8 Deadly Wastes:

Lean thinking aims to remove wastes from work processes. Before diving into the 8 wastes, it is important to understand what waste is. Waste is any action or step in a process that does not add value to the customer. In other words, waste is any process that the customer does not want to pay for.

The original seven wastes (Muda) was developed by Taiichi Ohno, the Chief Engineer at Toyota, as part of the Toyota Production System (TPS). The seven wastes are Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing and Defects. They are often referred to by the acronym ‘TIMWOOD’. The 8th waste of non-utilized talent or ‘Skills’ of workers was later introduced in the 1990s when the Toyota Production System was adopted in the Western world. As a result, the 8 wastes are commonly referred to as ‘TIMWOODS’. In the following section we will examine each of these wastes in detail.

1. Transport

Waste in transportation includes movement of people, tools, inventory, equipment, or products further than necessary. Excessive movement of materials can lead to product damage and defects. Additionally, excessive movement of people and equipment can lead to unnecessary work, greater wear and tear, and exhaustion.

In the office, workers who collaborate with each other often should be close together. In the factory, materials necessary for production should be easily accessible at the production location and double or triple handling of materials should be avoided.

Some of the countermeasures to transportation waste include developing a U-shape production line, creating flow between processes, and not over-producing work in process (WIP) items.

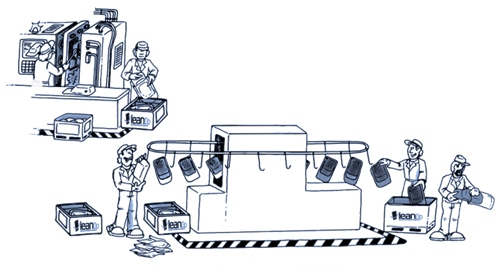

2. Inventory

Oftentimes it is difficult to think about excess inventory as waste. In accounting, inventory is seen as an asset and oftentimes suppliers give discounts for bulk purchases. But having more inventory than necessary to sustain a steady flow of work can lead to problems including: product defects or damage materials, greater lead time in the production process, an inefficient allocation of capital, and problems being hidden away in the inventory. Excess inventory can be caused by over-purchasing, overproducing work in process (WIP), or producing more products than the customer needs. Excess inventory prevents detecting production-related problems since defects have time to accumulate before it is discovered. As a result, more work will be needed to correct the defects.

In-office inventory waste could be files waiting to be worked on, customers waiting for service, unused records in a database, or obsolete files. Manufacturing inventory waste could include broken machines sitting around, more finished products than demanded, extra materials taking up work space, and finished products that cannot be sold.

Some countermeasures for inventory include: purchasing raw materials only when needed and in the quantity needed, reducing buffers between production steps, and creating a queue system to prevent overproduction.

Illustration of Inventory Waste (LeanOp)

3. Motion

The waste in motion includes any unnecessary movement of people, equipment, or machinery. This includes walking, lifting, reaching, bending, stretching, and moving. Tasks that require excessive motion should be redesigned to enhance the work of personnel and increase the health and safety levels.

In the office, wasted motion can include walking, reaching to get materials, searching for files, sifting through inventory to find what is needed, excess mouse clicks, and double entry of data. Manufacturing motion waste can include repetitive movements that do not add value to the customer, reaching for materials, walking to get a tool or materials, and readjusting a component after it has been installed.

Some countermeasures for motion include making sure the workspace is well organized, placing equipment near the production location, and putting materials at an ergonomic position to reduce stretching and straining.

Illustration of Motion Waste (LeanOp)

4. Waiting

The waste of waiting includes: 1) people waiting on material or equipment and 2) idle equipment. Waiting time is often caused by unevenness in the production stations and can result in excess inventory and overproduction.

In the office, waiting waste can include waiting for others to respond to an email, having files waiting for review, ineffective meetings, and waiting for the computer to load a program. In the manufacturing facility, waiting waste can include waiting for materials to arrive, waiting for the proper instructions to start manufacturing, and having equipment with insufficient capacity.

Some countermeasures for waiting include: designing processes to ensure continuous flow or single piece flow, leveling out the workload by using standardized work instructions, and developing flexible multi-skilled workers who can quickly adjust in the work demands.

Illustration of Waiting Waste (LeanOp)

5. Overproduction

Overproduction occurs when manufacturing a product or an element of the product before it is being asked for or required. It may be tempting to produce as many products as possible when there is idle worker or equipment time. However, rather than producing products just when they are needed under the ‘Just In Time’ philosophy, the ‘Just In Case’ way of working leads a host of problems including preventing smooth flow of work, higher storage costs, hiding defects inside the WIP, requiring more capital expenditure to fund the production process, and excessive lead-time. Additionally, over-producing a product also leads to an increase in likelihood that the product or quantities of products produced are beyond the customer’s requirements.

