- Setting productivity improvement goals.

- Immediate elimination of non-value added activities.

- Ability to estimate potential savings based on analysis results.

Introduction to analyse Individual Productivity:

Productivity analysis is carried out to identify areas of potential productivity improvement projects based on the statistical data collected during the analysis. The analysis also pinpoints areas of delay and interruption that lead to loss of productivity. The first step in any productivity improvement initiative is understanding the current state of operations. Productivity analysis provides baseline indicators that will also provide data that will be used to determine potential productivity improvement objectives and potential cost savings.

Reliable data derived from productivity analysis also makes the following results possible:

Tools:

Graphic rating scales. A typical graphic scale uses sequential numbers, such as 1 to 5, or 1 to 10, to rate an employee’s relative performance in specific areas. Scales are often used to rate behavioural elements, such as “understands job tasks” or “participates in decision-making.” Or they may note the frequency that an employee performs a certain task or behaviour, such as “always,” “often,” “sometimes,” or “never” coming to work on time. You can customise the scales to suit your business needs.

360 degree response. This well-named system takes into account employee’s performance feedback, opinions and assessments from the circle of people in the company with which they work. This may include coworkers, supervisors, and others. When you evaluate inputs from multiple sources, you can note positive and negative similarities and trends. You can also identify areas that may need additional measurement and support.

Self-assessment. Asking an employee to evaluate their own performance can be very effective. Often, employees can be more critical of your performance than you are. You can use a form that requires a multiple choice answer, an essay-type answer, or a combination of both. Comparing a self-appraisal to your own objective evaluation can be helpful in finding similarities and discrepancies along with a richer understanding of employee performance. This can generate interactions that can be beneficial to employee development.

Management by Objectives (MBO). Also known as “management by results”, it is a process by which employees and managers together create objectives. They jointly set individual objectives, how they align with the company’s goals, and how performance will be measured and evaluated. MBO gives employees a clear understanding of what is expected and allows them to participate in the process, which can promote better communication and increase motivation. checklist. Using a simple “yes-no” checklist is a quick and easy way to identify employees with deficiencies in various performance areas. It will also identify people who need additional training and knowledge to become more skilled

Features / Characteristics:

1. Procedure for Handing over Symbols:

Measurement, in general terms, is the process of assigning symbols to observations in some meaningful and consistent way. The symbols must express the position of a certain scale as it is associated with the word ‘measure’. In the process of measurement the investigator does not specify the numbers of his choice, but according to certain and clear rules.

2. No Absolute Zero Point:

There is no absolute zero point in mental measurement. This is relative to some arbitrary standard. A student has secured zero marks in an examination or subject. It doesn’t mean that he doesn’t know anything about that exam or subject. We cannot claim that the guy with I.Q. One with I.Q out of 110 is twice as intelligent as the boy. 55’s.

3. Process of Quantification:

Measurement involves the process of quantification. In the process of measurement, numbers are used to represent the quantities of a property. Quantification indicates how much or to what extent that particular quality is present in a particular object.

4. A Complicated Process:

The process of measurement in behavioural science is complex as well as difficult. Attribute or characteristic is not measured directly by scale but character is measured indirectly by behaviour. The basis of measurement is the behaviour of a subject. All the characteristics of behaviour are measured with the help of behaviours. Both direct and covert behaviours are used in the process of measurement.

5. Sense of Infinite:

Measurement in behavioural science conveys a sense of infinity. This means that we cannot measure the entire characteristic of an individual.

6. Mental measurement is often subjective:

The accuracy of the measurement depends on the person who measures it. It also depends on various factors like test condition, type of test items, defect in language, physical and emotional state of etc.

7. Units Not Fixed:

Units in mental measurement are not fixed. We cannot get the same value for each individual. It is heavily dependent on psychological and educational tests which differ in content and purpose. A person can get different marks in different intelligence tests.

8. Instruments in Measurement Not Accurate:

The tools used in educational and psychological measurement are never accurate; Rather they are approximate.

9. Units are fundamental in physical measurement:

Units are fundamental in physical measurement, but in the case of mental measurement they are derived.

- In a manufacturing industry, an engineer selects 10 parts that represent the expected range of process variation. Three operators measure 10 parts three times per part in a random order. Using MINITAB, he conducts a cross gauge R&R study to assess the variability in measurements that can occur from the measurement system.

