- Introduction to Production Systems

- Characteristics of Production Systems

- Components: Rules, Working Memory

- Control Strategy

- Types of Production Systems

- Simple Production Systems

- Stateful Production Systems

- Rule-Based Production Systems

- Conflict Resolution Strategies

- Applications in AI

- Advantages and Limitations

- Conclusion

Introduction to Production Systems

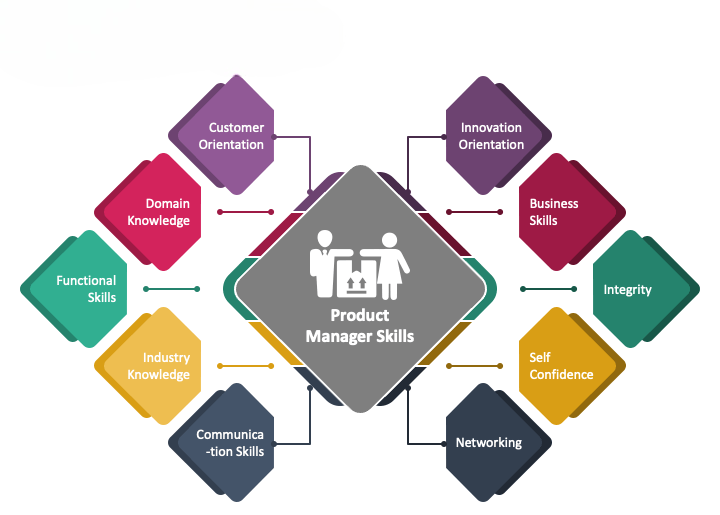

A production system is a type of knowledge-based system used in artificial intelligence (AI) to model decision-making processes, where rules are applied to manipulate data. It consists of a set of rules, working memory, and a control strategy, enabling it to produce outputs based on inputs and predefined rules, which is essential for Data Science Training Production systems form the backbone of many AI applications, particularly in rule-based systems like expert systems, decision-making systems, and machine learning algorithms. In AI, production systems are essential because they enable machines to process and act upon a large number of conditions or facts through a process of rule-based reasoning. The purpose of such systems is to automate decision-making or problem-solving tasks that would otherwise require human expertise. Production systems can be applied in a wide range of fields, from robotics and industrial control to natural language processing and medical diagnosis.

Would You Like to Know More About Data Science? Sign Up For Our Data Science Course Training Now!

Characteristics of Production Systems

A production system has several defining characteristics that make it an effective approach for solving problems in AI. These include:

- Rule-Based Structure: The most distinguishing feature of a production system is its use of rules. These rules typically follow an “if-then” format, where conditions (the “if” part) trigger actions (the “then” part). The rules encapsulate expert knowledge in a structured way, allowing systems to reason about different situations and make decisions accordingly.

- Working Memory: Working memory is a storage area where facts or conditions are maintained. It represents the current state of the system and is continuously updated as the system processes new information. Working memory allows the production system to store intermediate results and make decisions based on the most current data, which is an essential concept in the What is Data Science guide..

- Control Strategy: The control strategy governs the way the rules are applied and the sequence in which they are processed. It decides which rules should be fired (i.e., applied) and in what order, ensuring that the system behaves in a logical and consistent manner. The control strategy plays a critical role in the efficiency and effectiveness of the production system.

- Inference Process: The inference process refers to the sequence of operations in which the system applies rules to the working memory to deduce new facts, make decisions, or take actions. Inference may be forward or backward, depending on whether the system is trying to derive new facts or reach a goal state.

- Dynamic Updates: Production systems are dynamic in nature. As facts and conditions change, the system updates its working memory and applies new rules. This allows production systems to adapt to different scenarios and process continuously changing inputs.

Components of a Production System: Rules, Working Memory

A production system is composed of several key components that collaborate to support decision-making and problem-solving.The primary component is rules, which serve as the system’s core. Each rule is structured as “IF condition THEN action,” where the condition represents the premise and the action is the conclusion, highlighting one of the explore in our Differences Between Data Scientists Vs Software Engineers. These rules encapsulate domain-specific knowledge and manipulate the system’s working memory based on prevailing conditions. For instance, in a medical diagnostic system, a rule could be, “IF the patient has a cough AND fever, THEN diagnose flu.” The working memory holds the facts and data required for decision-making and is an active structure that updates continuously as new facts are processed. It contains both the current information and the system’s state, such as sensor readings in a robot control system. The control strategy dictates the order and priority of rule execution, employing methods like forward chaining (data-driven reasoning) or backward chaining (goal-driven reasoning). In forward chaining, the system begins with known facts and applies rules to derive new facts, while in backward chaining, it starts with a goal and works backward to identify the facts that support it. Finally, the inference engine applies the rules to the working memory, guided by the control strategy. It decides which rules to activate and in what sequence, continuously updating the working memory until a solution or goal is reached.

