- Developed by Mikel Harry and Bill Smith, Motorola.

- Motorola was amongst the first recipients of the Malcolm Baldrige Award.

- National Quality Award in 1988.

Throughout its history and evolution, Six Sigma turned into a business driven, multi-dimensional structured approach to reinforce Business Strategies into various aspects such as:

- Improving Processes

- Lowering Defects

- Reducing Process Variability

- Reducing Costs

- Increasing Customer Satisfaction

- Increasing Profit

Table of Contents

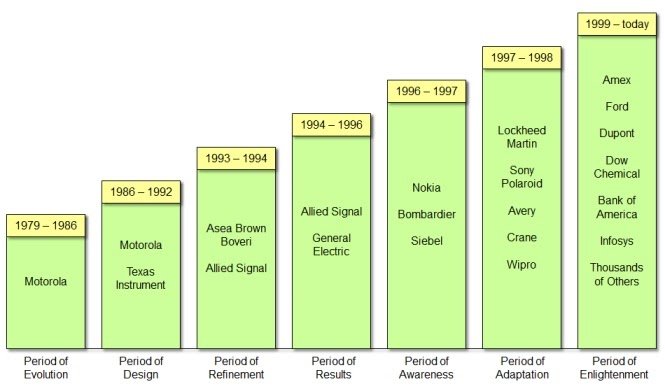

1979 – 1986: Period of Evolution:

During the period of evolution, Six Sigma had gone through several versions from RDMAICSI to DMAIC.

Mikel Harry and Bill Smith played a critical role in this period to evolve six sigma technology.

1986 – 1992: Period of Design:

When Six Sigma was picked up by other organizations after Motorola won it’s Malcolm Baldridge National Quality Award, they designed the Six Sigma methodology to suit different industries (other than manufacturing).

1993 – 1994: Period of Refinement:

Six Sigma went through yet another phase of refinement and steps such as Design of Experiments were taken to advanced levels by individuals such as Taguchi, etc.

1994 – 1996: Period of Results:

Most manufacturing organizations started gaining the results and reflecting them in their quarterly financial statements.

1996 – 1997: Period of Awareness:

In this period, the world started to know the power of Six Sigma. It was no longer a methodology known to a few organizations.

1997 – 1998: Period of Adaptation:

Organizations learn Six Sigma techniques and implemented it in their day-to-day processes. Eventually, they started gaining benefits.

1999 – till date: Period of Enlightenment:

Six Sigma has now become the basic hygiene requirement of most of the organizations. Individuals with Six Sigma expertise are given preference over other individuals.

History of Continuous Improvements:

In 1800’s: Management encouraged employee-driven improvements, and incentive programs were set in place to reward employees that brought about positive changes in the organization.

In 1894: National Cash Register’s program included reward schemes, employee development opportunities, and improving labour-management relationships.

Early 1900’s: much attention was given to scientific management

1930’s: Continuous Improvement programs were introduced in Japan by management experts like Deming, Juran, and Gilbreth.

1970’s: Japanese developed their own ideas and quality control

1980’s: Evolution of Six Sigma

1990’s: Introduction of Balance Scorecards

2000’s: Evolution of Hybrid Methodologies such as Lean Six Sigma, Agile, among others.

- The roots of Six Sigma as a measurement standard can be traced back to Carl Friedrich Gauss (1777-1855) who introduced the concept of the normal curve. Six Sigma as a measurement standard in product variation can be traced back to the 1920’s when Walter Shewhart showed that three sigma from the mean is the point where a process requires correction. Many measurement standards (Cpk, Zero Defects, etc.) later came on the scene but credit for coining the term “Six Sigma” goes to a Motorola engineer named Bill Smith. (Incidentally, “Six Sigma” is a federally registered trademark of Motorola).

- In the early and mid-1980s with Chairman Bob Galvin at the helm, Motorola engineers decided that the traditional quality levels — measuring defects in thousands of opportunities – didn’t provide enough granularity. Instead, they wanted to measure the defects per million opportunities. Motorola developed this new standard and created the methodology and needed cultural change associated with it. Six Sigma helped Motorola realize powerful bottom-line results in their organization – in fact, they documented more than $16 Billion in savings as a result of our Six Sigma efforts.

- Since then, tens of thousands of companies around the world have adopted Six Sigma as a way of doing business. This is a direct result of many of America’s leaders openly praising the benefits of Six Sigma. Leaders such as Larry Bossidy of Allied Signal (now Honeywell), and Jack Welch of General Electric Company. Rumor has it that Larry and Jack were playing golf one day and Jack bet Larry that he could implement Six Sigma faster and with greater results at GE than Larry did at Allied Signal. The results speak for themselves.