- Gauge R&R (ANOVA) Report for Measurement result

- In the Components of Variation Graph, % Contribution from Part-to-Part > Total Gauge R&R. Thus, most of the variation is due to the difference between the parts.

- The chart by operator R shows that operator B measures parts inconsistently.

- In the X bar chart by the operator, most of the points are out of control range. Thus, most of the variation is due to the difference between the parts.

- The By Part graph shows that the gap between the parts is large.

- In the BY operator graph, the differences between the operators are smaller than the differences between the parts, but significant (p-value = 0.00). The measure of operator c is slightly less than the measure of other operators.

- In the operator* part interaction graph, the lines are nearly parallel and the p-value for the operator * the part interaction found in the table is 0.974. These results indicate that no significant interactions exist between each part and the operator.

Syntax with examples:

- A company needs to know how productive its operations are in order to make investment decisions. For example, you might work in a production plant that makes a car, where production has slowed significantly over the past two years. Based on its productivity measurements, the company can conclude that the loss in productivity is due to outdated equipment that needs to be updated.

- So the management invests money in modernising the plant. Continuously measuring productivity allows a company to compare the efficiency of its operations over time and make adjustments accordingly.

- Another important reason to measure productivity is that it allows you to gauge the efficiency of your workforce. For example, if your company has been asked by a customer to accommodate a challenging delivery, you’ll know if you can meet the timeline if you’re constantly measuring the productivity of your workforce. Managers also need to know how each individual employee is performing.

- This information helps them make important decisions that affect overall workplace efficiency. For example, understanding how efficiently each employee performs helps managers determine who can take on additional responsibilities or who would be ideal to lead a team project.

- Allows for better operational decision making. Another important reason for monitoring productivity is that it can help managers transform the company. For example, data collected during the measuring process can reveal delays in the production process.

- Alternatively, it may reveal problems in the customer lifecycle. Recognizing this can help you make operational changes such as expanding your customer service team or investing in new production equipment.

- focus on profit

- getting the job done

- time management

- Feedback and peer evaluation

- Comparison of labour time for goods produced

- monitoring employee progress

- customer satisfaction

- focus on profit

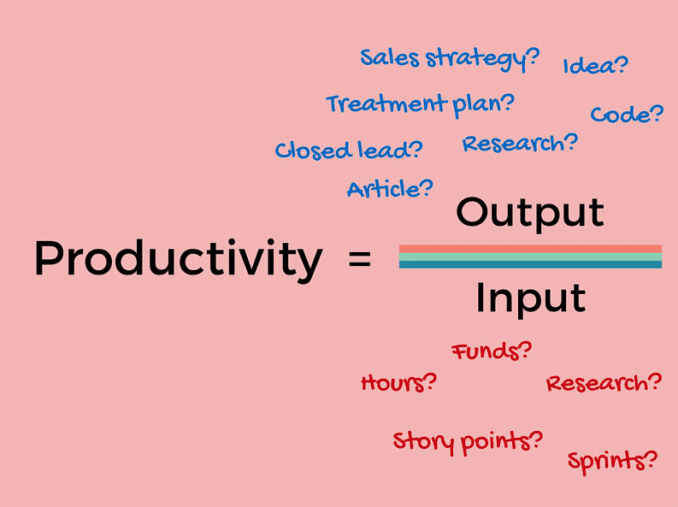

- A popular way to measure productivity in a factory setting is to compare total labour time, also called input, with the number of products manufactured or output. By doing this, companies can calculate a ratio that shows them how efficiently their employees are working.

- To measure productivity in this way, you would divide the total number of products made by the total number of hours worked by all employees. Then, you’ll use the result as a cost-benefit ratio, which you can monitor

- Various productivity measurement strategies include monitoring employee progress on a regular basis. These approaches allow you to stay on top of the work being done and make changes or set new goals when necessary.

- One way is daily check-ins or team meetings. This includes meeting with your team daily to discuss workflow, issues that have come up or new developments in your work processes. Comparing how much work employees have completed over the course of a day or a week will give you a general idea of how productive they are.

Why should I need measure and analyse Individual Productivity?

There are many reasons why it is necessary to measure workplace productivity.

Investment decisions are easy

Measures employee effectiveness and abilities:

Tips for measuring productivity:

Each company has its own methods for measuring productivity. The diversity of methods reflects the fact that each company is different in terms of its structure and focus. Therefore, companies generally design productivity measuring tools to suit their needs. That being said, there are several broad categories of productivity measures that you should expect over the course of your career.