Control Strategy

- In forward chaining, the system begins with known facts and applies rules to generate new facts. This process continues until a goal is reached or no further rules can be applied.

- Forward chaining is often used in data-driven systems where the objective is to explore all possibilities based on existing knowledge. Backward Chaining:

- In backward chaining, the system starts with a goal or hypothesis and works backward to find the facts that support it. The system looks for rules that can help deduce the goal and then checks if the required conditions are met.

- This approach is commonly used in goal-driven systems where the objective is to find the necessary conditions for a particular outcome. Conflict Resolution:

- In cases where multiple rules are applicable at the same time, the control strategy must resolve conflicts and decide which rule to apply first. This is done using conflict resolution strategies, such as priority-based or recency-based strategies, which can be influenced by factors like Data Analyst Salary Trends in the United States. Recency and Specificity:

- The recency-based strategy prioritizes the most recently added facts. The specificity-based strategy selects the rule with the most specific conditions.

The control strategy of a production system is the mechanism by which rules are selected for execution. It dictates how the system decides which rules to apply in which order. Several common approaches to control strategy include:

Forward Chaining:Types of Production Systems

There are several types of production systems, each differing in structure, approach, and use cases. The main types include simple production systems, stateful production systems, and rule-based production systems. Simple production systems consist of basic rules designed to perform straightforward reasoning tasks. These systems are generally used in situations where the rules are static and the environment is well understood. They are commonly applied in scenarios where decisions can be made by applying rules based on simple conditions, such as in medical diagnostics or rule-based decision-making systems. Stateful production systems maintain a history of events or states. Unlike simple production systems, they store the current state and information about past states, enabling them to handle more complex tasks that require memory of previous actions or decisions, which can be relevant when considering Data Analyst Salary Trends in India. These systems are often used in dynamic process control, robotics, and other applications that need to track long-term context. Rule-based production systems rely on explicit rules to determine the actions the system should take. These rules are typically structured as “if-then” statements, where conditions trigger specific actions. Rule-based systems are commonly employed in expert systems, natural language processing, and automated decision support systems, where well-defined rules are crucial to simulating human expertise.

Conflict Resolution Strategies

In production systems, conflict resolution arises when multiple rules are applicable to the same situation. To manage this, several strategies are employed:

-

Priority-Based Resolution:

- Rules are assigned priorities, and the system fires the highest-priority rule first.

- This is useful when certain rules are considered more important or when some rules need to be executed before others. Recency-Based Resolution:

- This strategy prioritizes rules whose conditions have been more recently added to the working memory.

- It is often used when newer facts are believed to be more relevant for decision-making. Specificity-Based Resolution:

- In specificity-based resolution, the system chooses the rule with the most specific conditions. More specific rules have conditions that more closely match the current state of the system. Random Selection:

- In some cases, when there is no clear priority, a production system may choose a rule randomly from those that can be applied. This is less common but can be used when no other strategy fits.

Want to Pursue a Data Science Master’s Degree? Enroll For Data Science Masters Course Today!

Applications in AI

Production systems are extensively used in AI for tasks involving knowledge representation, decision-making, and reasoning. Key applications include expert systems, planning and scheduling, game playing, and natural language processing (NLP). Expert systems simulate the decision-making abilities of human experts by applying rules within specific domains such as medical diagnosis, legal advice, and troubleshooting, a concept commonly explored in Data Science Training These systems can replicate human expertise and provide solutions to complex problems. In planning and scheduling, production systems are used to manage tasks that must be performed in a specific sequence to achieve a goal, optimizing resources and ensuring efficiency, as seen in logistics and robotics. Game-playing AI, such as chess or checkers, uses production systems to evaluate potential moves and determine the best course of action based on predefined strategies. Lastly, in NLP, production systems help parse sentences, analyze grammar, and generate responses based on linguistic patterns and rules.

Advantages and Limitations

-

Advantages of Production Systems:

- Transparency: Rules in production systems are often explicit and human-readable, making them easy to understand and modify.

- Flexibility: New rules can be added or existing rules can be modified without significantly altering the overall system.

- Scalability: Production systems can be scaled to handle more complex tasks by adding more rules to the system.

- Expert Knowledge Representation: They are an excellent way to represent expert knowledge in a formalized and structured manner. Limitations of Production Systems:

- Inefficiency: As the number of rules grows, the system can become inefficient in terms of memory and processing time.