In an office environment, overproduction could include making extra copies, creating reports no one reads, providing more information than needed, and providing a service before the customer is ready. Manufacturing overproduction involves producing more products than demanded through a ‘push production system’ or producing products in higher batch sizes than needed.

There are three countermeasures for overproduction. Firstly, using a ‘Takt Time’ ensures that the rate of manufacturing between stations are even. Secondly, reducing setup times enables manufacturing small batches or single-piece flow. Thirdly, using a pull or ‘Kanban’ system can control the amount of WIP.

Illustration of Overproduction Waste (LeanOp)

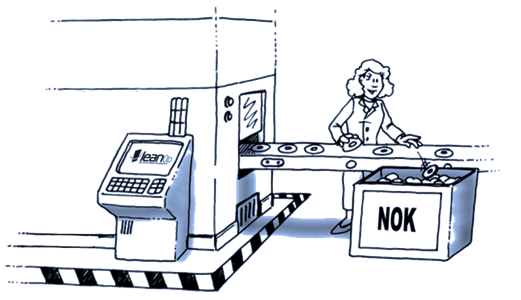

6. Over-processing

Over-processing refers to doing more work, adding more components, or having more steps in a product or service than what is required by the customer. In manufacturing this could include using a higher precision equipment than necessary, using components with capacities beyond what is required, running more analysis than needed, over-engineering a solution, adjusting a component after it has already been installed, and having more functionalities in a product than needed. In the office, over-processing can include generating more detailed reports than needed, having unnecessary steps in the purchasing process, requiring unnecessary signatures on a document, double entry of data, requiring more forms than needed, and having an extra step in a workflow.

One simple way to counter over-processing is to understand the work requirements from the standpoint of the customer. Always have a customer in mind before starting work, produce to the level of quality and expectation that the customer desires, and make only the quantities needed.

Illustration of Over-processing Waste (LeanOp)

7. Defects

Defects occur when the product is not fit for use. This typically results in either reworking or scrapping the product. Both results are wasteful as they add additional costs to the operations without delivering any value to the customer.

Here are four countermeasures for defects. Firstly, look for the most frequent defect and focus on it. Secondly, design a process to detect abnormalities and do not pass any defective items along the production process. Thirdly, redesign the process so that does not lead to defects. Lastly, use standardized work to ensure a consistent manufacturing process that is defect free.

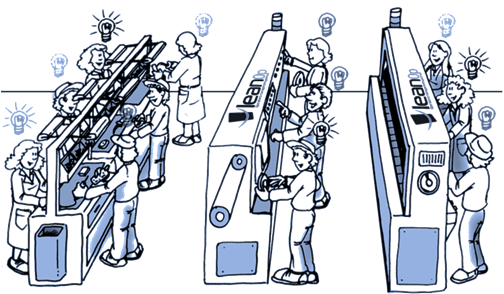

8. Skills – The 8th Waste

Even though it was not part of the Toyota Production System (TPS), many people are well aware of the 8th waste – the waste of human potential. The 8th waste is also described as the waste of unused human talent and ingenuity. This waste occurs when organizations separate the role of management from employees. In some organizations, management’s responsibility is planning, organizing, controlling, and innovating the production process. The employee’s role is to simply follow orders and execute the work as planned. By not engaging the frontline worker’s knowledge and expertise, it is difficult to improve processes. This is due to the fact that the people doing the work are the ones who are most capable of identifying problems and developing solutions for them.

In the office, non-utilized talent could include insufficient training, poor incentives, not asking for employee feedback, and placing employees in positions below their skills and qualifications. In manufacturing, this waste can be seen when employees are poorly trained, employees not knowing how to effectively operate equipment, when employees are given the wrong tool for the job, and when employees are not challenged to come up with ideas to improve the work.

Illustration of Skills Waste (LeanOp)

Identifying and Eliminating the 8 Wastes

The first step to reducing waste is recognizing that they exist and having an effective process for identifying them. Value Stream Mapping (VSM) is a Lean management method for analyzing the current state and designing a future state. It shows the flow of information and material as they occur. VSM is an effective tool for mapping out the processes involved, displaying the relationship between production processes in a visual manner, and for separating value-added and non-value-added activities.

In order to identify wastes, use the VSM and start with the end customer in mind. Work backwards from the end customer to the start of the production processes. Document instances of the 8 wastes in the processes and develop a plan for eliminating or reducing them. Continue challenging your team to find more wastes and continuously improve your processes. Engage with the frontline workers and elicit their ideas for improvement. As your team begins reducing efficiencies they will gain more confidence in their problem-solving capabilities and over time reducing waste becomes a part of their daily routine.