course will help you pass the certification exam and get you career-ready in the latest six sigma methods all from the comfort of your own home.