One way to measure profitability is by monitoring the organisation’s profitability and sales. For example, in simple words, if your company made a profit of one million dollars in one year and a profit of two million dollars the next year, it is a clear sign of increased productivity, although a thorough analysis of the company would be necessary. Profit and Loss Sheet to understand what is causing the increase in profitability.

Focusing on profits can be a popular choice for companies operating in areas where it is often difficult to measure how long a specific activity will take. For example, consider a team that is responsible for managing advertising campaigns for multiple clients. The company may decide that it is more important to secure a few key customers by creating a high-quality advertising campaign than to secure as many customers as possible.

Comparison of labour time for goods produced:

Monitoring employee progress

- What are you doing tomorrow?

- Visually, this may seem like a ridiculously simple question – but it is not.

- You see, as human beings, we often set ourselves unrealistic goals and targets – sometimes without knowing it. And it results in one thing: an inability to get to the bottom of an ever-increasing to-do list.

- To avoid this, make sure you make a strategic plan for each day. Write down exactly what you want to achieve and then narrow it down to the tasks you know you can do and that are the highest priority. Everything else can wait.

- This is probably the hardest element of productivity, but one that you can master in time.

- To stay focused, you only need to focus on one project at a time, and it goes right back to that to-do list plan we mentioned above.

- If you know what you need to do each day, you can tackle each task one by one. Do not fly between tasks; Instead, put all your attention and effort into just one task until it’s done.

- Repeat that process throughout the day, every day, and you’ll have your to-do list minced—trust us.

- We only have a limited amount of time to play with each day, so it makes sense to figure out how best to use it.

- This can happen only if you make the right choice.

- What really matters? What tasks or projects can I look forward to tomorrow, next week or next month? Where are you most likely to be profitable and delight your customers?

- Always focus on the tasks that provide the greatest **** for your limited time.

- We all work at different speeds, but the key to staying productive is to maintain a consistent pace.

- For you, that could be lightning fast. For others, it may be too slow. There is neither right nor wrong – it is what works for each person.

- So, remember – it doesn’t matter how fast or slow you go, as long as you don’t stop doing what you’re doing.

Trends:

1. Your ability to plan (strategically)

2. Your desire to stay focused (one project at a time!)

3. Making the Right Choice

4. Your Consistency

- Measures of process performance are ‘vital signs’ of organisational health, providing an assessment of the current state, giving clues to potential health issues, and showing progress towards recovery.

- A government organisation implementing a new service did a lot of planning, a large number of process models, and many sessions with a wide range of stakeholders. Green lights everywhere, so the service started with proper ‘ribbon cutting’.

- Two days later, everyone was relieved that the launch went well; Two weeks later, there was a gradually increasing murmur of complaints; Two months later, service delivery was at a virtual standstill and the murmur was a hoarse one. A month after that, it was finally discovered that a critical process in service delivery was failing frequently, causing significant rework and extremely long delays. Further analysis found ways to reduce the delay by as much as 95%.

- Normal service delivery resumed after the backlog was resolved. The memories of the customer, and employee fuss, however, will never be erased. It didn’t have to be like that.

- Careful analysis of process performance expectations before launch, and proper measurement of process performance from launch, would have either avoided the problem entirely, or would have been detected early and allowed resolution before it became a major issue.

- There is much to be gained from effective process-based management, but every organisation has the right to demand, in fact, the obligation that those involved consistently demonstrate that the benefits promised have been realised.

- The process of process management also needs continuous improvement. For this to be possible, there must be a regular assessment of the effectiveness of the changes made. Process practitioners are not just in the business of making recommendations; His aim is to bring about a positive change and prove that he has done so.

Benefits:

Conclusion:

The challenge facing researchers and practitioners is to develop an internally consistent and comprehensive productivity measurement system that accounts for the productivity of individual workers, work groups, business units and organisations. The degree to which this goal can be achieved will determine the organisation’s ability to effectively manage resources and direct human effort toward organisational goals. It can help them regain their lost industrial leadership and understand the apparent contradictions that arise when the expected productivity gains are not achieved. Continuous productivity measurement systems enable researchers and practitioners to speak a common language as they each play their part in solving the problems associated with poor productivity growth. The concept of productivity is still often misunderstood; Discussion of the relationship of productivity to financial or practical measures of effectiveness, efficiency, quality, innovation, and performance takes the form of debate. A general definition of productivity, at all levels of organisational analysis, is a prerequisite for the development of a comprehensive measurement system.