- Overview of Six Sigma

- Impact on Quality Management

- Six Sigma Principles

- DMAIC Methodology

- Six Sigma Tools and Techniques

- Integration of Lean Six Sigma

- Advantages of Six Sigma

- Future Trends in Six Sigma

Overview of Six Sigma

Six Sigma is a data-driven methodology aimed at improving process quality by identifying and eliminating defects, reducing variation, and increasing overall efficiency. Developed by Motorola in the 1980s and later popularized by General Electric, Six Sigma has become a globally recognized standard for process improvement and quality management. The term “Six Sigma” comes from statistics, where a Power of Six Sigma level of quality equates to just 3.4 defects per million opportunities (DPMO), signifying a near-perfect performance level. The Six Sigma approach relies on a structured methodology known as DMAIC (Define, Measure, Analyze, Improve, Control), which guides teams through the process of identifying problems, analyzing data, and implementing solutions to eliminate defects, a process further strengthened by Data Science Training. Statistical tools, such as regression analysis, hypothesis testing, and control charts, are employed to drive decisions and monitor progress. By reducing defects and improving processes, organizations can boost efficiency, reduce costs, and enhance customer satisfaction. Six Sigma fosters a culture of continuous improvement, focusing on data-driven decision-making and long-term performance enhancement, making it a powerful tool for achieving operational excellence across various industries.

To Explore Data Science in Depth, Check Out Our Comprehensive Data Science Course Training To Gain Insights From Our Experts!

Impact on Quality Management

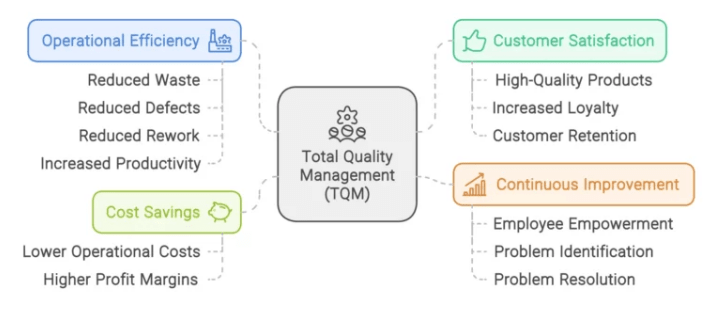

Six Sigma is essential in quality management as it optimizes processes, enhances consistency, and minimizes errors. This methodology offers a structured approach for identifying the root causes of defects and implementing sustainable solutions. By improving process efficiency, Six Sigma reduces waste, boosts productivity, and leads to significant cost savings. It also encourages data-driven decision-making, which helps organizations mitigate risks and improve customer satisfaction, particularly when Using JIRA for Agile and Scrum Project Tracking. Six Sigma is widely adopted across industries such as manufacturing, healthcare, IT, finance, and logistics. These sectors use Six Sigma to achieve high-quality standards, maintain compliance, and drive operational excellence.

The focus on continuous improvement and performance measurement ensures that organizations can sustain long-term quality while enhancing overall business operations. With its systematic approach and emphasis on reducing variation, Six Sigma is a key driver of success in achieving superior quality and customer satisfaction across diverse industries.

Six Sigma Principles

- Sustainable Results: Six Sigma prioritizes long-term improvements over quick fixes, ensuring lasting change that drives ongoing success and quality performance.

- Customer-Centric Approach: Six Sigma emphasizes meeting customer requirements through consistent, high-quality products or services. By aligning processes to customer needs, it ensures satisfaction and loyalty.

- Data-Driven Decision-Making: Decisions are based on quantitative data rather than intuition, facilitating objective problem-solving and ensuring accuracy in identifying areas for improvement.

- Continuous Improvement: The methodology promotes iterative optimization, addressing inefficiencies and refining processes for sustained performance, supported by Quality Planning.

- Process Standardization: By developing standardized processes, Six Sigma reduces variations, ensuring repeatable and reliable results, which enhances efficiency and consistency.

- Employee Involvement: Successful Six Sigma projects require active commitment from employees at all levels, fostering a culture of quality and continuous improvement within the organization.

- Risk Management: Six Sigma also focuses on identifying and mitigating risks in processes. By analyzing data and predicting potential failures, it helps organizations minimize disruptions, maintain quality, and achieve operational stability in the long run.

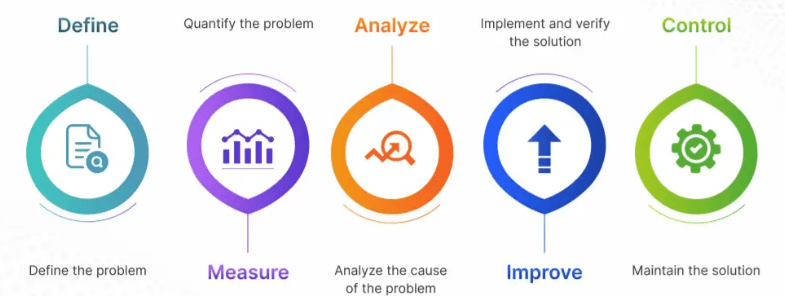

- Define: The initial stage involves having an apparent problem, goal, and project definition. It also entails comprehending the customers’ requirements, determining what constitutes success, and assembling a project team.