- Rule Conflicts: Managing rule conflicts can be complex, especially in large systems.

- Lack of Learning: Traditional production systems do not have the ability to learn from experience unless explicitly programmed to do so.

- Limited Flexibility: In dynamic environments, where rules may change frequently, production systems may struggle to adapt.

Simple Production Systems

Simple Production Systems are fundamental in artificial intelligence, using basic rules to perform straightforward reasoning tasks. These systems typically operate with rules in the form of “IF condition THEN action,” where the condition serves as a premise, and the action is the result. Simple production systems are most effective in environments where the rules are static, and the conditions are clearly defined. They are ideal for tasks that involve applying a sequence of rules based on simple conditions, such as in medical diagnostics or legal advice, where predefined conditions lead to predictable outcomes, and understanding this can help clarify the Data Engineer vs Data Scientist difference. For instance, in a medical system, a rule might state: “IF the patient has a cough AND fever, THEN diagnose flu.” While simple production systems are easy to implement and effective in domains with well-understood rules, they may struggle with more complex scenarios that require adaptability or the handling of contradictory rules. Despite these limitations, they remain a powerful tool in AI for tasks requiring clear decision-making based on predefined conditions, making them suitable for applications where quick and predictable decisions are essential.

Stateful Production Systems

Stateful Production Systems are a type of production system that keeps track of past events or states, allowing them to handle more complex tasks than simple production systems. Unlike basic systems, which only consider the current state, stateful systems maintain a history of actions and conditions, enabling them to make decisions based on both the present and previous states. This feature makes them particularly useful for applications where long-term context or memory of past actions is required. For example, in robotics, a stateful system can remember past movements and adjust its future actions accordingly, improving its performance and adaptability. Similarly, in dynamic process control, stateful systems can track a sequence of operations and adjust actions to ensure optimal outcomes over time. The ability to recall and utilize past states allows stateful production systems to adapt to changing environments, making them more versatile than simple systems. However, maintaining a history of states introduces complexity, requiring more memory and processing power. This added resource demand makes stateful systems more suitable for tasks that involve dynamic decision-making, learning from past experiences, or managing long-term processes. Despite their complexity, stateful production systems are essential for handling evolving environments where past decisions impact future outcomes.

Rule-Based Production Systems

Rule-Based Production Systems are AI systems that use a set of explicit, predefined rules to determine the actions or decisions a system should take. These rules are typically structured in an “IF condition THEN action” format, where the condition is the premise, and the action is the conclusion or output. The primary strength of rule-based systems lies in their ability to apply logical reasoning to a set of rules, making them highly effective in domains requiring well-defined decision-making processes. They are commonly used in expert systems, where human expertise is encoded into rules to replicate decision-making in specific fields like medical diagnosis, legal advice, or troubleshooting, which is closely tied to the growing Data Science Scope in India. Rule-based systems can process large amounts of information quickly and provide consistent outputs based on the given rules. However, they are limited in their flexibility, as they rely on predefined conditions and struggle to adapt to situations outside of the rule set. Despite this, rule-based systems excel in scenarios where clear, structured decision-making is needed, and the environment is well-understood. Their simplicity and transparency in logic make them valuable in areas like natural language processing (NLP), automated decision support, and systems that simulate human expertise, ensuring they remain a core component of AI applications.

Conclusion

Production systems are a powerful tool in artificial intelligence, enabling machines to process and act upon large volumes of data by applying predefined rules. These systems play a crucial role in various AI applications, including expert systems, planning, game-playing, and natural language processing (NLP). In expert systems, production systems allow machines to simulate human expertise, making decisions in domains such as medical diagnosis, legal advice, and troubleshooting. In planning, production systems help manage sequences of actions to achieve specific goals, optimizing resources in fields like logistics and robotics. For game-playing AI, such as in chess or checkers, production systems evaluate potential moves and determine the best course of action based on established strategies, which is a concept often explored in Data Science Training In NLP, they assist in parsing sentences, analyzing grammar, and generating appropriate responses. Despite their broad applicability, the effectiveness of production systems depends on selecting the right control strategy, managing rule conflicts, and overcoming limitations such as efficiency and adaptability. Control strategies, like forward and backward chaining, dictate the order in which rules are applied, influencing the system’s performance. Additionally, challenges such as handling contradictory rules and maintaining system efficiency in real-time processing need to be addressed. As AI continues to evolve, production systems are expected to remain a cornerstone of rule-based reasoning, providing machines with the ability to make decisions in increasingly complex environments. Their role in enabling machines to handle sophisticated tasks through structured rule applications ensures they will remain integral to future advancements in AI.