The Evolution of Six Sigma

- Before, January 15, 1987, Six Sigma was solely a statistical term. Since then, the Six Sigma crusade, which began at Motorola, has spread to other companies who are continually striving for excellence. While it is progressing, it has extended and evolved from a problem-solving technique to a quality strategy and ultimately into a sophisticated quality philosophy. However, this unique philosophy only became well known after GE’s Jack Welch made it a central focus of his business strategy in 1995. Today, Six Sigma is the fastest growing business management system in industry .

- To elaborate the evolution of Six Sigma, one Six Sigma authority has to be introduced: Mikel Harry, who is called the “godfather” of Six Sigma and is acknowledged as the leading authority on theory and practice. Even though he did not invent the concept, the way that it is currently practiced bears the unmistakable marks of Harry’s personality and personal history. Harry’s history path is followed here to reveal the evolution of Six Sigma.

- The evolution began in the late 1970s, when a Japanese firm took over a Motorola factory that manufactured television sets in the United States and the Japanese promptly set about making drastic changes to the way the factory operated. Under Japanese management, the factory was soon producing TV sets with 1/20th the number of defects they had produced under Motorola management. Finally, Motorola recognized its quality was awful. Since then. Motorola management decided to take quality seriously. When Bob Galvin became Motorola’s CEO in 1981, he challenged his company to achieve a tenfold improvement in performance over a five-year period.

- In 1984, after Harry was awarded a doctorate from Arizona State University, he joined Motorola where he worked with Bill Smith, a veteran engineer who was in Mikel Harry’s words, “the father of Six Sigma”. During 1985, Smith wrote an internal quality research report which caught the attention of Bob Galvin. Smith discovered the correlation between how well a product did in its field life and how much rework had been required during the manufacturing process. He also found that products that were built with fewer nonconformists were the ones that performed the best after delivery to the customer. Although Motorola executives agreed with Smith’s supposition, the challenge then became how to create practical ways to eliminate the defects. With the concept of “logic filter”, one of Harry’s papers at Arizona State University, together with Smith, Harry developed a four-stage problem-solving approach: Measure, Analyze, Improve, Control (MAIC). Later, the MAIC discipline became the road map for achieving Six Sigma quality.

- Six Sigma is a set of management techniques designed to improve business processes by considerably reducing the odds of defects. It was introduced in the 1980’s by Bill Smith, while working as an engineer for Motorola. To this day, he is considered the father of this process.

- While the Six Sigma method is a relatively new and revolutionary process, which keeps on expanding on a worldwide scale as we speak, the methodology used to define it can be traced back to the eighteenth century. Simply put, Six Sigma is not a self-contained method, but rather a complete and diverse blending of quality management practices and techniques over the years.

- However, this should be perceived as a weakness. In fact, knowing that some of the methods and techniques found in Six Sigma have been successfully used throughout history should render this process quite tempting to try out.

- Let’s review a quick timeline containing the most important events that created the Six Sigma of today.

- The Moving Assembly Line of Henry Ford 1913

- All reputed entrepreneurs out there know that Henry Ford was simply a master of automation, who wished for all his workers to be well-paid and share in the production of an affordable vehicle. As a result, he created the moving assembly line in 1913, completely breaking the mold for those times. In the context of the Industrial Revolution continuously blossoming, it was entirely necessary for only good automobile parts to be available to use right away, as opposed to workers having to sort through endless piles of parts to find one that actually fit.

- This required entirely new and distinct methods of testing and assurance that would ultimately render the automobile assembly process faster and more cost-effective, without compromising quality whatsoever. No longer was it lucrative to spend time on testing each individual piece, so Henry Ford foresaw the necessity of implementing an automation process, which he successfully did.

Overview of Six Sigma

- The set of principles that comprise Six Sigma has its origins in the search for quality in mass production, beginning in the late 18th century, though the field of statistics itself – upon which many of Sigma’s tools are based- has been around for a long time.

- Central pillar of statistical theory, as utilized in Six Sigma, is German mathematician Friedrich Gauss’ Normal Distribution curve (also called a ‘Bell Curve’). One standard deviation, represented by the Greek alphabet ‘σ’ (‘sigma’), away from the mean in terms of statistical quality control, processes and products are measured and evaluated to find the variation from acceptable standards, and the spread of the distribution signifies variability.

- Six Sigma methodology is not a revolutionary way of thinking, also it does not provide a radically new set of quality tools. Six Sigma is more of an evolutionary development moving towards continuous improvement that combines the best elements from many earlier quality initiatives. Some of the tools used in Six Sigma, such as quality function deployment (QFD), are relatively new, most, such as the fishbone diagram, etc have been developed long back.

- Six Sigma holds a lot of importance in the field of quality and continuous improvement. Therefore, understanding quality’s roots and the reasons behind the methods will allow practitioners to be better prepared to launch successful projects for large scale initiatives.