- Measure: Data collection quantifies performance using measures like DPU or process capability, much like Top AI Content Generator Tools optimize content output.

- Analyze: Statistical analysis is used to determine the root cause of defects. Methods such as Pareto charts, fishbone diagrams, and regression analysis are employed.

- Improve: This stage is dedicated to applying solutions to correct the root causes. It includes testing, validating, and perfecting improvements.

- Control: The last stage ensures that the improvements are maintained in the long term. Control measures, such as monitoring systems and routine audits, are implemented.

- Improved Efficiency and Quality: Lean Six Sigma improves process speed and quality simultaneously, leading to faster delivery and fewer errors in products or services.

- Data-Driven Waste Reduction: Six Sigma’s data analysis tools enhance Lean’s waste reduction efforts by identifying root causes and validating improvement decisions.

- Structured Improvement Approach: The DMAIC framework from Six Sigma, combined with Lean tools like 5S and Value Stream Mapping, offers a structured and practical improvement roadmap.

- Enhanced Customer Satisfaction: By delivering high-quality outputs consistently, Lean Six Sigma boosts customer satisfaction, enhanced by Minitab Data for analysis.

- Cross-Functional Collaboration: Lean Six Sigma promotes teamwork across departments, encouraging shared responsibility for quality, efficiency, and performance goals.

- Sustainable Results: The combined approach emphasizes long-term gains through continuous improvement, ensuring that improvements are maintained and expanded over time.

- Combining Strengths: Lean focuses on eliminating waste, while Six Sigma targets reducing variation and defects. Integrating both creates a powerful methodology for comprehensive process improvement.

Are You Interested in Learning More About Data Science? Sign Up For Our Data Science Course Training Today!

DMAIC Methodology

Six Sigma Tools and Techniques

Six Sigma employs a wide range of tools and techniques designed to identify problems, reduce variation, and improve process performance. One of the most foundational tools is the DMAIC framework (Define, Measure, Analyze, Improve, Control), which guides problem-solving in a structured, data-driven manner. Within this framework, several analytical tools are used to support decision-making. Pareto Charts help identify the most frequent causes of issues, allowing teams to focus on high-impact areas. The Fishbone Diagram (Ishikawa) is used for root cause analysis, mapping out all potential causes of a problem, a technique that can be enhanced with Data Science Training for deeper insights. Control Charts monitor process behavior over time and help maintain stability. Another key technique is Failure Mode and Effects Analysis (FMEA), which assesses potential points of failure and prioritizes risks. Histograms and Box Plots are used to visualize data distribution and identify trends or outliers. Process Mapping is also widely used to visualize workflows and uncover inefficiencies. Additionally, tools like 5 Whys and Regression Analysis help drill down to underlying issues and understand relationships between variables. Combined, these tools provide Six Sigma teams with a comprehensive toolkit to drive continuous improvement, enhance quality, and achieve operational excellence.

Gain Your Master’s Certification in Data Science by Enrolling in Our Data Science Masters Course.

Integration of Lean Six Sigma

Advantages of Six Sigma

Implementing Six Sigma brings a wide range of advantages to organizations across various sectors. One of the most significant benefits is better quality, as the methodology focuses on minimizing defects, reducing errors, and eliminating process variability, leading to more reliable and consistent products or services. This, in turn, contributes to increased customer satisfaction by ensuring that customer expectations are consistently met, which enhances loyalty and retention. Cost reduction is another major advantage, as streamlining operations and minimizing errors help organizations save significantly on rework, waste, and inefficiencies. Six Sigma also promotes increased efficiency by identifying and eliminating non-value-added activities, boosting overall productivity and improving workflow, much like how Python Keywords streamline coding processes. A critical aspect of its success lies in data-driven decision-making, where organizations rely on statistical analysis and measurable insights rather than assumptions, ensuring more accurate and effective decisions. This structured, evidence-based approach often leads to a competitive advantage, as organizations that implement Six Sigma are viewed as leaders in quality and operational excellence. Finally, employee engagement is enhanced through active involvement in process improvement initiatives, fostering a collaborative culture that improves morale, accountability, and organizational cohesion. Overall, Six Sigma implementation supports sustainable growth and continuous improvement.

Go Through These Data Science Interview Questions & Answer to Excel in Your Upcoming Interview.

Future Trends in Six Sigma

The future of Six Sigma is evolving rapidly as new technologies and work models reshape how quality improvement is achieved. One of the most significant trends is the integration of Artificial Intelligence (AI) and Machine Learning, which enhances Six Sigma by enabling faster, more accurate data analysis, predictive modeling, and real-time decision-making. Six Sigma automation is also on the rise, with organizations increasingly using Robotic Process Automation (RPA) and other digital tools to streamline repetitive tasks and reduce human error, making processes more efficient and reliable, especially when enhanced by Data Science Training. Another major trend is the expanded role of big data analytics in driving more precise and insight-driven decision-making within Six Sigma frameworks. The shift to remote working has also influenced how Six Sigma projects are conducted, leading to the adoption of cloud-based collaboration platforms that allow for seamless execution across geographically dispersed teams. Additionally, there is a growing movement toward the integration of Agile and Lean methodologies with Six Sigma, creating a more flexible and responsive approach to process improvement. These combined trends point toward a smarter, faster, and more adaptive future for Six Sigma in today’s dynamic business environment.